Very excited by this idea!

When I worked in RF (a million years ago, at least) stagger tuning was a time honoured method for getting flat response from IF amps and similar.

I have often considered the idea but haven't been game to try it out. With the rise of foamcore modelling, this may be the time. I have seen it done with pipe/TLs

PIPE RESONATOR FAMILY

and BRs

MCAP-CR Family

but never with horns.

This is the kind of application I have been trying to use the 'Transmission Line' software for. I have had some success with Akabak but when you don't have a clear design process, there is no substitute for 'make it longer and see what happens'.

Kind regards,

Im4blakk

When I worked in RF (a million years ago, at least) stagger tuning was a time honoured method for getting flat response from IF amps and similar.

I have often considered the idea but haven't been game to try it out. With the rise of foamcore modelling, this may be the time. I have seen it done with pipe/TLs

PIPE RESONATOR FAMILY

and BRs

MCAP-CR Family

but never with horns.

This is the kind of application I have been trying to use the 'Transmission Line' software for. I have had some success with Akabak but when you don't have a clear design process, there is no substitute for 'make it longer and see what happens'.

Kind regards,

Im4blakk

Blakksheep,

Thanks for the links to the MCAP website - neat speakers! I was thinking of a multiple PVC panpipe TL and tried simulating it and it doesn't work as well as the horns - too peaky with the resonances.

My design process was to pick longest length for lowest freq, then scale successive lengths smaller to fill in between the full length and the half length. With five pipes, each successive one is 10% smaller.

Thanks for the links to the MCAP website - neat speakers! I was thinking of a multiple PVC panpipe TL and tried simulating it and it doesn't work as well as the horns - too peaky with the resonances.

My design process was to pick longest length for lowest freq, then scale successive lengths smaller to fill in between the full length and the half length. With five pipes, each successive one is 10% smaller.

With five pipes, each successive one is 10% smaller.

Sounds like a party I went to years ago... With each successive pipe, your aspect ratio of reality to unreality is 66.6667% off.

What is the sound of one hand clapping?

😀

Sounds like a party I went to years ago... With each successive pipe, your aspect ratio of reality to unreality is 66.6667% off.

What is the sound of one hand clapping?

😀

Nobody knows. They are all off in the forest trying to not hear a tree falling....

😉

blakktarrysubstance

X all I have to say is WOW. I might have to work up to that build. Looks very cool. Good luck to any who tackle this build. Love to see pictures.

Each layer is an easy build, take it one layer at a time, one day at a time. In five days you will have a Pentahorn! I would do it but I can only do sims in the near future. I will have to live vicariously through you guys🙂

Let me know if you have any questions on how to start. I think Bcmbob having done the DNA will agree that this should not be too hard, just time consuming. Rest assured it will sound good because the models I have done so far seem to match listening impressions and measurements.

Let me know if you have any questions on how to start. I think Bcmbob having done the DNA will agree that this should not be too hard, just time consuming. Rest assured it will sound good because the models I have done so far seem to match listening impressions and measurements.

MCM is down to 1 in stock Monacor SP50X driver ($20 at MCM 5 Inch 50W 8 Ohm Full Range Dual Cone Speaker | SP-50X (SP50X) | Distributed By MCM)

cogitech, are you going to draw this? I may be able to make a Sketchup model.

cogitech, are you going to draw this? I may be able to make a Sketchup model.

Tom,

That would be awesome if you can do s 3d model in sketchup. The plenum and throat hole cutouts is tricky but should be doable based on info I have given. 5 inch wide slots to match each horn width and depth of slot as prescribed. The 0.5 in xps foam is definitely the way to build this as a test.

Good luck guys!

That would be awesome if you can do s 3d model in sketchup. The plenum and throat hole cutouts is tricky but should be doable based on info I have given. 5 inch wide slots to match each horn width and depth of slot as prescribed. The 0.5 in xps foam is definitely the way to build this as a test.

Good luck guys!

Tom,

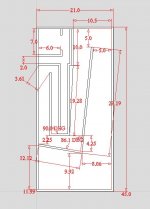

Thanks for drawing it up! Looks great. I actually intended to have a slight expanding taper in the rectangular section by slightly angling the dividers but it can work pretty well as vertical (straight up and down) sections with each successive one slightly larger than the previous. For example: 2.0, 2.5, 3.0 in. This way is certainly easier to build. Very nice work there. Having a good drawing will really help folks to get over the initial hurdle to try building it. I hope you give it a try. 🙂

Thanks again.

Regards,

X

Thanks for drawing it up! Looks great. I actually intended to have a slight expanding taper in the rectangular section by slightly angling the dividers but it can work pretty well as vertical (straight up and down) sections with each successive one slightly larger than the previous. For example: 2.0, 2.5, 3.0 in. This way is certainly easier to build. Very nice work there. Having a good drawing will really help folks to get over the initial hurdle to try building it. I hope you give it a try. 🙂

Thanks again.

Regards,

X

Last edited:

Your not wrong there, I've spent 2 days thinking 'Eh?'....... it looks interesting enough to maybe give it a go, IF I can find a drive unit in the UK/EU (for reasonable money)Tom,

Having a good drawing will really help folks to get over the initial hurdle to try building it.

X

Sippy,

Thanks for seeing that I may be on to something here. The Monacor SP50X will work and should be available in EU/UK. If you have a driver in mind, post the T/S params and I will run sim to see if it works.

Regards,

X

Thanks for seeing that I may be on to something here. The Monacor SP50X will work and should be available in EU/UK. If you have a driver in mind, post the T/S params and I will run sim to see if it works.

Regards,

X

That, at least in terms of broad principle, is not a matter of question. This sort of thing dates back to at least the 1930s, making it another example of what once was old, is again new.

Several of Lowther's designs have a similar approach. Horst (Hm) has been advertising his twin differentially tuned pipe horns on the various audio forums for years -he's using two drivers in physically independent lines, but the outcome is inherently the same as far as the pipe tuning is concerned. Similar ideas were employed around the turn of the century to address some of the problems with Voigt style tapped pipe-horns, and Voigt himself patented the idea back in the '30s (methinks the assessors didn't look too hard for prior art). I've done a few different designs of this general sort over the past few years, some using a single unit, others twin. I never pursued it because I always found it to be more trouble than the results were worth; that depends on perspective though.

Anyway, no reason why more pipes / horns can't be added if you feel so inclined. However: couple of words of warning, since I've already been there.

1/ The boxes can get very complicated very quickly when you need to pack a lot of pipes / horns into a given space.

2/ There's a practical limit to how high you can run any back-load, unless you don't mind chronic group-delay, which will itself put a natural stop on the number of pipes / horns that will be of much use.

3/ You'll almost certainly need to do considerable physical prototyping if damping is employed (which it certainly will, unless you like listening to pipe harmonics), since damping is a rather nebulous subject: its behaviour varies so much with position and type (and sub-type: not all Dacron is created equal, or even near for e.g.). Not something you'll be able to do effectively with your favourite foam-core either, since you'll need something stiffer / less liable to leach LF.

Several of Lowther's designs have a similar approach. Horst (Hm) has been advertising his twin differentially tuned pipe horns on the various audio forums for years -he's using two drivers in physically independent lines, but the outcome is inherently the same as far as the pipe tuning is concerned. Similar ideas were employed around the turn of the century to address some of the problems with Voigt style tapped pipe-horns, and Voigt himself patented the idea back in the '30s (methinks the assessors didn't look too hard for prior art). I've done a few different designs of this general sort over the past few years, some using a single unit, others twin. I never pursued it because I always found it to be more trouble than the results were worth; that depends on perspective though.

Anyway, no reason why more pipes / horns can't be added if you feel so inclined. However: couple of words of warning, since I've already been there.

1/ The boxes can get very complicated very quickly when you need to pack a lot of pipes / horns into a given space.

2/ There's a practical limit to how high you can run any back-load, unless you don't mind chronic group-delay, which will itself put a natural stop on the number of pipes / horns that will be of much use.

3/ You'll almost certainly need to do considerable physical prototyping if damping is employed (which it certainly will, unless you like listening to pipe harmonics), since damping is a rather nebulous subject: its behaviour varies so much with position and type (and sub-type: not all Dacron is created equal, or even near for e.g.). Not something you'll be able to do effectively with your favourite foam-core either, since you'll need something stiffer / less liable to leach LF.

Scottmoose,

How do you accomplish modeling multiple horns (more than 2)? Does MJK worksheets have a way of doing that or are you using another package? If you have any simulation results I would be interested to see what you did.

How do you accomplish modeling multiple horns (more than 2)? Does MJK worksheets have a way of doing that or are you using another package? If you have any simulation results I would be interested to see what you did.

Can't help but think there should be a simpler solution than essentially having five or more discreet horns. Will it really be worth the effort?

Maybe something like a long and thin karlson-like slot would get you most of the way? And/or an asymmetric cross section to the horn? Or a tapped horn with resonators?

Maybe something like a long and thin karlson-like slot would get you most of the way? And/or an asymmetric cross section to the horn? Or a tapped horn with resonators?

Squeak,

Thanks for the feedback - I was hoping to get this sort of comments to guide the process but some folks wanted to see some rough plans. I also wonder if it is worth the effort but, for some Masters of the FC Craft - this sort of a design is probably seen as a fun challenge. Certainly, I would not build this as a first cut in wood. That is where the speed at which foam core speakers come in really handy. I am not familiar with a tapped horn with resonators and how that works - so you have links to that sort of design? I am going to try to approximate a Karlson aperture with AkAbak soon and see how that can help a single horn. It may work really well - we will see. I am not sure how an asymmetric cross sectional area horn will help? Plus, I can't model that with a 1-dim lumped model like AkAbak - it will require a full 3-dim model.

Regards,

X

Thanks for the feedback - I was hoping to get this sort of comments to guide the process but some folks wanted to see some rough plans. I also wonder if it is worth the effort but, for some Masters of the FC Craft - this sort of a design is probably seen as a fun challenge. Certainly, I would not build this as a first cut in wood. That is where the speed at which foam core speakers come in really handy. I am not familiar with a tapped horn with resonators and how that works - so you have links to that sort of design? I am going to try to approximate a Karlson aperture with AkAbak soon and see how that can help a single horn. It may work really well - we will see. I am not sure how an asymmetric cross sectional area horn will help? Plus, I can't model that with a 1-dim lumped model like AkAbak - it will require a full 3-dim model.

Regards,

X

I'll try to find some when I get a free moment; it's probably still on an old HDD.

Not directly with Martin's worksheets; I used my own software.

As I recall, I took a look at up to 3 pipes & decided the whole thing was far more trouble than it was worth. A back-load of any kind is only useful over a very limited BW given the issues with group delay etc., which naturally restricts the number of pipes / resonators / whatever which will be of practical value. Adding a second should be able to address the one potential major harmonic issue you'd run into with a single pipe, assuming it's damped & the driver is positioned sensibly, but of course, you then have the harmonic modes etc. of the 2nd pipe to take into account also. Mass-loading them will help, but since you could do that with a single pipe in the first place to address all of the potential problems, it rather negates the point of using multiples so presumably you won't want to go down that route. Fun to play with though.

Not directly with Martin's worksheets; I used my own software.

As I recall, I took a look at up to 3 pipes & decided the whole thing was far more trouble than it was worth. A back-load of any kind is only useful over a very limited BW given the issues with group delay etc., which naturally restricts the number of pipes / resonators / whatever which will be of practical value. Adding a second should be able to address the one potential major harmonic issue you'd run into with a single pipe, assuming it's damped & the driver is positioned sensibly, but of course, you then have the harmonic modes etc. of the 2nd pipe to take into account also. Mass-loading them will help, but since you could do that with a single pipe in the first place to address all of the potential problems, it rather negates the point of using multiples so presumably you won't want to go down that route. Fun to play with though.

Last edited:

Hi. I just installed Akabak and Winebottler to run in on my Macbook. The plan is to model different enclosures and room placements and maybe learn a bit in the process

Akabak is indeed – a handful. So far Ive managed to enter driver values. Ive found a tutorial but not the manual for Akabak that theyre refering to?

Any idea where I can find a manual?

Regards /Bo

Akabak is indeed – a handful. So far Ive managed to enter driver values. Ive found a tutorial but not the manual for Akabak that theyre refering to?

Any idea where I can find a manual?

Regards /Bo

The manual is part of the download Zip archive. It is in the manual directory. There are lots of samples in the scripts directory. Make sure you download the "AkAbak v210 no installer" zip file.

The manual is part of the download Zip archive. It is in the manual directory. There are lots of samples in the scripts directory. Make sure you download the "AkAbak v210 no installer" zip file.

Awrite, found it. Thanks 🙂

Regards /Bo

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- The PANPIPE (Pentahorn) BLH Speaker