Think I saw quite a bit of criticism of such 'upgrades' to Zenith and Mission Mechanic arms many years ago...I remember well that ceramic bearing balls were a failure in improvement terms.

Well that's not surprising, ceramic ball bearings are great for very high speed high temperature use, or if no lubricant can be used, or in the wet. They are amazing for that. None of that is of any use to a turntable AFAICT. Ceramic bearings are very cute of course.

@Warrjon. You might also want to consider an AT-23 which would look great on that arm and the rare but lovely DL-109 which is not as pretty but does work well.

(I know shouldn't be encouraging you)

(I know shouldn't be encouraging you)

Yes, JP, do tell what the diameter of the balls is. There was a gentleman, now deceased, who did a number of replacements of units with damaged ruby bearings. Lots of pictures and info, but no specific sizes/sources were given. Sadly, his information departed with him.

Yes, Jim Howard. The ball is 3/64".

WOW...I go crazy when I get arms with very low friction; who did the job?

I did - typically do my own work.

I don't plan on using an MC, I will be selling my last MC which is an almost brand new (2 months old) Rega Apheta 2.

I have an old Linn K5 (AT95e) which I bought new with an LP12 in 1983 that now sports an LPGear HE stylus, this is a surprisingly good cartridge for the money. I also bought a Technics EPC100 and EPC205C and have my eyes on a Stanton 881S so MM only from now on.

Don't understand why you splash out for such a beautiful arm, but not want to run the best possible cartridge on it? I'd love to have that arm for my old AT33PTG.

jeff

Don't understand why you splash out for such a beautiful arm, but not want to run the best possible cartridge on it? I'd love to have that arm for my old AT33PTG.

jeff

I wouldn't say the EPC100 and EPC205 or Stanton 881S are low end cartridges. I have had a few MC carts, Linn Troika, Apheta and Apheta 2, I prefer MM.

I have just fitted the AT95 to my Rega RP8 and played it through Boozhounds phono pre, Total out lay for this would be under $500. My Rega Apheta 2 and Aria phono set me back $4.3K, Does the Apheta sound 10 times better definitely not, I prefer the AT95 although it has less detail but this could be the stylus HE against Fine Line.

Finally my SP10 arrived.

Set it up and gave it a test. Bearing spins well. I have ordered a new thrust pad, ceramic bearing and oil. I'll pull it down strip it and paint it Black, or maybe gun metal grey........... Time to build a plinth...

I have a few things to fix.

Runs slightly slow. I only have 1 scope probe, I've ordered another so I will adjust the PLL as soon as it arrives

One of the platter mounting screws is stripped in the sub platter. Haven't decided how to repair this yet, I may either drill it out to 8mm and insert a plug then re-tap - or re-drill and tap all 3 M4 and make new mounting screws, jury is out on this one.

Checked platter vertical runout and 0.09mm (0.0035") This maybe due to stripped thread. I'll polish the platter in the lathe then check it again once I have repaired the stripped thread.

I'll re-balance the platter and sub platter once I have repaired and polished it. More work I need to build a balancing rig.

Set it up and gave it a test. Bearing spins well. I have ordered a new thrust pad, ceramic bearing and oil. I'll pull it down strip it and paint it Black, or maybe gun metal grey........... Time to build a plinth...

I have a few things to fix.

Runs slightly slow. I only have 1 scope probe, I've ordered another so I will adjust the PLL as soon as it arrives

One of the platter mounting screws is stripped in the sub platter. Haven't decided how to repair this yet, I may either drill it out to 8mm and insert a plug then re-tap - or re-drill and tap all 3 M4 and make new mounting screws, jury is out on this one.

Checked platter vertical runout and 0.09mm (0.0035") This maybe due to stripped thread. I'll polish the platter in the lathe then check it again once I have repaired the stripped thread.

I'll re-balance the platter and sub platter once I have repaired and polished it. More work I need to build a balancing rig.

Attachments

Hi guys I have just finished one of the sp 10 II purchased as part of spare parts after a couple of years of free time work.

There are too many photos to publish, so those interested in going to see the link are here.

Good work. I like the colour you painted it. What is the colour btw.

I hope to have mine operational in a month..... My biggest problem is I live in a rural area so I have order everything online and wait.

color for car body

Standox brand / Fiat car

color code 628 gray slate name

Looks great! Did you clear over the black stripe or did you mask it?

Platter

Hi,looking for info on the stainless steel platter mentioned multiple times,would love on for Sp10Mk2

Dave

Hi,looking for info on the stainless steel platter mentioned multiple times,would love on for Sp10Mk2

Dave

Looks great! Did you clear over the black stripe or did you mask it?

Hi the description explains that the whole frame has been sandblasted, the black strip has been completely redone.

I was undecided whether to make it silver or black, then for aesthetics I preferred to make it black strip.

https://i.postimg.cc/prd6FMNH/DSCN5101.jpg

Not sure if I should start a new thread for my SP10 or carry on here. So If the mods want a new thread let me know.

Anyway I'll carry on.

I knew the TT was running fast on 33 and 78 but I got a reasonable deal on it.

I spent a couple hrs today diagnosing the problem which turned out to be a bad transistor TR129 in the Control Circuit board.

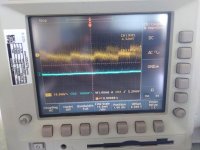

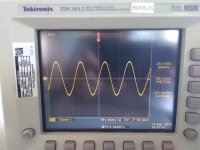

First pic is period adjustment waveform pretty yuck, 2nd pic is the input to the CC PCB so the issue is most likely on the CC. The wave on the base of TR109 was good and base of TR129 nothing. These are a 2SC828 and one substitute is KSC1815Y and are available at RS Comp although I had to buy 200, I'm set for life to repair may SP10's.

Check the PS and tweaked the 32.5V checked ripple on both 32.5 and 5V less than 1mV so button it up and leave it.

Next is to repair the stripped thread in the sub platter

..

Anyway I'll carry on.

I knew the TT was running fast on 33 and 78 but I got a reasonable deal on it.

I spent a couple hrs today diagnosing the problem which turned out to be a bad transistor TR129 in the Control Circuit board.

First pic is period adjustment waveform pretty yuck, 2nd pic is the input to the CC PCB so the issue is most likely on the CC. The wave on the base of TR109 was good and base of TR129 nothing. These are a 2SC828 and one substitute is KSC1815Y and are available at RS Comp although I had to buy 200, I'm set for life to repair may SP10's.

Check the PS and tweaked the 32.5V checked ripple on both 32.5 and 5V less than 1mV so button it up and leave it.

Next is to repair the stripped thread in the sub platter

..

Attachments

This is a great place for it, or start your own, it's all good!

Keep posting lots of photos, it helps all people following to keep these incredible machines alive.

Keep posting lots of photos, it helps all people following to keep these incredible machines alive.

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread