How to unsubscribe without replying?

Lucadelcarlo,

In the email you get there is this...

Unsubscription information:

To unsubscribe from this thread, please visit this page:

http://www.diyaudio.com/forums/subscription.php?do..........

Hi,

I tried the aperiodic TL midrange after reading Planet 10 and xrk's posts.(thanks guys!)

I liked it very much, and I recently made a spiral 'Nautaloss' version with a little bit of 'Cornu' added in. (can it be thought as something like a reverse Cornu? LOL)

I wanted a very compact footprint, and thinking of trying a configuration with the driver on top(firing upward - if the box is standing upright) next time.

Is there anything I'm missing/doing wrong? (probably - 😀)

Please feel free to correct me.

Attached pic is the 'Hardcover' spiral TL, and the 'Dagger TL' for size comparison. (both use the same 2 inch driver)

I tried the aperiodic TL midrange after reading Planet 10 and xrk's posts.(thanks guys!)

I liked it very much, and I recently made a spiral 'Nautaloss' version with a little bit of 'Cornu' added in. (can it be thought as something like a reverse Cornu? LOL)

I wanted a very compact footprint, and thinking of trying a configuration with the driver on top(firing upward - if the box is standing upright) next time.

Is there anything I'm missing/doing wrong? (probably - 😀)

Please feel free to correct me.

Attached pic is the 'Hardcover' spiral TL, and the 'Dagger TL' for size comparison. (both use the same 2 inch driver)

Attachments

Bolex,

Looks great as usual. For the spiral you need to put a good absorber right behind the driver to prevent that first main reflection. Otherwise looks all good - neat idea to get more baffle area by putting driver on the side. The Dagger works either sealed or with a small vent best vertex. It is surprising how the impedance plot changes and how the phase tracks - they are different but I am not sure which is better.

Looks great as usual. For the spiral you need to put a good absorber right behind the driver to prevent that first main reflection. Otherwise looks all good - neat idea to get more baffle area by putting driver on the side. The Dagger works either sealed or with a small vent best vertex. It is surprising how the impedance plot changes and how the phase tracks - they are different but I am not sure which is better.

xrk,

Thanks!

Check on the damping material, and the vent on the Dagger😀.(visible on the last pic - nice design, by the way)

I made this version hoping the small footprint will be suitable for horn loading. (it had to be shallow or the midrange horn would protrude too much into the room)

I've seen people loading horns with sealed, dipole, even cardioid arrangements, but I couldn't find anything with aperiodic.(I tried, and it sounds pretty good...)

Is there a reason for people not doing this more?😕

(maybe a question for another thread?)

Thanks!

Check on the damping material, and the vent on the Dagger😀.(visible on the last pic - nice design, by the way)

I made this version hoping the small footprint will be suitable for horn loading. (it had to be shallow or the midrange horn would protrude too much into the room)

I've seen people loading horns with sealed, dipole, even cardioid arrangements, but I couldn't find anything with aperiodic.(I tried, and it sounds pretty good...)

Is there a reason for people not doing this more?😕

(maybe a question for another thread?)

The Dagger is a great low distortion compact sealed back chamber for horns or any other speaker where you want low coloration. Check out how low harmonic distortion is for SS 10F/8424:

http://www.diyaudio.com/forums/full...2in-4in-drivers-round-4-a-57.html#post4455666

http://www.diyaudio.com/forums/full...2in-4in-drivers-round-4-a-57.html#post4455666

Thanks for the confirmation!

The Dagger was the first aperiodic TL design I tried, and I was very excited by it's distortion free characteristics.

Also, recently I used it to load a EV HP640 horn clone, and it sounded very nice. So it's good to hear from you that the usage of aperiodic enclosures in horn loading is 'legitimate', and I'm not barking up the wrong tree... 😀

I'm now contemplating using two of aperiodic enclosures to load a single 'Tumbling Dice' FC horn - with a K-pipe in the middle to emulate a 'Unity horn'...

Thanks again, xrk!

The Dagger was the first aperiodic TL design I tried, and I was very excited by it's distortion free characteristics.

Also, recently I used it to load a EV HP640 horn clone, and it sounded very nice. So it's good to hear from you that the usage of aperiodic enclosures in horn loading is 'legitimate', and I'm not barking up the wrong tree... 😀

I'm now contemplating using two of aperiodic enclosures to load a single 'Tumbling Dice' FC horn - with a K-pipe in the middle to emulate a 'Unity horn'...

Thanks again, xrk!

Hey xrk,The Nautaloss might be just what I'm after!

I've looked at 3 sided pyramids ie the Dagger but the nautaloss seems even better!

I'm looking for the cleanest cabinet I can find for my midrange. I'm using this driver http://bcspeakers.com/products/lf-driver/10-0/8/10md26.pdf ideally between 200-2000hz. It's a bit of an animal but no low bass so suits my needs and should kick but as a mid.

As for building it.... I want the mid cabinet to not be much taller than the driver. That means the curl will have to go to the side. Construction wise I was thinking a birch ply carcass with xrk's patented foam board for the curl. Once thats securely in backfill the surrounding space with something like sand to kill any vibration.

How's that sound?

I've looked at 3 sided pyramids ie the Dagger but the nautaloss seems even better!

I'm looking for the cleanest cabinet I can find for my midrange. I'm using this driver http://bcspeakers.com/products/lf-driver/10-0/8/10md26.pdf ideally between 200-2000hz. It's a bit of an animal but no low bass so suits my needs and should kick but as a mid.

As for building it.... I want the mid cabinet to not be much taller than the driver. That means the curl will have to go to the side. Construction wise I was thinking a birch ply carcass with xrk's patented foam board for the curl. Once thats securely in backfill the surrounding space with something like sand to kill any vibration.

How's that sound?

Also with regards to the build....

The spiral seems to go off from the driver to one side. In most builds. Is this to better confine the backwave and reduce reflections or could I channel the spiral from one side of the driver so it fills the cabinet better?

Or...

Could I start in the middle and channel it into 2 spirals? Half the length each maybe?

The spiral seems to go off from the driver to one side. In most builds. Is this to better confine the backwave and reduce reflections or could I channel the spiral from one side of the driver so it fills the cabinet better?

Or...

Could I start in the middle and channel it into 2 spirals? Half the length each maybe?

JRKO,

That's a nice driver and should give you gut punching mid bass. Depending on the aspect ratio of a cabinet you are looking for, the spiral could be along an axis parallel to the driver axis (like a Cornu) or along an axis perpendicular to the driver axis, like a Nautaloss proper. Both will attenuate the backwave but the Cornu style will have a flat wall directly behind driver membrane where it may wreak havoc with the coloration. You could put a pointy cone there aimed at driver magnet to prevent a standing wave there. Or use lots of felt or BASF (Magic Eraser sponges) sound abatement foam. The Cornu style will give you a flattish box with a wide baffle. For a 10in driver, I suggest the usual Nautaloss style with spiral axis perpendicular to driver axis.

Here is way to size it: Make a rectangular enclosure as wide as the driver bezel or a little wider. Size depth and height to be at least equal to Vas of driver if you desire published bass extension of driver in a sealed cabinet. If you can give up extension but prefer higher power handling, make box volume smaller than Vas (say 1/2 or 1/4th Vas). Aim for a circa 3 ft long spiral (a little shorter doesn't hurt). Draw a tapered spiral within the cabinet you just sized so that it starts out as same as driver dia, and tapers to a point within about 3ft. Cut out the foam core board into strips of same as speaker box internal width. Use hot melt glue to lay down on spiral drawn on one side wall. Add lots of foam core bracing strips internally to prevent FC walls from flapping or vibrating. You can use bendy plywood/MDF too. Then stuff progressively tighter with fiberglass or polyfill. Line adjacent side walls within 1 driver dia with felt/foam to prevent side reflections. Then glue on last side wall with PVA glue and clamp with heavy weight overnight.

When you measure the response it should resemble an infinite baffle in how clean and low coloration it is. A trapezoidal baffle shape will reduce diffraction artifacts (500Hz to 2kHz) is an important range for trapezoidal baffle.

Good luck.

That's a nice driver and should give you gut punching mid bass. Depending on the aspect ratio of a cabinet you are looking for, the spiral could be along an axis parallel to the driver axis (like a Cornu) or along an axis perpendicular to the driver axis, like a Nautaloss proper. Both will attenuate the backwave but the Cornu style will have a flat wall directly behind driver membrane where it may wreak havoc with the coloration. You could put a pointy cone there aimed at driver magnet to prevent a standing wave there. Or use lots of felt or BASF (Magic Eraser sponges) sound abatement foam. The Cornu style will give you a flattish box with a wide baffle. For a 10in driver, I suggest the usual Nautaloss style with spiral axis perpendicular to driver axis.

Here is way to size it: Make a rectangular enclosure as wide as the driver bezel or a little wider. Size depth and height to be at least equal to Vas of driver if you desire published bass extension of driver in a sealed cabinet. If you can give up extension but prefer higher power handling, make box volume smaller than Vas (say 1/2 or 1/4th Vas). Aim for a circa 3 ft long spiral (a little shorter doesn't hurt). Draw a tapered spiral within the cabinet you just sized so that it starts out as same as driver dia, and tapers to a point within about 3ft. Cut out the foam core board into strips of same as speaker box internal width. Use hot melt glue to lay down on spiral drawn on one side wall. Add lots of foam core bracing strips internally to prevent FC walls from flapping or vibrating. You can use bendy plywood/MDF too. Then stuff progressively tighter with fiberglass or polyfill. Line adjacent side walls within 1 driver dia with felt/foam to prevent side reflections. Then glue on last side wall with PVA glue and clamp with heavy weight overnight.

When you measure the response it should resemble an infinite baffle in how clean and low coloration it is. A trapezoidal baffle shape will reduce diffraction artifacts (500Hz to 2kHz) is an important range for trapezoidal baffle.

Good luck.

Thanks xrk!

I'll look into the bendy MDF as it should stand up better for sure. As for extension, I'm not really needing downward extension (15 inch covering bass duties) but sticking to the full length, full vas version will be better for ultimate rear wave killing I guess? Looking to power handling I'm not going to be setting any records with a 6w class A amp but as the fully active system sensitivity will be around 96dB I won't be missing much in the way of volume.

Now I wonder about a nautaloss for the 15 incher.........

I'll look into the bendy MDF as it should stand up better for sure. As for extension, I'm not really needing downward extension (15 inch covering bass duties) but sticking to the full length, full vas version will be better for ultimate rear wave killing I guess? Looking to power handling I'm not going to be setting any records with a 6w class A amp but as the fully active system sensitivity will be around 96dB I won't be missing much in the way of volume.

Now I wonder about a nautaloss for the 15 incher.........

I finished gluing the last panel on one of my speakers last night. Was dry this morning. I just glued the last panel on second speaker tonight. Should be ready by morning.

I decided to drop the two drivers into the baffle just to give a listen. The speakers were playing music out of the box so i could hear the difference as i set them in.

Wow. These things sound incredible! The upper midbass was really tight. I was holding at arms length, so the comb filtering/lobing was obvious. Also, i have never sat and listened to a full ranger. Odd how quickly the treble drops off axis. I cant wait until i can get them both up and running, and sit in the sweet spot.

I cranked the subwoofer crossover up to 200 hz, and it sounded very full. Smooth. Nothing stood out or odd (other than minor integration issue with sub due to quick test and high crossover point).

To be honest, if the spiral and braces weren't such a p.i.t.a., i would build lots of them and give away to friends!

It was totally worth the effort. I wanted to mass load the boxes and use varnish on them to stiffen them a bit. But i decided to keep them as is to keep it simple and cheap.

Next up is wood corner supports for screws on back of baffle.

I decided to use fiberglass insulation for stuffing. I jammed it into the end of the line and tried to loosen it as it got closer to baffle. But, the fiberglass is hard to loosen and "fluff". I like the sound of overdamped speakers and still seem to have good midbass.

I may try the spiral on other projects. I may build a styrene cutter so i can build spirals out of xps foam...

Awesome design... thanks.

I decided to drop the two drivers into the baffle just to give a listen. The speakers were playing music out of the box so i could hear the difference as i set them in.

Wow. These things sound incredible! The upper midbass was really tight. I was holding at arms length, so the comb filtering/lobing was obvious. Also, i have never sat and listened to a full ranger. Odd how quickly the treble drops off axis. I cant wait until i can get them both up and running, and sit in the sweet spot.

I cranked the subwoofer crossover up to 200 hz, and it sounded very full. Smooth. Nothing stood out or odd (other than minor integration issue with sub due to quick test and high crossover point).

To be honest, if the spiral and braces weren't such a p.i.t.a., i would build lots of them and give away to friends!

It was totally worth the effort. I wanted to mass load the boxes and use varnish on them to stiffen them a bit. But i decided to keep them as is to keep it simple and cheap.

Next up is wood corner supports for screws on back of baffle.

I decided to use fiberglass insulation for stuffing. I jammed it into the end of the line and tried to loosen it as it got closer to baffle. But, the fiberglass is hard to loosen and "fluff". I like the sound of overdamped speakers and still seem to have good midbass.

I may try the spiral on other projects. I may build a styrene cutter so i can build spirals out of xps foam...

Awesome design... thanks.

I finished gluing the last panel on one of my speakers last night. Was dry this morning. I just glued the last panel on second speaker tonight. Should be ready by morning.

I decided to drop the two drivers into the baffle just to give a listen. The speakers were playing music out of the box so i could hear the difference as i set them in.

Wow. These things sound incredible! The upper midbass was really tight. I was holding at arms length, so the comb filtering/lobing was obvious. Also, i have never sat and listened to a full ranger. Odd how quickly the treble drops off axis. I cant wait until i can get them both up and running, and sit in the sweet spot.

I cranked the subwoofer crossover up to 200 hz, and it sounded very full. Smooth. Nothing stood out or odd (other than minor integration issue with sub due to quick test and high crossover point).

To be honest, if the spiral and braces weren't such a p.i.t.a., i would build lots of them and give away to friends!

It was totally worth the effort. I wanted to mass load the boxes and use varnish on them to stiffen them a bit. But i decided to keep them as is to keep it simple and cheap.

Next up is wood corner supports for screws on back of baffle.

I decided to use fiberglass insulation for stuffing. I jammed it into the end of the line and tried to loosen it as it got closer to baffle. But, the fiberglass is hard to loosen and "fluff". I like the sound of overdamped speakers and still seem to have good midbass.

I may try the spiral on other projects. I may build a styrene cutter so i can build spirals out of xps foam...

Awesome design... thanks.

Glad you like them. Please post pics!

The sound from the Nautaloss is very open and natural like an open baffle without the big baffle.

Thanks for trying it!

This is picture with fiberglass installed before final panel installed.

I just glued little triangles to back of baffle where bolt holes go for additional support.

I got some window sealant rope caulking and rolled it flat and thin. Cut in two strips and placed on baskets to help seal. Tomorrow i will drill the holes, fill with last pieces of fiberglass, and then install the tc9's.

I am excited to finish.

What i learn here may be applied to other speakers (maybe a fast setup) and even car audio.

Hot glue and foam core is giving me some ideas.

Probably fiberglass and some type of sealant is involved...

I just glued little triangles to back of baffle where bolt holes go for additional support.

I got some window sealant rope caulking and rolled it flat and thin. Cut in two strips and placed on baskets to help seal. Tomorrow i will drill the holes, fill with last pieces of fiberglass, and then install the tc9's.

I am excited to finish.

What i learn here may be applied to other speakers (maybe a fast setup) and even car audio.

Hot glue and foam core is giving me some ideas.

Probably fiberglass and some type of sealant is involved...

Attachments

Last edited:

You might want to glue some pieces of heavy duty triple ply corrugated cardboard on the backside of baffle where screws go to serve as anchors for the threads to grab. I use Spax drywall screws. That brown fiberglass is unusual. Is that rockwool?

I cut little triangles out of scrap 3 ply and hot glued them where screw holes are for support/anchors.

I wanted bonded logic, but they only had HUGE rolls of it at Lowe's. I don't need that much right now. (Last time I was there a while back they had smaller rolls).

I found some small bags of fiberglass called Kwik Fill.

Yeah, its an odd color, but feels like fiberglass. 😀 Itches the same (although less itchy because the small roll was easier to deal with).

I wanted to use rockwool, but was not sure if it was too stiff to work with. The end of the spiral was hard to stuff due to bracing. The fiberglass was easy to stuff into small openings. For future projects, I plan on using bonded logic for some projects, but rock wool for most sealed stuff...

I have to go to store to get screws. #8 screws 3/4" long are perfect length for two Elmers foam core layers, one 3 ply layer and the 1/8th inch thick woofer flange.. I will check out the spax drywall screws.

I wanted bonded logic, but they only had HUGE rolls of it at Lowe's. I don't need that much right now. (Last time I was there a while back they had smaller rolls).

I found some small bags of fiberglass called Kwik Fill.

Yeah, its an odd color, but feels like fiberglass. 😀 Itches the same (although less itchy because the small roll was easier to deal with).

I wanted to use rockwool, but was not sure if it was too stiff to work with. The end of the spiral was hard to stuff due to bracing. The fiberglass was easy to stuff into small openings. For future projects, I plan on using bonded logic for some projects, but rock wool for most sealed stuff...

I have to go to store to get screws. #8 screws 3/4" long are perfect length for two Elmers foam core layers, one 3 ply layer and the 1/8th inch thick woofer flange.. I will check out the spax drywall screws.

I installed the tc9's and hooked up the speakers to my stereo. An older yamaha receiver (htib type that I purchased from swap meet sans remote for 30 bucks).

Then I cranked up the sub crossover as high as it would go (200Hz on old 80 watt yamaha sub with 12" old school kicker 12" in sealed, overbuilt box).

I could tell something was off a bit due to not having proper crossover. At very low volume it sounded a bit flat. But when i cranked up the volume, it really sounded clean.

The room has no treatments and bare wood floors. Regardless, the imaging was awesome.

I can only imagine how awesome these would sound as midranges.

It's hard for me to use these as my main speakers, as I have a pair of dtqwtII's. I get spoiled with those. Ironically, Troels likes down tilting treble, so they lack a little sparkle, kinda like the tc9's. I have crap hearing so could probably use a tiny bit more sizzle.

But boy do the dtqwt's measure flat!

These tc9's seem to be as good as measured and talked about. I will try to play with the drivers in other projects and measure them when weather is warmer.

I measured the dtqwt's twice while setting up measurement stuff and tested some car audio junk i had laying around. I will use troels measurements and mine so i can compare other projects. Sort of a baseline.

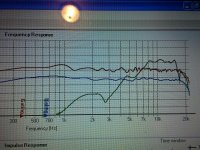

Green is crappy tweeter, red and blue are dtqwtII's.

I dont think these will work for me on their own, obviously. I need to build some stands that are woofer enclosures to get me down to 80 hz. I just dont have time or money for dsp (i can use analog pre amp inputs on my receiver for two way part of set up in future).

I would like to hook these up like you did, to a sub (or woofers and sub, i looooooove bass!).

How did the imaging sound when you did the dual woofer spiral sub? Did you cross it over high, maybe around 200 or so?

Then I cranked up the sub crossover as high as it would go (200Hz on old 80 watt yamaha sub with 12" old school kicker 12" in sealed, overbuilt box).

I could tell something was off a bit due to not having proper crossover. At very low volume it sounded a bit flat. But when i cranked up the volume, it really sounded clean.

The room has no treatments and bare wood floors. Regardless, the imaging was awesome.

I can only imagine how awesome these would sound as midranges.

It's hard for me to use these as my main speakers, as I have a pair of dtqwtII's. I get spoiled with those. Ironically, Troels likes down tilting treble, so they lack a little sparkle, kinda like the tc9's. I have crap hearing so could probably use a tiny bit more sizzle.

But boy do the dtqwt's measure flat!

These tc9's seem to be as good as measured and talked about. I will try to play with the drivers in other projects and measure them when weather is warmer.

I measured the dtqwt's twice while setting up measurement stuff and tested some car audio junk i had laying around. I will use troels measurements and mine so i can compare other projects. Sort of a baseline.

Green is crappy tweeter, red and blue are dtqwtII's.

I dont think these will work for me on their own, obviously. I need to build some stands that are woofer enclosures to get me down to 80 hz. I just dont have time or money for dsp (i can use analog pre amp inputs on my receiver for two way part of set up in future).

I would like to hook these up like you did, to a sub (or woofers and sub, i looooooove bass!).

How did the imaging sound when you did the dual woofer spiral sub? Did you cross it over high, maybe around 200 or so?

Attachments

how might the Nautiloss approach using bent foamcore in a plywood shell fare with a large (12-15"} coaxial woofer working at high spl? Would the spiral line be unduely modulated? or would its behavior be a plus compared so say bendable plywood / scored mdf? - just curious. Fane's double whizzer cone 12 might be a candidate. I have some Eminence 12cx with qts ~0.5 which were made for a one cubic foot sealed box / midbass - up application for a former president of Cetec-Gauss. Long ago, Stromberg-Carlson had some hideous looking enclosures made with plywood baffle - the shell and internal damped line pieces were made of Celotex (like old ceiling tiles} - the outside was covered in roofing paper. They seemed very acoustically inert.

here's one example - some, IIRC, had no vent

here's one example - some, IIRC, had no vent

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

...I just dont have time or money for dsp (i can use analog pre amp inputs on my receiver for two way part of set up in future...

Nice TC9 build thanks sharing.

Just an idea here 🙂 if you have some old computer laying around here is nice video guide for cheap DSP http://www.diyaudio.com/forums/pc-based/302900-brutefir-dsp-pc-step-step.html, it won't help in time manner and probably not practical in long run but it could be crazy good flexible tool to find right XO and EQ for new build paired to subwoofer. Old computer with onboard two or 5.1 channel sound should be enough to dial in one speaker using free Rephase to create EQ and XO even linear phase if you wan't.

since in the principle of this speaker, the importance is given to absorb rear wave as much as possible...apart from snail like structure, any other design is good to use? the one that could be simpler to construct. i was thinking of using pvc pipes bent at right angles. below is a crappy image just to give an idea. total length of the pipe from speaker driver to tail end is 1/2 wavelength. also tapering affect can be given by using reducing dia pipes after every bend. will this still do better job of absorbing rear waves?

The "Dagger" rear chamber works probably just as well and is easier to make. However, if you want the same larger volume, it will be very long. Use 3 or 5 triangular sides for a tall pyramid. Stuff with polyfill/fiberglass/rockwool progressively denser to the vertex. Measures like an open baffle as no obvious back wave reflection visible.

More on Dagger here:

10F/8424 & RS225-8 FAST Ref Monitor

A very good approximation of Dagger, although round symmetry (which has some resonance modes), is a sports pylon or cone for kids soccer practice etc. The cones are great for this - semi pliable material is self-damping.

Amazon.com : Cintz 9" Orange Field Cone Markers, Set of 10 : Soccer Training Cones : Sports & Outdoors

More on Dagger here:

10F/8424 & RS225-8 FAST Ref Monitor

A very good approximation of Dagger, although round symmetry (which has some resonance modes), is a sports pylon or cone for kids soccer practice etc. The cones are great for this - semi pliable material is self-damping.

Amazon.com : Cintz 9" Orange Field Cone Markers, Set of 10 : Soccer Training Cones : Sports & Outdoors

- Home

- Loudspeakers

- Full Range

- The Nautaloss Ref Monitor