There is a saying that may apply here, "Don't let great be the enemy of the good."

I still like the idea of a 4U x 500mm chassis, and I would rather have a simple implementation with no UMS holes than wait a coupe months for the store to figure out exactly what the new UMS hole pattern needs to be. I have become used to drilling and tapping my own holes for almost all of projects that I've built, and I currently don't have any plans to build other amps with PCBs that conform to the UMS hole pattern.

The one thing that would be a benefit would be to have a rear plate similar to the 4U Deluxe chassis with holes for the RCA connectors and power inlet/on-off switch. Those holes are more difficult to drill/cut than the PCB mounting holes. But again, it's not a show stopper to have to drill my own holes in the back plate. That's what my big floor standing drill press and stepped bit are for. The mounting holes are simple enough with a bench top drill press and careful use of a hand tap.

Thanks 2 pico for getting this effort started.

I still like the idea of a 4U x 500mm chassis, and I would rather have a simple implementation with no UMS holes than wait a coupe months for the store to figure out exactly what the new UMS hole pattern needs to be. I have become used to drilling and tapping my own holes for almost all of projects that I've built, and I currently don't have any plans to build other amps with PCBs that conform to the UMS hole pattern.

The one thing that would be a benefit would be to have a rear plate similar to the 4U Deluxe chassis with holes for the RCA connectors and power inlet/on-off switch. Those holes are more difficult to drill/cut than the PCB mounting holes. But again, it's not a show stopper to have to drill my own holes in the back plate. That's what my big floor standing drill press and stepped bit are for. The mounting holes are simple enough with a bench top drill press and careful use of a hand tap.

Thanks 2 pico for getting this effort started.

Well I already decided to do our own custom order. I won't bother trying to convince the store about this.

We will get a price with the holes.

Then you guys can decide what you want to do.

We will get a price with the holes.

Then you guys can decide what you want to do.

Regardless if they are going into UMS or not, i think it is a good idea to add the extra holes to this chassis.

I do not know what i will be building in the future so the extra holes may come in handy.

No problem. If this is done as a custom batch the holes can be whatever you like.

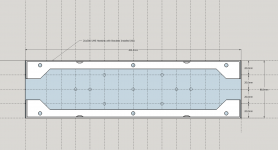

As a way of providing context, attached is a 3Ux300 UMS design. It takes the 2Ux300 UMS (again as yet unpublished, but it's what you see in the ACA heatsinks), and merges it with the 3Ux300 UMS. You can then upsize a 2U project to use 3U heatsinks, or downsize a 4U project to use 3U heatsinks. Why has it never made it past the drawing board? Well, for starters it's a bit of a dog's breakfast (a mess) isn't it? Again, not to say it's not a good idea or won't be implemented, but adding holes with wild abandon is not something we want to be doing. Less is more. These are important holes that will adorn the chassis of DIYers for many years to come, and should be carefully considered with input from stakeholders (designers, builders, etc).

As I have mentioned a few times, it's about time for a UMS 2.0 revision. It's been 8 years. Take the learnings from the last 8 years of this interesting experiment, and make any adjustments necessary.

- Publish the existing 2Ux200 and 2Ux300 specs.

- Confirm a 3Ux300 spec (whether it's a hybrid monster, or not).

- Possibly add Pico's 4Ux500 ideas into a 4Ux500 spec (The symmetrist in me would like to see more of the 500mm heatsink being able to be used as well as split and centered boards catered for in each of the split heatsinks)

- Possibly add a 3Ux400 or 3Ux500

- Possibly adjust or abandon the current vertical offset of the UMS on the heatsink in favor of vertical symmetry

Keep in mind that each standard requires Hifi2000 to consume and keep stock on their limited shelving space. There needs to be a good market demand and turnover.

All these are good and interesting possibilities. Feedback will be welcomed by builders and designers. Past customers will be surveyed.

There is a saying that may apply here, "Don't let great be the enemy of the good."

I am constantly guilty of making simple things complex, so I also like leaning on Occam's razor. If the point you are trying to make is that throwing in a few extra holes is no big deal, I do take that on board. We could potentially knock out this batch of 16 (or a subset thereof) with Pico's pattern while discussions are brewing about cementing a documented UMS pattern for 4Ux500. That would be a win/win/win for all concerned.

I still like the idea of a 4U x 500mm chassis, and I would rather have a simple implementation with no UMS holes than wait a coupe months for the store to figure out exactly what the new UMS hole pattern needs to be.

Personally I'm a big fan of lower profile, wide and deep chassis. More floor space, less wasted vertical space. This is a good opportunity to see what people like. The upcoming VFET offering (shhhhhh) will go the opposite way and looks super interesting (expect to hear news about this in the coming week or two).

We've been asked many times over the years for a 3Ux300. A 4Ux500 is a neat idea and Gianluca and I are very happy to roll it out as an experiment. But the devil is in the details.

Here's what is probably going to happen:

- The store will make available a standard 4Ux500 Dissipante chassis. There will be a limit of 16 of them available for pre-order (unless some of those are consumed by a custom order from Pico or others), shipping in 2 weeks. At this stage, these will be standard chassis, not deluxe (no baseplate, no UMS, no max vented covers, no rear holes, no rear faceplate holes).

- If people such as yourself want to buy them, great. It will give us confidence to work on this format more in the future.

- Currently there is no such thing as a 500mm baseplate. The 400mm baseplate can be used, or we could make custom 500mm ones for this run.

There's a lot of interest in this thread, but I'm presuming what people want is varied - plain, UMS or "Pico" heatsinks, plain, Deluxe or custom rear panels, will a 400mm baseplate do or do you want a 500mm baseplate. Anything is possible, but the easiest thing for us to do for sure is just roll this out as a standard item first and people can customize it as they like, as they can currently with any other chassis from the store.

Down the line, a 4Ux500 Deluxe could be born.

As for Pico's needs, that's no problem either. We just need to know what he wants.

It sounds like he has very specific requirements and we're happy to help.

I have become used to drilling and tapping my own holes for almost all of projects that I've built, and I currently don't have any plans to build other amps with PCBs that conform to the UMS hole pattern.

Yep, everyone has different needs. The UMS pattern and the Deluxe chassis line was designed to help the masses solve the hardest part of their DIY build - the chassis. And produced as a simple standardized item to keep the price as affordable as possible. It's not for everyone and it has compromises. In the case of this F6 x 5Ux400 issue, you can see the result of some of those compromises having an unintended result. That's cool - we are learning as we go and are always appreciative of feedback. We do send a lot of feedback request emails to try and stay in touch with customers and learn from their feedback and constantly improve things.

I The one thing that would be a benefit would be to have a rear plate similar to the 4U Deluxe chassis with holes for the RCA connectors and power inlet/on-off switch. Those holes are more difficult to drill/cut than the PCB mounting holes.

No problem - it can use the existing 4U Deluxe rear panel.

Thanks 2 pico for getting this effort started.

Indeed. As I've mentioned, we already have a few more UMS patterns waiting to be finalized and published, so this is a good opportunity to get that done. I'd estimate it will take a month. We have a lot on at the moment.

Well I already decided to do our own custom order. I won't bother trying to convince the store about this.

We will get a price with the holes.

Then you guys can decide what you want to do.

Whatever you like 🙂

In order to produce a custom order, we'll need to know exactly what you want:

- The size (4Ux500 comprised of 2x250mm heatsinks per side)

- If a baseplate is required

- If a baseplate is required, then whether a custom 500mm baseplate is required or whether the existing 400mm baseplate is ok

- How many rows of vents should be in the covers (standard (2 rows) or maximally vented (3 rows))

- What pattern should be drilled and tapped into the heatsinks (your supplied pattern, no problem)

- If the front panel should have the 9 blind "Deluxe" holes in the rear of it, or any other CNC

- If the rear panel should be standard or have custom CNC work

Thanks again for your feedback about how the F6 fits on the the 5Ux400 split heatsink chassis. I think this has been a good and stirring discussion and will help to cement the much needed documentation 2U, 3U, 4U and 5U UMS patterns of various depths over the coming weeks, which will see DIYers through the next decade of do-it-yourself audio.

Pico - hope we can meet in person next week for a coffee. It would be great to meet you. I'll be in touch.

Attachments

Last edited:

Jason - Ill be using this chassis specifically for the new Vfet kit so whatever guidance you can give would be greatly appreciated

The VFET will have its own unique and special chassis designed just for it, more on that later in another thread 🙂 News about it be published soon, including a mailing list to join for people that are interested. However let's not get off topic. I knew I shouldn't have even mentioned it here but I just wanted to make a point about dimensional aesthetics and preferences.

The VFET will have its own unique and special chassis designed just for it, more on that later in another thread 🙂 News about it be published soon, including a mailing list to join for people that are interested. However let's not get off topic. I knew I shouldn't have even mentioned it here but I just wanted to make a point about dimensional aesthetics and preferences.

Oh damn ok that complicates things for me cause I was getting into this group buy thinking I could use the new Vfet kit like any other build on the 4U/5U chassis but doesn’t look to be the case. I’m glad you said something

Oh damn ok that complicates things for me cause I was getting into this group buy thinking I could use the new Vfet kit like any other build on the 4U/5U chassis but doesn’t look to be the case. I’m glad you said something

Wait a second we might be able to help you.

If they are using T brackets like before we can probably still make it work.

Last edited:

Oh damn ok that complicates things for me cause I was getting into this group buy thinking I could use the new Vfet kit like any other build on the 4U/5U chassis but doesn’t look to be the case. I’m glad you said something

Owing to the scarcity of the VFETs, there will (unfortunately) be a very limited number available. Demand will be much greater than supply. A lot of thought has gone into how allocation can be as fair as possible, and every interested forum member will have an equal, even and fair chance. You don't need to worry about a chassis for it - that is taken care of. It isn't appropriate for me to say more here now, please wait for an announcement with accurate details.

We can meet in person anytime.

Awesome, I'll shoot you an email.

Last edited:

Owing to the scarcity of the VFETs, there will (unfortunately) be a very limited number available. Demand will be much greater than supply. A lot of thought has gone into how allocation can be as fair as possible, and every interested forum member will have an equal, even and fair chance. You don't need to worry about a chassis for it - that is taken care of. It isn't appropriate for me to say more here now, please wait for an announcement with accurate details.

Is there some kind of preorder reservation for the Vfet kit, or will people receive an email notification that it is available for order?

I am unaware of what method will be used to ensure that people who desperately want this will have a reasonably fair chance of placing an order.

I guess you could do it as a raffle, people place an order into the raffle and people get chosen at random, that would be assuming you are flooded with more orders than you can place.

Last edited:

Details will be posted in the announcement (and yes, it will be raffle based).

Finally, I can stop refreshing my browser every ten minutes!

In the case of this F6 x 5Ux400 issue, you can see the result of some of those compromises having an unintended result. That's cool - we are learning as we go and are always appreciative of feedback.

No problem - it can use the existing 4U Deluxe rear panel.

In order to produce a custom order, we'll need to know exactly what you want:

- The size (4Ux500 comprised of 2x250mm heatsinks per side)

- If a baseplate is required

- If a baseplate is required, then whether a custom 500mm baseplate is required or whether the existing 400mm baseplate is ok

- How many rows of vents should be in the covers (standard (2 rows) or maximally vented (3 rows))

- What pattern should be drilled and tapped into the heatsinks (your supplied pattern, no problem)

- If the front panel should have the 9 blind "Deluxe" holes in the rear of it, or any other CNC

- If the rear panel should be standard or have custom CNC work

If the F6 pcb is eventually revised, I would like some input.

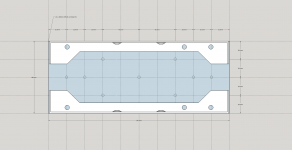

1) 4U x 500mm - 2 x 4U x 250mm heatsinks per side

2 and 3) Baseplate - only if it can be made at least 460mm to 480mm long and there is enough interest (400mm wouldn't cut it). I will let the people decide.

If we go with no base plate, it might be of interest to people if we do a hole pattern in the base for mounting the psu or 2 x psus. Let the people vote on that too.

4) A single row of vents on each side will be plenty, however having some vents that run across the rear end of the top plate of the chassis would be good for Front End pcbs that mount almost virtually on the back panel, eg a BA3 or BA1/BA2 build, as well as future designs.

5) The proposed drill pattern. It would be nice to know how much additional holes might cost to decide whether we add more mounting holes along the heatsink to place mosfets - at the same 40mm spacing.

6) I think the front panel only needs to have the 4x blind construction holes for assembly, I don't think we need the other holes, but I want to be sure everyone is happy. The other holes are rarely used, with a 500mm case there is plenty of room so it's unlikely they would be necessary is my feeling.

Regarding any other CNC - If someone has an idea they want to propose we could discuss it. I am happy with plain.

7) I think for the rear we could go with the standard mounting, at the very least I think the IEC connector should be precut - maybe we should decide as a group what binding posts, RCAs, XLRs people prefer etc. I am biased towards using Neutrik for everything as it is really good quality stuff at a sensible price, but we will see if there is some kind of consensus with that.

Last edited:

Details will be posted in the announcement (and yes, it will be raffle based).

The only concern I’d have about a raffle is a the scenario where people reach out to 50 of their closest, non-audio friends to enter for a chance to win (on their behalf.) I guess every system can be gamed to some extent.

Then we could make it they need to be members for at least 3 or 6 months, so manipulation doesn't occur.

Last edited:

- Home

- Amplifiers

- Pass Labs

- Ultimate 4U 500mm Chassis - Who is interested?