True enough!!

Hey any thoughts on moving the driver a few " up m? I think currently it's 36.6, but what would happen if I centered it at 40" id?

Hey any thoughts on moving the driver a few " up m? I think currently it's 36.6, but what would happen if I centered it at 40" id?

Ideally we want the driver and vent at an odd harmonic, so either on the top or bottom and due to the vent they shift down a bit along the line to approximately at 0.21, 0.349, 0.424, 0.7, 0.848 offset from the top [i.d.].

??? My sim is at 49.82 cm/0.349, your drawing at 'close enough' the same at 49.78 cm. At 40 cm, it slightly deepens the 100-200 Hz mid bass notch and shifts tuning a hair, so probably not noticeable unless comparing the two in room, though personally would adjust the difference in the base height.

GM

??? My sim is at 49.82 cm/0.349, your drawing at 'close enough' the same at 49.78 cm. At 40 cm, it slightly deepens the 100-200 Hz mid bass notch and shifts tuning a hair, so probably not noticeable unless comparing the two in room, though personally would adjust the difference in the base height.

GM

Yeah I'll just leave it.

Since sketch looks ok, and I know I've got the numbers right according to your design, I think I'm ready to start moving ahead on construction plans!

(That and work is now out of the busy season mostly.)

Can't wait to get cutting!

Since sketch looks ok, and I know I've got the numbers right according to your design, I think I'm ready to start moving ahead on construction plans!

(That and work is now out of the busy season mostly.)

Can't wait to get cutting!

just realized my current dim ratio is .7653. it's almost the same size as a sheet of 8.5 x 11, so it's easy to visualize.

is it too close to .75, which is 3/4 - definitely a musical ratio?

my fav ratio was .437, which makes the box 37x16.2 - too wide / flat for my visual hopes.

ALSO - I was thinking of making a 60 degree angled base, about 1.5" total thickness. Basically giving the base an extra 2.75" front & sides. The question is - should I add the base just as far in the back, or leave out the extra base extension, so that the speaker can be against the wall? There will be binding posts, so I'd have to inset them if I wanted it flush to the wall anyway; simpler to leave a 1 or 2" gap between the speaker & wall.

I calculated the 1/4 wave of the 1" gap and it's about 3500 hz... so assuming lower frequencies don't really see a gap, I doubt it should be any kind of issue.

Let me know your thoughts.

is it too close to .75, which is 3/4 - definitely a musical ratio?

my fav ratio was .437, which makes the box 37x16.2 - too wide / flat for my visual hopes.

ALSO - I was thinking of making a 60 degree angled base, about 1.5" total thickness. Basically giving the base an extra 2.75" front & sides. The question is - should I add the base just as far in the back, or leave out the extra base extension, so that the speaker can be against the wall? There will be binding posts, so I'd have to inset them if I wanted it flush to the wall anyway; simpler to leave a 1 or 2" gap between the speaker & wall.

I calculated the 1/4 wave of the 1" gap and it's about 3500 hz... so assuming lower frequencies don't really see a gap, I doubt it should be any kind of issue.

Let me know your thoughts.

also thinking about making a wooden V on the rear wall behind speaker so that ALL the back-wave reflection is deflected away from cone.

Anyone tried that in an MLTL, or does it mess with enclosure volume too much?

Anyone tried that in an MLTL, or does it mess with enclosure volume too much?

Yes, done it on some cabs and even a room, just need it to have a > 12 deg included angle. Its volume needs to be accounted for in the design and if there's a void, then ideally needs to be filled with sterile sand or similar.

GM

GM

just realized my current dim ratio is .7653. it's almost the same size as a sheet of 8.5 x 11, so it's easy to visualize.

is it too close to .75, which is 3/4 - definitely a musical ratio?

my fav ratio was .437, which makes the box 37x16.2 - too wide / flat for my visual hopes.

ALSO - I was thinking of making a 60 degree angled base, about 1.5" total thickness. Basically giving the base an extra 2.75" front & sides. The question is - should I add the base just as far in the back, or leave out the extra base extension, so that the speaker can be against the wall? There will be binding posts, so I'd have to inset them if I wanted it flush to the wall anyway; simpler to leave a 1 or 2" gap between the speaker & wall.

I calculated the 1/4 wave of the 1" gap and it's about 3500 hz... so assuming lower frequencies don't really see a gap, I doubt it should be any kind of issue.

Let me know your thoughts.

Don't recall there being a musical ratio for room ratios such as the golden ratio or ratios that are pleasing to the eye such as 1:1.4:2, though WRT high aspect ratio cabs we're only interested in the first one, i.e. 1:1.618 and 1:1.4.

This book, pg. 242 has a chart to choose acceptable ratios with some good ones already chosen: http://docshare04.docshare.tips/files/28838/288382396.pdf

Or browse these for a bunch more: calculating acceptable small room ratios - Google Search

The main thing about tilting is of course making sure it doesn't tip over, so if the base doesn't extend far enough to the rear to stabilize it, then the base must either be massive [heavy] or have some sort of isolated brace ~2/3 up the back.

Note that room eigenmodes [standing waves] are 1/2WL resonators, so ~13543/2/1 = ~6771.65 Hz. That Chapter 13 is all about room modes.

GM

I was referring to the whole idea of avoiding musical ratios... . 1:2 ratio or a square box is obviously the worst shape you can have for standing waves!

I think with stuffing and the line length the ratio isn't a big worry, just curious other's thoughts.

I think with stuffing and the line length the ratio isn't a big worry, just curious other's thoughts.

OK, didn't know there was such a ratio; I know pitch ratio, is this what you're referring to?

Regardless, room ratios suffice to minimize the amount of damping required.

GM

Regardless, room ratios suffice to minimize the amount of damping required.

GM

Another design thought:

Driver offset!

Probably a good idea to move drivers a couple CM away from centre, to minimize diffraction effects?

Driver offset!

Probably a good idea to move drivers a couple CM away from centre, to minimize diffraction effects?

Yeah, I use to recommend it [and vents] on baffles wide enough to have a driver at least 1.5x from one sidewall at a golden or acoustic ratio. Ditto offsetting any vertical board stiffeners if span is wide enough to need stiffening, but quit once it became obvious that folks weren't interested enough.

GM

GM

So are we talking any kind of tangible difference? I know "best practice" is a great thing to follow, though I also realize we're sometimes talking about changes that might improve the 14khz response by 5% ...

And it takes quite the ego to believe you're going to increase the emotional impact of a piano by doing that!

And it takes quite the ego to believe you're going to increase the emotional impact of a piano by doing that!

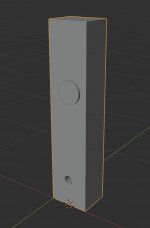

That render actually shows a 2cm driver offset.

What if vent was offset in the opposite direction... It would increase driver to vent distance... But I think it would look cool to have the boxes "lean" towards each other.

What if vent was offset in the opposite direction... It would increase driver to vent distance... But I think it would look cool to have the boxes "lean" towards each other.

So are we talking any kind of tangible difference? I know "best practice" is a great thing to follow, though I also realize we're sometimes talking about changes that might improve the 14khz response by 5% ...

And it takes quite the ego to believe you're going to increase the emotional impact of a piano by doing that!

Depends on baffle size and how it interacts with the room's acoustics along with how far away from any room boundary and the LP they are; but in general, if you can hear the difference between a tweeter on a baffle and one with a damping ring around it, then in theory you can.

Re offsetting bracing, here again it's generally about subtleties when building with wood, other lossy materials; build it out of metal and the differences are anything but subtle, not just in resonances, but in structural strength.

For speaker bracing, it can allow thinner and/or lighter construction for a given desired stiffness, a big deal with larger cabs, horns, but not so much with your size cabs unless wanting to make it out of 1/4" no void ply, sheet metal, etc., and mass load it some other way.

GM

That render actually shows a 2cm driver offset.

What if vent was offset in the opposite direction... It would increase driver to vent distance... But I think it would look cool to have the boxes "lean" towards each other.

Whatever 'floats yer boat' 😉 since a 2 cm more offset would require a high res measurement just to 'see' it, much less hear it since it's only a ~1% change.

GM

Construction is well underway.

18mm Baltic Birch.

Using full 5' / 60" height, then offsetting the base internally.

That gives me about an inch and a quarter air space (if I sealed it in with another bottom of 18mm).

I was toying with the idea of a base weight for added stability. Sand? Wood? No...

Then I thought of adding concrete in the gap! Looks like it would it add 9lbs, but it would be in the bottom. Pushing the wood sideways, I'm actually impressed at it's current stability, in spite of the height.

I may just opt for some horizontal base "legs" to put spikes on... Like thick 1/4" pieces to spread the weight more widely on the floor.

Any thoughts? Other ideas?

18mm Baltic Birch.

Using full 5' / 60" height, then offsetting the base internally.

That gives me about an inch and a quarter air space (if I sealed it in with another bottom of 18mm).

I was toying with the idea of a base weight for added stability. Sand? Wood? No...

Then I thought of adding concrete in the gap! Looks like it would it add 9lbs, but it would be in the bottom. Pushing the wood sideways, I'm actually impressed at it's current stability, in spite of the height.

I may just opt for some horizontal base "legs" to put spikes on... Like thick 1/4" pieces to spread the weight more widely on the floor.

Any thoughts? Other ideas?

Folks that mounted tires would just give or sell for scrap price their used tire weights, so maybe [still] an option and I've used Portland cement since it's heavier than sand and being finer will fill/settle for greater density. Recommend wearing a good face mask if not using a Saran Wrap or similar lining and premixing with water in a bucket to pour in.

Note that mass loading is a good plan, i.e. weight added to the top, held in place with industrial strength Velcro to ease moving the speaker around. With all the weight on top it maximizes cab preloading and the recommended outriggers.

FWIW, I built similar ~ 48" high columns w/5.25" 'FR' drivers for an older buddy with balance problems and was grateful I hadn't spiked them in the carpet as he had wanted when he lost his balance turning around too quickly late one night, grabbing the speaker and 'riding' it down rather than pulling it on top of him.

GM

Note that mass loading is a good plan, i.e. weight added to the top, held in place with industrial strength Velcro to ease moving the speaker around. With all the weight on top it maximizes cab preloading and the recommended outriggers.

FWIW, I built similar ~ 48" high columns w/5.25" 'FR' drivers for an older buddy with balance problems and was grateful I hadn't spiked them in the carpet as he had wanted when he lost his balance turning around too quickly late one night, grabbing the speaker and 'riding' it down rather than pulling it on top of him.

GM

Weight to the top? With Velcro? Trying to visualize...

Doesn't sound like something that will pass the WAF.

I could strap them to the wall behind possibly.

Doesn't sound like something that will pass the WAF.

I could strap them to the wall behind possibly.

Yes, with industrial Velcro, [much] harder to pull apart, so normally just used square pieces as required after I learned the hard/expensive way running it around the perimeter of a very large, expensive art poster. 🙁

Slate, marble, etc., and decorative planters [both fake and real plants], [small] statues, trophies filled with lead, etc., were popular in my time. One guy used a ~ 2 ft high stack of LP albums on each speaker and the aforementioned buddy stacked commercial size ice cream drums full of many decades worth of spare change left at the end of the day.

I normally recessed the top plate a little to provide a security/alignment lip, which of course also hides the indented Velcro.

Of course strapping or a guy wire or similar tether with screw in wall hooks works too. We did the latter as a safety measure when wall mounting heavy audio, video monitors.

GM

Slate, marble, etc., and decorative planters [both fake and real plants], [small] statues, trophies filled with lead, etc., were popular in my time. One guy used a ~ 2 ft high stack of LP albums on each speaker and the aforementioned buddy stacked commercial size ice cream drums full of many decades worth of spare change left at the end of the day.

I normally recessed the top plate a little to provide a security/alignment lip, which of course also hides the indented Velcro.

Of course strapping or a guy wire or similar tether with screw in wall hooks works too. We did the latter as a safety measure when wall mounting heavy audio, video monitors.

GM

- Home

- Loudspeakers

- Full Range

- W6-2144 - Design time!!