Member

Joined 2003

FWIW the absolute SPL calibration and absolute SPL measurements are completely unnecessary for designing with VituixCAD. Relative SPL is all that’s needed so you can skip the SPL calibration and just make sure to not touch the volume knob between measurements.

Controlled / calibrated level is quite nice especially if measurement data is not captured at once for whole project, or input sensitivity must be adjusted in the middle of capturing due to clipping and limit in output voltage range. Controlling input sensitivity is annoying with generic sound cards and measurement programs. This is main reason why I purchased CLIO many years ago.

I posted a thread without realizing there was a specific VituixCAD section. It's about making sure measurements and settings are OK before starting designing an active crossover, anyone care to take a look? https://www.diyaudio.com/community/...woofer-tweeter-measurements-via-delay.390973/

You are right Kimmo. As always 🙂 I've changed Preamp. gain to value of 1 and modified mic sensivity to have correct SPL Levels and currently VituixCAD and ARTA charts have identical SPL values.Catalogue mic sensitivity is irrelevant. Preamp. gain is not included in PIR file so it must be 1.

How did you determine the 22mm acoustic center distance of the woofer? Also, have you given any consideration to the possibility that the acoustic center of the woofer will vary a bit with frequency? Ideally, the measurements should be conducted in such a way that they include all of that information in the captured response data for the woofer relative to that for the tweeter at the chosen measurement locations.I assume that the acoustic center of the tweeter is in the same plane as the baffle, and that the acoustic center of the woofer is 22mm behind the baffle.

Although it's possible to modify the measured tweeter and woofer responses to simulate their off-axis responses, that will add approximations to the simulations. By choosing an appropriate measurement setup, it should be possible to avoid much of that.All frequency measurements are made 1m in front of the baffle, at the height of the center points of the speaker elements. On my baffle (20.5 cm x 38 cm) both elements are centrally located. The center point of the woofer (SEAS ER18RNX) is 16 cm below the center point of the tweeter (Scan Speak d2608)

Out of interest, I have created a scale diagram showing the physical locations of a set of seven measurement points taken at angles θt = 0°, ±5°, ±10°, and ±15° from the tweeter axis. For simplicity, this diagram ignores the fact that the acoustic center of the woofer may be behind the plane of the front baffle.You will find in the options a setting for listening distance. This is the distance used for simulation, recommended to keep at 2m+. Coordinates are entered relative to 0,0,0, so 2m listening distance places the simulation at (0,0,-2000). Most people will use the tweeter as the listening height, so the tweeter is entered as 0,0,0 and other drivers coordinates are entered relative to the tweeter. However, some may want to use the midrange as listening height or some point inbetween midrange and tweeter, the choice is at your discretion. You’ll find with your small bookshelf that at 2m distance it won’t change the result much if you use tweeter axis or woofer axis as the listening axis since the relative difference in driver distance and angle will be small.

The measurement distance was assumed to be 2 meters, as per the minimum distance that was recommended above. When we get to angles of θt = ±15°, we can see that we are approximately 0.5 meters above and below the tweeter axis.

It is also apparent that, when the listening axis is set to the θt=0° condition, we are actually listening to the woofer at θw=+5.71° off its axis. In the crossover region around 3kHz, this means that the response of the woofer is likely to already be beaming a little. It's also interesting to note that the output of the woofer is also –0.043dB lower than that of the tweeter, due simply to the increased distance that the sound waves from the woofer need to travel. This effect will of course be zero along the midplane between the drivers, where the listening position is equidistant from each driver.

When trying to optimize a crossover design, it may be worthwhile performing individual measurements of the woofer and tweeter at each of the nominated listening positions, θt = 0°, ±5°, ±10°, and ±15°. Of course, a smaller subset could also be used, say θt = 0°, ±5°, +10°, and +15°, and a higher weighting applied to the data taken for the on-axis (tweeter) case at θt = 0°.

By taking a matched pair of measurements of the tweeter and woofer response at each given angle θt, we can therefore ensure that the relative path length differences (including driver geometric offsets), woofer and tweeter off-axis radiation patterns, and any variations in acoustic center locations as a function of frequency are fully captured at each design location. This will help to maximize the accuracy of the simulations when computing the summed responses at the design locations.

As a simple check, the summed responses of the woofer and tweeter could be calculated from their individual measurements and compared to a separate measurement where both the woofer and tweeter were driven simultaneously. These two sets of results should be identical in magnitude response and phase response. In this way, we require three sets of distinct measurements at each listening location: 1) woofer alone, 2) tweeter alone, and 3) woofer and tweeter.

Member

Joined 2003

.

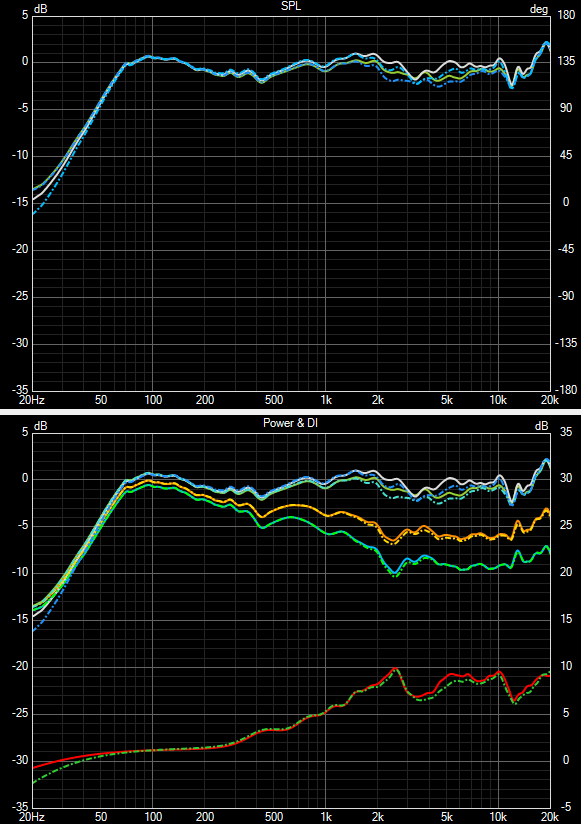

Here I have a 17cm woofer and 1" tweeter in a small waveguide, separated by 16cm. Comparison of listening axis at the tweeter height (solid) vs woofer height (dashed) at 2m listening distance. Crossover is 3kHz.

Of course you don't need such complex analysis to see the differences in listening axis, just adjust y axis location of the drivers accordingly in VituixCAD.It is also apparent that, when the listening axis is set to the θt=0° condition, we are actually listening to the woofer at θw=+5.71° off its axis. In the crossover region around 3kHz, this means that the response of the woofer is likely to already be beaming a little. It's also interesting to note that the output of the woofer is also –0.043dB lower than that of the tweeter, due simply to the increased distance that the sound waves from the woofer need to travel. This effect will of course be zero along the midplane between the drivers, where the listening position is equidistant from each driver.

Here I have a 17cm woofer and 1" tweeter in a small waveguide, separated by 16cm. Comparison of listening axis at the tweeter height (solid) vs woofer height (dashed) at 2m listening distance. Crossover is 3kHz.

Thanks Kimmo.

For exploration of the MLTL I am about to design from all aspects I use Hornresp which is great. It can handle “whatever” type of enclosure and return spl, impedance, phase, delay, port velocity etc. I have got designs compared in Hornresp with the famous MathCad and they return very similar result. My newbie thoughts is that the output from a 2 way MLTL could be seen as a base reflex enclosure. Both are vented enclosures.

So if that true in some way, the “only” thing is that the port is on the back baffle. In 2pi or 4pi measurements I guess it has affect versus a room position even if LF are spreading quite well. Maybe that’s why +/-180 degrees measuring is sooo important and solve the “problem”’or at least to a major extent. At least I am trying to get some kind of a grip of it.....

I posted some stuff on how to take the output from Hornresp and load it into VituixCad here:

https://www.diyaudio.com/community/threads/an-improved-transmission-alignment-ii.391041/

This is very useful to evaluate the affect of a baffle, and VituixCad is definitely the way to go to simulate crossovers.

Dear Kimmo, or other experienced VituixCAD users, is Clio Pocket providing (pseudo) dual channnel measurement with the microphone, so that one can easily remove the time of flight to get the correct phase to use in VituixCAD (which e.g. UMIK-1 cannot do)? I searched through some older threads here and it seems to be the case, I saw the system in action and I really like it, so I consider buying it.

Edit: Pardon my stupid question, I should have used search on the thread. Clio Pocket can indeed measure time of flight as explained here: https://www.diyaudio.com/community/threads/vituixcad.307910/page-150#post-6595973 So I now need to get one, it is a very smart tool worth the asked price.

Edit: Pardon my stupid question, I should have used search on the thread. Clio Pocket can indeed measure time of flight as explained here: https://www.diyaudio.com/community/threads/vituixcad.307910/page-150#post-6595973 So I now need to get one, it is a very smart tool worth the asked price.

Last edited:

^Pocket is able to measure timing. It does not support mic calibration file, but it should be possible to purchase calibrated MIC-02 (or MIC-01) and load cal file to Convert IR to FR tool in VCAD so that is not final limit. I haven't found automatic file naming for off-axis measurement sequence from user manual of ver 2.1 though program is able to plot 2D directivity charts with compatible file naming. Pocket doesn't support automatic turning tables either so it's not yet adequate for all of us. Purpose of these limits is to separate Pocket from more expensive full versions: Standard and QC.

Last edited:

I have a question to forum users. Have you ever made nearfield measurement in coaxial speaker? Where should I put mic? In center of speaker, 5mm apart from tweeter? Or maybe on one of the sides, in the middle of the midwoofer membrane, 5mm apart?

I have two drivers from KEF Q100 speakers an will try to use in my DIY construction.

I have two drivers from KEF Q100 speakers an will try to use in my DIY construction.

If someone is curious about different mic positions during nearfield measurements on coaxial driver:^As center as possible ...

Yes, but that is a no brainer with a coax, i.e. a separate non moving tweeter assembly where otherwise a moving dustcap resides..

It's good to see verification that it's not a particularly good approach to use if one wants to get a measurement that is reasonably representative of its sound pressure response at a more typical 2–3 meter listening distance.If someone is curious about different mic positions during nearfield measurements on coaxial driver:

Farfield measurements of coaxial driver it's not a problem. I couldn't find anything on the web how to make nearfield measurement.

It all depends what one is looking for?^As center as possible if tweeter is small, but for example PA coaxials have small horn so mic can be located close to inner edge of mid cone.

Nearfield measurements are mostly just done to get a sense of either the "resonances" in the cabinet (standing waves etc), or to get a good sense of the lower frequency part of the speaker. Often those internal cabinet issues are big enough to not see the "obstruction" of the horn assembly.

Sometimes it can give an idea of some cone resonances as well.

So my answer would be, do both. I would just never give one and only answer to such question.

But as can be seen @mecedo measurements, the difference isn't to big, expect for 2kHz an upward.

Which was to be expected anyway.

So in other words, what are you are trying to measure and see with nearfield measurements @mecedo ?

That is a much more important question, than just flying by general rules of thumb and ideas and just following those without really understanding why.

I needed nearfield measurement to merge it with my spatial farfield measurementsWhat are you are trying to measure and see with nearfield measurements @mecedo ?

- Home

- Design & Build

- Software Tools

- VituixCAD