One of my (many) project ideas is to make a TT that does that. The platter would have two hobby servo motors to do x-y movement of the spindle, and they would be powered by concentric slip rings under the platter using contacts that would only be engaged while the servo motors were being adjusted. I have yet to design the offset-sensing apparatus.

Thanks JP, very nice. A giant leap for playback performance.TX-1000 before and after Center Search.

As simple a thing as centering makes such a difference.

LD

One of my (many) project ideas is to make a TT that does that. The platter would have two hobby servo motors to do x-y movement of the spindle, and they would be powered by concentric slip rings under the platter using contacts that would only be engaged while the servo motors were being adjusted. I have yet to design the offset-sensing apparatus.

Attachments

Just read this about the Nakamichi player on the moment I have a discussion with some pressing plants about the centre hole after receiving a new record box from David Gilmour .

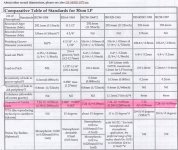

For my own W@F measurements I use some known testrecords were the older ones are within spec ,the later ones not as you can see in the picture .

Important thing to keep in mind because not all plants are serious about that.

For my own W@F measurements I use some known testrecords were the older ones are within spec ,the later ones not as you can see in the picture .

Important thing to keep in mind because not all plants are serious about that.

Looks like the eccentricity spec for RIAA is much sloppier than any of the others. 1.27mm off center who cares if the hole diameter is perfect?

Last edited:

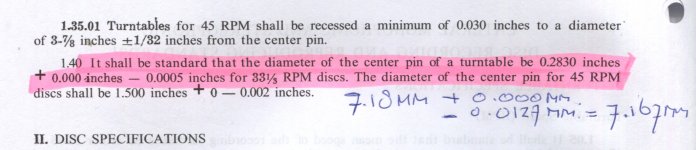

Mama. Let's hope it's a typo and should be 0.005"/ 0.13mm. Then again, there are many production records that don't meet the consensus hole size or centre specs, IME.Looks like the eccentricity spec for RIAA is much sloppier than any of the others. 1.27mm off center who cares if the hole diameter is perfect?

Even if records did meet those specs, the limits still seem set by what might just about be achievable in mass production rather than what's needed to be inaudible..........

LD

Records where the cartridge moves back and forth by a whole millimetre are unfortunately not uncommon. These would have a hole 0.5mm off centre. Many years ago I measured a whole bunch of records and found that the average was a whopping 0.35mm. Admittedly my measuring method was crude but by measuring each of dozens of records repeatedly my errors should be small.

I have also been toying with the idea of a method for reducing/eliminating eccentricity. Rather than add a complex centreing mechanism to the deck that would inevitably impact sound quality I would build a separate measuring rig. This would probably look a lot like a record player. It would measure the direction of the eccentricity and mark this on the edge of the label and also record the magnitude of said eccentricity. The actual centreing mechanism would be built into the record clamp. Dial the clamp to the magnitude, align with the mark on the label and tighten. Hole size variations could be dealt with using a retracting tapered spindle.

If you can reduce the level of eccentricity to less than the pitch of the groove a whole world of possibilities opens up for the tonearm designer.

Unfortunately I don't currently possess the tools (or the money to buy them) that would be required to make this system. Also if I bought another record player, even if it wasn't actually a record player, into the house I might end up single.

Niffy

I have also been toying with the idea of a method for reducing/eliminating eccentricity. Rather than add a complex centreing mechanism to the deck that would inevitably impact sound quality I would build a separate measuring rig. This would probably look a lot like a record player. It would measure the direction of the eccentricity and mark this on the edge of the label and also record the magnitude of said eccentricity. The actual centreing mechanism would be built into the record clamp. Dial the clamp to the magnitude, align with the mark on the label and tighten. Hole size variations could be dealt with using a retracting tapered spindle.

If you can reduce the level of eccentricity to less than the pitch of the groove a whole world of possibilities opens up for the tonearm designer.

Unfortunately I don't currently possess the tools (or the money to buy them) that would be required to make this system. Also if I bought another record player, even if it wasn't actually a record player, into the house I might end up single.

Niffy

- Home

- Source & Line

- Analogue Source

- Turntable speed stabilty