Is it a Kirby -- my Mom killed one after about 20+ years and then bought another at the Salvation Army.

Kirby vacs were sold door-to-door like Encyclopediae -- the company was "rolled up" into Chicago Pacific which was eventually purchased by Warren Buffet. I had the pleasure of working for ChicPac's die casting plant in Cleveland as a forklift driver in college!

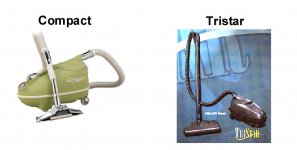

Speaking of moms and vacuums, my mom had a door to door salesman sell her a Compact Revelation vacuum back in 1956 I think.

That thing lasted forever, even after she died in 1984.

My father used it up to his death too in 1992.

Helluva machine too!

The company evenutally turned into Tristar, a premium level cleaning machine with a premium price.

Attachments

Last edited:

There is something ironic about reparing an electronic device that is normally used for repairing electronic devices 😀

Tony.

Tony.

Not as ironic as trying to fix something with no fault.

I spent half a day changing resistors in a USB PC scope only to find I couldn't fix the problem. Turned out to be a fault in the PC software not scaling the digital data correctly.

I spent half a day changing resistors in a USB PC scope only to find I couldn't fix the problem. Turned out to be a fault in the PC software not scaling the digital data correctly.

Yeah that sucks. reminds me of when I was at uni, and every programming assignment using pascal that needed pointers I could never get my program working properly. I'd spend hours debugging and couldn't work it out.

It wasn't till I was doing my industrial training year, and was only doing one subject, I had the time to do so much debugging I finally realised there was nothing wrong with my program at all. It was a compiler bug! That meant that likely all of the other programs were afflicted by the same bug! Memory pointers were getting corrupted causing completely random behaviour.

I compiled with a different compiler I had access to at work and the program worked perfectly. Two years of pain finally put to an end 😉

Tony.

It wasn't till I was doing my industrial training year, and was only doing one subject, I had the time to do so much debugging I finally realised there was nothing wrong with my program at all. It was a compiler bug! That meant that likely all of the other programs were afflicted by the same bug! Memory pointers were getting corrupted causing completely random behaviour.

I compiled with a different compiler I had access to at work and the program worked perfectly. Two years of pain finally put to an end 😉

Tony.

In the late 1980's I wanted to get into PC programming using DOS.

So bought in an 8086 Assembler/Editor.

My code often had bugs I couldnt find and when I debugged the program I found the Assembler object codes were sometimes wrong.

So I set about writing my own Assembler using the bad Assembler but not using bad instructions.

It took quite a while but I eventually got it working and went on to write a 500,000 line PCBCAD program with it. In those days RAM was only 512K so I had to split the software into modules like schematic entry or PCB entry and load them in as overlays into memory.

So bought in an 8086 Assembler/Editor.

My code often had bugs I couldnt find and when I debugged the program I found the Assembler object codes were sometimes wrong.

So I set about writing my own Assembler using the bad Assembler but not using bad instructions.

It took quite a while but I eventually got it working and went on to write a 500,000 line PCBCAD program with it. In those days RAM was only 512K so I had to split the software into modules like schematic entry or PCB entry and load them in as overlays into memory.

My 6 year old DIY built PC began acting erratically a few months ago. Sometimes it would post, but fail to boot. Sometimes it wouldn't post at all. These events were rare and usually cured by power cycling and starting over. It is a rack mounted PC on the bottom of the stack in my bench, so I put up with it.

This continued off and on, but a new twist appeared about a month ago, some of the USB ports did not work, usually the port that the keyboard was plugged into. A second keyboard plugged into the front panel USB jack worked fine.

Yesterday I was working on a PC board layout in an old version of Eagle when IT happened. The machine just locked up. The screen froze and nothing would happen, so I killed power and lost about an hour's work.

The PC would power on, post sometimes, attempt to boot Windows a few times, and occasionally get me to the screen where you enter the PIN, but didn't respond to any keyboard input, and only the small screen was active and it's display resolution was wrong.

It's a 6 year old PC with a cheap ASRock MB hosting a 4th Gen core i7-4790K with a mild overclock feeding an equally old 27 inch LG 1080 display and a cheap Walmart 4K TV over HDMI for the large display. The TV does not even recognize any input from the PC.

Given the age of the PC and it's components I assumed the usual "dead caps on the motherboard" diagnosis, but ripped it apart anyway and dug in. The first step in any flakey operation diagnosis is to test the CMOS ram backup battery.......It measures 2.06 volts unloaded. Should be over 3 volts.

Removal of the battery for about a half hour while I tested it and found another probably cleared or invalidated the CMOS ram forcing a boot from default firmware settings. I put in a new battery and fired the machine up. This time it would recognize USB and let me hold down F2 to get into the bios. Some of the settings were scrambled. I applied the defaults, then tweaked a few settings for my setup. I don't remember the overclock settings, but don't need them any more since I use another PC for video editing. I left them all at the default 4 GHz settings. I suspect that something in the overclock settings got scrambled causing the random weirdness and eventual lockup.

This morning everything looks OK, only time will tell.

This continued off and on, but a new twist appeared about a month ago, some of the USB ports did not work, usually the port that the keyboard was plugged into. A second keyboard plugged into the front panel USB jack worked fine.

Yesterday I was working on a PC board layout in an old version of Eagle when IT happened. The machine just locked up. The screen froze and nothing would happen, so I killed power and lost about an hour's work.

The PC would power on, post sometimes, attempt to boot Windows a few times, and occasionally get me to the screen where you enter the PIN, but didn't respond to any keyboard input, and only the small screen was active and it's display resolution was wrong.

It's a 6 year old PC with a cheap ASRock MB hosting a 4th Gen core i7-4790K with a mild overclock feeding an equally old 27 inch LG 1080 display and a cheap Walmart 4K TV over HDMI for the large display. The TV does not even recognize any input from the PC.

Given the age of the PC and it's components I assumed the usual "dead caps on the motherboard" diagnosis, but ripped it apart anyway and dug in. The first step in any flakey operation diagnosis is to test the CMOS ram backup battery.......It measures 2.06 volts unloaded. Should be over 3 volts.

Removal of the battery for about a half hour while I tested it and found another probably cleared or invalidated the CMOS ram forcing a boot from default firmware settings. I put in a new battery and fired the machine up. This time it would recognize USB and let me hold down F2 to get into the bios. Some of the settings were scrambled. I applied the defaults, then tweaked a few settings for my setup. I don't remember the overclock settings, but don't need them any more since I use another PC for video editing. I left them all at the default 4 GHz settings. I suspect that something in the overclock settings got scrambled causing the random weirdness and eventual lockup.

This morning everything looks OK, only time will tell.

Last edited:

So today, the bedroom window air conditioner (GE 8000BTU) was taken out of the window for the season....

For the last 3 years (it's now 12 years old, lightly used) the keypad on the unit was erratic.

However, it always worked perfectly via the remote control.

But that keypad bugged me - couldn't turn it on that way, set the speeds, temp, timer, etc.

It was those damned "tact" switches.

I'm used to those things becoming buggy on all sorts of stuff.

Got some Deoxit, dribbled it into each switch, let it soak in, worked the switches some, voila!

Back to usefulness.😀

For the last 3 years (it's now 12 years old, lightly used) the keypad on the unit was erratic.

However, it always worked perfectly via the remote control.

But that keypad bugged me - couldn't turn it on that way, set the speeds, temp, timer, etc.

It was those damned "tact" switches.

I'm used to those things becoming buggy on all sorts of stuff.

Got some Deoxit, dribbled it into each switch, let it soak in, worked the switches some, voila!

Back to usefulness.😀

A car cover. Last night there was a 90 km/hr wind warning, and sure enough my car cover was off the summer car this morning, despite some hefty bungee cording. An inspection yielded a surprise: 0 damage, as the 100% nylon buckles, straps, and zipper had merely worked themselves free. A good amount of needle and thread to reinforce and make loops for more bungees before a new attempt to put it on again.

Recently, I purchased a piece of electronic equipment that is mounted in a steel box made of two parts. Inside there is a mains transformer and two PCBs. At the front, there is a slanting control panel, a switch and an output connector with a fastening nut. The purpose of this equipment is to generate 1MHz wavetrains to be used for physical therapy.

My first impression upon opening the box, was to NOTICE the metal box was NOT EARTHED!!! The power cord is a European 3 wire type with Live, Neutral and Earth. The supply voltage is 230V AC. I also noticed insufficient power supply smoothing and had to change the smoothing capacitors. I also added bleeding resistors across the internal DC rails. I based my calculation for the bleeding resistors on the equation 5CR = 120, so that, after two minutes the capacitors would be discharged, and at the same time, not put unnecessary load on the DC power supplies.

The DC power supply implementation is from a centre tapped coil with a voltage of 20V - 0 - 20V. The rectified output between the rails was measured to be 57V DC. Study of the circuit indicates two voltage regulators are used on one rail with a maximum voltage of 28V DC. The 5V for the logic circuits is achieved through these regulators. In fact, one of them gets quite hot and I was about to change the heatsink with a larger one.

More inspection of the equipment showed the output is achieved using a 2SC5200 transistor mounted on a generous heatsink. I replaced the fixing bolt, added washers and a small aluminium plate instead of the original poor transistor fixation.

Since, using a metal box for electrical equipment requires mandatory earthing, I attached a wire to the box using a screw and connected the other end to the mains connector earth. Besides of being illegal, safety cannot and must never be ignored. This is not a matter of being obliged, but a matter of safe practice, which can save my own life.

My first impression upon opening the box, was to NOTICE the metal box was NOT EARTHED!!! The power cord is a European 3 wire type with Live, Neutral and Earth. The supply voltage is 230V AC. I also noticed insufficient power supply smoothing and had to change the smoothing capacitors. I also added bleeding resistors across the internal DC rails. I based my calculation for the bleeding resistors on the equation 5CR = 120, so that, after two minutes the capacitors would be discharged, and at the same time, not put unnecessary load on the DC power supplies.

The DC power supply implementation is from a centre tapped coil with a voltage of 20V - 0 - 20V. The rectified output between the rails was measured to be 57V DC. Study of the circuit indicates two voltage regulators are used on one rail with a maximum voltage of 28V DC. The 5V for the logic circuits is achieved through these regulators. In fact, one of them gets quite hot and I was about to change the heatsink with a larger one.

More inspection of the equipment showed the output is achieved using a 2SC5200 transistor mounted on a generous heatsink. I replaced the fixing bolt, added washers and a small aluminium plate instead of the original poor transistor fixation.

Since, using a metal box for electrical equipment requires mandatory earthing, I attached a wire to the box using a screw and connected the other end to the mains connector earth. Besides of being illegal, safety cannot and must never be ignored. This is not a matter of being obliged, but a matter of safe practice, which can save my own life.

Last edited:

I repaired a model railway electronic shuttle controller.

I built it up and it didnt work.

12 volts getting in to the safety diode then just zero volts.

Checked for shorts on the pcb.

Thought duff capacitor so replaced 100nf and 470uf.

Still the same.

Removed processor and powered it up and then 12 volts got passed safety diode ok.

Then hit me, processor had been in wrong way around.

So put processor back in and amazingly it worked.

I built it up and it didnt work.

12 volts getting in to the safety diode then just zero volts.

Checked for shorts on the pcb.

Thought duff capacitor so replaced 100nf and 470uf.

Still the same.

Removed processor and powered it up and then 12 volts got passed safety diode ok.

Then hit me, processor had been in wrong way around.

So put processor back in and amazingly it worked.

I built up a stereo power amplifier.

Its a TDA7376B power amp and a 12ax7 valve front end.

I powered it up and it kept popping at the speaker.

Thought I had killed it so powered off.

I checked all components and for solder shorts but seemed fine.

So powered up again monitoring +15v rail.

It was going up and down.

I then realised the valve heater was maybe pulling too much current.

So powered heater from my Farnell PSU and amp from my 20watt SMPS.

Worked fine.

Looks like I need a classic transformer, bridge and smoothing caps configuration

or a higher power SMPS.

The 20 watts SMPS should have been ok but the amp has 1000uf smoothing caps and the valve heater low impedance on power up and it was just too much for it.

Its a TDA7376B power amp and a 12ax7 valve front end.

I powered it up and it kept popping at the speaker.

Thought I had killed it so powered off.

I checked all components and for solder shorts but seemed fine.

So powered up again monitoring +15v rail.

It was going up and down.

I then realised the valve heater was maybe pulling too much current.

So powered heater from my Farnell PSU and amp from my 20watt SMPS.

Worked fine.

Looks like I need a classic transformer, bridge and smoothing caps configuration

or a higher power SMPS.

The 20 watts SMPS should have been ok but the amp has 1000uf smoothing caps and the valve heater low impedance on power up and it was just too much for it.

Possibly the worst mistake I have made with making a new pcb.

I completely forgot to add the negative rail generator IC a 7660.

The fix was of course a new pcb, thank goodness for cheap Chinese pcb makers.

I completely forgot to add the negative rail generator IC a 7660.

The fix was of course a new pcb, thank goodness for cheap Chinese pcb makers.

Last edited:

Just fixed a Cerwin - Vega XLS subwoofer plate amp. Can come in handy some day.

Horribly leaky caps in regulated power supply on the main board.

Horribly leaky caps in regulated power supply on the main board.

Consonance PM-1 (or was it MP-1?) 2-box vacuum tube phono stage. Maida style regulator in the power supply box took its last hot & steamy one.

My preamp was making random static noises on the left channel similar to when you have a dirty volume pot. It would be fine for a while, then static noise that would eventually stop again. I thought it was a bad solder joint on the socket since you could make it make noise by moving the tube... All were fine. So I changed the tube. Voilà! It was a bad connection in the base of the tube (6N8S). I could fix it but j'men câlisse... To the garbage with it.

LOL Ya. It's Québecois slang.

They even have it on a shirt now. There are two ways to spell Câlisse.

https://www.amazon.ca/J`-men-Calice-BLACK-S/dp/B015WHFQV8

They even have it on a shirt now. There are two ways to spell Câlisse.

https://www.amazon.ca/J`-men-Calice-BLACK-S/dp/B015WHFQV8

- Home

- Member Areas

- The Lounge

- What did you last repair?