Any actual evidence yet of what the audible detriment and purported improvement is? Any evidence on the MK3 and R?

From the reports I've had on the OEM/POM platter the overarching feedback is the drop in noise floor and additional detail retrieved which is possibly a result of the lower noise. I have a friend who has a few high end TT's including a Goldmund Reference, my plan is to take my SP10 inverted bearing TT to his place and using the same pivoting TA and cart do a back to back in his system.

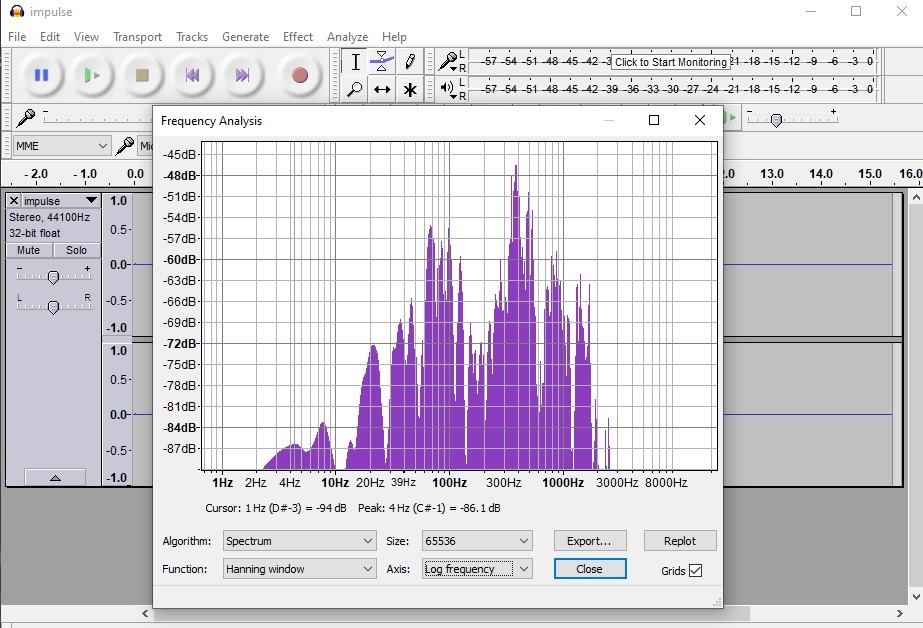

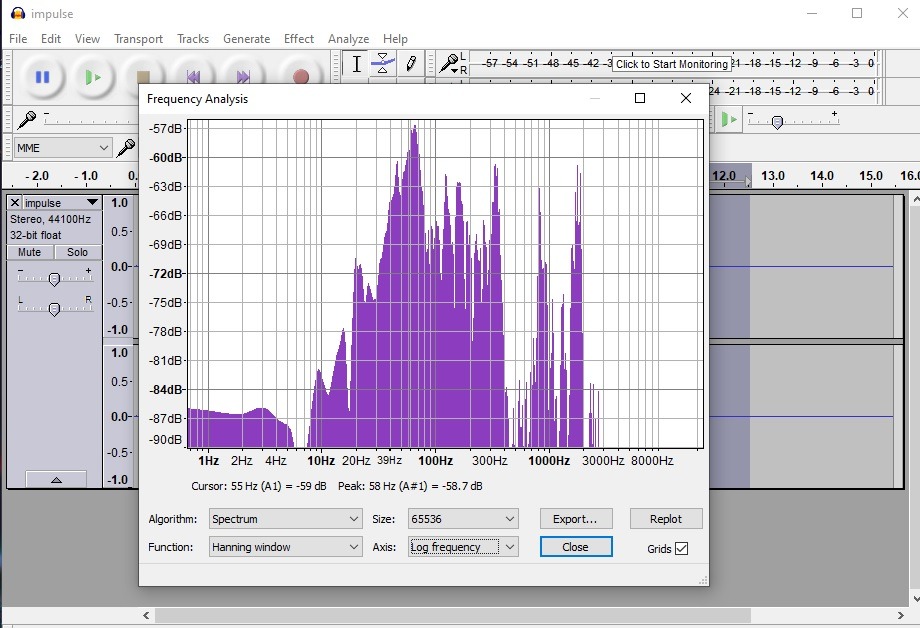

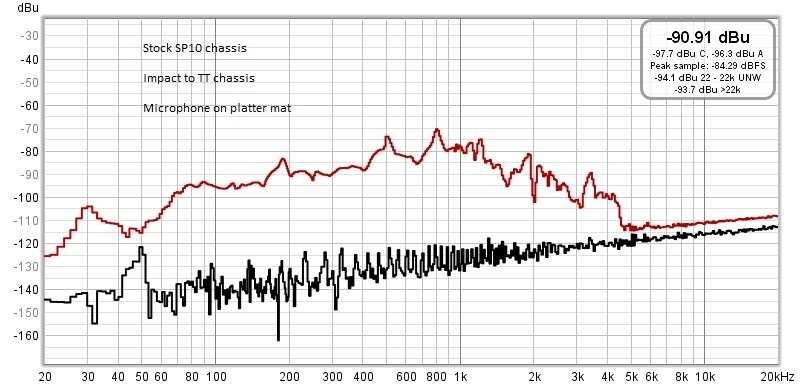

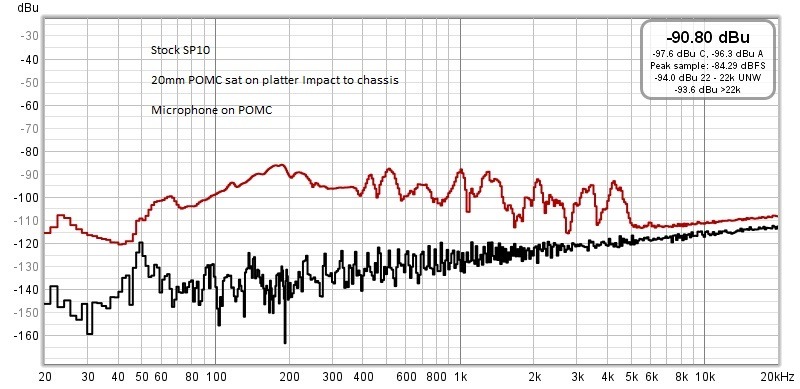

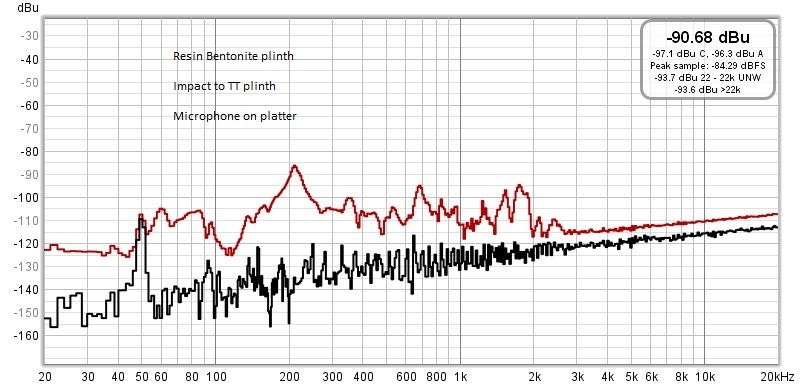

Here are some test results. Testing was done using a marble dropped from a predetermined height. For those who don't know the reasoning for impulse testing - this test excites the natural resonance in the unit under test, these resonances will be excited by any program material at the same frequencies causing peaks and dips in the frequency response at the problem frequencies.

These are impulse response tests on the plinth. 1st is Resin/bentonite 2nd is Permalli. This test was performed before and after I migrated my motor/platter from the R/B to the Permalli plinths.

These are stock SP10's. 1st is totally stock SP10 in a marine plywood plinth and 2nd same TT with OEM/20mm POM platter.

This one is a remote mounted motor in a resin/bento plinth with POM platter.

Here are some test results. Testing was done using a marble dropped from a predetermined height. For those who don't know the reasoning for impulse testing - this test excites the natural resonance in the unit under test, these resonances will be excited by any program material at the same frequencies causing peaks and dips in the frequency response at the problem frequencies.

These are impulse response tests on the plinth. 1st is Resin/bentonite 2nd is Permalli. This test was performed before and after I migrated my motor/platter from the R/B to the Permalli plinths.

These are stock SP10's. 1st is totally stock SP10 in a marine plywood plinth and 2nd same TT with OEM/20mm POM platter.

This one is a remote mounted motor in a resin/bento plinth with POM platter.

The SP10 in various guises, has been my main turntable since 1998. I can claim to know it intimately. I have compared my SP10II Kaneta Bento/Res plinth, POM/gunmetal platter with the SP10R which I have owned since 2018.

The 10R is the best measuring turntable that I know of. It sits in a bento/res plinth on a MinusK isolation base. It supports an SME IV and an SME V12 with various excellent cartridges, phono stages and pre-amps. It has been given the best opportunity to perform in my system over an extended period.

I have compared the 10R with my modified mkII over a 5 year period, swapping cartridges back and forth.

In my opinion Technics missed an opportunity with the 10R by retaining the legacy chassis format. Out of the box, I was concerned that the underneath on/off switch cover produced a noticeable rattle when lightly tapped. To my ears, the Kaneta bento/res POM mkII is preferred to the 10R by a good margin.

The most audible differences are in perceived vinyl noise floor, and image stage depth, where the POM is superior. If I had to choose a single word to express what I hear, it would be clarity. There is just more audible low level detail.

The mkII modifications were installed over an 8 year period, and I have compared each modification to a stock mkII in a bento/res plinth.

Warrjon's build of the POM/gunmetal platter, with decoupled centre spindle was an audible improvement.

I have previously captured some impulse measurements comparing various mats and bare POM platter. They showed measurable differences in settling times, with POM platter superior. The measurement tools were moderately sensitive to observe differences but not absolute values.

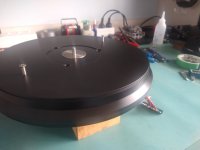

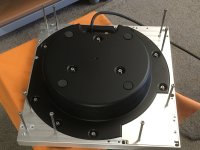

Below are pictures of the Kaneta/bentores/POM/gunmetal 10mkII and the 10R on the MinusK. Also the 10R underneath.

The 10R is the best measuring turntable that I know of. It sits in a bento/res plinth on a MinusK isolation base. It supports an SME IV and an SME V12 with various excellent cartridges, phono stages and pre-amps. It has been given the best opportunity to perform in my system over an extended period.

I have compared the 10R with my modified mkII over a 5 year period, swapping cartridges back and forth.

In my opinion Technics missed an opportunity with the 10R by retaining the legacy chassis format. Out of the box, I was concerned that the underneath on/off switch cover produced a noticeable rattle when lightly tapped. To my ears, the Kaneta bento/res POM mkII is preferred to the 10R by a good margin.

The most audible differences are in perceived vinyl noise floor, and image stage depth, where the POM is superior. If I had to choose a single word to express what I hear, it would be clarity. There is just more audible low level detail.

The mkII modifications were installed over an 8 year period, and I have compared each modification to a stock mkII in a bento/res plinth.

Warrjon's build of the POM/gunmetal platter, with decoupled centre spindle was an audible improvement.

I have previously captured some impulse measurements comparing various mats and bare POM platter. They showed measurable differences in settling times, with POM platter superior. The measurement tools were moderately sensitive to observe differences but not absolute values.

Below are pictures of the Kaneta/bentores/POM/gunmetal 10mkII and the 10R on the MinusK. Also the 10R underneath.

Attachments

what is pom? Material like that of platters Michell Orbe or Gyrodec a composite of vinyl and/or methacrylate?

It's not really what IET is intended for. I understand why hobbyists attempt to press it in to service in this manner and that it can give meaningful insights, but to say that the raw measurements without appropriate modeling are a direct representation of what happens during playback is a rather significant mischaracterization. Maybe there could be some overlap, but excitation from mechanical impulse vs. that of playback is entirely different.

At the end of the day the litmus test is that of the actual result - the audio signal difference between a modified and unmodified system done in as controlled a manner as can be done in a non-lab environment. Multiple passes, error bars, etc. I think it's a real shame to do all this work purporting the intent is audible improvement to then resort to handwaving. This is the data that would be a true benefit to the community.

I do appreciate the effort to convey anecdotal impressions, but they're not evidence nor relevant to anything or anyone outside that individual. There's in excess of a century's worth of science on this, and anyone who's done honest controlled testing would understand. Not a bother when someone is doing something for themselves, but I feel there is a reasonable burden of proof to be met when broadly proclaiming (solved) problems, and that proof centers around the actual end result.

I've said before the machine work looks great and I bet it's a tremendous amount of fun to do. Please do consider adding value to thread in the form of testing and data done with some degree of rigor specific to the audio output of the system.

At the end of the day the litmus test is that of the actual result - the audio signal difference between a modified and unmodified system done in as controlled a manner as can be done in a non-lab environment. Multiple passes, error bars, etc. I think it's a real shame to do all this work purporting the intent is audible improvement to then resort to handwaving. This is the data that would be a true benefit to the community.

I do appreciate the effort to convey anecdotal impressions, but they're not evidence nor relevant to anything or anyone outside that individual. There's in excess of a century's worth of science on this, and anyone who's done honest controlled testing would understand. Not a bother when someone is doing something for themselves, but I feel there is a reasonable burden of proof to be met when broadly proclaiming (solved) problems, and that proof centers around the actual end result.

I've said before the machine work looks great and I bet it's a tremendous amount of fun to do. Please do consider adding value to thread in the form of testing and data done with some degree of rigor specific to the audio output of the system.

This statement is correct. It is commonly known as Delrin. But, there are actually two POM's. POM-C and POM-H. Delrin is POM-H. Warren can chime in and tell us what he uses. I don't want to muddy the water but I would think POM-C would actually be slightly better for our purposes.Acetal or Polyoxymethylene (POM), commonly known under DuPont's brand name Delrin®

Don

Acetal is the umbrella term for POM, Acetal can be POM-C or POM-H, Delrin is DuPont's proprietary POM-H and must conform to DuPont's specification.

I use POM-C.

Clearaudio also use POM for platters. SAT XD-1 uses a polymer of unspecified nature. So polymers like POM are not just used by us DIY folk. And considering we don't have R&D budgets I think we do a pretty good job.

I use POM-C.

Clearaudio also use POM for platters. SAT XD-1 uses a polymer of unspecified nature. So polymers like POM are not just used by us DIY folk. And considering we don't have R&D budgets I think we do a pretty good job.

It's not really what IET is intended for. I understand why hobbyists attempt to press it in to service in this manner and that it can give meaningful insights, but to say that the raw measurements without appropriate modeling are a direct representation of what happens during playback is a rather significant mischaracterization. Maybe there could be some overlap, but excitation from mechanical impulse vs. that of playback is entirely different.

I'm not surprised at your response. What qualifications do you have to make this incorrect assumption. Both @Bon and I have years of experience in the fields of performance testing complex systems and recreation of seismic data from proxy.

It's impossible to play an audio track and with a confidence of better than 1 Sigma differentiate between modifications. This requires testing the system with the equipment we have and remembering I no longer have access to the vibration laboratory where I worked where this could be done with an audio track and an LDV.

Impulse testing is a valid method to approximate with a confidence better than 3 Sigma what the unit will do when excited by an external force.

Finally unlike some I'm not here to push a business I run on the side. I'm posting DIYing modifiactions I have done to a humble SP10mk2 to improve it for MY OWN USE, so anyone else wishing to copy has the opportunity.

now getting off my soapbox..........

what is pom? Material like that of platters Michell Orbe or Gyrodec a composite of vinyl and/or methacrylate?

Methacrylate or acrylic has been used for platters by a lot of different TT manufacturers for many years. Clearaudio used it until switching to POM. POM has similar acoustic impedance to acrylic and rigid vinyl (the LP) so it makes a good platform for the LP. A clamp or weight must be used as the POM is slippery and the LP will slip on the POM.

POM has greater density than acrylic hence its ability to attenuate vibration is better. The downside - POM's grain structure is not uniform through the material so if a platter is machined from flat plate it can warp, this is why I fix the POM to a substrate. I prefer flat plate to round bar because the grain structure is running horizontal in the plate which increases it's attenuation properties.

If you want to use a POM platter and have access to a machine shop that can spin an SP10 platter I'm happy to share my CAD drawing so you can have a POM platter made.

"My next project is a new microprocessor controller for the mk2 motor using the latest in STM processors."

Is this another way of trying to deal with precession? Other?

Is this another way of trying to deal with precession? Other?

Warren, I'm having trouble with your chaotic wobble video. I think that shows vertical movement. I would think most spindle issues would manifest themselves in horizontal movement. And, could be "chaotic".

Precession is dealt with in the new inverted bearing. The uC is to improve dynamic speed stability. The SP10mk2 is very good especially when considering the design is 50years old and totally analog.

I've picked the low hanging fruit with mechanical improvements, although the inverted bearing is still to be tested but the theory is sound and the measurement is a vast improvement.

ucontrollers are cheap and readily available so why not use one to drive a TT motor. STM have the development tools available off the shelf to build an FOC (Field Orientated Control) motor controller. The benefit of FOC is it monitors the actual motor drive phases as well as a tacho.

The challenge will be tuning the software to provide minimal speed variations on a varying load. From a helicopter view this will improve W&F. Down in the trenches what I'll be attempting is to reduce micro speed variations to as minimal as possible.

I've picked the low hanging fruit with mechanical improvements, although the inverted bearing is still to be tested but the theory is sound and the measurement is a vast improvement.

ucontrollers are cheap and readily available so why not use one to drive a TT motor. STM have the development tools available off the shelf to build an FOC (Field Orientated Control) motor controller. The benefit of FOC is it monitors the actual motor drive phases as well as a tacho.

The challenge will be tuning the software to provide minimal speed variations on a varying load. From a helicopter view this will improve W&F. Down in the trenches what I'll be attempting is to reduce micro speed variations to as minimal as possible.

Warren, I'm having trouble with your chaotic wobble video. I think that shows vertical movement. I would think most spindle issues would manifest themselves in horizontal movement. And, could be "chaotic".

Yes it shows vertical wobble which is a transnational movement from the horizontal wobble of the spindle amplified by the radius of the platter.

It is 40mm POM with a gunmetal substrate. Only 25mm is above plinth level. I recall Warrjon saying that he did not detect a significant difference between 40mm and the 60mm POM he now uses. That was with his bento/res plinth. Things may have changed with the Permali.That platter dwarfs the motor.🙂

I think 40mm is close to the sweet spot between performance, constructional complexity and aesthetics. I find very tall platters a visual distraction.

Ahhh.... Thanks.Yes it shows vertical wobble which is a transnational movement from the horizontal wobble of the spindle amplified by the radius of the platter.

I'm not surprised at your response. What qualifications do you have to make this incorrect assumption. Both @Bon and I have years of experience in the fields of performance testing complex systems and recreation of seismic data from proxy.

Impulse testing is a valid method to approximate with a confidence better than 3 Sigma what the unit will do when excited by an external force.

That's fantastic. Then I'll ask the question yet again rephrased: to what degree is a known acoustic signal or set of signals designed to mimic what occurs in a typical listening environment going to present as vibrational "signal" to the stylus via the platter with and without these modifications? Same question in regard to reflected energy from/to the stylus.

It's impossible to play an audio track and with a confidence of better than 1 Sigma differentiate between modifications. This requires testing the system with the equipment we have and remembering I no longer have access to the vibration laboratory where I worked where this could be done with an audio track and an LDV.

This response is why I said "...done in as controlled a manner as can be done in a non-lab environment." 84% probability is reasonably sufficient for this, and I think any real data regardless of conclusiveness would be illuminating.

That said, as both you and Bon have repeatedly stated how easy it is for you and others to hear these differences, measuring them would be trivial.

Finally unlike some I'm not here to push a business I run on the side. I'm posting DIYing modifiactions I have done to a humble SP10mk2 to improve it for MY OWN USE, so anyone else wishing to copy has the opportunity.

now getting off my soapbox..........

I can't recall ever seeing anyone push "commercial" interests in this thread for the nine years that I've contributed to it. Even the participants for whom this area was/is their core business gave/give freely of their knowledge and time. Several have refused to answers questions in private, instead directing people to ask here so that the discourse could be of benefit to the entire community.

I've directed well over 100 people here over the years as a mainly fact-based solid resource for SP-10MKII/2A 'tables, and I'm sure others have done the same. I couldn't care less what you or anyone else does or who you do it for, but I do care about the integrity of this thread as a resource. To that end, I will challenge things that are posted in this thread as fact without sufficient supporting evidence.

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread