I think you're referring to the Telstart Durlast soccer football, consisting of 20 hexagons and 12 pentagons and introduced to the 1970 world soccer championship by German manufacturer Adidas? Yes this would yield to an almost perfect spherical surfaceHexagon + pentagon makes a nice curved face with no gaps...

.

.Best regards!

But that has ~0.39 steradian per face which is a lot more than these cell arrays. There are many ways to breakup a spherical surface into more polygons that this as witnessed in Buckminster Fuller's designs. (though hexagons and pentagons are prefered for cell arrays, not triangles, insect eyes are a better inspiration perhaps).

Yes, Kay, the Adidas soccer football. But as Mark points out, it does have a lot more curve than most horn fonts. And of course at its edges it isn't clean and square if it's not connected into an entire sphere. Would that matter? I don't know.

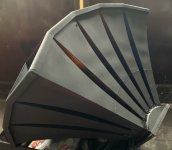

One thing I have learned during this project is that with a bit of patience and well set up printer, 3D printing is the way to go even for large things glued together from pieces. And sometimes the result is better than trying to print all in one piece. Including the throat adapter, my horn was made out of 65 pieces. If I was a bit more careful when glueing the parts together and if I sanded some parts before that, the result would be close to perfect. Today I sprayed the horn with some leftover black paint and found also an anti-gravel spray, so I used it. It creates a thick flexible layer with a texture. It is drying now but I hope it will strengthen and dampen the walls enough for testing. If yes, it could be applied before glueing the cells together.

It starts to look like the real thing🙂 I need one more can for spraying the inside of the cells better. The surfaces between the cells will need painting with a brush. Maybe it will not be damped enough, but it certainly feels more solid now.

Attachments

I added a can of Body 930. It is beginning to get heavy. The tar based paint looks kind of cool and I think I will just apply it on the outside as well. It does not smell too bad after 5 hours and in the cellar room, which just next to the garage, it will not matter at all. When it is completely dry, I will mount the driver and try to measure if the damping is good enough or not. A second layer with "casting" into the thin mouth areas should be fine if the first layer is not. The cells are still a bit flexible, but definitely not ringing.

Thank you all for the kind words. If anyone would like to try to make his own, the models are available on Thingiverse: 500 Hz exponential multicell horn for JBL2445 by pelanj - Thingiverse

I have not yet tried to use or measure it, so it is without any warranty🙂

I have not yet tried to use or measure it, so it is without any warranty🙂

Not me! I went in the other direction with a huge [stated] conical WG that until just recently realized it was actually parabolic since its top/bottom was parallel like a Smith horn.

Just wait my little delta 3D printer to grow, now is only good for key rings ;-)I am curious if there are people crazy enough to make one🙂

No, back in the early '70s there was no reason to waste expensive film/processing on a DIY project unless wanting to market it, especially since our then toddler daughter was already fine tuning her adult life 'persona', so were all basically just a bunch of cut list calculations and maybe a few sketch details [often on the building material] if horns since there was none interested in my audio 'dementia' beyond auditioning/partying with, their fave recordings through them.

- Home

- Loudspeakers

- Multi-Way

- The construction of a multicell horn