@FartyMcfly thank you, this helps a lot! I think I will do the same as you, and also put in some time to understand Art's initial notes and measurements.

Combination of Cubos, Nova Acoustics VS12 and SynTripP sounds like it would be pretty messy to me😉I'm also using 2 cubo kicks for 90-200hz, so if I can get some decent reinforcement on the frequencies above that (without making a mess) - I would be really happy! Still have a few outputs left on my Driverack 4820 crossover.

If you are crossing in the 200Hz range, definitely skip the SynTripP bass reflex ports, and the secondary horn is hardly needed.

The 10" are excursion limited in the 100Hz range, going an octave higher you may want to consider higher power drivers than the B&C 10CL51 to keep up with a

I bet these, or even the smaller voice coil CD65-T (with neo magnet available) would work out and save some $$$: https://en.toutlehautparleur.com/co...dience-bianco-75cd-t-8-ohm-1-4-inch-exit.html3. Is there some decent alternative to the Celestion CDX14-3050 that I can buy on Thomann?

Combination of Cubos, Nova Acoustics VS12 and SynTripP sounds like it would be pretty messy to me😉

Ok, it really seems like my initial post here turned out to be what IT-people call a classic XY-problem. I appreciate the feedback. I guess I should have provided more relevant information straight from the start.

My setup is as following:

2 x Nova Acoustics VS215 subs

2 x Nova Acoustics VS12 tops

2 x Cubo Kick 12s (built those as the Nova setup was seriously lacking in the 100-200hz range)

As I've mentioned before, after getting a better amp for my subs, I found the high/midrange to be seriously lacking. Pushing the volume higher only results in distortion and ear pain (which is a no-go). As I like to keep my tops wide apart for a nice stereo image, I thought some fillers would be nice here. And I started investigating if there would be some good tops I could build myself. That's how I stumbled upon the SynTripP.

So considering my current setup, my desire to have better mid/high range that would spread out nicely over a field/forest clearing (it's used outdoors 90% of the time), and also my motivation to get in that workshop and build something nice, what would you recommend? Fully replacing the tops?

What's the lowest crossover point where one would want to skip the bass reflex port?

The 10" are excursion limited in the 100Hz range, going an octave higher you may want to consider higher power drivers than the B&C 10CL51 to keep up with a

Any tips there on a driver that would fit with the current design?

I'd recommend Peter Morris PM90, the horn loaded/ported 2x12" probably would outrun 4 VS215 subs crossed at 100Hz.So considering my current setup, my desire to have better mid/high range that would spread out nicely over a field/forest clearing (it's used outdoors 90% of the time), and also my motivation to get in that workshop and build something nice, what would you recommend? Fully replacing the tops?

https://soundforums.net/community/threads/new-diy-mid-high-90deg-aka-pm90.11601/

The VS12 could be used for center fill.

The Cubos could be used for DJ subs.

Completely depends on the SPL desired.What's the lowest crossover point where one would want to skip the bass reflex port?

There is no horn gain at 100Hz, 2x10" can do ~121dB at 6mm excursion, while at 200Hz could do over 133dB, but would probably smoke the B&C 10CL51 after a short time at that level.

The B&C 10NDL88-8 power handling is over +6dB more than the 10CL51, and has a bit more Xmax.Any tips there on a driver that would fit with the current design?

It has a different cone profile, so the cone filler parts would need to be changed accordingly.

@weltersys thank you for the deailed information. The PM90 looks like a beast, but I need something a bit more portable. So I'll build 2 SynTripPs and see where that takes me! I'll come back to report.

Hello everyone, i want to get into building soundsystems and I think I will go for 1 syntripP and 1 keystone sub (for the start, when I have more money i plan on adding onto it) I have a large CNC machine, and some expierience with woodworking. I attached a picture of the cnc, I think it would be well suited for making cabinets.

Are there cad files available, i looked through this thread for a bit but have Not found any.

Also what currently available drivers would you guys recommend.

Greetings from germany,

Ben

Are there cad files available, i looked through this thread for a bit but have Not found any.

Also what currently available drivers would you guys recommend.

Greetings from germany,

Ben

Attachments

Are there cad files available, i looked through this thread for a bit but have Not found any.

Hi there, you can find various plans here: https://drive.google.com/drive/u/0/folders/1Uc8v5Qk3jz8snis_ovhLCcN1j12PVRWf

But I recommend you read the last few posts on this forum 🙂

The recommended drivers are the Celestion CDX14-3050 and 2 x B&C Speakers 10CL51

hi guys, first time writing but i followed this project from the beginning, since there are a lot of pages in this thread and i can't keep up with all of them i'd like to ask you if there is a fully 3d printable version of this horn.

Hey all!

I have been slowly picking away at building a pair of these for an outdoor space I have up in Maine. I have read through this whole forum a few times as well as a variety of other build logs people have out on the internet. I know at one point in my scrolling I saw someone build a version of these speakers with a plate amplifier on the back, but I cannot find the post now. While I know that strays from the goal of lightest/most compact overall package, it has the potential to save space other spots in my system. I am wondering if anyone has experimented with this and what other pros/cons I may not be considering for this option.

I found the Dayton PPA800DSP to mostly fit the bill. It seems like it should be good to run 600w RMS @ 4 ohm for the 10CL51 and 100w RMS @ 8 ohm for the CDX14-3055 (underpowered?). It has a built in passive HPF @ 1000hz on the HF channel while the LF channel is full range. That should be ok when thinking about my crossover for these drivers right?

Thank you so much to Art for spending so much time on the design, build, and in the threads answering questions. You have really made this design possible for me and many others. Also many thanks to the people who have done this process before me and provided additional insight to the build process.

I just need to get my electronics sorted and figure out the cone profile of the 10CL51 to laythe out or 3d print my cone plugs and my first pair should be done.

Stoked to finally get involved in the thread in a more active capacity! Great to meet any of y'all still active on here.

I have been slowly picking away at building a pair of these for an outdoor space I have up in Maine. I have read through this whole forum a few times as well as a variety of other build logs people have out on the internet. I know at one point in my scrolling I saw someone build a version of these speakers with a plate amplifier on the back, but I cannot find the post now. While I know that strays from the goal of lightest/most compact overall package, it has the potential to save space other spots in my system. I am wondering if anyone has experimented with this and what other pros/cons I may not be considering for this option.

I found the Dayton PPA800DSP to mostly fit the bill. It seems like it should be good to run 600w RMS @ 4 ohm for the 10CL51 and 100w RMS @ 8 ohm for the CDX14-3055 (underpowered?). It has a built in passive HPF @ 1000hz on the HF channel while the LF channel is full range. That should be ok when thinking about my crossover for these drivers right?

Thank you so much to Art for spending so much time on the design, build, and in the threads answering questions. You have really made this design possible for me and many others. Also many thanks to the people who have done this process before me and provided additional insight to the build process.

I just need to get my electronics sorted and figure out the cone profile of the 10CL51 to laythe out or 3d print my cone plugs and my first pair should be done.

Stoked to finally get involved in the thread in a more active capacity! Great to meet any of y'all still active on here.

Search for posts containing 'Hypex' from user MrSpeakers in this thread. I suspect that one of MrSpeakers' posts was the one you read.

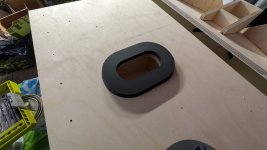

Build pics!

I modelled everything based on Art's dimensions, and generated my own cut sheet because I wanted to KNOW that everything would fit. So far so good.

3D printed the throat adapters, cone plugs and spacer for the pole mount (this needed a slight lift as it was hitting the back of the lower horn wall).

Next steps are to install baffle material on the inner walls (carpet underlay ok?), rout and drill for handles, fly points and speakon connections, and wire up before final assembly.

Stoked to have made it this far relatively smoothly!

I'll upload my 3D model and cut sheet at some point.

P.S. drivers are 10CL51 and DE780TN

I modelled everything based on Art's dimensions, and generated my own cut sheet because I wanted to KNOW that everything would fit. So far so good.

3D printed the throat adapters, cone plugs and spacer for the pole mount (this needed a slight lift as it was hitting the back of the lower horn wall).

Next steps are to install baffle material on the inner walls (carpet underlay ok?), rout and drill for handles, fly points and speakon connections, and wire up before final assembly.

Stoked to have made it this far relatively smoothly!

I'll upload my 3D model and cut sheet at some point.

P.S. drivers are 10CL51 and DE780TN

Attachments

-

PXL_20250125_222127897.jpg324.3 KB · Views: 151

PXL_20250125_222127897.jpg324.3 KB · Views: 151 -

PXL_20250124_031051121.jpg351 KB · Views: 152

PXL_20250124_031051121.jpg351 KB · Views: 152 -

PXL_20250125_221524675.jpg95.4 KB · Views: 157

PXL_20250125_221524675.jpg95.4 KB · Views: 157 -

PXL_20250124_031025408.jpg331.6 KB · Views: 161

PXL_20250124_031025408.jpg331.6 KB · Views: 161 -

PXL_20250202_210209382.jpg324.1 KB · Views: 153

PXL_20250202_210209382.jpg324.1 KB · Views: 153 -

PXL_20250203_032352614.jpg426.7 KB · Views: 152

PXL_20250203_032352614.jpg426.7 KB · Views: 152 -

PXL_20250203_032319384.jpg358.3 KB · Views: 151

PXL_20250203_032319384.jpg358.3 KB · Views: 151 -

PXL_20250203_032248769.jpg300.2 KB · Views: 148

PXL_20250203_032248769.jpg300.2 KB · Views: 148 -

PXL_20250202_210238416.jpg330.9 KB · Views: 144

PXL_20250202_210238416.jpg330.9 KB · Views: 144 -

PXL_20250202_210226093.jpg339.3 KB · Views: 146

PXL_20250202_210226093.jpg339.3 KB · Views: 146

Last edited:

The old-style felt/jute type carpet underlayment is very good for damping/absorption, but closed cell foam as is more typical now won't work for that purpose.Next steps are to install baffle material on the inner walls (carpet underlay ok?)

Your build is looking good!

In the big picture, how do NDL88's perform in generic horn loading? i've seen it mentioned they are better suited for direct radiator applications, maybe a short horn. is this splitting hairs? i have some 15ndl88s I want to do something with and i've been reluctant to consider a horn for them.

sorry if this is off topic, seems a good place to ask though😉

sorry if this is off topic, seems a good place to ask though😉

This all looks great! Very nice looking throat adapters 👍Build pics!

I modelled everything based on Art's dimensions, and generated my own cut sheet because I wanted to KNOW that everything would fit. So far so good.

3D printed the throat adapters, cone plugs and spacer for the pole mount (this needed a slight lift as it was hitting the back of the lower horn wall).

Next steps are to install baffle material on the inner walls (carpet underlay ok?), rout and drill for handles, fly points and speakon connections, and wire up before final assembly.

Stoked to have made it this far relatively smoothly!

I'll upload my 3D model and cut sheet at some point.

P.S. drivers are 10CL51 and DE780TN

One constructive comment : some of your threads inserts for mounting the 10CL51s look like they're not flush with the material they're inserted into. This means the speaker won't be pulled completely tight against the baffle.

You can use a tool like this to cut an extra millimetre around the mouth of your hole so that the lip of the threaded insert sits inside the material and everything is nice and flush.

I use threaded inserts all the time in my cabinet making day job and this little step makes all the difference to how well they work (and how neat they look)

Hey Farty, thanks mate!

Ya I know, and I thought about this. I think it's ok though. We're talking a fraction of a mm and there's plenty of gasket on the speaker rim inboard of the inserts, that I'm confident has squished down around these small protrusions. The driver is fully seated down to the metal rim externally, and there's a void in the gasket at each hole anyway. I'll pull one and check though, and maybe just file the inserts down to be sure. They're epoxied in now.

Ya I know, and I thought about this. I think it's ok though. We're talking a fraction of a mm and there's plenty of gasket on the speaker rim inboard of the inserts, that I'm confident has squished down around these small protrusions. The driver is fully seated down to the metal rim externally, and there's a void in the gasket at each hole anyway. I'll pull one and check though, and maybe just file the inserts down to be sure. They're epoxied in now.

Sounds like it's gonna be fine 😎

Looking forward to seeing the finished builds!

Looking forward to seeing the finished builds!

1/2" of that type damping would be plenty.OK good to know, thanks Art. Would this stuff be overkill?

- Home

- Loudspeakers

- Multi-Way

- SynTripP: 2-way 2-part Virtual Single Point Source Horn