Ever since eyeballing my Dad's big multiways when I was a teenager , Yamaha as well as JBL, I've wanted a kabuki style, and when I came across a chunk of panel I could resize for a simple open baffle one, it was go time.

Planned compromises from my usual single driver is a tweeter in the original design, a little more efficient than the woofer, which has some roughness without a crossover, but I recall as quite good to 4000 hz without toe in at about 20% off axis. Some sub drivers lowish for OB qts, but have worked well with a stereo 50 watt amp in much larger baffles, so I'm somewhat optimistic they'll be okay at 40+ hertz in small baffles with a lot more power and some eq. for mono distributed and space saving bass.

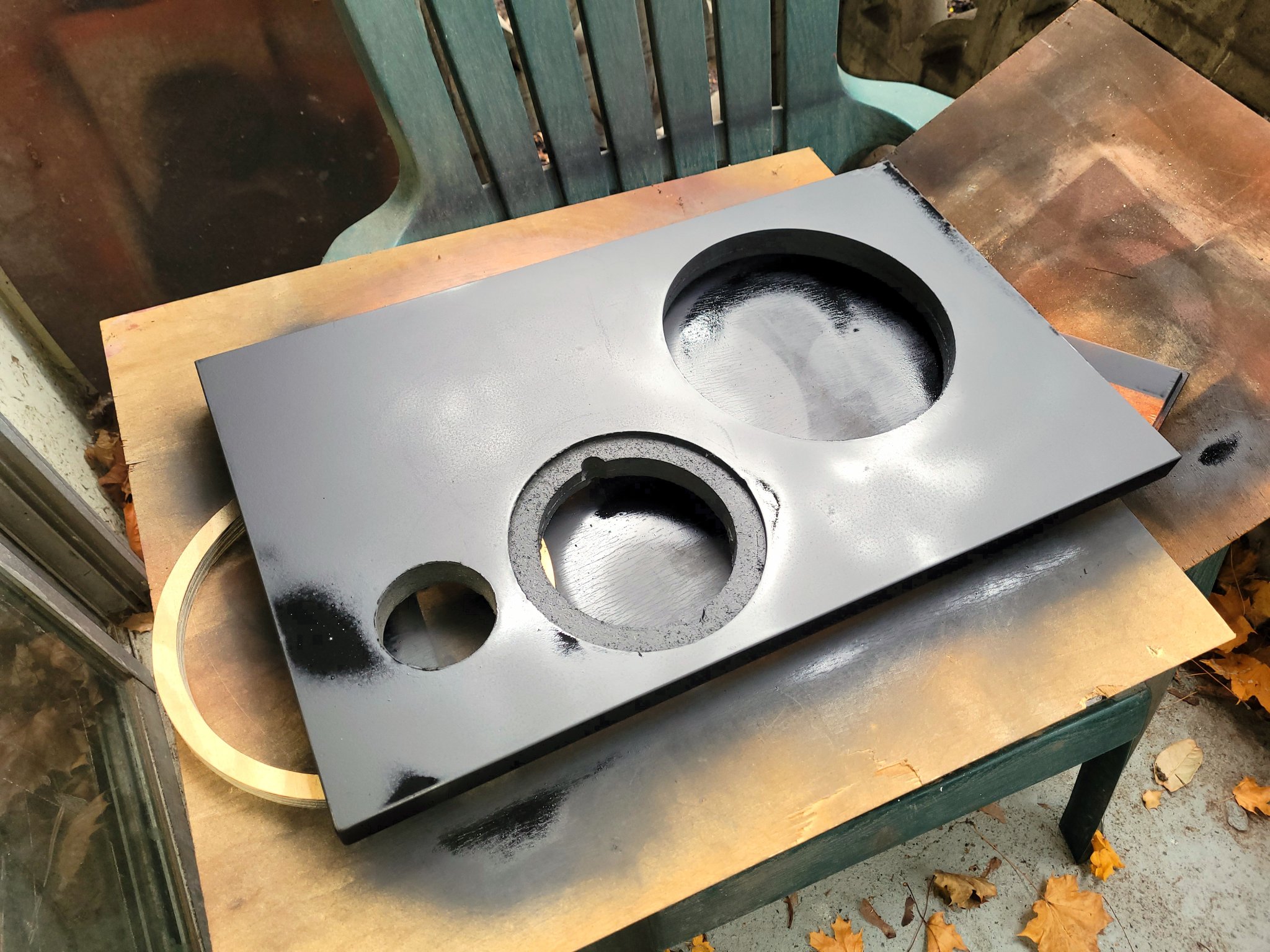

If not, these will be passive three ways and utilize what I've already got for subs. That's enough sawdust for one afternoon before setting up a bigger router with a deeper bit to go through an inch and a quarter thick baffle.

The look is going for vintage, and I shied away from using my first choice of smaller paper mids for an all paper driver build, as much for looks as them handling below 80 hz more comfortably than my original choice.

Turning out to be a fun little project.

Naturally after planning my mid countersink allowances to use 1/8" weatherstripping for flushmounting, locally I can only find 1/4" thick.

Planned compromises from my usual single driver is a tweeter in the original design, a little more efficient than the woofer, which has some roughness without a crossover, but I recall as quite good to 4000 hz without toe in at about 20% off axis. Some sub drivers lowish for OB qts, but have worked well with a stereo 50 watt amp in much larger baffles, so I'm somewhat optimistic they'll be okay at 40+ hertz in small baffles with a lot more power and some eq. for mono distributed and space saving bass.

If not, these will be passive three ways and utilize what I've already got for subs. That's enough sawdust for one afternoon before setting up a bigger router with a deeper bit to go through an inch and a quarter thick baffle.

The look is going for vintage, and I shied away from using my first choice of smaller paper mids for an all paper driver build, as much for looks as them handling below 80 hz more comfortably than my original choice.

Turning out to be a fun little project.

Naturally after planning my mid countersink allowances to use 1/8" weatherstripping for flushmounting, locally I can only find 1/4" thick.

Literally waiting for the paint to dry, before applying a little satin black decor. The weirdo in me tried the drivers out like the old Dynaudio flagships-tweeter and mid lower, with a woofer on top.

The 17" stands adust the floor reinforcement for the bass as expected, so that's a no.

Worked great for allowing toe in, no padding down for the tweeter, and keeping the roughish upper midrange off axis though.

The 17" stands adust the floor reinforcement for the bass as expected, so that's a no.

Worked great for allowing toe in, no padding down for the tweeter, and keeping the roughish upper midrange off axis though.

My current speakers are a line array based on a design by Danny Ritchie at GR-Research. These use 16 GR-Research NEO3 planar magnetic tweeters and six Bohlender-Graebener NEO 10 midrange drivers in each tower. They play down to about 180Hz with an efficiency of ~98db/w. I'm driving them with a DIY 300B PSET amp (~15W).

The bass is handled by a pair of four-driver H-frame towers using Rythmik/GR-Research 12" servo woofers powered by Rythmik HX800 amps.

The bass is handled by a pair of four-driver H-frame towers using Rythmik/GR-Research 12" servo woofers powered by Rythmik HX800 amps.

Thanks. I wish I could do that kind of work by hand 🙂 . These are CNC cut out of a composite material to be strong enough with all the cutouts. I had them painted (by an autobody shop) the same color as the Miata I owned at the time (Mazda Ceramic Metallic).@Jaytor did you CNC the baffles or cut them out by hand? They look great.

The woofer towers are 1.5" MDF (two sandwiched 3/4" in some places), also CNC cut. Each woofer driver is in its own small H-frame which are all bolted together.

Last edited:

Thanks. It's not obvious, but the the floor to ceiling panels behind the speakers are ATS quadratic residue diffusors wrapped in Guilford of Maine fabric. These really made a big positive difference. I highly recommend them for anyone looking for effective wide-range diffusors at a decent price.Nice job, jaytor. Good execution on the speakers and nice room treatments

The only way to get more speakers into my room is to stack them on top of each other. Right now I'm enjoying a pair of old Hammer Dynamics 12" fullrange drivers in scrap plywood baffles. Not exactly neutral, but with some BSC filtering they sound surprisingly "rich" (and WAF is of course reaching new levels...)

.

.

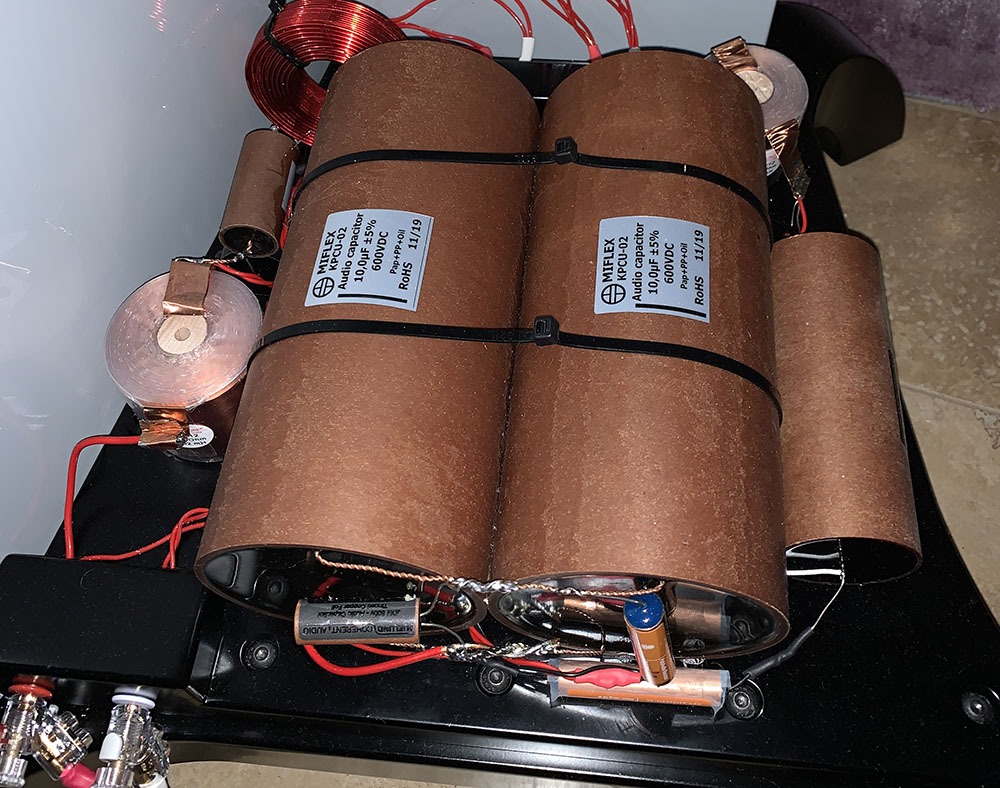

My Kabukenstein open baffles, simplest passive crossover I could get to sound pleasant between tweeters and woofers, and line level crossovers between dual mono 10 inch subwoofers.

For when home theatre is used, a

passive three way centre speaker, with matching woofers, and a crossover to suit the TV stand dictated baffle dimensions.

For when home theatre is used, a

passive three way centre speaker, with matching woofers, and a crossover to suit the TV stand dictated baffle dimensions.

Last edited by a moderator:

Just delivered (unexpectedly in B.C. from Quebec) in 6 calendar days.

Columbia hickory plywood, bought sight unseen a little apprehensively.

No dings or marks, and perfectly square, cut to within less than a 32nd of an inch of the stated 24" x 48" dimensions.

Seeing it now, I'm discarding the idea of a tint, and will just go with some linseed oil for a matte finish.

Columbia hickory plywood, bought sight unseen a little apprehensively.

No dings or marks, and perfectly square, cut to within less than a 32nd of an inch of the stated 24" x 48" dimensions.

Seeing it now, I'm discarding the idea of a tint, and will just go with some linseed oil for a matte finish.

Last edited by a moderator:

I've finished cutting to dimensions for the evening. Still liking the looks of the delivered hickory plywood...no voids encountered on the factory or my cut edges-however...

Not sure why I looked up Columbia plywood, but it's using soy flour and resin for glue. I've never encountered this before and haven't yet found if an oil finish like the slow drying linseed I got for this will react with it.

Anyone use this kind of glue with.a deep penetrating oil?

I could switch to a water based urethane, but am pretty partial to the look of oil if it's not going to react.

Not sure why I looked up Columbia plywood, but it's using soy flour and resin for glue. I've never encountered this before and haven't yet found if an oil finish like the slow drying linseed I got for this will react with it.

Anyone use this kind of glue with.a deep penetrating oil?

I could switch to a water based urethane, but am pretty partial to the look of oil if it's not going to react.

Linseed oil is IHMO not a good choice for a piece of furniture, or a set of speakers in that respect.

Dries slowly, goes rancid and attracts mold, water resistance low, durability low. Its only advantage is it is cheap.

Plenty of other oils that will be a much better option, like tung oil, orange oil.

I personally use what modern day luthiers use for their guitars and other stringed instruments - wiping varnish.

Any poly varnish diluted with turpentine 1:2 or 1:1 and wiped multiple times with light sanding in between.

https://www.liutaiomottola.com/PrevPubs/WipingVarnish/WipingVarnish.htm

Dries slowly, goes rancid and attracts mold, water resistance low, durability low. Its only advantage is it is cheap.

Plenty of other oils that will be a much better option, like tung oil, orange oil.

I personally use what modern day luthiers use for their guitars and other stringed instruments - wiping varnish.

Any poly varnish diluted with turpentine 1:2 or 1:1 and wiped multiple times with light sanding in between.

https://www.liutaiomottola.com/PrevPubs/WipingVarnish/WipingVarnish.htm

Yes, thar comes up on a any quick search of myths about linseed oil. Especially so in direct comparisons with true unpolymerized Tung oil.

However, I've used even raw linseed oil in heavy use projects like the kitchen table and chairs I built about 25 years ago and still use with no ill effects, aside from refreshing it every 5 years or so.

I personally dislike the plasticky look of many guitar finishes for speakers, and am okay with returning to linseed for this.

Back to my question though, what's your opinion about the soy flour- resin glue used in this plywood? Should I expect a reaction between the oil and the glue? I didn't mask the exposed sides, but didn't apply oil to them either.

As my usual, the baffles got one coat of oil prior to cutting any driver hole, and will overall get a light 150 grit sanding with the raised grain, another oil coat, a light 220 sanding, and another coat with some mineral spirits.

However, I've used even raw linseed oil in heavy use projects like the kitchen table and chairs I built about 25 years ago and still use with no ill effects, aside from refreshing it every 5 years or so.

I personally dislike the plasticky look of many guitar finishes for speakers, and am okay with returning to linseed for this.

Back to my question though, what's your opinion about the soy flour- resin glue used in this plywood? Should I expect a reaction between the oil and the glue? I didn't mask the exposed sides, but didn't apply oil to them either.

As my usual, the baffles got one coat of oil prior to cutting any driver hole, and will overall get a light 150 grit sanding with the raised grain, another oil coat, a light 220 sanding, and another coat with some mineral spirits.

Last edited by a moderator:

Just used good quality cold pressed linsoil. It does need more attention, than normal oil and for outdoor use, you might want to add a fungicid

Where did you come across these?Do you guys know who makes these drivers in Serbia? Suppose to be better sounding then Voxativ

View attachment 1277475View attachment 1277476

Hi all,

it is not this one

https://www.cubeaudio.eu/drivers

but with a similar approach

east european, they prefer to make their own cnc machined baskets assembled with single parts instead of buying the default parts from China like Sonido in Bucarest does to save money and keep the price lower for the end customer

it is not this one

https://www.cubeaudio.eu/drivers

but with a similar approach

east european, they prefer to make their own cnc machined baskets assembled with single parts instead of buying the default parts from China like Sonido in Bucarest does to save money and keep the price lower for the end customer

- Home

- Loudspeakers

- Multi-Way

- Ultimate Open Baffle Gallery