Just wanted to make it clear that I DO expect the response to change with regard to stuffing. At the moment, though, the unstuffed line sounds quite good by itself, and the stuffed line sounds good.

I need to glue these things together sometime soon. THEN we'll know.

Dave

I need to glue these things together sometime soon. THEN we'll know.

Dave

steve said:I would advocate that less [stuffing] is more... as in I would use as little as necessary. I think this will reduce the load on the driver.. providing a more lively sound...

I agree. I am guessing the short sections push the resonances up the frequency scale, where less stuffing is required to absorb them.

Didn't Martin J King's (MJK on this forum) program give you a specific amount of stuffing for this? I would put in that amount of stuffing and then add or subtract "to taste", to borrow a cookbook term.

PS: In order to add or subtract the stuffing once the Line is glued together, I would check your friendly local discount "home 'n hardware" type store for a plumbing snake. I would think that would come in handy. You might want to think twice about using one that you might already have, considering where it likely has been.

kelticwizard said:

Didn't Martin J King's (MJK on this forum) program give you a specific amount of stuffing for this? I would put in that amount of stuffing and then add or subtract "to taste", to borrow a cookbook term.

PS: In order to add or subtract the stuffing once the Line is glued together, I would check your friendly local discount "home 'n hardware" type store for a plumbing snake. I would think that would come in handy. You might want to think twice about using one that you might already have, considering where it likely has been.

I can reach the middle turn fairly easy. It IS 6" wide, you know.

I did use King's worksheets before I ever began. It's in the 2nd post of this thread. The design calls for .25 lb. stuffing per cu. ft.

What I'm about to do is the sections worksheet. That should help us out significantly.

Dave

Kneadle:

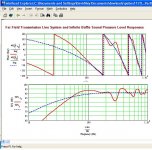

I take it, then, that the rust colored line is the predicted response of the Line when it is unstuffed, and the dotted blue line is the predicted response of the Line when it is stuffed with .25lb/cu. ft. ?

I take it, then, that the rust colored line is the predicted response of the Line when it is unstuffed, and the dotted blue line is the predicted response of the Line when it is stuffed with .25lb/cu. ft. ?

I think the blue line is some sort of reference line. The red line is the one I pay attention to. It's the one that changes. I did some doodling with the worksheets, and if I cram .55 lbs/cu.ft. of stuffing in the first 7 segments, then I have the flattest SPL readings between 60 and 200 Hz.

I have to tip my hand and admit that I have a loose understanding of the readouts. I'm sure that my design is not ideal, as I've said a few times, because the Sd is 1:1, and with the larger drivers, like mine, the pipe begins to choke a little.

Dave

PS--this has always been a sort of "prototype" project that sort of got out of control.

I have to tip my hand and admit that I have a loose understanding of the readouts. I'm sure that my design is not ideal, as I've said a few times, because the Sd is 1:1, and with the larger drivers, like mine, the pipe begins to choke a little.

Dave

PS--this has always been a sort of "prototype" project that sort of got out of control.

steve said:

I believe the blue line represents the ideal situation of an infinite baffle..

Oh. That makes sense.

I've searched King's site and I can't find a key to deciphering the readouts. He assumes a working knowledge of acoustics and electronics I don't have. I'd love to learn it, though. A website or book would be nice, if anyone is willing to offer a title or link.

Thanks,

Dave

The blue line is the driver in a sealed box (or maybe it is an infinite box -- the ref will be in one of the 1st papers) and is meant as a reference. The red line is the TL+terminus response.

dsve

dsve

kelticwizard said:PC7 and PC11 are epoxy glues that are rock hard and stick to PVC. I just got off the phone with the tech guy, and PVC it does work on.

I have used both, not on PVC but on other things, and forget about comparing these to other epoxy products. It cures rock hard, and holds like you wouldn't believe. Thick, it fills in slight indentations and can be sanded, primed and painted.

Available at "real" hardware stores, and probably True-Value types, though not sure about that.

I can't find any store that stocks anything like this. I drove all over the city this morning, and no one has PC7 or 11. They all have a big selection of various PVC cements and epoxies. ACE hardware has the best selection of these, and my 2 local plumbing suppliers have nothing better.

The epoxy I saw comes as some sort of putty that you actually manipulate with your hands.

Dave

My next suggestion, then, would be auto body putty like Bondo. I have no experience with it, one way or the other, bonding to PVC. You might want to check the can. It is available at most discount "home 'n hardware" type stores and, because you get a lot more of it for the same money, it might even be a better choice.

Also, mesh cloth can be used with Bondo, just like with PC7 and PC11, which might make it easier for you to glue. Just cut off some pieces, cover the mesh with Bondo, and wrap it around the joint. It's an option.

I will check a couple of auto body filler brand websites to see if it sticks to PVC. My guess is that it will, since PVC-which is part of the vinyl family-actually has quite a few things that stick to it.

This is in opposition to say, polyethylene, which almost nothing sticks to.

See you in a few. Gonna check out some auto body filler brand websites.

Also, mesh cloth can be used with Bondo, just like with PC7 and PC11, which might make it easier for you to glue. Just cut off some pieces, cover the mesh with Bondo, and wrap it around the joint. It's an option.

I will check a couple of auto body filler brand websites to see if it sticks to PVC. My guess is that it will, since PVC-which is part of the vinyl family-actually has quite a few things that stick to it.

This is in opposition to say, polyethylene, which almost nothing sticks to.

See you in a few. Gonna check out some auto body filler brand websites.

I was hoping you'd say something like "PC7 trades under brand name 'x'." If PC7 is an epoxy, then it's different from cement. I saw some epoxy at work. It's like a putty that, once exposed to air, dries over 12-24 hrs into something like solid PVC.

The hardware store had a little model for display. It had been cast in a plug shape, of sorts, like the rubber kind that stops a bathtub, but it was an absolute rock.

But nowhere did I see "PC7."

Dave

The hardware store had a little model for display. It had been cast in a plug shape, of sorts, like the rubber kind that stops a bathtub, but it was an absolute rock.

But nowhere did I see "PC7."

Dave

According to the Protective Coatings Website, Ace, True Value and Sears stock their products, if not PC7 or PC11. However, I do believe that PC7 is their most popular product.

http://www.pcepoxy.com/WhereToFind.htm

http://www.pcepoxy.com/WhereToFind.htm

The Bondo website says nothing about PVC pipe. Some board about DIY airplanes mentioned some problem with PVC pipe coated with Bondo gave them problems because of a different coefficient of expansion, but I don't think you plan to use these inside an engine.

I feeel a little shy about using Bondo, to be honest. The stuff stinks, it has styrene, and it is going into a baby's room. I do believe that other epoxies will do the job, just might not be so hard and durable as PC7 or PC11.

On the other hand, when I was at the dentist, he mixed up some concotion for a filling that was undeniably the same smell as Bondo. Which leads one to wonder about.....something. What's the next step in fashion dentistry-metalflake teeth?

If you can find somebody to recommend another epoxy, maybe that is the way to go.

I feeel a little shy about using Bondo, to be honest. The stuff stinks, it has styrene, and it is going into a baby's room. I do believe that other epoxies will do the job, just might not be so hard and durable as PC7 or PC11.

On the other hand, when I was at the dentist, he mixed up some concotion for a filling that was undeniably the same smell as Bondo. Which leads one to wonder about.....something. What's the next step in fashion dentistry-metalflake teeth?

If you can find somebody to recommend another epoxy, maybe that is the way to go.

The Ace Hardware Online Store has it. SKU# 17406. Don't know if that will help with your local store, though.

http://www.acehardwareoutlet.com/searchresults.asp?theSessionID=845626482

They have PC11 as well, SKU# 1002799.

http://www.acehardwareoutlet.com/searchresults.asp?theSessionID=845626482

They have PC11 as well, SKU# 1002799.

right-tool (http://www.right-tool.com/pc7epoxypaste.html) has the PC-7 epoxy. I'm just looking for something else to get me over their $10 minimum shipping restriction.

Thanks for the link. For the record, I did a google for "PC7" and never even came close, and my local ACE and Do-It-Best certainly don't have PC products.

Thanks for the link. For the record, I did a google for "PC7" and never even came close, and my local ACE and Do-It-Best certainly don't have PC products.

kelticwizard said:The Ace Hardware Online Store has it. SKU# 17406. Don't know if that will help with your local store, though.

http://www.acehardwareoutlet.com/searchresults.asp?theSessionID=845626482

I just searched there! I was searching "PC7", and the search engine wants "PC-7"!

I'll be jiggered.

Dave

** EDIT **

I have no idea why "PC7" at the ACE home page didn't find this. Will someone else try it from the ACE homepage?

I just found out that that individual website is operated by one AG Lock Co, which is an ACE Hardware Store in the 718 area code, (Brooklyn or Queens).

But I would think that they are the same as most other Ace Hardware Stores.

But I would think that they are the same as most other Ace Hardware Stores.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- TL Design I can't build