The 1mm movement

Harry,

See this post, about half way down the page, then look at the subsequent FFT plots (p3 bottom, p4 top) of the same PSU, just wired differently.

http://www.diyaudio.com/forums/showthread.php?threadid=985&pagenumber=3

A.

Harry,

See this post, about half way down the page, then look at the subsequent FFT plots (p3 bottom, p4 top) of the same PSU, just wired differently.

http://www.diyaudio.com/forums/showthread.php?threadid=985&pagenumber=3

A.

🙂Nednai said:HPotter: it turns out that I'm not your personal shopper. To answer your previous question, use PMAI (Plan, Measure, Assess, Improve). A good tool to start with is an XmR chart. Joint Commission's web site has more info if you need it.

I guess I should say no more.🙂

Just wondering, how does it finally ended? Any photo of the final assembly?

I really like you way of making P2P. I've made some projects P2P, including an OPA2134 based preamp.

It has been a long time since this thread but I was a bit late coming here 🙂

I really like you way of making P2P. I've made some projects P2P, including an OPA2134 based preamp.

It has been a long time since this thread but I was a bit late coming here 🙂

Didn't really end up; I never finished that amp. It was more of an exercise in introduction to p2p wiring. I later built Aleph 5 this way though: http://www.diyaudio.com/forums/pass-labs/4018-more-beauty-p2p-wiring.html

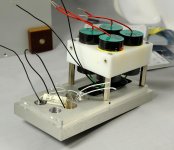

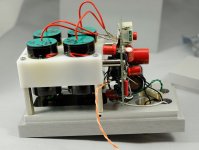

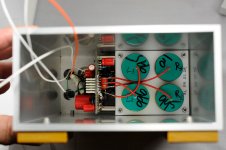

Recently, I've built few DACs using p2p method and I'm very satisfied with the results, in fact this is my best effort yet 😉

Recently, I've built few DACs using p2p method and I'm very satisfied with the results, in fact this is my best effort yet 😉

Attachments

I have heard that you made a p2p Nelson Pass F5. Any pictures?

What an effort to assemble those dacs, I like'em alot. The messier it look the best it tends to sound 😀

What an effort to assemble those dacs, I like'em alot. The messier it look the best it tends to sound 😀

I'm sorry, I misreaded the other user's comment. He was praising your p2p habilities, not specifically for F5. It was in that thread, so my brain did its work and associated random things 😀

"I have heard that you made a p2p Nelson Pass F5. Any pictures?"

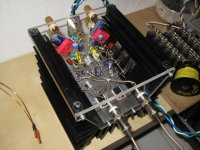

I built mine (F5) P to P -- pretty easy to do. I would will see if I can scare up some pictures.

JJ

I built mine (F5) P to P -- pretty easy to do. I would will see if I can scare up some pictures.

JJ

I bet you will 😱"I have heard that you made a p2p Nelson Pass F5. Any pictures?"

I built mine (F5) P to P -- pretty easy to do. I would will see if I can scare up some pictures.

JJ

Thank you, regards

Regi

Peter, you have (brass?) threaded inserts in your nylon block, are these screwed into the nylon or do they need an arbor press or some other tool? I'm trying to find similar items that I could insert with my limited workshop.

Thanks

Steve

Thanks

Steve

Didn't really end up; I never finished that amp. It was more of an exercise in introduction to p2p wiring. I later built Aleph 5 this way though: http://www.diyaudio.com/forums/pass-labs/4018-more-beauty-p2p-wiring.html

Recently, I've built few DACs using p2p method and I'm very satisfied with the results, in fact this is my best effort yet 😉

Peter, in post #4 in your "More beauty of point to point" you show a pic from the top that reveals 3 out puts on each side. What are those thick pads under the outputs? Or is it just the reflection off the heat sink surface that makes them look that fat?

Thanks in advance,

Russellc

Kind of an old hat, but anyway, here's my p2p Mini Aleph built inside a heatsink (15cm wide/high/deep). Toasty.

And mind you, I built this using lead-free solder (99% Zn and 1% Cu).

In the 5th picture you'll notice that the Zener is facing in the wrong direction. That cost me quite some nerves. And yes, the IRF9610's are mounted with superglue. 😀

And mind you, I built this using lead-free solder (99% Zn and 1% Cu).

In the 5th picture you'll notice that the Zener is facing in the wrong direction. That cost me quite some nerves. And yes, the IRF9610's are mounted with superglue. 😀

Attachments

-

22k.JPG97.2 KB · Views: 468

22k.JPG97.2 KB · Views: 468 -

psu.JPG221.9 KB · Views: 457

psu.JPG221.9 KB · Views: 457 -

startoff.JPG189.5 KB · Views: 451

startoff.JPG189.5 KB · Views: 451 -

both_alephCS.JPG190.9 KB · Views: 439

both_alephCS.JPG190.9 KB · Views: 439 -

both_alephCS_inst.JPG217.1 KB · Views: 428

both_alephCS_inst.JPG217.1 KB · Views: 428 -

grounding_lug.JPG228.6 KB · Views: 304

grounding_lug.JPG228.6 KB · Views: 304 -

output_rs.JPG229.1 KB · Views: 279

output_rs.JPG229.1 KB · Views: 279 -

close1.JPG270.2 KB · Views: 320

close1.JPG270.2 KB · Views: 320 -

minia_side2.JPG230.8 KB · Views: 348

minia_side2.JPG230.8 KB · Views: 348

very cool - that's something I like - design for yourself, as the master speaks...

reminds me of some of my own amps, although a gainclone is much more easy in p2p

btw, how does it sound?

reminds me of some of my own amps, although a gainclone is much more easy in p2p

btw, how does it sound?

As in post 64, I had the idea of using a plastic as a capacitor frame. I bought some nylon block and found it surprisingly unhappy about my drilling (smoke, etc). My question is whether I should persist with Nylon, or try and find an easier to work plastic? The ebay shop where I got my nylon block also offers polyethylene, polypropylene, ptfe and others. Any suggestions would be most welcome

Thanks

Thanks

...

btw, how does it sound?

Very sweet. I'm feeding FE108EZ horns with it. The bass lacks some control that a LM3886 with regulated supply could offer, but the Mini-Aleph's midrange sweetness is unique. At least to my ears.

As in post 64, I had the idea of using a plastic as a capacitor frame. I bought some nylon block and found it surprisingly unhappy about my drilling (smoke, etc). My question is whether I should persist with Nylon, or try and find an easier to work plastic? The ebay shop where I got my nylon block also offers polyethylene, polypropylene, ptfe and others. Any suggestions would be most welcome

Thanks

Be careful with ptfe, fumes and smoke from ptfe can be can be highly toxic and corrosive. I imagine machining polypropylene is not wildly different from nylon, but I'm no expert with these materials. You can find many article on machining polypropylene though, and it seems to be quite cheap.

Use some liquid coolant to keep the plastic's temperature down when machining. Alcohol (Isopropanol) or even water should do the trick. Stay away from acetone, it dissolves many plastics. Polyethylene is resistant to actone though, that's why the squeeze bottles are usually made of it.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- The beaty of p2p wiring