In response to questions about Panzerholtz and Delignent sourcing in USA

My Panzerholtz source is Roger Cullen. He did a great job for me and I highly recommend him. He was also very easy for me to work with.

I have no connection with him other than as a customer.

He is a distributor for both P'holtz and Delignent. His primary business is machining. I always have him cut my pieces to finish size as he cuts them on a CNC mill and they are dead nuts on and it also reduces shipping cost. At least the 1 inch stuff I get.

rcullen@precisioncompositindustries.com

cell 704.888.9930

company location is in North Carolina, USA

Precision Composite Industries can be googled but it doesn't say a whole lot about our stuff

Don

My Panzerholtz source is Roger Cullen. He did a great job for me and I highly recommend him. He was also very easy for me to work with.

I have no connection with him other than as a customer.

He is a distributor for both P'holtz and Delignent. His primary business is machining. I always have him cut my pieces to finish size as he cuts them on a CNC mill and they are dead nuts on and it also reduces shipping cost. At least the 1 inch stuff I get.

rcullen@precisioncompositindustries.com

cell 704.888.9930

company location is in North Carolina, USA

Precision Composite Industries can be googled but it doesn't say a whole lot about our stuff

Don

JP, just curious, what does "easier version" mean.I've an easier version of this 8.5 x 20:

View attachment 1311803

Haven't attempted one yet, but thinking a custom ground HSS cutter may make quicker work over a standard insert. I'd likely use a parting tool and then "mount" the piece on a mock spindle and take a light facing cut on it.

Don

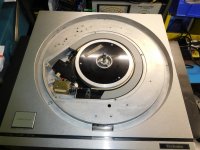

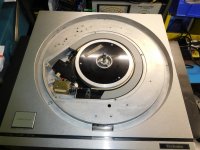

Got the turntable ready to go into the plinth when it arrives, and mount the tonearm.

Spun the platter on my lathe and cleaned up with Scotch pads - didn't want to remove much material.

VR101 and VR102 adjusted per specs, brake reassembled and adjusted, and I added some chassis damping material, with extra securing using dabs of polyurethane adhesive (don't want them dropping down near the PCBs).

The plinth is used, but will serve until I build exactly what I want it to live in. The tonearm is an EPA-b500 with a -a501H arm. I am also looking for a -250 arm at a reasonable (hah!) price.

Getting anxious to get this in operation now!

Spun the platter on my lathe and cleaned up with Scotch pads - didn't want to remove much material.

VR101 and VR102 adjusted per specs, brake reassembled and adjusted, and I added some chassis damping material, with extra securing using dabs of polyurethane adhesive (don't want them dropping down near the PCBs).

The plinth is used, but will serve until I build exactly what I want it to live in. The tonearm is an EPA-b500 with a -a501H arm. I am also looking for a -250 arm at a reasonable (hah!) price.

Getting anxious to get this in operation now!

I am also looking for a -250 arm at a reasonable (hah!) price.

Out of Japan is likely your best bet, though EPA wands have been a bit thin lately, aside from the over-priced pieces that haven't been moving. I'm not shopping for an A250 at the moment, but I do occasionally grab others, so if you're bidding on something feel free to let me know so we don't bid against each other.

And no, @6L6 - they're not all here!

Yes, JP - I've noticed the supply is sparse other than one overpriced item the seller isn't interested in moving, apparently.

Thanks for the heads up on bidding - will do!

Thanks for the heads up on bidding - will do!

Ive seen photos of that collection, yes, they may, in fact, be!

Maybe for 501Hs.

@GKTAUDIO if I see one and I remember I'll drop you an e-mail.

I am also looking for a -250 arm at a reasonable (hah!) price.

Do you want one? They are all NOS 😀

Attachments

Last edited:

Just curious. What are the basic reasons people select the different EPA tone arms. I have a 100. Other than straight vs curved or pivot to spindle (or effective) length I don't know much about the others.

Don

Don

100/100MK2/500 have the same geometry. Ergonomics on the 100MK2 are better than the 100, and the VTA range is 20mm on the 100MK2/500 vs. 6mm on the 100. Pin races on the 100 are finished to a higher standard.

500 has steel ball bearings, but those can be upgraded to 100 spec. There are five straight wands available, an "S" universal, and a P-mount:

EPA-A501H - 8g

EPA-A501M - 10g

EPA-A501L - 18g

EPA-A501E - 6g

EPA-A501G - 14g

EPA-A250 - 14g

EPA-A505 - 6g

They're geared toward lighter cartridges and mounting a modern long MC on the straight wands can be an issue. All have dynamic damping similar to the EPA-100s with a fluid chamber in front of the CW and a magnet in the rear, only not adjustable.

I use 500s as I can have many carts mounted on different wands and the bases on different 'tables which allows swapping things around with great ease - all I need to do is adjust the AS and height.

500 has steel ball bearings, but those can be upgraded to 100 spec. There are five straight wands available, an "S" universal, and a P-mount:

EPA-A501H - 8g

EPA-A501M - 10g

EPA-A501L - 18g

EPA-A501E - 6g

EPA-A501G - 14g

EPA-A250 - 14g

EPA-A505 - 6g

They're geared toward lighter cartridges and mounting a modern long MC on the straight wands can be an issue. All have dynamic damping similar to the EPA-100s with a fluid chamber in front of the CW and a magnet in the rear, only not adjustable.

I use 500s as I can have many carts mounted on different wands and the bases on different 'tables which allows swapping things around with great ease - all I need to do is adjust the AS and height.

Last edited by a moderator:

That is very useful to see those data compiled, JP.

Do you happen to know the ball bearing diameter? What type of balls would you change to?

Do you happen to know the ball bearing diameter? What type of balls would you change to?

OK, thanks, JP. Not sure I want to get into the re-grinding and polishing.

Good to have that table, too.

Good to have that table, too.

The plinth arrived and it's nicer than I had expected. The seller did a great job packing, so as heavy as it is, it arrived safely.

A little stain to refresh the surface, followed by some Feed and Wax, and it's ready for me to make a larger hole in the arm board for the EPA-B500 base, or make another because I think it needs to be raised above the plane that the table chassis sits on, based on the factory "obsidian" plinths (please correct me if I'm wrong).

Need to get some longer metric screws for the arm base and much longer ones for the table to plinth connection, but I might have to make them, as long metric screws aren't readily available locally.

Also need to determine the size of the ground spike/screw on the table and make or buy a suitable replacement nut. Looks like 7 or 8mm.

A little stain to refresh the surface, followed by some Feed and Wax, and it's ready for me to make a larger hole in the arm board for the EPA-B500 base, or make another because I think it needs to be raised above the plane that the table chassis sits on, based on the factory "obsidian" plinths (please correct me if I'm wrong).

Need to get some longer metric screws for the arm base and much longer ones for the table to plinth connection, but I might have to make them, as long metric screws aren't readily available locally.

Also need to determine the size of the ground spike/screw on the table and make or buy a suitable replacement nut. Looks like 7 or 8mm.

Attachments

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread