jag said:

I tried this today, works really well. Instead of turning the chuck, I popped open the top cover and pulled on the pulley belt to turn the tapping bit. Did a lot of 6-32 (Zen4 on way) taps on scrap aluminum and no problems at all 😀

How long did it take you?😉

PRAGMATISM

Hi Jack,

And you never bought the wife a present thinking how usefull it would be to you one day?

Main thing is, use the darn thing!😉

See ya,🙂

Hi Jack,

And you never bought the wife a present thinking how usefull it would be to you one day?

Main thing is, use the darn thing!😉

See ya,🙂

Getting A Real Close Look....

One of my most usefull tools (I have plenty - some secret) is the viewfinder lens assembly from a Sony camcorder.

With bright light this is a most usefull tool for close inspections, especially SMD soldering/resoldering.

Eric.

One of my most usefull tools (I have plenty - some secret) is the viewfinder lens assembly from a Sony camcorder.

With bright light this is a most usefull tool for close inspections, especially SMD soldering/resoldering.

Eric.

Peter Daniel said:

How long did it take you?😉

It takes about 10 secs to align the drilled hole to the tap (and clamp it). Sometimes, it goes through in first shot - another 10-15 secs. Sometimes, I have to back it up and retry - adds 20-30 secs to the original 10 secs (always goes through in second try).

But, time is not really the issue for me - it always produces perfect threads - no broken bits, and no destroyed threads. And I need to tap a total of 14 threads for Zen4 - this is a good method to do that even if it takes 2 mins per hole (all done in half hour), especially considering that a lot of people seem to be having a tough time tapping. Actually, I tapped a total of 12 6-32 holes in about 5-10 minutes (and all of them perfect 😎 ).

Re: a drill press without a bunch of shavings

I live in an appt and am using kitchen to do this. I am happy 😀 that my wife would even let me do it there - the least I can do is keep it clean 😉

jackinnj said:my youngest son bought me a drill press when he was in high school -- turns out he uses it most of the time (hmmmm, I wonder why he bought it) -- I can';t believe that the picture shows a press without a bunch of aluminum or wood shavings beneath it!

I live in an appt and am using kitchen to do this. I am happy 😀 that my wife would even let me do it there - the least I can do is keep it clean 😉

jag said:

I tapped a total of 12 6-32 holes in about 5-10 minutes (and all of them perfect 😎 ).

It's not bad then.😉

Al shavings

When cleaning those shavings do not do what I did, I used to clean them with a vacumn cleaner, they clogged up the hose really really bad, I was lucky that it was my shopvac rather than my central vac system, otherwise it would have been a real plain try to locate where in the pipes that they clogged up. Imagine it could have been inside walls or between floors.

When cleaning those shavings do not do what I did, I used to clean them with a vacumn cleaner, they clogged up the hose really really bad, I was lucky that it was my shopvac rather than my central vac system, otherwise it would have been a real plain try to locate where in the pipes that they clogged up. Imagine it could have been inside walls or between floors.

I have been meaning to ask what does one do to prevent the shaving from flying all over the place, especially when drill on drill press.

FDEGROVE

Yeah, I bought my wife a present which I thought would be helpful to me, but she never wears it.

<b>PRAGMATISM

Hi Jack,

And you never bought the wife a present thinking how usefull it would be to you one day?<b>

Yeah, I bought my wife a present which I thought would be helpful to me, but she never wears it.

<b>PRAGMATISM

Hi Jack,

And you never bought the wife a present thinking how usefull it would be to you one day?<b>

Wauw!

THis is a great thread! 🙂 I'm almost ashamed I didn't find it earlier This is a goldmine on DIY info 🙂

This is a goldmine on DIY info 🙂

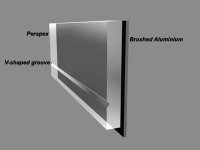

I have two questions, relating to the picture below. The goal is to have text on the aluminium (photolithic process), glue the perpex plate over it, and have blue leds shine through the perspex on the aluminium. The V-shaped groove should remain matte, and light up in the blue glow.

- How do I glue the perspex to the aluminium in an "invisible way"?

- How do I make the v-shaped groove without a milling machine?

Thanx for all help.

Bouke

THis is a great thread! 🙂 I'm almost ashamed I didn't find it earlier

This is a goldmine on DIY info 🙂

This is a goldmine on DIY info 🙂I have two questions, relating to the picture below. The goal is to have text on the aluminium (photolithic process), glue the perpex plate over it, and have blue leds shine through the perspex on the aluminium. The V-shaped groove should remain matte, and light up in the blue glow.

- How do I glue the perspex to the aluminium in an "invisible way"?

- How do I make the v-shaped groove without a milling machine?

Thanx for all help.

Bouke

Attachments

GLUE

Hello Bouke,

You could try a spray-on glue.

Personally I would use some screws though since I fear the glueing will show up sooner or later.

To hide it you could use a tainted perspex.

For the rest of your QQ,I wouldn't know.

Cheers,😉

Hello Bouke,

You could try a spray-on glue.

Personally I would use some screws though since I fear the glueing will show up sooner or later.

To hide it you could use a tainted perspex.

For the rest of your QQ,I wouldn't know.

Cheers,😉

One way to make a V shape groove is to use a table saw with a blade for plastic. You just have to tilt the blade 45 deg and adjust the height. I imagine you woud still have to polish it, to have it matched with the rest.

On visible part I wouldnt use glue, because it will always show and with time might change properties as well.

Just a thought, if you plan to use pots knobs there, you could use the nuts on the pots to hold everything together.

On visible part I wouldnt use glue, because it will always show and with time might change properties as well.

Just a thought, if you plan to use pots knobs there, you could use the nuts on the pots to hold everything together.

Alternatively...

If you drill and tap the perspex from the rear, the effect is actually quite nice.

Make sure the blind holes are all the same depth, and positioned exactly. They will just look a cloudy white colour.

If you drill and tap the perspex from the rear, the effect is actually quite nice.

Make sure the blind holes are all the same depth, and positioned exactly. They will just look a cloudy white colour.

Bouke,

2 options to glue the plexiglas (i guess that's perspex)

1)

use 1,1,1 trichlorehtane to dissolve the plexiglas on the surface and one can expect supersmooth glue joint without any bubbles or air cavities.

I tired it out with plexi2plexi joints and plexi2metal, works fine. Just .... the stuff is deadly poisonous, you normally don't get it without a master degree in chemistry and a company letter head.

2)

Röhm sells some plexiglas glues under the Acrifix brand which meant to harden/settle from the ultraviolet component in our daylight; those glues also make fine glue joints. If you glue the plexi on brushed alu, should be fine.

I used to use AcriFix 92.

V-groove: i agree with Peter. Leave the goove unpolished, you want the blue light get scattered on the groove's surface; the rest of the blue light is caught within the plexi by total reflection if you couple the light into the edges of the plexi frontplate.

2 options to glue the plexiglas (i guess that's perspex)

1)

use 1,1,1 trichlorehtane to dissolve the plexiglas on the surface and one can expect supersmooth glue joint without any bubbles or air cavities.

I tired it out with plexi2plexi joints and plexi2metal, works fine. Just .... the stuff is deadly poisonous, you normally don't get it without a master degree in chemistry and a company letter head.

2)

Röhm sells some plexiglas glues under the Acrifix brand which meant to harden/settle from the ultraviolet component in our daylight; those glues also make fine glue joints. If you glue the plexi on brushed alu, should be fine.

I used to use AcriFix 92.

V-groove: i agree with Peter. Leave the goove unpolished, you want the blue light get scattered on the groove's surface; the rest of the blue light is caught within the plexi by total reflection if you couple the light into the edges of the plexi frontplate.

Bernhard,

If you give trichlorehtane to everybody in this forum, U will loose all your members

If echelon is online right now it will be snooping us for sure 😀

If you give trichlorehtane to everybody in this forum, U will loose all your members

If echelon is online right now it will be snooping us for sure 😀

SHAVINGS

Chris,

Maybe you could ask fellow member Remp for a special version of his mulcher?

Cheers, 😉

Chris,

When cleaning those shavings do not do what I did, I used to clean them with a vacumn cleaner, they clogged up the hose really really bad, I was lucky that it was my shopvac rather than my central vac system, otherwise it would have been a real plain try to locate where in the pipes that they clogged up. Imagine it could have been inside walls or between floors.

Maybe you could ask fellow member Remp for a special version of his mulcher?

Cheers, 😉

Can do.

At present I am thinking to think up a noise free electric lawn mower since my neighbour next door likes me but hates my very noisy two stroke mower.

Few years ago we had an elderly man who persisted in cutting his grass at 6 am regularly every Sunday morning just when the guys next door were sleeping after hard party time.

One of them shot him. His defence was he tried to hit the lawn mower and missed.

At present I am thinking to think up a noise free electric lawn mower since my neighbour next door likes me but hates my very noisy two stroke mower.

Few years ago we had an elderly man who persisted in cutting his grass at 6 am regularly every Sunday morning just when the guys next door were sleeping after hard party time.

One of them shot him. His defence was he tried to hit the lawn mower and missed.

Gentlemen,

Thank you so far for the glueing advice 🙂 I'll ask my University chemistry friends to arrange some of that 1.1.1 trichorethane or similar stuff.. I like the idea of perspex (plexiglass) solveant... Maybe they can think of some less lethal solveants

Bouke

Thank you so far for the glueing advice 🙂 I'll ask my University chemistry friends to arrange some of that 1.1.1 trichorethane or similar stuff.. I like the idea of perspex (plexiglass) solveant... Maybe they can think of some less lethal solveants

Bouke

- Status

- Not open for further replies.

- Home

- Design & Build

- Equipment & Tools

- Useful tools and techniques