Don’t risk it

You are close to the limit. Small gain, not worth noting or worth the risk. Build 2 more cabs if you need a noticeable and safe difference. Love mine for the size and quality of sound and output for size.

You are close to the limit. Small gain, not worth noting or worth the risk. Build 2 more cabs if you need a noticeable and safe difference. Love mine for the size and quality of sound and output for size.

You are close to the limit. Small gain, not worth noting or worth the risk. Build 2 more cabs if you need a noticeable and safe difference. Love mine for the size and quality of sound and output for size.

haha, guess what i am planning. especially aiming for the lowend-extension by 4x monostack

Hi guys, I take it the B&C 15NW100 would do fine in this design also? My friend has these drivers and i said i would find and make a simple TH design for him to try. Also is there a high pass frequency he should be using? I see 38hz mentioned further up this page?????

dUAL THAM 15

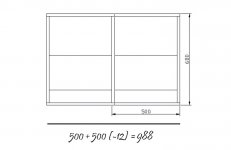

Hi, is it possible to join two tham15 side by side and make dual tham 15? And to make box double the with without middle side, is it something like this doable like in dual bassreflex?

Hi, is it possible to join two tham15 side by side and make dual tham 15? And to make box double the with without middle side, is it something like this doable like in dual bassreflex?

You can share one side to both drivers s1 path. Mouths should be close together.

like this:

View attachment 658544

You can share one side to both drivers s1 path. Mouths should be close together.

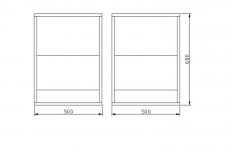

Hi USRFobiwan, I would like to build a similar "dual enclosure" but need to have the speakers standings. So on, would both options work well or one would be better than another ? I'm thinking about vibrations and most important, saving space and wood.

1

2

To be honest i would just build singles instead of a 'dual standing up' version. You can position them anyway you want, and stack them anyway you want, and can build more for your needs.

True that ! Flexibility first you are right, but I just have this project where I need to have everything "sticked" together and where I need to save every Kg possible.

The Tham15 is a pretty compact cabinet and there are multiple options to save weight, you can use 15mm ply with 12mm bracing throughout and use a neodymium driver, like for example the B&C 15NBX100, relative affordable and lightweight.

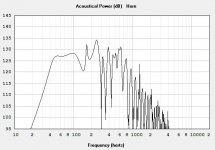

Here is the sim with the B&C 15nbx100 (black) and 15BG100 (grey) @xmax

You can push 800w per single cabinet at xmax of the driver. if you HP at 45hz/18db. Which is inside the powerband of the driver capabilities and you have a little headroom left.

Here is the sim with the B&C 15nbx100 (black) and 15BG100 (grey) @xmax

You can push 800w per single cabinet at xmax of the driver. if you HP at 45hz/18db. Which is inside the powerband of the driver capabilities and you have a little headroom left.

Attachments

You can push 800w per single cabinet at xmax of the driver. if you HP at 45hz/18db.

In my experience and by all the thousands of emails we have got since we published the THAM15 design I would say that you easily can push 1200 watts with a 24 dB HP @ 35 Hz with drivers like the 15TBX100 or similar.

Hornresp is a great tool, but it is not reliable at predicting correct respons or cone travel at high power levels.

regarding the worry about cabinet width , assuming Hornresp is ballpark then here's what would happen by reducing THAM15 by 1.8cm - then 6.8cm for that LF15N401 RCF woofer. (- don't know if a little width reduction makes mounting the speaker difficult or not as never seen a THAM15 in person)

@Fredi, Yes i think you can reduce inner width. See my tham gallery there is some room left, I think it's safe to cut 2 cm on each side (4cm total)

@circloman, We all know the HR xmax 'prediction' is a bit off. And of course you can push whatever power you want into it. But I was using modest (safe) margin in output. If you are going to push all the power on the driver, I say build more cabinets. Doing 1200w into it will not last hours and it will go into power compression in some time or worse. Even with the TBX100 i will not exceed 1000w continues. You do know they determine those ratings in free air with pink noise?

@circloman, We all know the HR xmax 'prediction' is a bit off. And of course you can push whatever power you want into it. But I was using modest (safe) margin in output. If you are going to push all the power on the driver, I say build more cabinets. Doing 1200w into it will not last hours and it will go into power compression in some time or worse. Even with the TBX100 i will not exceed 1000w continues. You do know they determine those ratings in free air with pink noise?

Well, accounting for the fact that one needs to think about real power burnt as heat on the speaker, not apparent power as immediate consumption, and that with lower band used with impedance peaks across the range, and coil getting cooled by nearly sinusoidal movement compared to high frequency noise, I would believe it could do 1200W with dynamic program power (crest 8-10db) content. On the other hand, for heavy and compressed music with DR of 3-5db, it sounds like obvious and not so long taking death of the driver. In a nutshell, IT DEPENDS...

a 30 watt soldering pencil gets pretty warm. - accidentally I once burnt a 3" coil Eminence 15 in about one minute with LF sine and a "transform" eq on a 120W rated amplifier with magic smoke released. And was not one bit "loud".

Using power as measure of a subwoofer's capability is one of the worst things to do, as its actual power handling can vary greatly depending on type of alignment, the level AND the contents of the signal being played back on it, ambient temperature, etc. So saying that "I hooked up the subwoofer to a 1.2kW amp and didn't experience any problems" is about as useful a benchmark as is benchmarking a subwoofer driver by the weight of its magnet.

For my designs, I instead look at what signal level (in V or dB (relative to reference) it would take to reach a certain level of distortion (e.g. 10% THD), in the design passband using a short (5 second) sine sweep across the passband. The test signal is short enough to avoid significant heating of the voice coil, and can give a good idea of the subwoofer's linear output capability, as that's more likely than not going to be limited by the driver's excursion potential.

Maybe we should rate subwoofers instead in terms of what voltage they can be fed before their output reaches a particular distortion level in their passband. For example, my recently-rebuilt Enigma subwoofer, could be rated as a "23.3V/10%THD subwoofer", or a "92dB+9.2dB/10% subwoofer", as I can drive it with a 23.3V signal across its passband before THD hits 10% at any frequency 🙂.

For my designs, I instead look at what signal level (in V or dB (relative to reference) it would take to reach a certain level of distortion (e.g. 10% THD), in the design passband using a short (5 second) sine sweep across the passband. The test signal is short enough to avoid significant heating of the voice coil, and can give a good idea of the subwoofer's linear output capability, as that's more likely than not going to be limited by the driver's excursion potential.

Maybe we should rate subwoofers instead in terms of what voltage they can be fed before their output reaches a particular distortion level in their passband. For example, my recently-rebuilt Enigma subwoofer, could be rated as a "23.3V/10%THD subwoofer", or a "92dB+9.2dB/10% subwoofer", as I can drive it with a 23.3V signal across its passband before THD hits 10% at any frequency 🙂.

I hope it was more of the talk about "reliability" in the means of lifetime. There is nothing wrong to also measure power, if one does that properly. For the distortion, yes, but it is not in just strict relation with the driver alone. Distortion will change with the box too. So you cannot easily chose just the driver without knowing more about the application. For some distortion can even be irrelevant. It is complex equation to get to the good outcome indeed.

Hornresp is a great tool, but it is not reliable at predicting correct respons or cone travel at high power levels.

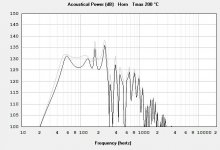

The voice coil temperature is going to be rather high for an input power of 1.2 KW. Are you using the Power Compression tool with an temperature of at least 200 degrees Celsius specified?

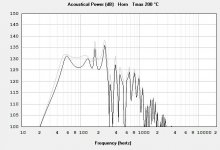

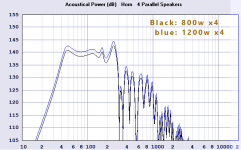

Here is the 200c power compression (black) with the NBX100 at 800w (80v) in the tham15.

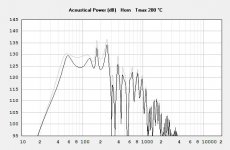

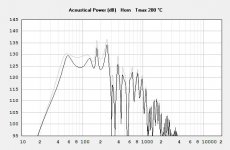

And here at 1200w:

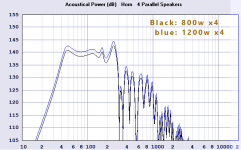

If you look carefully you are spending 400w more power on a few db more output and risking more change of driver failure, more power compression. This makes no sense especially if you build multiples...

And here at 1200w:

If you look carefully you are spending 400w more power on a few db more output and risking more change of driver failure, more power compression. This makes no sense especially if you build multiples...

Last edited:

- Home

- Loudspeakers

- Subwoofers

- THAM15 - a compact 15" tapped horn