So I'll get a 1 kg delivered, and now I've paid for the 500 g they sent (it was 500 g, not 400). Very much more expensive than I planned, but not all that much in life. I guess I have my spare wire for my other experimental project.

That's the sucky part of this one - the 0.5 kg costs R225 and the kg costs R294. They gave me a bit of discount, but I still had to fork out another R210 and VAT. Still, I have a use for the wire. And at least I didn't have to pay any extra shipping.

I'm not too worried. Like I said, it's more than I planned (R1000 for components vs R760), but that extra R240 isn't much in comparison to the R4000 this build has cost.

I got my kg. But it is bare copper. The lady that has been helping me has been phenomenal, which is a good thing. I just can't wind my inductors yet. Hopefully I can have the crossovers built by the end of the weekend. The build has gone well so far.

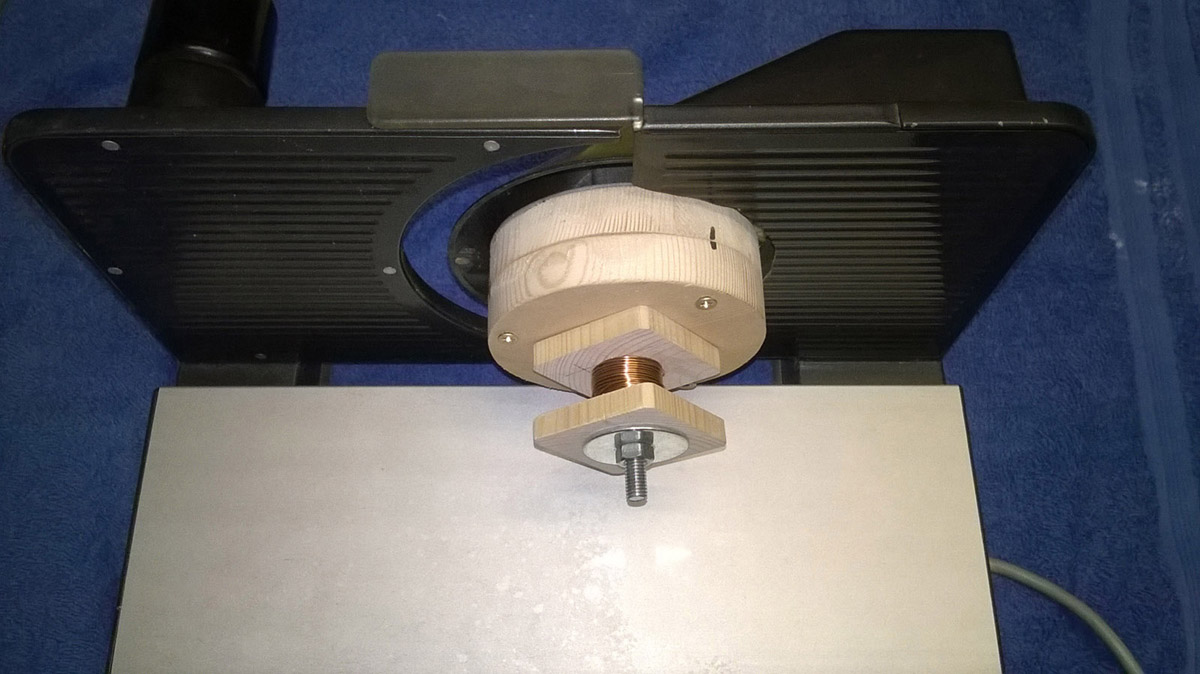

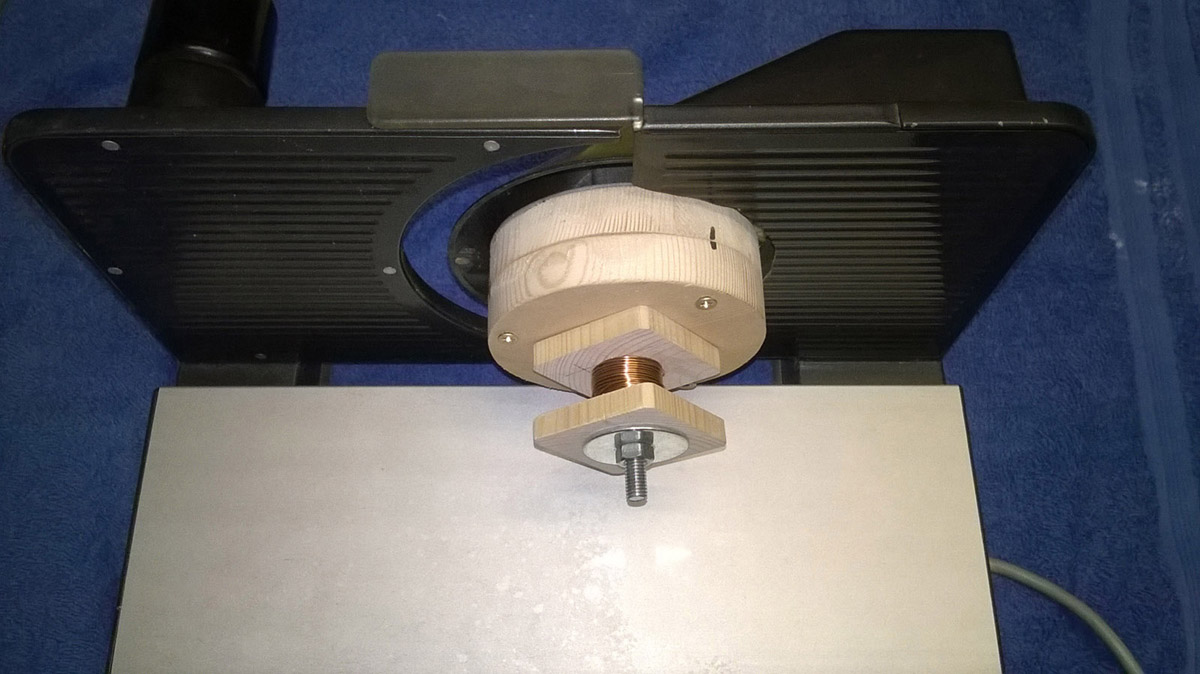

Here are pics of what I've done so far. I'm going to attach the crossover to the rear panel and screw it on. Everything else is glued together.

I tested the speakers without crossovers and tweeters disconnected. I must say that I'm very impressed! They sound extremely good. The W170S's have a smooth soft characteristic.

I tested the speakers without crossovers and tweeters disconnected. I must say that I'm very impressed! They sound extremely good. The W170S's have a smooth soft characteristic.

Attachments

And I've finally gotten my kg of wire. Now the painful process of turning coils starts. 177 turns for 4 inductors, then another two, each with about 80 turns.

The speaker size is actually very nice. They're very big, sure, but it seems appropriate. The drivers look good against the size of the baffle, and the depth just seems right. I've been really impressed so far, and I'm very excited because of how they sound already. I believe these may become my main speakers, so I'm also going to make nice stands. It occurred to me to make stands, but now I'm convinced I'll need them. 🙂

I also have to plan the finish. I was thinking of a glossy black mirror finish. The veneer option would look nice, but I think I might struggle to get it looking perfect. I'm going to rather get the speakers 100% done, and then start planning the finish. I'll take my time as well.

The speaker size is actually very nice. They're very big, sure, but it seems appropriate. The drivers look good against the size of the baffle, and the depth just seems right. I've been really impressed so far, and I'm very excited because of how they sound already. I believe these may become my main speakers, so I'm also going to make nice stands. It occurred to me to make stands, but now I'm convinced I'll need them. 🙂

I also have to plan the finish. I was thinking of a glossy black mirror finish. The veneer option would look nice, but I think I might struggle to get it looking perfect. I'm going to rather get the speakers 100% done, and then start planning the finish. I'll take my time as well.

I have managed to overcome that tiresome work of manual wounding inductors by using this magnificient piece of machinery. Built like tank.

http://www.diyaudio.com/forums/equipment-tools/295848-diy-coil-winder.html

http://www.diyaudio.com/forums/equipment-tools/295848-diy-coil-winder.html

I am hooked on this thread. I had a PM lately about using a Zobel on a woofer. The guy swears it sounds excellent! And I agree, because it gives optimal voicecoil damping to get rid of the HF resonances. 😀

This is SO John DeVore! But not $5000. 😎

Lojzek is into something with winding his own coils.

I must do this myself. Easy enough to buy enamelled copper wire. It crossed my mind that nylon fishing line comes on handy plastic spools like some aircores. Maybe you can get some? My Wilmslow aircores are not baked, just wound around a plastic bobbin with a bit of tape to hold it all together. Heat might be an issue with some bass coils, but not on tweeters. Old Wharfedale coils don't look like rocket science either.

What works in your favour is that doubling turns QUADRUPLES inductance.

This is SO John DeVore! But not $5000. 😎

Lojzek is into something with winding his own coils.

I must do this myself. Easy enough to buy enamelled copper wire. It crossed my mind that nylon fishing line comes on handy plastic spools like some aircores. Maybe you can get some? My Wilmslow aircores are not baked, just wound around a plastic bobbin with a bit of tape to hold it all together. Heat might be an issue with some bass coils, but not on tweeters. Old Wharfedale coils don't look like rocket science either.

What works in your favour is that doubling turns QUADRUPLES inductance.

Attachments

Thanks. What I've done is build a basic rig, and now the coils aren't on any bobbin. I wind them, glue them and then remove them. I have the two 0.15's theoretically, and now I've attempted to roll a 0.82mH. It ended up with 160 turns, 1.1cm long, 1.2cm inner diameter and 7cm outer diameter. On a calculator site, that comes to 1.64mH. So now what? Unwind some or can I centre tap it? I'm guessing the centre would be somewhere near 115 turns and about 5.9 outer diameter?

I calculated for winding on a 1.2cm former, 1.1cm thick. I calculate for 1.25mm diameter wire. I used two web site calculators rather than opening my physics text books. The average was 160 turns, 8 turns per layer. The final diameter theoretically came to 6cm. But in practice, it's very difficult to wind a perfect inductor, so after 160 turns, I ended up at 7cm diameter. This is for 0.82mH. I'm going to have to set up a measurement to measure them all I think.

I will post images of what I've done as well.

I will post images of what I've done as well.

Ok, so my 0.15mH inductors are fine. The massive 0.82mH measures about 0.56mH. Now at least I can match these things somewhat.

Interesting side note: I've always loved TIP35/6C as output devices because they're unbelievably robust. I essentially shorted my amp through the inductor at about 200Hz at (admittedly only) 0.4V. Still, it turned the inductor into a motor and made some sparks. Amp is perfectly fine. 🙂

Interesting side note: I've always loved TIP35/6C as output devices because they're unbelievably robust. I essentially shorted my amp through the inductor at about 200Hz at (admittedly only) 0.4V. Still, it turned the inductor into a motor and made some sparks. Amp is perfectly fine. 🙂

This is SO John DeVore! But not $5000.

Oppa John DeVore style!

My tweeters are much further of axis, but I'm sure it'll be fine. The speakers look great already. I must say, winding these coils isn't the most fun I've had. But as my posts indicate, I can at least measure them.

The massive 0.82mH measures about 0.56mH. Now at least I can match these things somewhat.

By the way you have wound your larger inductor you lost 0,1mH because of it being thick only 11 mm. If it were 23 mm, you'd measure 0,66mH. 22 m of wire is perfectly enough to make an 0,82 mH coil.

Thanks. I will use wider formers next time because it's much easier as well. At least now I know. 🙂

I've attached some pics of what I've done so far. The big coil on the left is the first one. It's a bit bigger than the other one, but that's because it has glue in the middle because I needed to add windings. Still, they're both fine. Two more to go and i have everything. Hopefully today the speakers can be closed up!

I've attached some pics of what I've done so far. The big coil on the left is the first one. It's a bit bigger than the other one, but that's because it has glue in the middle because I needed to add windings. Still, they're both fine. Two more to go and i have everything. Hopefully today the speakers can be closed up!

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Visaton 2 way tower or Monitor Audio Bronze 5