wow. reminds me of my first speaker design book; a 90-120 page paperback done by Radioshack in the 90s!

Probably Ray Alden's, good book overall, but has some math errors IIRC. When I got online in '96, Vance's Cookbook was the DIYer's 'bible': Loudspeaker Design Cookbook: Vance Dickason: 9781882580101: Amazon.com: Books

GM

GM

Last edited:

I found it! it's this one:

Building Speaker Systems Speakers for Your Listening Pleasure: McComb Gordon: Books - Amazon.ca

Building Speaker Systems Speakers for Your Listening Pleasure: McComb Gordon: Books - Amazon.ca

Eusubius, perhaps it was this? Copyright 1984. Mine was a second edition.

Don't recall this one, though was given a Weems 1984 2nd edition w/projects and Caudle's trash, err TRS, 80 computer program, which I loaned to a coworker with one, but could never get it to work properly, at least it didn't spit out what I knew to be good alignments.

GM

Remember seeing it, but didn't recognize the author, so didn't pay it any attention. Looking him up just now, he wrote a bunch of books in his relatively short life, especially robotics: Gordon McComb - Google Search

GM

hey GM; if you were using 703 (figured out what that is! built panels with it for the studio years ago) - would you just put a slice of 703 on the back wall, across from the driver?

what about top of the box (to eliminate vert reflections)?

When using Polyfil, do you know what most guys use to hold the poly in the right area? wires? wood bracing?

thanks!

what about top of the box (to eliminate vert reflections)?

When using Polyfil, do you know what most guys use to hold the poly in the right area? wires? wood bracing?

thanks!

Greets!

We always want at least one of every parallel walls to be damped, so normally top, one side and back and no more length than required to get rid of any 'hollowness'. That, or just small pads and use some form of electronic impulse response test to critically damp the vent or this simple 'click' test: Click Test | GM210 | Flickr

Historically, a cheesecloth 'fish net' was stuffed or suspended behind the driver or loosely covered the back of the drivers/XOs and just tossed/packed wads in.

Another way I became fond of when needing a significant amount was a damping 'blanket' suspended diagonally from the top to somewhat 'flap in the breeze' like Bozak did at one time with their Concert Grand [requires a crossbar ~1/2 way down to limit forward movement].

GM

We always want at least one of every parallel walls to be damped, so normally top, one side and back and no more length than required to get rid of any 'hollowness'. That, or just small pads and use some form of electronic impulse response test to critically damp the vent or this simple 'click' test: Click Test | GM210 | Flickr

Historically, a cheesecloth 'fish net' was stuffed or suspended behind the driver

Another way I became fond of when needing a significant amount was a damping 'blanket' suspended diagonally from the top to somewhat 'flap in the breeze' like Bozak did at one time with their Concert Grand [requires a crossbar ~1/2 way down to limit forward movement].

GM

During my teenage years our local high school had about 20 TRS-80 computers in one classroom, the all-in-one "console" variety that ran TRS-DOS from a pair of 5-1/4" floppies....w/projects and Caudle's trash, err TRS, 80 computer program...

However, at home most of my computing was done on a Commode, er, Commodore 64. 😛 Had to shake the VHF converter behind the TV occasionally to get a decent signal on channel 3 - an action we not-so-affectionately referred to as "jiggling he handle". Thanks for the memories!

And to get back on topic, thanks for the Hornresp tips. I'm just getting started with it, and these answered a lot of my more vexing questions.

Last edited:

LOL! 😀 This was my daughter's first computer, winding up mostly playing games on it. I got a Compaq, but flat didn't have the patience to deal with it, so sold it to one of my bosses, swearing I wouldn't buy another until I could just talk to it!

You're welcome! Trying to get 'up to speed' with all the new BP, dipole alignments.

GM

You're welcome! Trying to get 'up to speed' with all the new BP, dipole alignments.

GM

Noticed that I'd made a response to this much earlier 'train of thought', but it's not here, so for the sake of continuity/completeness.................

Hmm, sound power is 1/f = exponential, so [0.28*4.358]^0.5 = ~1.05 dB mean. Just quickly comparing SPL @ ~100, 43 Hz I get a ~1.09 dB difference with the '489.9' [mean] alignment, so close enough for me.

Anyway, if you look up what a human's hearing acuity curve is combined with the room dominating down this low and the sims exaggerating any peaking's intensity, you'll find that most folks would be hard pressed to be able to hear the difference between the '600' and '400' unless there's no damping in the box, so you're 'splitting hairs' here.

Regardless, it's your system, so use HR's Wizard to 'slide' your way to finding the elusive 3 dB 'bump' 😉.

GM

400 shows me flat, 600 shows a 4.5 - 5db bump, and 500 shows me ...a 1db bump?

I'm looking for that elusive 3db apparently

Hmm, sound power is 1/f = exponential, so [0.28*4.358]^0.5 = ~1.05 dB mean. Just quickly comparing SPL @ ~100, 43 Hz I get a ~1.09 dB difference with the '489.9' [mean] alignment, so close enough for me.

Anyway, if you look up what a human's hearing acuity curve is combined with the room dominating down this low and the sims exaggerating any peaking's intensity, you'll find that most folks would be hard pressed to be able to hear the difference between the '600' and '400' unless there's no damping in the box, so you're 'splitting hairs' here.

Regardless, it's your system, so use HR's Wizard to 'slide' your way to finding the elusive 3 dB 'bump' 😉.

GM

No, looking at it again, I do really like that huge 35hz bump... And having just built a PAL, which has a similar rise down to 37-39hz, I know I like the sound of music through that sub. It has NO damping, so definitely a bit of that hollow sound. It's for PA, so you don't notice it in a system.

PLUS - I believe the length of yours matches up perfectly to a 5' height, correct?? So 5x5 BB plywood should work perfectly for the box. Might have some extra for plywood for for bases / tops....

Might take two 5x5s... Or to save $ I can use 3/4" BB on fronts, and some kind of 1/2" for sides. That will lighten box, and make it easier to stabilize with weight /wide base on the bottom.

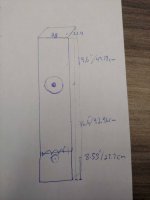

I'm going to try and draw the design out, so I can post it here and have you confirm that I've got everything right.

PLUS - I believe the length of yours matches up perfectly to a 5' height, correct?? So 5x5 BB plywood should work perfectly for the box. Might have some extra for plywood for for bases / tops....

Might take two 5x5s... Or to save $ I can use 3/4" BB on fronts, and some kind of 1/2" for sides. That will lighten box, and make it easier to stabilize with weight /wide base on the bottom.

I'm going to try and draw the design out, so I can post it here and have you confirm that I've got everything right.

Hmm, the PAL sub is a TH IIRC, so not comparing apples to apples, but worst case is you add more stuffing to knock it down a bit.

Well, the baffle is ~19.61 + ~36.57 = ~56.18" [3/16] and add 1.5" for the side plates gives you some excess from 5 ft/60" to fudge with.

Speakers ideally need to be massive or at least massively loaded after the fact [heavy plant, decorative rock/whatever perched on top], ditto any base. FWIW, I mostly used concrete pavers, which around here are many and varied in size, shape, color, texture and used industrial Velcro to hold stuff together. Be forewarned though if never having used it, it's a lot harder to pull apart than the lower grades normally sold to consumers.

GM

Well, the baffle is ~19.61 + ~36.57 = ~56.18" [3/16] and add 1.5" for the side plates gives you some excess from 5 ft/60" to fudge with.

Speakers ideally need to be massive or at least massively loaded after the fact [heavy plant, decorative rock/whatever perched on top], ditto any base. FWIW, I mostly used concrete pavers, which around here are many and varied in size, shape, color, texture and used industrial Velcro to hold stuff together. Be forewarned though if never having used it, it's a lot harder to pull apart than the lower grades normally sold to consumers.

GM

I'm picturing a large rock with a giant piece of Velcro stuck to it, on top of the speaker... [emoji848]

Got any pics?

Got any pics?

You could do that if in an appropriate stand or ground flat large enough to use just the Velcro, but I was referring to decorative rock, i.e. marble, slate or even concrete and thick ceramic tile. Use your imagination if needing something decorative, otherwise do as some and just stack brick or similar on top.

A buddy has huge containers filled with all the 'pocket' change he accumulated over ~60 yrs perched on top of his skinny/tall MLTLs. I had to make a really wide/deep/rigid 1x4 gusseted frame base to keep them stable for when he stumbles into them [got a vertigo problem].

No, my active speaker building 'career' for friends, relatives, neighbors, etc., ~ended in '75 with just some sporadic helping others build my designs or kits, so with no net, audio clubs other than HAM radio, no reason to.

GM

A buddy has huge containers filled with all the 'pocket' change he accumulated over ~60 yrs perched on top of his skinny/tall MLTLs. I had to make a really wide/deep/rigid 1x4 gusseted frame base to keep them stable for when he stumbles into them [got a vertigo problem].

No, my active speaker building 'career' for friends, relatives, neighbors, etc., ~ended in '75 with just some sporadic helping others build my designs or kits, so with no net, audio clubs other than HAM radio, no reason to.

GM

Did the numbers to start sketching...

11.55 internal width doesn't leave room for driver!

To give 1.5 x driver width = 26.33 wide, by 22.79.

I think 22.8 W x 26.33 D would work fine with dampening on side walls too.

11.55 internal width doesn't leave room for driver!

To give 1.5 x driver width = 26.33 wide, by 22.79.

I think 22.8 W x 26.33 D would work fine with dampening on side walls too.

Sorry, I realized you were talking 11.55 D, not W!

I'm debating between 37 x 16.2 (D), and:

28 x 21.4.

A traffic path will be on front of speakers, so I'm tempted by the shallow dims... Though they will look big from front.

Maybe my bro can render...

I'm debating between 37 x 16.2 (D), and:

28 x 21.4.

A traffic path will be on front of speakers, so I'm tempted by the shallow dims... Though they will look big from front.

Maybe my bro can render...

- Home

- Loudspeakers

- Full Range

- W6-2144 - Design time!!