I haven't a radial arm saw in quite a while. That was my first purchase back in the day. You are doing the lighting correctly. Man it is tuff unless you the fluorescent route.

Assuming those are LEDs? I have been replacing fluorescent tubes with LED and find them both better on color balance and even better on the light dispersion. (And they use a lot less power - my power company says we use a lot more power than our neighbors.. I wonder why... 🤣

I am jealous, what a nice space for hobby purposes. Plenty of room for equipment and parts storage. Maybe an audio system?

I am jealous, what a nice space for hobby purposes. Plenty of room for equipment and parts storage. Maybe an audio system?

Are you a sparx, or just like the rest of the US and Canada free for all anyone can do their own electrical?Had a GFCI that wanted to nuisance trip occasionally. Finally it wouldn’t stay Re-set this morning. Black wire infinite ohms to ground, even on meg ohm setting. Pulled the white off the load side - and sure enough, short ground to neutral. At least the GFCI did what it was supposed to. Pulled the wire nut and separated the two feeds and one box downstream was the culprit. Pulled the cover off and the short clears. But damned if I can find any place where the insulation is worn through, scraped, or anything. I’m shortening up all the pigtails to the outlets it feeds to make room in the box, and I may as well replace the 7 foot section of incoming cable to tomorrow when I can see. I used the red plastic anti short bushings like youre supposed to (a 250 foot roll of Armorlite comes with a pack of 25 so there is no excuse) and I can’t get it to short moving the white wire around.

The light fixtures came yesterday afternoon but so far all I’ve done is unpack. I’m going to put cheater cords on the two 105W LED flat panel high bays that are going to light the 14’ high warehouse section and use them for work lights while doing insulation and Sheetrock.

Still blows me away they let ya'll fill ya boots on your own 110V hard wiring over there...

Yep - all LED. Each 4 foot strip is 45 watts and supposed to do 5900 lumens - the equivalent of two F32T8. I’ve got the regular T8 LED tubes in the closet, bathroom, and upstairs since those areas don’t need that kind of brightness. I’ve got the color temp set to 4k.

Much of the equipment and inventory storage is in the front room and upstairs, which won’t be fully finished out. That’s where the big PA systems normally live. The electronics bench will contain one of my tube based systems, and the bigger one goes in the wood shop. And of course those doors open, so the rest of the universe can hear it occasionally….

Yeah, they “let us” do our own electrical - but the regulations vary county to county. In the high tax districts they micro manage everything - more so they can assess every nickel and drive up the price you pay for everything making the assessment that much more. It IS more about money than safety. Here they're only valued everything at about 50% for tax purposes - and getting an inspection if you wanted one is like pulling teeth.

Much of the equipment and inventory storage is in the front room and upstairs, which won’t be fully finished out. That’s where the big PA systems normally live. The electronics bench will contain one of my tube based systems, and the bigger one goes in the wood shop. And of course those doors open, so the rest of the universe can hear it occasionally….

Yeah, they “let us” do our own electrical - but the regulations vary county to county. In the high tax districts they micro manage everything - more so they can assess every nickel and drive up the price you pay for everything making the assessment that much more. It IS more about money than safety. Here they're only valued everything at about 50% for tax purposes - and getting an inspection if you wanted one is like pulling teeth.

Not a free for all at all. All electrical wiring is subject to inspection and it depends heavily on jurisdiction as to just what is allowed in terms of DIY. Most local regulators would much prefer if a licensed electrician did the work, but will OK competent home owners.

We have at minimum the NEC (National Electrical Code) that must be met and many jurisdictions have additional or differing requirements that must be met based on local conditions. Here we have arc fault interrupters required on circuits that feed wall outlets in bedrooms and other living spaces, GFCI (RCD) in kitchens, laundries, bathrooms and outdoors.

Twenty years ago I did a significant amount of rewiring in my 2nd house, under the supervision of electricians (I apprenticed briefly) the only work that passed without any changes being required was mine. LOL

Before that I rewired my first house and it was all inspected and passed. I made sure to go introduce myself to the electrical inspector in that town and asked him if he would like to inspect prior to work and I would discuss the changes I planned to make, and ask for suggestions. He was quite happy to wander around that house and advise. I did exactly what he recommended and passed without any difficulty.

Uninspected wiring mishaps may result in problems with homeowners insurance or worse so not following the rules is at your risk obviously.

Many people here do use sparkies.

We have at minimum the NEC (National Electrical Code) that must be met and many jurisdictions have additional or differing requirements that must be met based on local conditions. Here we have arc fault interrupters required on circuits that feed wall outlets in bedrooms and other living spaces, GFCI (RCD) in kitchens, laundries, bathrooms and outdoors.

Twenty years ago I did a significant amount of rewiring in my 2nd house, under the supervision of electricians (I apprenticed briefly) the only work that passed without any changes being required was mine. LOL

Before that I rewired my first house and it was all inspected and passed. I made sure to go introduce myself to the electrical inspector in that town and asked him if he would like to inspect prior to work and I would discuss the changes I planned to make, and ask for suggestions. He was quite happy to wander around that house and advise. I did exactly what he recommended and passed without any difficulty.

Uninspected wiring mishaps may result in problems with homeowners insurance or worse so not following the rules is at your risk obviously.

Many people here do use sparkies.

Last edited:

The inspectors back in Collin county are more likely to pass garbage-grade contractor work than overbuilt DIY. It’s all to drive up prices. Around here there’s a manpower shortage. Lower taxes, and you get what you pay for. Got to be on top of things yourself, though, because if you hire something out it’s pretty much all on you to make sure they’re not cutting corners. DIYing, it doesn’t cost THAT much to wire something to code. But you do see it all the time - running 3 wire circuits when 4 is called for, unmarked neutrals, lack of ground rods, running URD into the inside panel, using #8 or even 10 to feed the stove or 4 ton AC, NM-B for exposed work. My worst offense out here was running that old PA distro on the front porch for 8 months straight till the breaker boxes were ready in the buildings. Don’t have to do that anymore. And I’ve seen far worse being used on job sites. I bought a new feed cable for it - the old one was pretty beat up. Worth the $200 if it saves a shower of sparks or getting myself 60 hertzed next time I set up the big PA.

I appreciate those that have tackled building structures and I'm jealous of many of these presented. I'd like to have that shop space or even just a garage. I rebuilt my cabin/house stripping the original down to frame sticks and back. Inside to outside. A small livable space.

I'm contributing a different build project. One that uses similar skills and materials and requires total completion before one can "move in" and utilize. The materials come in barrels, eight quarter timbers, fasteners by the pound. You fabricate all the parts custom by machining, shaping/gluing, and making the parts before assembling the structure twice. Once to fit the fabricated parts, then remove, glue joints and refasten them again using screws and bolts, mostly bronze. These fabricated parts all have compound curve shapes, all requiring fitted notched joints. No parts are square or straight. You start with 2 sheets of plans, selected tools and materials and factor in a huge amount of motivation. It required years of after daily work and weekends of countless hours. Here's where the works starts and finishes in gross steps.

After making custom parts,

Finish carpentry,

Persistence over 4 years, completed.

And the payback,

The 100K mile voyage thru 32 years, mostly sunmers with winters at home. This World wide voyage continues successfully with the same boat, same wife who is a total half and full partner of this total endeavor.

I'm contributing a different build project. One that uses similar skills and materials and requires total completion before one can "move in" and utilize. The materials come in barrels, eight quarter timbers, fasteners by the pound. You fabricate all the parts custom by machining, shaping/gluing, and making the parts before assembling the structure twice. Once to fit the fabricated parts, then remove, glue joints and refasten them again using screws and bolts, mostly bronze. These fabricated parts all have compound curve shapes, all requiring fitted notched joints. No parts are square or straight. You start with 2 sheets of plans, selected tools and materials and factor in a huge amount of motivation. It required years of after daily work and weekends of countless hours. Here's where the works starts and finishes in gross steps.

After making custom parts,

Finish carpentry,

Persistence over 4 years, completed.

And the payback,

The 100K mile voyage thru 32 years, mostly sunmers with winters at home. This World wide voyage continues successfully with the same boat, same wife who is a total half and full partner of this total endeavor.

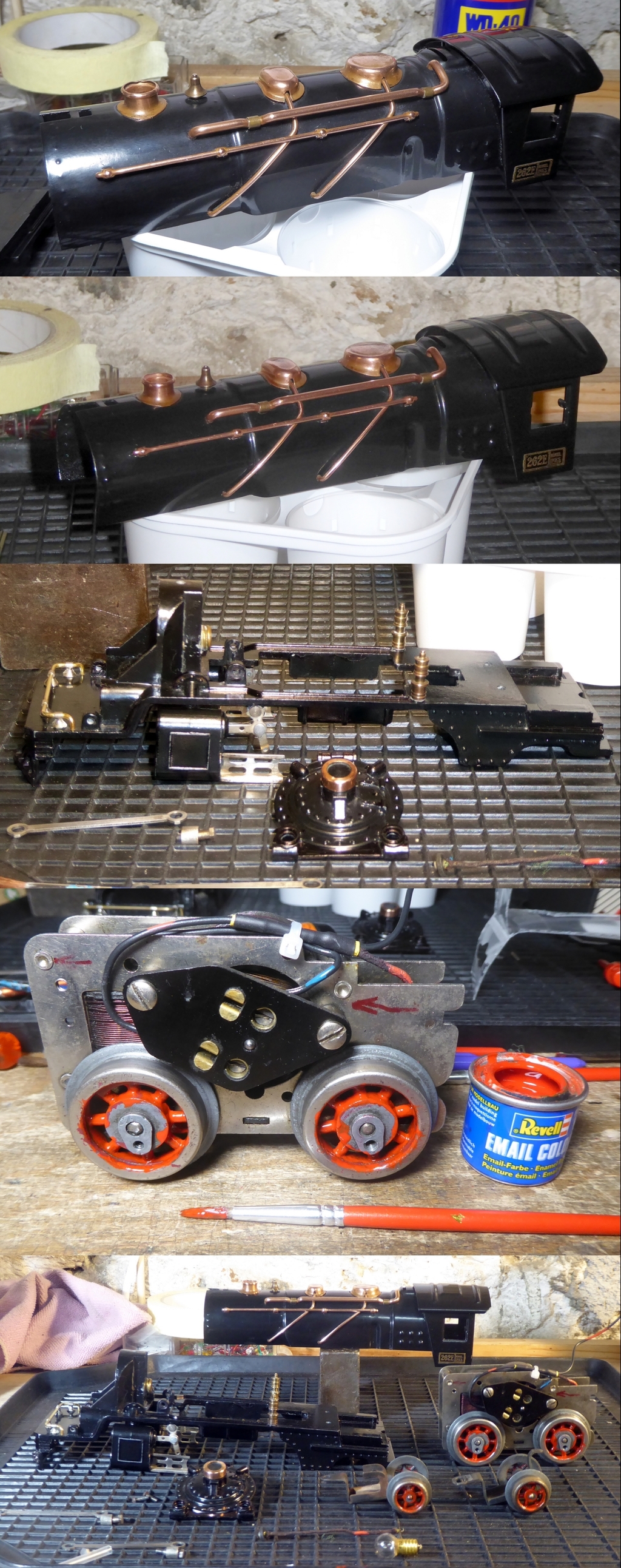

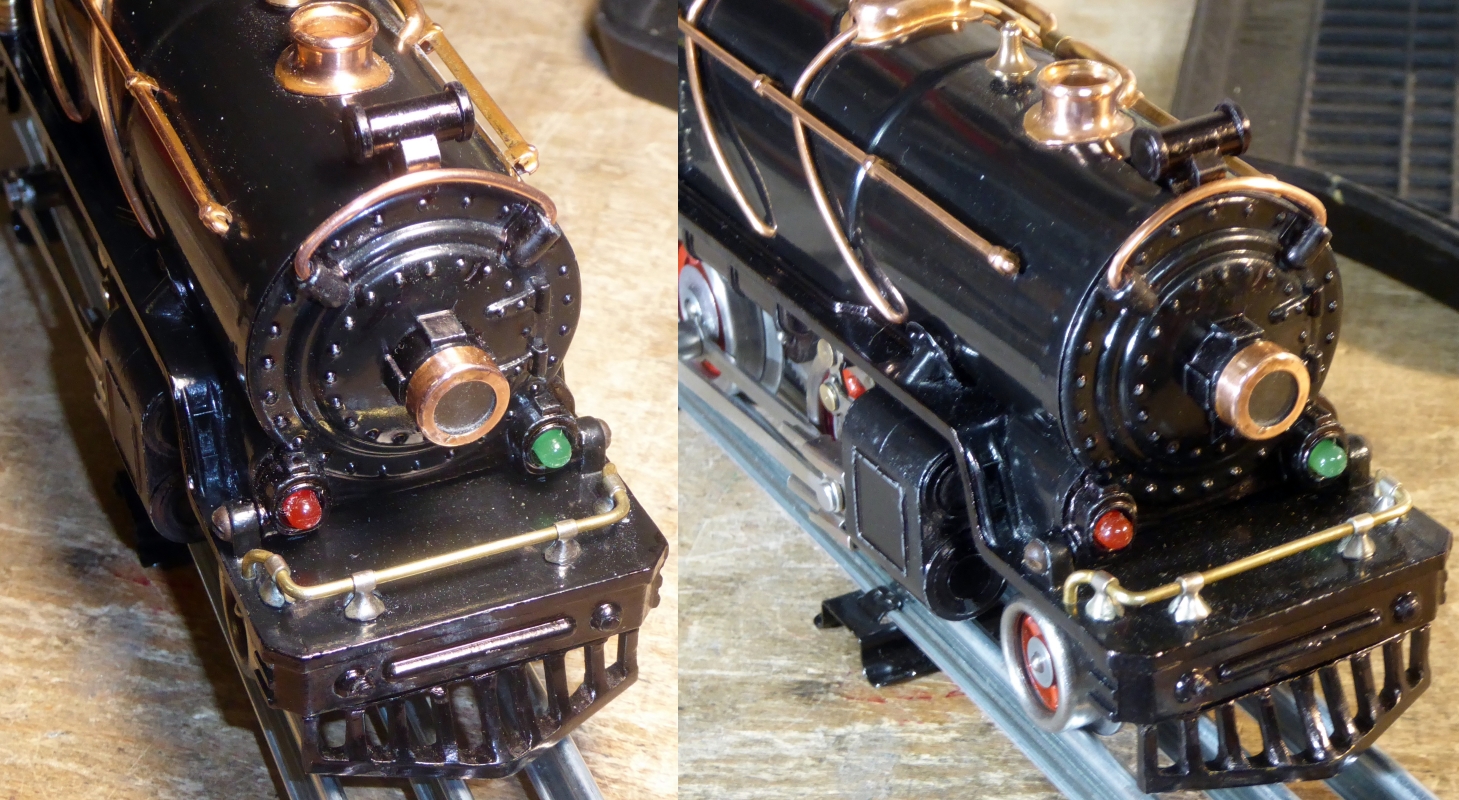

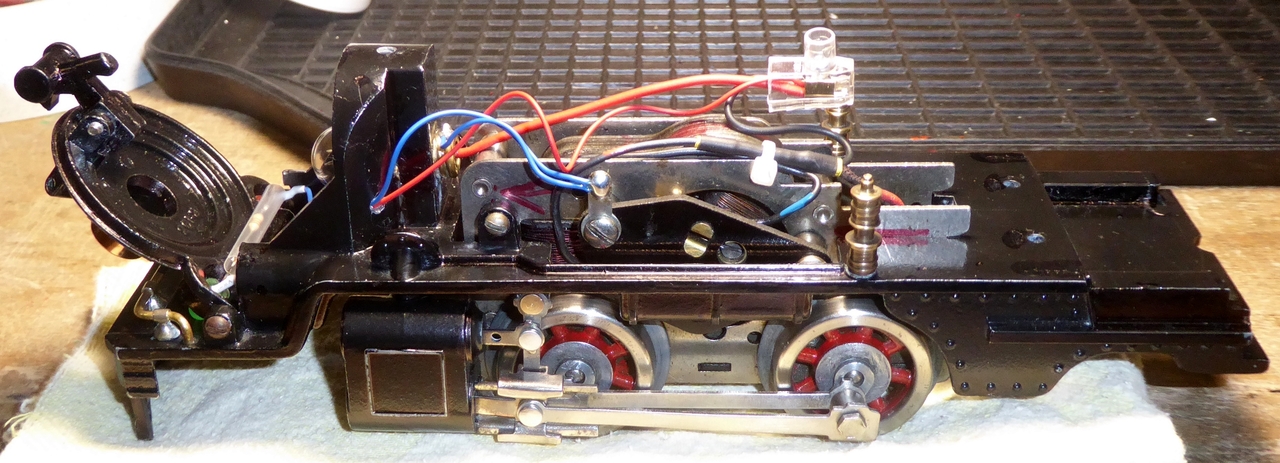

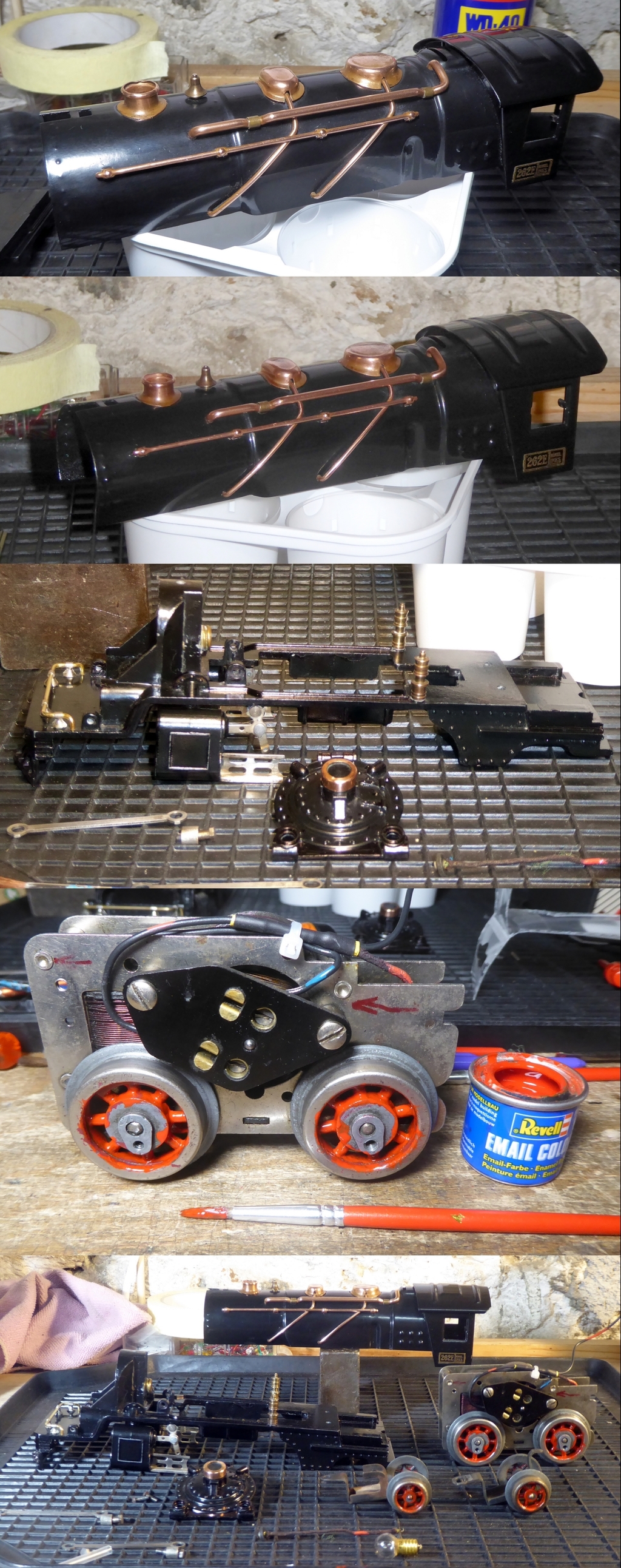

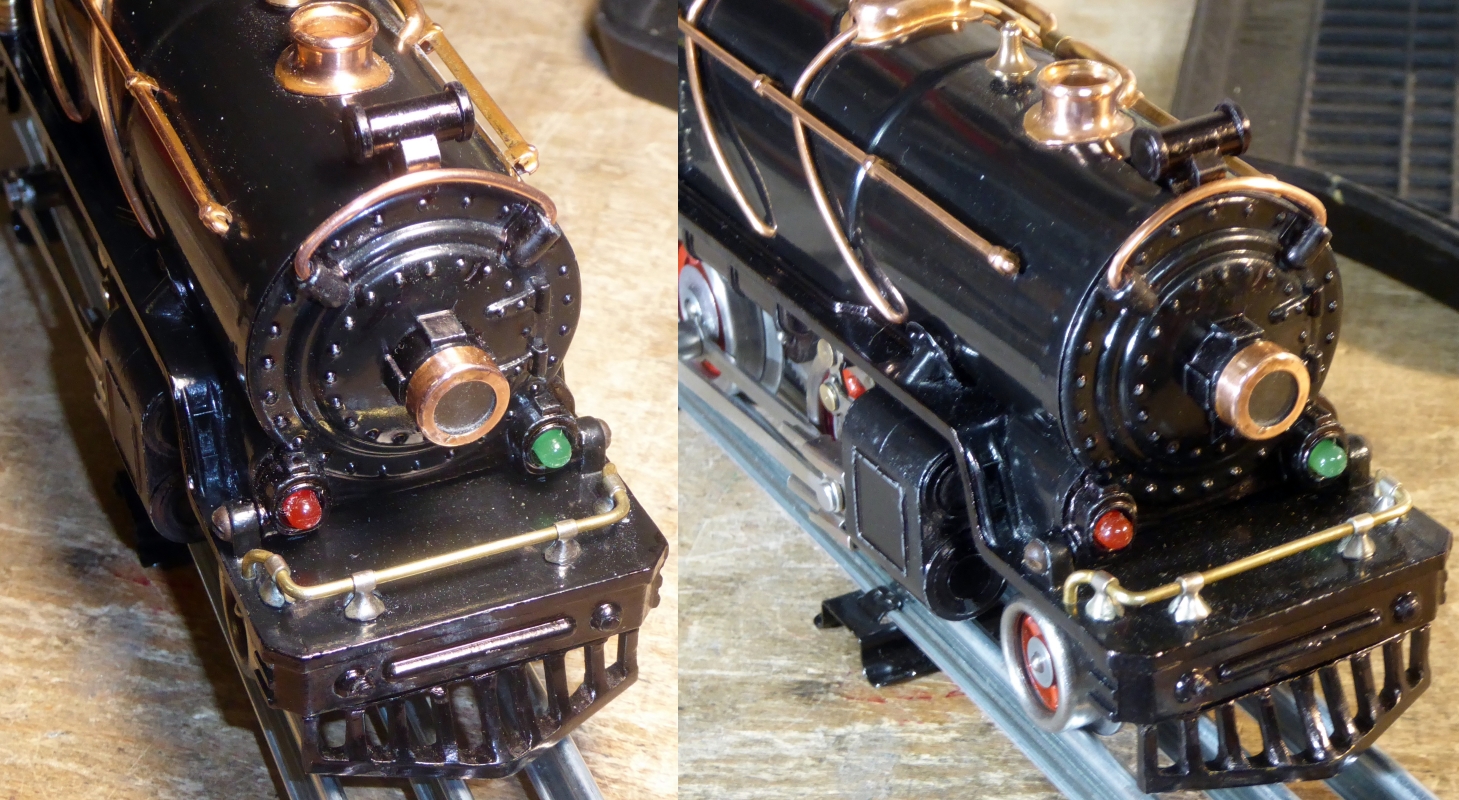

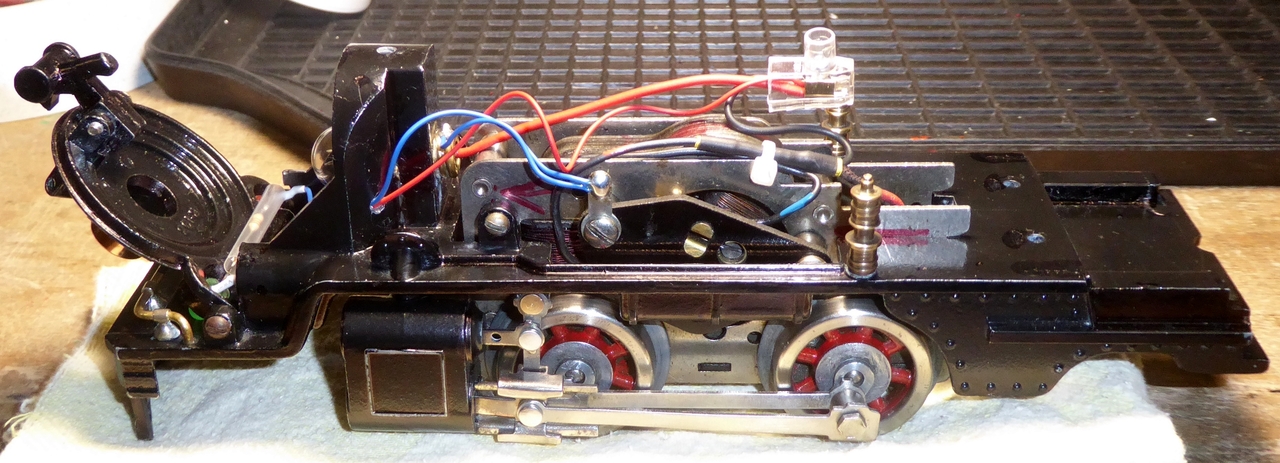

Non- audio RE build and mod of a 1934 Lionel 262E :

T

T

Taking somebody to the Train Station are you? Watching Yellowstone now….. had to quit for the night to watch.

Damn, that engine probably has a flux capacitor. You could go back to 1934 with that.

This phase is getting closer (and closer, and closer….). It may look like it’s almost done, but when it is there’s the entire house to do.

Damn, that engine probably has a flux capacitor. You could go back to 1934 with that.

This phase is getting closer (and closer, and closer….). It may look like it’s almost done, but when it is there’s the entire house to do.

Attachments

The ground was finally the right consistency to dig for the drain pipe. Not to gooshy on top and not brick hard on the original grade. This is as far as I got on the concrete forms before being chased off by rain this AM. It will be 4 days after the rain event before that can be finished up. The epoxy paint for the floor inside is en route, hopefully will be here on the 26th.

Attachments

The epoxy paint for the floor inside is en route, hopefully will be here on the 26th.

You mean : in transit - is that correct ? At least, that's the translation I would offer, being French native ! 😊 😉

My last non-audio restoration / rebuild : Princess Elizabeth...

... Pictured alog with her sister Lady Patricia...

Oh, and Merry Christmas ! 😀

T

The floor paint came on the 26th. 2 days to acid wash and clean it back up (it all doesn’t come up in the first rinse), then 2 days to wait for the epoxy to cure. Clear coat was quick, then wait another 3 days. Finally starting to clear the cabinets and work benches out of the front half. Got the walkway ready for the concrete, but now it’s too damn cold. When the nights get into the 30’s again that can be done. Cold is ok for concrete but freezing is not. By then the front half of the shop will be empty. Maybe we’ll get a week in the 50’s in February for the rest of the epoxy.

Attachments

I salute you. What a journey! 👍👍👍I appreciate those that have tackled building structures and I'm jealous of many of these presented. I'd like to have that shop space or even just a garage. I rebuilt my cabin/house stripping the original down to frame sticks and back. Inside to outside. A small livable space.

I'm contributing a different build project. One that uses similar skills and materials and requires total completion before one can "move in" and utilize. The materials come in barrels, eight quarter timbers, fasteners by the pound. You fabricate all the parts custom by machining, shaping/gluing, and making the parts before assembling the structure twice. Once to fit the fabricated parts, then remove, glue joints and refasten them again using screws and bolts, mostly bronze. These fabricated parts all have compound curve shapes, all requiring fitted notched joints. No parts are square or straight. You start with 2 sheets of plans, selected tools and materials and factor in a huge amount of motivation. It required years of after daily work and weekends of countless hours. Here's where the works starts and finishes in gross steps.

View attachment 1389302

After making custom parts,

View attachment 1389303

Finish carpentry,

View attachment 1389305

Persistence over 4 years, completed.

View attachment 1389306

And the payback,

View attachment 1389307

The 100K mile voyage thru 32 years, mostly sunmers with winters at home. This World wide voyage continues successfully with the same boat, same wife who is a total half and full partner of this total endeavor.

Building a boat is a HUGE undertaking. I remember seeing concrete hulls all over the place about 40 yrs ago. People started them, and rarely finished them. The real money and sustained effort was in the decking, masts, sails and outfitting so most of them were abandoned.

Last edited:

During that latest hard freeze I managed to get the warehouse cleared. It hasn’t been that clean since it was built. Got to get it prepped for floor epoxy, when we get the next 3 days of 50 degree weather. Had 2 days above freezing at night, so I played hooky from work to get that concrete down. Cold this AM, and supposed to plummet again tonight.

Attachments

Never feed them after midnight. Bright light! Bright light! I’ll be able to see when coming home at night for sure. Rented that scissor lift over the weekend and got most of the overhead lights installed and wired. Floor epoxy was ready in the warehouse. Unfortunately, didn’t get the two in barn done. The damn machine refused to lift over about six feet on the surface. It’s packed decomposed granite, 6” thick, with the rubber stall mats on top. Pretty solid, drive through it all the time - and it’s still easy on unshod horse feet. Darn thing’s “pothole detection” mechanism went off and stopped lifting before I got to the ceiling. Just too much give for it. Everything else was on concrete, so no issues.

I’ll end up having to erect scaffolding on top of the horse stalls to finish those. Isn’t going to be any safer. Maybe I’ll get the neighbor to lift me in his front end loader. At least the tools and supplies wint fall out of that.

I’ll end up having to erect scaffolding on top of the horse stalls to finish those. Isn’t going to be any safer. Maybe I’ll get the neighbor to lift me in his front end loader. At least the tools and supplies wint fall out of that.

Attachments

Well, I’m no longer working on the shop. Inside the house started a couple weeks ago. Just got done cleaning and rearranging, starting the interior wall framing later this week. The shop is now packed to the rafters with all the speakers and electronics (which are supposed to live there) and all the household goods….

Attachments

- Home

- Member Areas

- The Lounge

- The ultimate non-audio build thread