Noted! I have been printing with no base layer (starting from the bottom with just infill).

Just had the thought that I might fill the infill altogether with something cheaper (and faster) than printing it. That way if there are any microscopic gaps/cracks there is just no chance of interior air leakage into the part.

Some kind of closed cell foam or something... Might even be able to use it to bond the part to the wood....

Just had the thought that I might fill the infill altogether with something cheaper (and faster) than printing it. That way if there are any microscopic gaps/cracks there is just no chance of interior air leakage into the part.

Some kind of closed cell foam or something... Might even be able to use it to bond the part to the wood....

Some kind of closed cell foam or something... Might even be able to use it to bond the part to the wood....

Gorilla glue is neat for this type of application, you can give a light mist of water on the parts that will make it expand and harden.

Noted! I have been printing with no base layer (starting from the bottom with just infill).

Just had the thought that I might fill the infill altogether with something cheaper (and faster) than printing it. That way if there are any microscopic gaps/cracks there is just no chance of interior air leakage into the part.

Some kind of closed cell foam or something... Might even be able to use it to bond the part to the wood....

PL Premium from caulk gun is much cheaper than Gorilla and will fill and seal all those pores. Glue a plastic sheet on it with the PL works too then a screw can be used to hold in place so removable.

Thanks for the suggestions on glues! After some research the gorilla glue piqued my interest.

Mark- do you mean bondo? I think I'll have to get some anyway to finish the horn. I believe Art calls for a fillet of bondo on the inside of the horn.

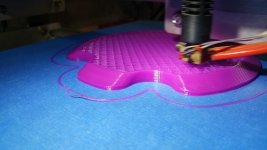

I'm printing another version of the part with less infill. Time to complete (start to finish) is about an hour at this point

Mark- do you mean bondo? I think I'll have to get some anyway to finish the horn. I believe Art calls for a fillet of bondo on the inside of the horn.

I'm printing another version of the part with less infill. Time to complete (start to finish) is about an hour at this point

Attachments

Jenny,

Gorilla tape is great, Gorilla glue is a terrible mess, and has poor shelf life once opened. I have thrown out three times as much as used, though it does do a good job of expanding into pores (and blowing glue joints apart if not properly clamped or fastened) and is strong.

Bondo works well for filling holes, but tends to crack out of corners on road cabinets. Bondo glass has decent structural strength, but will not take a radius very smoothly.

For the fillet inside the horn I use a caulk gun with paintable silicon caulk. The caulk remains semi-flexible (won't crack out) and is easy to smooth out after application with a "popsicle stick" or spoon.

Art

Gorilla tape is great, Gorilla glue is a terrible mess, and has poor shelf life once opened. I have thrown out three times as much as used, though it does do a good job of expanding into pores (and blowing glue joints apart if not properly clamped or fastened) and is strong.

Bondo works well for filling holes, but tends to crack out of corners on road cabinets. Bondo glass has decent structural strength, but will not take a radius very smoothly.

For the fillet inside the horn I use a caulk gun with paintable silicon caulk. The caulk remains semi-flexible (won't crack out) and is easy to smooth out after application with a "popsicle stick" or spoon.

Art

Last edited:

Paintable (make sure it is paintable) silicon caulk would work for that too, though the T-nuts would be no more visible than the speaker holes through grill cloth.

It's probably not sandable, though, right?

I am kind of in love with the look of the horn, so I don't know if I'll be covering with a grill cloth. I know it's supposed to help smooth the response, but depending on how it tests I may opt for no cover.

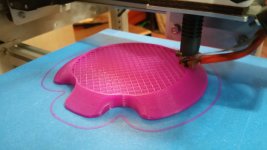

Heated build platform is doing the trick... 0% warping

I am kind of in love with the look of the horn, so I don't know if I'll be covering with a grill cloth. I know it's supposed to help smooth the response, but depending on how it tests I may opt for no cover.

Heated build platform is doing the trick... 0% warping

Attachments

Caulk is not very sandable, get it right while it is wet.

Without grills, insects and rodents may take up residence in the "hidey holes" the ports provide. I hate it when that happens...

Without the grill frame there will be an ugly discontinuity (both visual and sonic) between the first and second part of the horn.

Without grills, insects and rodents may take up residence in the "hidey holes" the ports provide. I hate it when that happens...

Without the grill frame there will be an ugly discontinuity (both visual and sonic) between the first and second part of the horn.

Last edited:

Not sure if this will be useful in these applications but I've used Durham's Rock Hard Water Putty to fill in steps on round horns. It does cure very hard. The one very nice thing about it is that it expands slightly when cured. This allows it to be used to fill much larger gaps, holes ect. Other types of filler tend to shrink when cured and therefore crack. They usually specify no thicker than 1/4". I don't think that Durham's specified a min thickness. Just another items to have as an option in our bag of tricks.

Yep. Bondo is a brand of polyester putty.

And it really glues to wood quite well to.

I've used it more than once on messed up paint grade projects. Gets you out of a bind quickly.

I would do both a mechanical fastener and a glue fastener. Mainly due to wood movement over the life of the cabinet.

All wood shrinks and swells seasonally.

Plywood included.

Not the greatest for a rigid glue bond.

And it really glues to wood quite well to.

I've used it more than once on messed up paint grade projects. Gets you out of a bind quickly.

I would do both a mechanical fastener and a glue fastener. Mainly due to wood movement over the life of the cabinet.

All wood shrinks and swells seasonally.

Plywood included.

Not the greatest for a rigid glue bond.

It's probably not sandable, though, right?

I am kind of in love with the look of the horn, so I don't know if I'll be covering with a grill cloth. I know it's supposed to help smooth the response, but depending on how it tests I may opt for no cover.

Heated build platform is doing the trick... 0% warping

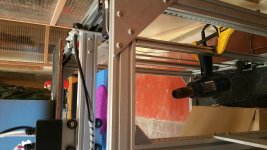

Glad you dialed in the heated platform. Once I figured out all the tricks in the settings it made a huge improvement to the max size I could print. Are you printing on glass surface? The best surface treatment is 50:50 PVA:water mix brushed onto 55C heated bed. Then heat bed all the way to regular temp after it dries. PLA sticks to it very well and you are assured a good foundation for remainder of print.

I like the pink PLA.

Small metal mesh screens on the ports should keep bugs out. If painting the horn - just same color paint (white especially) should hide it pretty well. Otherwise, decorative plastic screw top covers can be inserted for a clean look.

A side thought in regards to the 10" driver:

The channel has been routed to permit movement to xmax, but theoretically the driver can move further than that, so there is a potential for it to crash into the horn wall piece at some point.

Peering into the holes, the most amount of movement I eyeballed was about 4-5mm peak to peak at full volume (full volume being limiters starting to nudge on the CD) So it seems there is no need to actually move right up to xmax.

1 watt sin wave during testing did not produce a visible amount of movement, though it was so loud it just made my ears ring.

Volume wise I don't see the mid driver ever needing to be pushed so hard it would reach xmax, so it should never crash, but if there is a spike in voltage there is the potential to crash.

I was thinking in that case if the cone were to touch a snug profiled shape over a wide area the risk of damage may be reduced as opposed to hitting a corner somewhere.

Though perhaps the suspension/surround would be more impact resistant than the cone.

If we were to go into any kind of commercial under ART's licensing agreement, I worry this would be a risk factor of the product. Though From what I understand it is the compression driver that is the weakest point.

I do have a spare driver?! Time for some Mythbusters driver crash-testing? 🙂

The channel has been routed to permit movement to xmax, but theoretically the driver can move further than that, so there is a potential for it to crash into the horn wall piece at some point.

Peering into the holes, the most amount of movement I eyeballed was about 4-5mm peak to peak at full volume (full volume being limiters starting to nudge on the CD) So it seems there is no need to actually move right up to xmax.

1 watt sin wave during testing did not produce a visible amount of movement, though it was so loud it just made my ears ring.

Volume wise I don't see the mid driver ever needing to be pushed so hard it would reach xmax, so it should never crash, but if there is a spike in voltage there is the potential to crash.

I was thinking in that case if the cone were to touch a snug profiled shape over a wide area the risk of damage may be reduced as opposed to hitting a corner somewhere.

Though perhaps the suspension/surround would be more impact resistant than the cone.

If we were to go into any kind of commercial under ART's licensing agreement, I worry this would be a risk factor of the product. Though From what I understand it is the compression driver that is the weakest point.

I do have a spare driver?! Time for some Mythbusters driver crash-testing? 🙂

Last edited:

Without the grill frame there will be an ugly discontinuity (both visual and sonic) between the first and second part of the horn.

I was going to build a second frame the same as the grill frame for when I don't want to use the grill.

In storage the grill will go back on (rodents!)

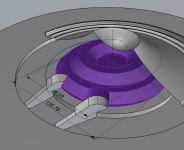

Here is another direction for the phase plug using the same 12mm (1/2") material that can be done with a trim router bit, 3/8" 45 degree chamfer, and 1.5" circle punch (using a paddle bit, hole saw, or forstner bit)

That comes out to 210cc

That comes out to 210cc

Attachments

Is it true to say that the larger the volume plug is the higher the rolloff of the mid will be?

Last edited:

t's probably not sandable, though, right?

I am kind of in love with the look of the horn, so I don't know if I'll be covering with a grill cloth. I know it's supposed to help smooth the response, but depending on how it tests I may opt for no cover.

Heated build platform is doing the trick... 0% warping

Bondo or other brand autobody putty can indeed be sandable.

I keep some in the shop that is really sandable. It is scatchand chip filler. Really sands out beautifully and feathers out to a really thin edge. Yet it is catalysed with the peroxide catalyst like normal Bondo.

A place that supplies car paint products will have exactly what you want. That's where I get mine from.

Is it true to say that the larger the volume plug is the higher the rolloff of the mid will be?

That's true but the effect will be minimal given the differences in volume we are talking about. Not having to provide 12mm Xdamage will help a lot. Reducing it to 7mm or whatever Xmax plus 1mm would be good if you haven't observed much movement. That reduces the volume a lot as it is Sd x stroke = volume

- Home

- Loudspeakers

- Multi-Way

- SynTripP: 2-way 2-part Virtual Single Point Source Horn