I'm not sure why outboarding the electronics would do anything for you. Please explain.

I agree.

I agree.

My personal goal for wanting to move the electronics is to simplify the plinth design and construction. Keeping the electronics in the plinth takes up space for mass and requires access for service. Both reasons could be accommodated but would increase the overall size of the plinth to equal the same weight.

Changed my mind on a solid block of aluminum for the plinth. Ordered Panzerholz instead. Should be here next week from London. 4 layers of 1" (25mm) with 1 layer of 1/4" (6.3 mm) thick aluminum between the bottom 2-3 and 3-4 layers for a plinth height of 4 1/2" (114 mm), overall W and D will be less than 20" x 20" (500mm x 500mm).

I'm still planning on ditching the stock top plate. The plinth will have more of a sculpted shape, via CNC.

I'm still planning on ditching the stock top plate. The plinth will have more of a sculpted shape, via CNC.

Panzer is cool stuff. I wish I had the ability to work it -- it is best if you tool it exactly as if it were cast iron.

Panzerholz = Tank Armor. Literally.

Panzerholz = Tank Armor. Literally.

Please kindly post contact (web site?) info on your Panzerholz supplier and cost of purchase/shipping. So far the closest that I have found orderable in the USA is material from the same German company which is similar to Panzerholz but designed for piano pin blocks. It may be quite adequate, but hard to get enough specs to determine how similar/different it might be.

Thanks, looking forward to seeing if it's as hard to cut as they say!Panzer is cool stuff. I wish I had the ability to work it -- it is best if you tool it exactly as if it were cast iron.

Panzerholz = Tank Armor. Literally.

Have you picked a color for yours yet?

Sure! The good, bad and ugly.Coast please share some pictures as you go, sounds like it is going to be a very cool project.

Sure.Please kindly post contact (web site?) info on your Panzerholz supplier and cost of purchase/shipping. So far the closest that I have found orderable in the USA is material from the same German company which is similar to Panzerholz but designed for piano pin blocks. It may be quite adequate, but hard to get enough specs to determine how similar/different it might be.

Plinths

I bought 3 ea 500 x 500 x 25mm pcs (20" x 20" x 1") @ £90 each plus £150 for shipping to Hawaii. Roughly $820 total.

There is a link on their site for phone and email. I emailed the yesterday, Andrew answered my questions and I paid via PayPal this morning. Delivery next week from London.

(FYI, their web page evidently needs updated as the pricing is a little higher)

Fat finger typing above, I bought "4" pcs for the $820, and my project.Sure.

Plinths

I bought 3 ea 500 x 500 x 25mm pcs (20" x 20" x 1") @ £90 each plus £150 for shipping to Hawaii. Roughly $820 total.

There is a link on their site for phone and email. I emailed the yesterday, Andrew answered my questions and I paid via PayPal this morning. Delivery next week from London.

(FYI, their web page evidently needs updated as the pricing is a little higher)

I have access to a CAD tech, CNC, and operator. (Actually, the company I work for also owns a cabinet shop, I have access to the men and tooling, including some metal working tools and a paint booth). We will see how much I have to spend on bits for the CNC to cut out my plinth! Besides the recess for the motor and recessed platter, the entire exterior gets shaped. The bottom and part of the 2 sides are the only flat areas in my design.

The Panzer does not weigh as much as aluminum, so the total estimated weight of the finished table now will be just a bit over 100lbs. (47.5 kg)

I'm looking at the bearing drain. I read somewhere that the piece of iron weighed 20lbs (9kg)? in the pics I've seen the size of the piece of iron doesn't seem to match the weight.

Andrew, the salesman at ltlewis, sent me info on cutting and tooling this morning

The Panzer does not weigh as much as aluminum, so the total estimated weight of the finished table now will be just a bit over 100lbs. (47.5 kg)

I'm looking at the bearing drain. I read somewhere that the piece of iron weighed 20lbs (9kg)? in the pics I've seen the size of the piece of iron doesn't seem to match the weight.

Andrew, the salesman at ltlewis, sent me info on cutting and tooling this morning

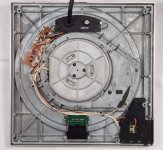

Not much going on at work today so I made a quick 2 hour mule plinth so I can test each phase of the rebuild.

6 layers of 3/4" (19mm) birch ply, 19 1/2" x 15 1/2" (495 x 394mm)

I have a Jelco 750 (9") that I will use for starters. Only 2mm difference in mounting distance different from the 4points Kuzma that I might use eventually.

6 layers of 3/4" (19mm) birch ply, 19 1/2" x 15 1/2" (495 x 394mm)

I have a Jelco 750 (9") that I will use for starters. Only 2mm difference in mounting distance different from the 4points Kuzma that I might use eventually.

If it's an electrolytic, change it.

The trimmers are up to you - I would look for something that fits if you are going to bother.

The trimmers are up to you - I would look for something that fits if you are going to bother.

Coast ---

Thanks for the source. A bit painful on the price!

Out of curiosity, has anyone considered using Epicurian breadboards for a plinth? One could stack up several, such as:

Big Block Cutting Boards - Epicurean

(not that this is much cheaper than Panzerholz)

Coast -- if the trim pots aren't sealed units, I'd replace them as the open type often used in the era tend to get flaky over the years. At a minimum, 'exercise' yours by twisting them left/right maybe 20 times. (be sure to return to the original setting, either carefully by eye, or by measurement.).

Thanks for the source. A bit painful on the price!

Out of curiosity, has anyone considered using Epicurian breadboards for a plinth? One could stack up several, such as:

Big Block Cutting Boards - Epicurean

(not that this is much cheaper than Panzerholz)

Coast -- if the trim pots aren't sealed units, I'd replace them as the open type often used in the era tend to get flaky over the years. At a minimum, 'exercise' yours by twisting them left/right maybe 20 times. (be sure to return to the original setting, either carefully by eye, or by measurement.).

I enjoyed listening to the SP10 in the test plinth this weekend. Speed has been good, but the strobe has suddenly stop working. Can anyone point me in the direction to see how to change to LED?

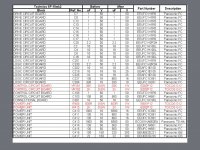

I ordered new caps for the table and power supply (ordered 1 or 2 extra of each)

Ordered a new thrust pad from Steve here on the forum (theanalogdept.com)

And Anderol465 for the bearing. (eBay) ISO Grade 68 synthetic.

Next up tear down! I will verify each step before the next.

Looks like I will plan my new plinth build around a SME 312. It has a good reputation, read satisfactory reviews when coupled with a heavy plinth SP10, and the long, low, sleek, black design will match my plinth design.

Any comments are appreciated!

I ordered new caps for the table and power supply (ordered 1 or 2 extra of each)

Ordered a new thrust pad from Steve here on the forum (theanalogdept.com)

And Anderol465 for the bearing. (eBay) ISO Grade 68 synthetic.

Next up tear down! I will verify each step before the next.

Looks like I will plan my new plinth build around a SME 312. It has a good reputation, read satisfactory reviews when coupled with a heavy plinth SP10, and the long, low, sleek, black design will match my plinth design.

Any comments are appreciated!

Coasttocoast,

Here is a tonearm from Analog Instruments you may be interested in. The wood Siggwan for NZ 1480.00 in development is a metal tonearm for estimated US $1700.00 analogInstruments - Home

The story of the man behind the tonearm.

Next build. - AudioEnz

Here is a tonearm from Analog Instruments you may be interested in. The wood Siggwan for NZ 1480.00 in development is a metal tonearm for estimated US $1700.00 analogInstruments - Home

The story of the man behind the tonearm.

Next build. - AudioEnz

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread