Currently my fold/unfold sketch uses "a" and "b" orthogonal do centerline for all segments. I will try to make "a" orthogonal to outside wall and see if I find significant difference. The segments used to bend horn path probably will stay orthogonal do centerline once they never are orthogonal to outside wall.

Looking at the notes I see a hard work to proper design that cone correction. The driver I choose doesn't have 3D model available nether other detailed information to allow that precise work so the other cone correction is easy to build and quick win 🙂

Everything as pros and cons 😉

Looking at the notes I see a hard work to proper design that cone correction. The driver I choose doesn't have 3D model available nether other detailed information to allow that precise work so the other cone correction is easy to build and quick win 🙂

Everything as pros and cons 😉

Do you guys know if the JBL/Selenium 15" driver 15SW1P still is available at your region? it fits very well on my project but looks like it stopped to be produced here in Brazil 🙁 (still looking for back up options).

English datasheet

http://www.selenium.com.br/english/linha_profissional/subwoofers/pdfs/15SW1P1.pdf

English datasheet

http://www.selenium.com.br/english/linha_profissional/subwoofers/pdfs/15SW1P1.pdf

I've been simulating a lot of drivers for a lot of manufactures to select some option for me and for who is interested to build this cab, so here is the list.

1st group (Drive reference = Snake HPX2150)

2nd group

Brands with all portfolio already checked: Note.: Feel free to suggest different one.

1st group (Drive reference = Snake HPX2150)

18sound 15LW1401 (sens. 98dB) - This is the best drive for this project. Even if it was designed for the Snake, this drive offer more or less the same SPL curve but with more Xmax, in other words, less distortion.

18sound 15LW2400 (sens. 97dB)

18sound 15NLW9300 (sens. 97dB)

FaitalPro 15FX560 (Sens. 98)

18sound 15LW2400 (sens. 97dB)

18sound 15NLW9300 (sens. 97dB)

FaitalPro 15FX560 (Sens. 98)

2nd group

18sound 15NLW9401 (sens. 97,5dB)

RCF LF15G401 (sens. 97dB)

RCF LF15P400 (sens. 97dB)

FaitalPro 15HP1020 (sens. 98dB)

FaitalPro 15HP1060 (sens. 97dB)

FaitalPro 15HP1010 (sens. 96dB)

FaitalPro 15HP1030 (sens. 96dB)

B&C 15RBX100 (sens. 95dB)

RCF LF15G401 (sens. 97dB)

RCF LF15P400 (sens. 97dB)

FaitalPro 15HP1020 (sens. 98dB)

FaitalPro 15HP1060 (sens. 97dB)

FaitalPro 15HP1010 (sens. 96dB)

FaitalPro 15HP1030 (sens. 96dB)

B&C 15RBX100 (sens. 95dB)

Brands with all portfolio already checked: Note.: Feel free to suggest different one.

Snake

JBL/Selenium

Eros

Oversound

Keybass

SPL

RCF

B&C

18sound

FaitalPRO

JBL/Selenium

Eros

Oversound

Keybass

SPL

RCF

B&C

18sound

FaitalPRO

Updated list

1st group (Drive reference = Snake HPX2150)

2nd group

Brands with all portfolio already checked: Note.: Feel free to suggest different one.

I could not check Ciare products due to website issue.

1st group (Drive reference = Snake HPX2150)

18sound 15LW1401 (sens. 98dB) - This is the best drive for this project. Even if it was designed for the Snake, this drive offer more or less the same SPL curve but with more Xmax, in other words, less distortion.

Precision Devices PDN15BR40 (Sens. 97dB) - As good as 15LW1401 with less power (1000W against 700W)

18sound 15LW2400 (sens. 97dB)

18sound 15NLW9300 (sens. 97dB)

FaitalPro 15FX560 (Sens. 98dB)

Precision Devices PD15BR40 (Sens. 97dB)

Precision Devices PD155N01D (Sens. 98dB)

Precision Devices PD1550 (Sens. 99dB)

Precision Devices PDN15BR40 (Sens. 97dB) - As good as 15LW1401 with less power (1000W against 700W)

18sound 15LW2400 (sens. 97dB)

18sound 15NLW9300 (sens. 97dB)

FaitalPro 15FX560 (Sens. 98dB)

Precision Devices PD15BR40 (Sens. 97dB)

Precision Devices PD155N01D (Sens. 98dB)

Precision Devices PD1550 (Sens. 99dB)

2nd group

18sound 15NLW9401 (sens. 97,5dB)

RCF LF15G401 (sens. 97dB)

RCF LF15P400 (sens. 97dB)

FaitalPro 15HP1020 (sens. 98dB)

FaitalPro 15HP1060 (sens. 97dB)

FaitalPro 15HP1010 (sens. 96dB)

FaitalPro 15HP1030 (sens. 96dB)

B&C 15RBX100 (sens. 95dB)

Celestion FTR15-4080HD (sens. 95dB)

RCF LF15G401 (sens. 97dB)

RCF LF15P400 (sens. 97dB)

FaitalPro 15HP1020 (sens. 98dB)

FaitalPro 15HP1060 (sens. 97dB)

FaitalPro 15HP1010 (sens. 96dB)

FaitalPro 15HP1030 (sens. 96dB)

B&C 15RBX100 (sens. 95dB)

Celestion FTR15-4080HD (sens. 95dB)

Brands with all portfolio already checked: Note.: Feel free to suggest different one.

Snake

JBL/Selenium

Eros

Oversound

Keybass

SPL

RCF

B&C

18sound

FaitalPRO

Precision Devices

Celestion

Dayton

Eminence

JBL/Selenium

Eros

Oversound

Keybass

SPL

RCF

B&C

18sound

FaitalPRO

Precision Devices

Celestion

Dayton

Eminence

I could not check Ciare products due to website issue.

Last edited:

Updated list (the order in group means nothing)

1st group (Drive reference = Snake HPX2150)

2nd group

Brands with all portfolio already checked: Note.: Feel free to suggest different one.

1st group (Drive reference = Snake HPX2150)

18sound 15LW1401 (sens. 98dB) - This is the best drive for this project. Even if it was designed for the Snake, this drive offer more or less the same SPL curve but with more Xmax, in other words, less distortion.

Precision Devices PDN15BR40 (Sens. 97dB) - As good as 15LW1401 with less power (1000W against 700W)

Beyma 15LX60V2 (Sens. 98dB) - as good as 15LW1401 with less power (1000W against 700W)

18sound 15LW2400 (sens. 97dB)

18sound 15NLW9300 (sens. 97dB)

FaitalPro 15FX560 (Sens. 98dB)

Precision Devices PD15BR40 (Sens. 97dB)

Precision Devices PD155N01D (Sens. 98dB)

Precision Devices PD1550 (Sens. 99dB)

Precision Devices PDN15BR40 (Sens. 97dB) - As good as 15LW1401 with less power (1000W against 700W)

Beyma 15LX60V2 (Sens. 98dB) - as good as 15LW1401 with less power (1000W against 700W)

18sound 15LW2400 (sens. 97dB)

18sound 15NLW9300 (sens. 97dB)

FaitalPro 15FX560 (Sens. 98dB)

Precision Devices PD15BR40 (Sens. 97dB)

Precision Devices PD155N01D (Sens. 98dB)

Precision Devices PD1550 (Sens. 99dB)

2nd group

18sound 15NLW9401 (sens. 97,5dB)

RCF LF15G401 (sens. 97dB)

RCF LF15P400 (sens. 97dB)

FaitalPro 15HP1020 (sens. 98dB)

FaitalPro 15HP1060 (sens. 97dB)

FaitalPro 15HP1010 (sens. 96dB)

FaitalPro 15HP1030 (sens. 96dB)

B&C 15RBX100 (sens. 95dB)

Celestion FTR15-4080HD (sens. 95dB)

Beyma 15G40 (sens. 97dB)

Beyma 15SW1300Nd (sens. 97dB)

RCF LF15G401 (sens. 97dB)

RCF LF15P400 (sens. 97dB)

FaitalPro 15HP1020 (sens. 98dB)

FaitalPro 15HP1060 (sens. 97dB)

FaitalPro 15HP1010 (sens. 96dB)

FaitalPro 15HP1030 (sens. 96dB)

B&C 15RBX100 (sens. 95dB)

Celestion FTR15-4080HD (sens. 95dB)

Beyma 15G40 (sens. 97dB)

Beyma 15SW1300Nd (sens. 97dB)

Brands with all portfolio already checked: Note.: Feel free to suggest different one.

Snake

JBL/Selenium

Eros

Oversound

Keybass

SPL

RCF

B&C

18sound

FaitalPRO

Precision Devices

Celestion

Dayton

Eminence

Beyma

Ciare

Peavey

P.audio

JBL/Selenium

Eros

Oversound

Keybass

SPL

RCF

B&C

18sound

FaitalPRO

Precision Devices

Celestion

Dayton

Eminence

Beyma

Ciare

Peavey

P.audio

Hello guys,

I'm backing with good news and also ask for more help.

My old loundspeakers were sold, so the TH project begun in real world.

The drivers already arrived.

Direct link: https://s27.postimg.org/6urvylo8j/Driver1.jpg

Direct link: https://s29.postimg.org/hz0199l9j/Driver2.jpg

The glue arrived.

direct link: https://s23.postimg.org/nal88rhi3/Glue.jpg

Now i need to buy and cut the pollywood. I still have a little doubt about 15mm or 18mm for 800W.

Do you guys know or developed a specific build sequence for TH? the folds and fastening looks simple but for sure using wrong sequence will make the build process harder or even impossible to complete.

In addition, I'd like to post here the frequency response results, as some guys do, to compare simulation and real world but I need to learn how to proper do it. Do you guys have a link, video, tutorial, or something the clear indicates how to proper measure the results? Just to remember I don't have semi or full anechoic chamber in my house 😛

To do that I bought a flat mic and a processor with real time measurement, maybe is enough.

direct link: https://s24.postimg.org/t2nveik85/Mic_RTA.jpg

direct link: https://s23.postimg.org/e12mwj5ff/Proc.jpg

I'm backing with good news and also ask for more help.

My old loundspeakers were sold, so the TH project begun in real world.

The drivers already arrived.

An externally hosted image should be here but it was not working when we last tested it.

Direct link: https://s27.postimg.org/6urvylo8j/Driver1.jpg

An externally hosted image should be here but it was not working when we last tested it.

Direct link: https://s29.postimg.org/hz0199l9j/Driver2.jpg

The glue arrived.

An externally hosted image should be here but it was not working when we last tested it.

direct link: https://s23.postimg.org/nal88rhi3/Glue.jpg

Now i need to buy and cut the pollywood. I still have a little doubt about 15mm or 18mm for 800W.

Do you guys know or developed a specific build sequence for TH? the folds and fastening looks simple but for sure using wrong sequence will make the build process harder or even impossible to complete.

In addition, I'd like to post here the frequency response results, as some guys do, to compare simulation and real world but I need to learn how to proper do it. Do you guys have a link, video, tutorial, or something the clear indicates how to proper measure the results? Just to remember I don't have semi or full anechoic chamber in my house 😛

To do that I bought a flat mic and a processor with real time measurement, maybe is enough.

An externally hosted image should be here but it was not working when we last tested it.

direct link: https://s24.postimg.org/t2nveik85/Mic_RTA.jpg

An externally hosted image should be here but it was not working when we last tested it.

direct link: https://s23.postimg.org/e12mwj5ff/Proc.jpg

@ USRFobiwan

The option A and B were left in the past, due to diaphragm displacement i tunned the project to safety region, you can find it on the history or wait some more posts will i complete the build so i will repost the design again.

@ turbodawg

Yeah, i simulated all drivers from the list posted on the topic #105 and I don't recommend the B&C 15TBW100 for this spec, see below the response @2,83V. To use it you should change a lot the dimensions.

Left the frequency response comparison between Snake HPX2150 and B&C 15TBW100, and right just the B&C one.

Direct image link https://s29.postimg.org/t0zpfx33r/15_TBW100.png

@ stewin

I never build a bandpass cab, from what I read till now, it can be more efficiency then tapped horn but, people always complain about it being a kind of "one note" cab and it maybe this came from high distortion additionaly it has more restricted bandwidth frequency response. So I think for who need just SPL it's a good option, for who need SPL and HI-FI response looks like Tapped are way better.

There are many guys much more experience then me to help you in this case.

The option A and B were left in the past, due to diaphragm displacement i tunned the project to safety region, you can find it on the history or wait some more posts will i complete the build so i will repost the design again.

@ turbodawg

Yeah, i simulated all drivers from the list posted on the topic #105 and I don't recommend the B&C 15TBW100 for this spec, see below the response @2,83V. To use it you should change a lot the dimensions.

Left the frequency response comparison between Snake HPX2150 and B&C 15TBW100, and right just the B&C one.

An externally hosted image should be here but it was not working when we last tested it.

Direct image link https://s29.postimg.org/t0zpfx33r/15_TBW100.png

@ stewin

I never build a bandpass cab, from what I read till now, it can be more efficiency then tapped horn but, people always complain about it being a kind of "one note" cab and it maybe this came from high distortion additionaly it has more restricted bandwidth frequency response. So I think for who need just SPL it's a good option, for who need SPL and HI-FI response looks like Tapped are way better.

There are many guys much more experience then me to help you in this case.

I just bought the polywood and the build process begun.

Direct image link: https://s23.postimg.org/dp19lzdyj/P_20170203_190913.jpg

Direct image link: https://s27.postimg.org/la5wcy91v/P_20170203_194148.jpg

Direct image link: https://s24.postimg.org/68zxl1ec5/P_20170203_212317.jpg

I will build 4 of them and I don't have much margin for errors so I decided to increase thickness from 15mm to 18mm, the dimensions were adjusted to keep the same frequency response as 15mm, so for who wanna build with 15mm that plan still works.

For 18mm here are the data updated.

Hornresp input data

Direct image link: https://s28.postimg.org/9c76i8qgd/SS15_MOD_Final_18mm_Inputs.png

Frequency response

Direct image link: https://s24.postimg.org/kkdsajxed/SS15_MOD_Final_18mm_FR.png

18mm polywood plan

Direct image link: https://s23.postimg.org/83gqatgbv/SS15_MOD_Final_18mm_Plan.png

Bracers and cone correction (2,35 L from the driver + 0,87L from bafle circular cut = 3,24 L total cone correction)

Direct image link: https://s23.postimg.org/nr4p6okt7/SS15_MOD_Final_18mm_Bracers.png

An externally hosted image should be here but it was not working when we last tested it.

Direct image link: https://s23.postimg.org/dp19lzdyj/P_20170203_190913.jpg

An externally hosted image should be here but it was not working when we last tested it.

Direct image link: https://s27.postimg.org/la5wcy91v/P_20170203_194148.jpg

An externally hosted image should be here but it was not working when we last tested it.

Direct image link: https://s24.postimg.org/68zxl1ec5/P_20170203_212317.jpg

I will build 4 of them and I don't have much margin for errors so I decided to increase thickness from 15mm to 18mm, the dimensions were adjusted to keep the same frequency response as 15mm, so for who wanna build with 15mm that plan still works.

For 18mm here are the data updated.

Hornresp input data

An externally hosted image should be here but it was not working when we last tested it.

Direct image link: https://s28.postimg.org/9c76i8qgd/SS15_MOD_Final_18mm_Inputs.png

Frequency response

An externally hosted image should be here but it was not working when we last tested it.

Direct image link: https://s24.postimg.org/kkdsajxed/SS15_MOD_Final_18mm_FR.png

18mm polywood plan

An externally hosted image should be here but it was not working when we last tested it.

Direct image link: https://s23.postimg.org/83gqatgbv/SS15_MOD_Final_18mm_Plan.png

Bracers and cone correction (2,35 L from the driver + 0,87L from bafle circular cut = 3,24 L total cone correction)

An externally hosted image should be here but it was not working when we last tested it.

Direct image link: https://s23.postimg.org/nr4p6okt7/SS15_MOD_Final_18mm_Bracers.png

Hi LORDSANSUI,

Looks good. As always, let's hope the T/S parameters are correct. Will you be able to make measurements?

Regards,

Looks good. As always, let's hope the T/S parameters are correct. Will you be able to make measurements?

Regards,

Hi Oliver,

I don't know how to proper mesure the T/S, maybe is not hard, but I'd like to measure frequency response first. Snake is the best Brazilian company for drivers and used to be very reliable, but we never know 😀

Do you have any documents about how to measure both of them?

I don't know how to proper mesure the T/S, maybe is not hard, but I'd like to measure frequency response first. Snake is the best Brazilian company for drivers and used to be very reliable, but we never know 😀

Do you have any documents about how to measure both of them?

Unfortunately I jumped (again?) into this thread a bit too late, but here are some suggestions for v2 of your horn, if you ever come to that.

1st of all is to remove the "dead" space in your horn by adjusting the layout to take into consideration a longer path length AND the cone compensation that you want to insert into the design. you can either achieve a lower Fb or, if you want, resize the horn a little smaller to bring Fb back up to your target.

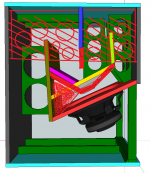

2nd is to use the bracing scheme I've tried to illustrate in the picture. Use solid 1/2 ply, with cutouts for where the internal panels fit in, and perforate the rest with a circle saw. Use two bracing panels like that and that should basically kill any vibration on the top external panel. If you do NOT brace that top panel properly, it may end up tossing whatever you put on it. Ask me how I know this 🙂.

Finally, consider inserting damping material into the section of the horn as illustrated - this will reduce the ripple above the passband with minimum impact in the TH's passband.

1st of all is to remove the "dead" space in your horn by adjusting the layout to take into consideration a longer path length AND the cone compensation that you want to insert into the design. you can either achieve a lower Fb or, if you want, resize the horn a little smaller to bring Fb back up to your target.

2nd is to use the bracing scheme I've tried to illustrate in the picture. Use solid 1/2 ply, with cutouts for where the internal panels fit in, and perforate the rest with a circle saw. Use two bracing panels like that and that should basically kill any vibration on the top external panel. If you do NOT brace that top panel properly, it may end up tossing whatever you put on it. Ask me how I know this 🙂.

Finally, consider inserting damping material into the section of the horn as illustrated - this will reduce the ripple above the passband with minimum impact in the TH's passband.

Attachments

- Home

- Loudspeakers

- Subwoofers

- TH 15" flat response to 35Hz (-3dB) - By LORDSANSUI