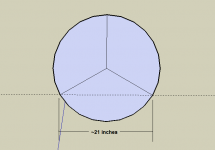

template

any ideas where one can get a measured diagram of the adaptor(template) for the TAD 4001 horn?

any ideas where one can get a measured diagram of the adaptor(template) for the TAD 4001 horn?

Tad horns

hey diycoax, Would you be into building a pair of TH-4001 Horns? If so email me ,I am very interested in them. I have the TD-4001 drivers and and want to use them but I have had a hard time finding a set of horns.

-Collin

dupuispro@gmail.com

hey diycoax, Would you be into building a pair of TH-4001 Horns? If so email me ,I am very interested in them. I have the TD-4001 drivers and and want to use them but I have had a hard time finding a set of horns.

-Collin

dupuispro@gmail.com

Very nice horn there!I have just made a radial horn out of pine.I wont post pics as this is your thread(Pics are in system pictures).Happy horn building!

Hi, diycoax

I am very interested in buying a pair of 2" horns, if you go on building some.

I live in France.

Is it possible?

Thanks

Diafan

I am very interested in buying a pair of 2" horns, if you go on building some.

I live in France.

Is it possible?

Thanks

Diafan

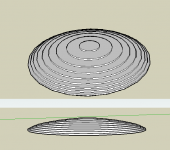

Actually, from the woodworking point of view it’s not that hard to make. Granted that I have a shop and a 5hp 220v 3ph shaper. The expensive part would be a custom made knife for a shaper head. Due to the out rich of this knife it would be done on the specific type of shaper head that is if I am not mistaken called Colete head (I do have it just don’t remember the name). Then a couple of templates would give the external radius.

I am not at all saying that the work is not good, it’s just not impossible to do and other Diyers that are crazy about horns could have it done.

I am not at all saying that the work is not good, it’s just not impossible to do and other Diyers that are crazy about horns could have it done.

R-Carpenter said:Actually, from the woodworking point of view it’s not that hard to make. Granted that I have a shop and a 5hp 220v 3ph shaper. The expensive part would be a custom made knife for a shaper head.

Beautiful work.

My guess is that it's turned (on a lathe), not cut with a shaper. Yielding 3 (maybe only 2) sections from a blank.

See if you can find Yuichi Arai's old webpage as that had a lot of useful photo's and tips for building these. Mine were made by a LOT of hand sanding.MJL21193 said:

Beautiful work.

My guess is that it's turned (on a lathe), not cut with a shaper. Yielding 3 (maybe only 2) sections from a blank.

MJL21193 said:

Beautiful work.

My guess is that it's turned (on a lathe), not cut with a shaper. Yielding 3 (maybe only 2) sections from a blank.

Could be. You would need one hell of a lathe thou. I think it would need something like a 30-inch diameter capability. I’ve see a lathe like this sold a while ago on US military auction.

http://www.vegawoodworking.com/laa.html

1446 is the one I have. It’s a heavy duty one and weights a lot. It’s limited to 23 on the paper so you could do 24-25inches. It would be a bit scary, spinning a heavy piece like this. All thou a laminated Baltic birch plywood, would insure uniformity in the spinning mass. I think a template would insure consistency of a shape.

I will repeat MJL and advise anyone from using a cheap home center lathe.

1446 is the one I have. It’s a heavy duty one and weights a lot. It’s limited to 23 on the paper so you could do 24-25inches. It would be a bit scary, spinning a heavy piece like this. All thou a laminated Baltic birch plywood, would insure uniformity in the spinning mass. I think a template would insure consistency of a shape.

I will repeat MJL and advise anyone from using a cheap home center lathe.

I made mine By hand with an electric planer,Block plane And a sander 🙂 I dont have a workshop or i would be going mad on designs.R-Carpenter said:Actually, from the woodworking point of view it’s not that hard to make. Granted that I have a shop and a 5hp 220v 3ph shaper. The expensive part would be a custom made knife for a shaper head. Due to the out rich of this knife it would be done on the specific type of shaper head that is if I am not mistaken called Colete head (I do have it just don’t remember the name). Then a couple of templates would give the external radius.

I am not at all saying that the work is not good, it’s just not impossible to do and other Diyers that are crazy about horns could have it done.

-(daz84)- said:

I made mine By hand with an electric planer,Block plane And a sander 🙂 I dont have a workshop or i would be going mad on designs.

You’d be building thing for the customers and wishing you had time for mad designs.

Teak Burma TH-4001 Horn...

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Diycoax,

Are you intending to make and sell these horns? If so l am looking to purchase a pair for my TAD project. if not, l would appreciate and tips on where l could source some 4001 horns.

Thanks all,

Mondie

Are you intending to make and sell these horns? If so l am looking to purchase a pair for my TAD project. if not, l would appreciate and tips on where l could source some 4001 horns.

Thanks all,

Mondie

whatever1 said:could I get some information on these horns ? I checked and the build pictures are not showing

Hi,

You can visit this webside.

Wooden Horn

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- TAD TH4001 clone project