Hi !

Just trying to get your opinion, Ricci, on this driver :

Single Product |

The LaVoce SAN214.50.

It has a neodymium magnet, so it's a bit lighter than the SW152.

It sims pretty well in the cab, has a high BL, a high Xmax.

Just getting curious about your thoughts on this one.

(I posted the sims in #464 : The Othorn tapped horn)

Thanks ! 🙂

Just trying to get your opinion, Ricci, on this driver :

Single Product |

The LaVoce SAN214.50.

It has a neodymium magnet, so it's a bit lighter than the SW152.

It sims pretty well in the cab, has a high BL, a high Xmax.

Just getting curious about your thoughts on this one.

(I posted the sims in #464 : The Othorn tapped horn)

Thanks ! 🙂

Hi !

Just trying to get your opinion, Ricci, on this driver :

Single Product |

The LaVoce SAN214.50.

It has a neodymium magnet, so it's a bit lighter than the SW152.

It sims pretty well in the cab, has a high BL, a high Xmax.

Just getting curious about your thoughts on this one.

(I posted the sims in #464 : The Othorn tapped horn)

Thanks ! 🙂

I have had a number of people ask me about this driver. It looks good on paper and the price is very tempting. It is on my short list of drivers to acquire for testing next spring. I'm hoping it is similar in performance to the 18Sound and B&C 21's for less money.

Thanks for the reply, also much gratitude and thanks for releasing the plans of this design and the others you have created - more quality bass in the world equals many happy people!

Sounds like a short wait on the 21" Tetracoil drivers from 18 Sound so not available immediately but not too far away... Would ask directly for some official specs before ordering. Do you think the dual coil arrangement will allow for better long term power handling and control than the 21SW152? The clearance when mounted in the Othorn looks to be less than a 1/4 inch from the hatch, do you think that will cause any issue in response due to its position in the horn?

With the 21NLW9601 I noticed the Fs is 37hz, is that a disadvantage in this cabinet? What is your preference between this driver and the 21SW152 in terms of suitability in this cabinet?

Apologies for all the questions, it seems all three drivers are likely to be very suitable in this design, just trying to gauge whether the 18 Sound drivers are up to the standard of the B&C which has already been proven a a great match!

Keen to try something other than the B&C in the name of experimentation and cash saving but also happy to run with the 21SW152 if need be...

The driver FS is modified once placed into an enclosure especially a high order enclosure such as a horn. I do not worry about the free air resonance but the resonances once in the final system.

The dual gap coil arrangement similar to what JBL calls Differential Drive does offer some notable advantages...Overall motor force, power handling and potentially more symmetric BL and lowered / more linear inductance being some. Negatives include potential for rocking due to the extremely long former and very deep motors. I have a JBL 2269H DD driver for testing. They also produce the 2268 and the WGTI series car audio drivers. RF T3 19 is another example. Fi had an example as did Memphis...Now 18Sound is looking at it. There is a story from 2 or 3 years back which I can't share unfortunately but it grows even more interesting now that B&C has bought 18 Sounds.

I have a 21nlw9601 and a 21ID on hand for testing but haven't gotten to them with high power yet. In general I'd rate the B&C's as a bit more durable in horns or high compression scenarios. The cones on the 18Sound drivers appear to be a bit lighter gauge and don't seem to be as thick or rigid as the B&C's. It lowers MMS and increases efficiency but this usually allows them to start distorting and flexing earlier also. Not many people talk about this stuff but it is important.

I have had a number of people ask me about this driver. It looks good on paper and the price is very tempting. It is on my short list of drivers to acquire for testing next spring. I'm hoping it is similar in performance to the 18Sound and B&C 21's for less money.

Thank for the fast answer, I'll give it a try during 2019 summer then.

Will post my feedback and maybe some measurements when it'll be done 🙂

The driver FS is modified once placed into an enclosure especially a high order enclosure such as a horn. I do not worry about the free air resonance but the resonances once in the final system.

The dual gap coil arrangement similar to what JBL calls Differential Drive does offer some notable advantages...Overall motor force, power handling and potentially more symmetric BL and lowered / more linear inductance being some. Negatives include potential for rocking due to the extremely long former and very deep motors. I have a JBL 2269H DD driver for testing. They also produce the 2268 and the WGTI series car audio drivers. RF T3 19 is another example. Fi had an example as did Memphis...Now 18Sound is looking at it. There is a story from 2 or 3 years back which I can't share unfortunately but it grows even more interesting now that B&C has bought 18 Sounds.

I have a 21nlw9601 and a 21ID on hand for testing but haven't gotten to them with high power yet. In general I'd rate the B&C's as a bit more durable in horns or high compression scenarios. The cones on the 18Sound drivers appear to be a bit lighter gauge and don't seem to be as thick or rigid as the B&C's. It lowers MMS and increases efficiency but this usually allows them to start distorting and flexing earlier also. Not many people talk about this stuff but it is important.

Thanks for the explanation and also info on the cone comparisons, exactly the sort of thing I was after!

I currently run several JBL subs which use the 2268 driver and feel they sound a little sloppy in the 50hz to 80hz region - could be due to the rocking you have mentioned, a potential negative of the dual gap coil arrangement... I guess 18 Sound may have addressed that in their Tetracoil drivers with beefed up suspension?

Will request some finalized specs on the 21NTLW5000 and make some decisions...

Keen to see the 21nlw9601 put through its paces, will keep an eye on Data-Bass in the future.

Thanks again for taking the time to reply, very much appreciated!

I currently run several JBL subs which use the 2268 driver and feel they sound a little sloppy in the 50hz to 80hz region - could be due to the rocking you have mentioned, a potential negative of the dual gap coil arrangement... I guess 18 Sound may have addressed that in their Tetracoil drivers with beefed up suspension?

This is not what I had meant exactly.

When you have a very long former any misalignment or rocking/tilting during the range of excursion, perhaps due to a slight suspension offset or centering problem, is magnified down near the voice coil. It can result in physical contact of the coil in the gap. Rubbing, scraping or other very bad noises result. It sounds like a mechanically damaged driver most of the time, not like what you are describing. I've run into drivers that were fine until asked for substantial excursion at which time the extra excursion would magnify the off centering of the coil in the gap and cause it. Again this is NOT like a subpar subwoofer or "loose" bass. This sounds like the speaker is blown or otherwise broken.

In general you either need much tighter MFG and assembly tolerances or you use a larger gap and sac some efficiency. I'm talking extremely long formers here like you would see on a XXX an RF 19, 21TLW5000, 2269H etc. Any time you increase the length of the former on a long throw sub it makes alignment and centering that much more critical. I would assume that 18 Sound has this taken care of. I was only mentioning it as a potential drawback of a long former dual gap design.

Ah I see, that sounds like fairly serious issue if present, maybe I'll end up being a test mule on that if I go the 21TLW5000 route. Tempted to take the chance on it as it looks to be a fine driver in most other aspects. B&C Sw152 still looks like the sure bet though...

Othorn bottom hatch construction

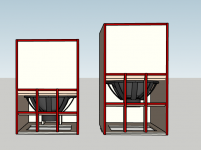

I finished building a pair of these beasties and WOW, they sound great! I am using B&C 21SW152-4 and powering them each with a bridged Behringer NU3000DSP.

I thought I would share the details of how I built the bottom hatch with driver bracing. I used 3/4" aluminum angle and T-bar. It's extremely solid and the driver is well braced from the magnet. The bracing at the back of the box butts up against an angled inset pocket for a speakon connector.

I finished building a pair of these beasties and WOW, they sound great! I am using B&C 21SW152-4 and powering them each with a bridged Behringer NU3000DSP.

I thought I would share the details of how I built the bottom hatch with driver bracing. I used 3/4" aluminum angle and T-bar. It's extremely solid and the driver is well braced from the magnet. The bracing at the back of the box butts up against an angled inset pocket for a speakon connector.

Attachments

That's a nice idea. And my, what big feet you have!I thought I would share the details of how I built the bottom hatch with driver bracing. I used 3/4" aluminum angle and T-bar. It's extremely solid and the driver is well braced from the magnet. The bracing at the back of the box butts up against an angled inset pocket for a speakon connector.

Your solution made me realize I should share my solution (even though I don't have pictures...)

I simply used two pieces of 1/2" baltic glued together with one cut for the hatch and the other cut for the lip. The leftover piece from the lip was glued to the hatch.

I finished building a pair of these beasties and WOW, they sound great! I am using B&C 21SW152-4 and powering them each with a bridged Behringer NU3000DSP.

I thought I would share the details of how I built the bottom hatch with driver bracing. I used 3/4" aluminum angle and T-bar. It's extremely solid and the driver is well braced from the magnet. The bracing at the back of the box butts up against an angled inset pocket for a speakon connector.

Excellent work. They look great.

Hi !

If I want a 10cm (~4") taller Othorn, what would be an easy modification without affecting too much the response curve ?

Making the last segment of the horn taller ?

It would "just" affect the sides panels, the back panel and the 2 reinforcements in the bottom corner.

Tried to edit the hornresp inputs but not really sure of what I'm doing.

Build should start in July, ordering 2x 21DS115-4 soon ! 😉

Thanks !

If I want a 10cm (~4") taller Othorn, what would be an easy modification without affecting too much the response curve ?

Making the last segment of the horn taller ?

It would "just" affect the sides panels, the back panel and the 2 reinforcements in the bottom corner.

Tried to edit the hornresp inputs but not really sure of what I'm doing.

Build should start in July, ordering 2x 21DS115-4 soon ! 😉

Thanks !

Hi !

If I want a 10cm (~4") taller Othorn, what would be an easy modification without affecting too much the response curve ?

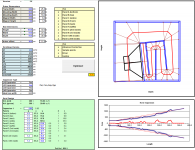

Interesting. I'd discussed something similar in my "Spreadsheet for Folded Horn Layouts" thread.

The Othorn can be approximated using parabolic segments for L12, L34 and L45, and an exponential segment for L23, at least according to the workbook I put together for it.

If you make the Othorn taller, it would be best to adjust everything else in the horn to take advantage of the additional volume. The "Othorn" workbook at the site below can assist with this. It's the latest version I have (v1.4), which lays out the panels slightly differently and fixes a few errors in the earlier versions. It will generate the corresponding Hornresp parameters and a Hornresp import file. I have not used it to build one yet (no time!) however.

If you are going to build a modified Othorn, I suggest going all the way and modeling it using the semi-inductance parameters for the driver that you want to use. If not provided, these can be derived from the driver's impedance curve.

Site: The Subwoofer DIY Page - Horn Folding

Attachments

This must have been a lot of work !

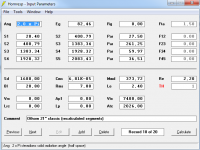

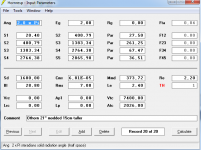

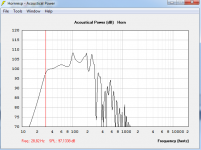

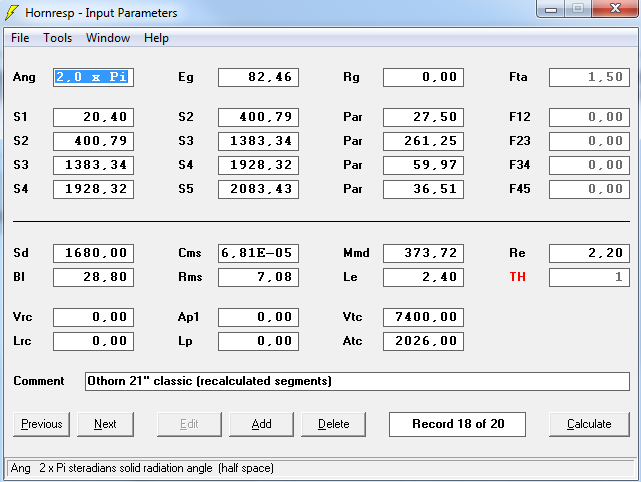

Just wondering, I opened your Excel file, exported a hornresp script but it sims way differently than the inputs Ricci gave us on the first page ?

f3 at 30hz instead of 28hz and a big dip at 87hz.

Even more weird when using the 21DS115-4 instead of the 21SW152-4

Ricci is using "20.40" at S1 where you are using "403", it has an huge impact on simulation, which one is correct ?

Just wondering, I opened your Excel file, exported a hornresp script but it sims way differently than the inputs Ricci gave us on the first page ?

f3 at 30hz instead of 28hz and a big dip at 87hz.

Even more weird when using the 21DS115-4 instead of the 21SW152-4

Ricci is using "20.40" at S1 where you are using "403", it has an huge impact on simulation, which one is correct ?

Just wondering, I opened your Excel file, exported a hornresp script but it sims way differently than the inputs Ricci gave us on the first page ?

The workbook simulates an Othorn-type fold, not the actual Othorn. If you want to try to use it to sim the closest approximation to the actual Othorn, adjust S1 in the workbook until S2 is similar to what the Othorn's S2 is, and the external dimensions similar to the actual external dimensions of the Othorn.

Alright, I understood it that way but thought the base file was made like THE Othorn 😉 .

Can't obtain the same inputs as Ricci within the workbook, maybe doing it the wrong way but since S1 = S2 once you click "Optimize", I don't see any solution.

Anyway, it's not the "easy" modification I was looking for but it could be an awesome tool for someone who want to build an Othorn-style horn !

(And quite interesting to look at even if it's way too complex for me)

Can't obtain the same inputs as Ricci within the workbook, maybe doing it the wrong way but since S1 = S2 once you click "Optimize", I don't see any solution.

Anyway, it's not the "easy" modification I was looking for but it could be an awesome tool for someone who want to build an Othorn-style horn !

(And quite interesting to look at even if it's way too complex for me)

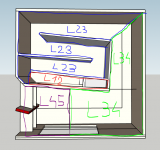

Alright, tell me if I did this right :

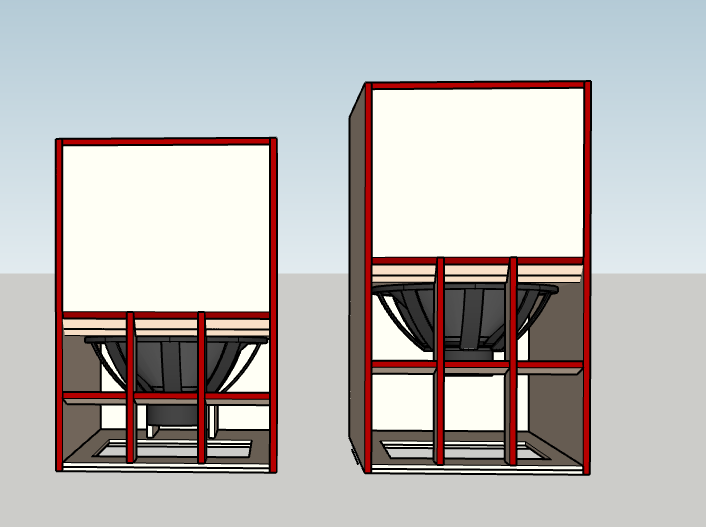

First I took the Ricci input datas and I edited those to match the attached picture(did that drawing fast sorry), it simmed exactly as the previous datas

From my sketchup file of the Othorn, I added 15 cm of height and then measured the area of S4 and S5 and added 7.5cm at L43.

Which resulted in : Taking too much space and can't find an option to do a "spoiler", watch the 3 last thumbnails

And looks like :

It will certainly need a stronger bracing than the original for the last "straigth" portion of the horn.

I want the Othorn to be 15cm higher to match the look I want to give to my system (Reggae-dub style), 91cm is a bit short otherwise.

And it looks less cubic as well ahah.

The T/S parameters comes from the B&C 21DS115-4ohm.

Thanks for taking a look 😀

First I took the Ricci input datas and I edited those to match the attached picture(did that drawing fast sorry), it simmed exactly as the previous datas

From my sketchup file of the Othorn, I added 15 cm of height and then measured the area of S4 and S5 and added 7.5cm at L43.

Which resulted in : Taking too much space and can't find an option to do a "spoiler", watch the 3 last thumbnails

And looks like :

It will certainly need a stronger bracing than the original for the last "straigth" portion of the horn.

I want the Othorn to be 15cm higher to match the look I want to give to my system (Reggae-dub style), 91cm is a bit short otherwise.

And it looks less cubic as well ahah.

The T/S parameters comes from the B&C 21DS115-4ohm.

Thanks for taking a look 😀

Attachments

- Home

- Loudspeakers

- Subwoofers

- The Othorn tapped horn