I own my SP10 or three years. When I bought it, I replaced the thrust cap with a new Torlon one, the ball with a [FONT=Arial, Arial, Helvetica]SiN4 Ceramic and use [/FONT][FONT=Arial, Arial, Helvetica]SFWO 010 oil to lubricate the bearing.[/FONT]

[FONT=Arial, Arial, Helvetica]HORROR!!! The platter kept spinning only 15s before stopping (on my former TD160 or LP12, it was more than 1 minute).😱

[/FONT]

[FONT=Arial, Arial, Helvetica]This afternoon, I read the following thing about the bearing:[/FONT]

[FONT=Arial, Arial, Helvetica]"[/FONT][FONT=Arial, Arial, Helvetica]Technics specify that 2-3 drops should be squirted into the hole adjacent to the sub-platter spindle (see above) every 2000 running hours (that’s not much, every few years). This means that the oil ends up in the shallow ‘well’ formed around the top of the motor bearing sleeve and then can slowly seep down to lubricate the sleeve & bearing shaft. In other words, the sleeve (and ball) does not need to be pre-filled with oil."[/FONT]

[FONT=Arial, Arial, Helvetica]TECHNICS SP-10MkII turntable – Pt 2 | D a r k L a n t e r n[/FONT]

[FONT=Arial, Arial, Helvetica]I remember having pre-filled the bearing, three years ago. Is it possible that I put to much oil and that this overfill has a kind of slight braking action?

[/FONT]

As JP said 15 seconds is about right. Remember these turntables were designed to run 24/7 and millions of hours in broadcast stations. Because they have extremely powerful engines bearing friction is not a problem for speed stability, unlike a belt drive TT that would wow dreadfully with a tight tolerance bearing.

This SP10 of mine came from radio station and was treated very harshly. When I dismantled the motor to replace the thrust pad the bearing was in almost perfect condition, apart from the worn thrust pad and ball.

My SP10 with no mechanical brake has a new torlon thrust pad and SiN4 ball. It sounds like you have everything up to snuff.

Hallo,

can anyone tell me how it works and what the Albert Porter style noise sink is made of?

Are there any drawings or a shared project?

can anyone tell me how it works and what the Albert Porter style noise sink is made of?

Are there any drawings or a shared project?

Just use lead or heavy construction to get plinth + TT 20+ kg. Heavy makes a significant and positive benefit.

My take on that is anything that can transfer vibration will be bidirectional, so my plinth does not have the sink. IMO the SP10 bearing is very good. Just clean it out and install a new thrust pad and ball if needed, oh and new oil.

If you want a great plinth build it from resin and bentonite (kitty litter). My other SP 10 has a resin plinth and it sounds great, absolutely blows a Rega RP8/Apheta 2 into last century.

If you want a great plinth build it from resin and bentonite (kitty litter). My other SP 10 has a resin plinth and it sounds great, absolutely blows a Rega RP8/Apheta 2 into last century.

Attachments

Just use lead or heavy construction to get plinth + TT 20+ kg. Heavy makes a significant and positive benefit.

.......thanks for that! At last some heavy-weight support for heavyweight supports.

😉😀

These TTs were designed for heavyweight plinths without springs, cat lavatories or any lightweight sprung system that reeks of AR, Linn, et al. The best results come when it has a really solid plinth on a really solid shelf attached firmly to a solid external mineral wall or on a substantial stand fixed direct to the ground slab.

Use carbon blocks between plinth and support....not some spongey expedient! 😉

Last edited:

My take on that is anything that can transfer vibration will be bidirectional, so my plinth does not have the sink. IMO the SP10 bearing is very good. Just clean it out and install a new thrust pad and ball if needed, oh and new oil.

If you want a great plinth build it from resin and bentonite (kitty litter). My other SP 10 has a resin plinth and it sounds great, absolutely blows a Rega RP8/Apheta 2 into last century.

Follow your own instincts but remember that the 'sink' was developed for use in a Panzerholst plinth of great substance.

....If you want a great plinth build it from resin and bentonite (kitty litter). My other SP 10 has a resin plinth and it sounds great, absolutely blows a Rega RP8/Apheta 2 into last century.

Do as Warren said. I did and am very happy! it will be heavy.

Rush

.......thanks for that! At last some heavy-weight support for heavyweight supports.

😉😀

These TTs were designed for heavyweight plinths without springs,

And that is exactly what the resin bentonite plinth is. I haven't got bathroom scales but this plinth is over 20kg.

I have an old house with sprung floors and walls are no better, so my SP10 is sat on spring isolators, these work very well and isolate the TT to 5Hz. I'd really like a MinusK but not in the budget.

My take on that is anything that can transfer vibration will be bidirectional, so my plinth does not have the sink. IMO the SP10 bearing is very good. Just clean it out and install a new thrust pad and ball if needed, oh and new oil.

If you want a great plinth build it from resin and bentonite (kitty litter). My other SP 10 has a resin plinth and it sounds great, absolutely blows a Rega RP8/Apheta 2 into last century.

Whuuuttt... Kitty litter? Man genius..

I just got something equivalent... Sony tts 8000. Was thinking of redoing the plinth.as old arm is series 1 sme 3009. For epa 100 tone arm.. So what's are good alternatives

Also it's 100v.. So out side is 220v ac... So can I use a 50v Ct transformer? Or a what is a reasonable choice

Whuuuttt... Kitty litter? Man genius..

I just got something equivalent... Sony tts 8000. Was thinking of redoing the plinth.as old arm is series 1 sme 3009. For epa 100 tone arm.. So what's are good alternatives

Also it's 100v.. So out side is 220v ac... So can I use a 50v Ct transformer? Or a what is a reasonable choice

Resin Kitty litter is not my idea, I stole it from someone else.

I have 2 SP10's the one in the 2nd pic is my current setup. I have an EPA100 with ECP205 and EPC100 (sold). The agricultural arm in the 2nd pic is better than the EPA100 and the EPA100 is a very good arm better than my previous RB808. I think I have about $50.00 invested in this arm as I had to buy a carbon rod and borosilicate tubes, the rest came from the scrap bin.

The 1st pic is the SP10 I bought not operational and have made a plinth (resin/bentonite, kitty litter) and my version a copy of the Clearaudio TT1.

If you have some DIY skills go for a linear arm with short arm wand, they really are very good.

Attachments

LOVE this thread (THANKS 6L6!). After reading it through... Here's the progress on mine....

Short version is the deck came from a super guy in Canada, rescued from a pile at a now defunct radio station. VERY far up north. Person I bought it from basically gave it to me (he knew "his" deck would be loved)—already refreshed internally—he kept it's mate from the station (they always come in twos!)—along with 6 pickup truck loads of their other discarded EQ—3 loads of which were vinyl I'm told. Incredible.

Missing the badge—but a friend donated a 3D printed one! which is undergoing beauty treatment.

I want to make GFRC plinth at some point...but I also need to listen to this thing—because apparently it's going to make my other decks all rejects and subsequently for sale (See pics ;-). One is a Rega knockoff that I made from parts inspired by the first deck I ever owned (RP1) which is pretty hideous in terms of build quality IMO—the other "beast" is made from a lot of nothing. But they are both belt drive. So this will all be a great comparo when the SP-10MK2 is up and running.

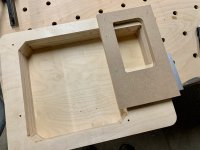

So for the SP-10 plinth—some shots of layout—building it out of the usual ply—this happens to be actual 5x5' finish cabinet grade ply—very dense and void free and fun to work with (my calls to the NA—in Canada—distributor of Panzerholz went unanswered). SME 9" newer style varieties are basically not possible to mount if you intend to follow the SME guides—and have a questionable resting point—visually speaking. We shall see what I can cook up there. I used some Jelco guides to account for 10" and shorter single mount arms. SME will fit I think if I shorten the travel they intend with their mount and nail the center point based on a short range of cart dimensions—ie act as if it's a center mount design with a few mm of wiggle room.

5 ply layers—solid bottom. About a 1" void for loading. Made a template after doing all my measurements—setup 2 routers—and off we go. Still have more layers to make—then some pins and glue up before next steps.

My calcs for weigh are 21lbs for deck alone, 15.4lbs in ply—leaving around 14lbs in lead. A friend hooked me up with some old telephone cable sheathing—pure lead. I'll hammer it out and stuff about half in there.

Might be able to listen to this sooner than later—Its been sitting far far too long—but then again I did accomplish making a killer phono-pre with a lot of help in the meantime! (6L6 again ;-).

Short version is the deck came from a super guy in Canada, rescued from a pile at a now defunct radio station. VERY far up north. Person I bought it from basically gave it to me (he knew "his" deck would be loved)—already refreshed internally—he kept it's mate from the station (they always come in twos!)—along with 6 pickup truck loads of their other discarded EQ—3 loads of which were vinyl I'm told. Incredible.

Missing the badge—but a friend donated a 3D printed one! which is undergoing beauty treatment.

I want to make GFRC plinth at some point...but I also need to listen to this thing—because apparently it's going to make my other decks all rejects and subsequently for sale (See pics ;-). One is a Rega knockoff that I made from parts inspired by the first deck I ever owned (RP1) which is pretty hideous in terms of build quality IMO—the other "beast" is made from a lot of nothing. But they are both belt drive. So this will all be a great comparo when the SP-10MK2 is up and running.

So for the SP-10 plinth—some shots of layout—building it out of the usual ply—this happens to be actual 5x5' finish cabinet grade ply—very dense and void free and fun to work with (my calls to the NA—in Canada—distributor of Panzerholz went unanswered). SME 9" newer style varieties are basically not possible to mount if you intend to follow the SME guides—and have a questionable resting point—visually speaking. We shall see what I can cook up there. I used some Jelco guides to account for 10" and shorter single mount arms. SME will fit I think if I shorten the travel they intend with their mount and nail the center point based on a short range of cart dimensions—ie act as if it's a center mount design with a few mm of wiggle room.

5 ply layers—solid bottom. About a 1" void for loading. Made a template after doing all my measurements—setup 2 routers—and off we go. Still have more layers to make—then some pins and glue up before next steps.

My calcs for weigh are 21lbs for deck alone, 15.4lbs in ply—leaving around 14lbs in lead. A friend hooked me up with some old telephone cable sheathing—pure lead. I'll hammer it out and stuff about half in there.

Might be able to listen to this sooner than later—Its been sitting far far too long—but then again I did accomplish making a killer phono-pre with a lot of help in the meantime! (6L6 again ;-).

Attachments

-

SP-10-Process_08.jpg613.2 KB · Views: 137

SP-10-Process_08.jpg613.2 KB · Views: 137 -

SP-10-Process_09.jpg818.1 KB · Views: 132

SP-10-Process_09.jpg818.1 KB · Views: 132 -

SP-10-Process_10.jpg588.4 KB · Views: 132

SP-10-Process_10.jpg588.4 KB · Views: 132 -

Sweet-SP10-Lead.jpg436.9 KB · Views: 130

Sweet-SP10-Lead.jpg436.9 KB · Views: 130 -

SP-10-Process_06.jpg736.5 KB · Views: 178

SP-10-Process_06.jpg736.5 KB · Views: 178 -

SP-10-Process_04-12%22-arm.jpg865 KB · Views: 167

SP-10-Process_04-12%22-arm.jpg865 KB · Views: 167 -

SP-10-Layout_03.jpg497.3 KB · Views: 137

SP-10-Layout_03.jpg497.3 KB · Views: 137 -

PF-Duo_01.jpg273.2 KB · Views: 147

PF-Duo_01.jpg273.2 KB · Views: 147 -

PF-BigBlock_04.jpg365.3 KB · Views: 282

PF-BigBlock_04.jpg365.3 KB · Views: 282 -

PF-BigBlock_05.jpg483.8 KB · Views: 286

PF-BigBlock_05.jpg483.8 KB · Views: 286

Thanks 6L6!

More pics... found a couple of hours today to move this forward...

!!!

I like the look, would be awesome varnished.

Mounting Epa100 to Sony tts8000

My friend had sp10 mk2.and we compared to Sony tts 8000. Speed control is equally stellar

You want to see if you can get hold of an SH100 this is the headshell that came with the EPA100. I have both and it is far superior to the SH98.

You want to see if you can get hold of an SH100 this is the headshell that came with the EPA100. I have both and it is far superior to the SH98.

Thank you for your info will try buy them.

How bout bearings? I had replaced with technics one.. Can use boga?

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread