Make the outer ring of your modified phase plug part of the magnetic circuit and it will be fine. Its no more difficult to cut or form a curve on that survface than a straight line.

You need to plot the normal flux along the gap for both designs. Its only the normal flux that contributes to the axial force. The tangential flux drives ring modes. This is very easy to do in that software.

You need to plot the normal flux along the gap for both designs. Its only the normal flux that contributes to the axial force. The tangential flux drives ring modes. This is very easy to do in that software.

Last edited:

I wanted turn myself that's why kept it straight 🙂 Normal flux is surprisingly quite similar in straight version (0.2T). Curved below.

Attachments

Last edited:

There is something wrong with those flux plots. They cannot be correct. Perhaps the grid is too coarse or something. You need a line placed where the VC would be, running along the voice coil, that extends past the voice coil on both ends. There should be at least ten elements along this line. The flux should fall almost to zero at each end of the plot. can you post the model?

The flux in the curved case looks pertty much the same as the original. You claimed that the changes messed up the magnetics which is not the case at all, if done correctly.

Does this phase plug correspond to my patent?

The flux in the curved case looks pertty much the same as the original. You claimed that the changes messed up the magnetics which is not the case at all, if done correctly.

Does this phase plug correspond to my patent?

Last edited:

Does this phase plug correspond to my patent?

Yes it does. I've created AxiDriver data for this plug.

There should be at least ten elements along this line. The flux should fall almost to zero at each end of the plot. can you post the model?

That's true. Set mesh size manually and now difference is small. Of course flux in gap is not homogeneous. BC DE250 cross section shows more elegant design. Do you know how large are real looses with non armco iron? FEMM seems to overestimate carbon steel.

Attachments

Only the manufacturer is going to know that, if even they know it. Its not easy to get and very few companies would supply it. And if they are Chinese you can bet that its what they "hope" it will be not what it actually is.

Are you sure that all the longer the coil is, plus its excursion? That looks very small and a huge waste of the flux field. Terrible design if thats true.

Are you sure that all the longer the coil is, plus its excursion? That looks very small and a huge waste of the flux field. Terrible design if thats true.

Wait a sec... jzagaja, are you:

1) Designing your own compression driver

2) Designing a retrofit-able phase plug

3) Doing this for fun?

1) Designing your own compression driver

2) Designing a retrofit-able phase plug

3) Doing this for fun?

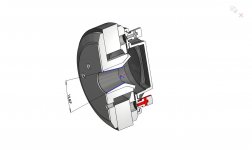

At this stage it is for fun meaning making my own diaphragms, phase plugs. I took D800Ti driver as parts (it is available for everyone) prior magnetizing. STX is now making it's own coils using Tokoku CCAW.

Hello Jack,

I think you have a lot of work to do in order to improve the linearity of the flux inside the gap.

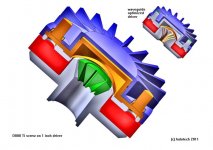

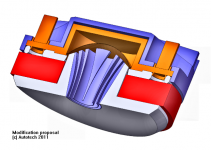

For comparison here is a project I used to study several years ago.

Best regards

Jean-Michel Le Cléac'h

I think you have a lot of work to do in order to improve the linearity of the flux inside the gap.

For comparison here is a project I used to study several years ago.

Best regards

Jean-Michel Le Cléac'h

That's true. Set mesh size manually and now difference is small. Of course flux in gap is not homogeneous. BC DE250 cross section shows more elegant design. Do you know how large are real looses with non armco iron? FEMM seems to overestimate carbon steel.

Attachments

Do you know real driver with such a smooth magnetic circuit? It seems for fast flare phase plug better use (now expensive) neodymium magnets (example JBL 476Be). Magnetizer is limited to outer diameter 250mm so for bass driver pole pieces must be mounted outside.

Sorry to change the subject but does Erich or anyone know anything about the group buy shipment? Last I heard, we were hoping for a productive September. Thanks. Fingers crossed.

How does the SEOS-RAAL fit up with the RAAL 140-15D?

.

Does the INOX front plate get covered in any way? Particularly any of the the sawtooth edge?

.

What benefits or changes to the response are there from using the waveguide?

.

Does the INOX front plate get covered in any way? Particularly any of the the sawtooth edge?

.

What benefits or changes to the response are there from using the waveguide?

SEOS-RAAL mounting copies RAAL 140-15D frontplate. Throat covers sawtooth (design width 27mm). We don't have this driver so I can't show any measurements.

- Home

- Group Buys

- Waveguides and horns