New method for lamellas to voice coil has been designed to allow for closer spacing from about 1.1 mm to about .7mm. this allows for more coverage, less sealing, better aesthetics coming to that of the mbl.

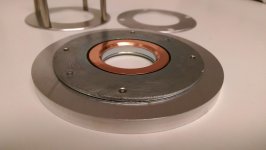

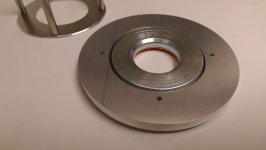

Casing for MT50 is finished from 3mm thick aluminium and anodized HT37 casing is still awaiting anodize.

Attachments

Last edited:

Really? Well, your 'play' has been pretty serious looking to this mortal. 😉 This next group might drive me to up my meds on viewing...post 'warning disclaimers', please. *L*

You go, my friend. Show us what a 'summer project' can be. *S*

You go, my friend. Show us what a 'summer project' can be. *S*

Casing arrived... Its perfect the bolts and things fit well and complete the look while completing their function. This is for the mid-range I just need to dissemble the unit for a test fit. Completion of one mid-range is close and it will be gorgeous.

Attachments

Last edited:

Depends on the look you are after David? If you want something more sleek you could use a pan head bolt with the same drive. If you want it black you have less selection.

http://www.shop4fasteners.co.uk/media/4829/socket_head_button_flange_screws_self_colour_section.jpg

I would use this one:

[/url][/IMG]

[/url][/IMG]

Bernt

I would use this one:

Bernt

Last edited:

Bernt,

That is what we call a panhead with the washer integrated. That was the same thing I was suggesting.

That is what we call a panhead with the washer integrated. That was the same thing I was suggesting.

Thanks for the suggestions. There will be some nice touches of my own man It will look great sending some more parts to get at least one mid-range module done. The other is a matter of building the driver.

Good looking parts to start with. "The guts"...the meat of the matter, yes. That'll be a challenge, but it's in capable hands. 😉

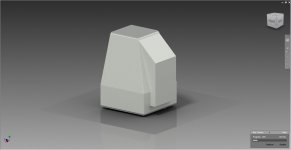

Forgot to add A piece the Motor cover I also Decided to go ahead and replicate the cabinet This was the part I feared was going to be hard to replicate with nearly no information on the web but I am pretty satisfied.

Porgress

Here is the piece I forgot the motor cover which still needs anodizing and I started working on modeling the cabinet I was fearful I would not be able to model it as there is nearly no information anywhere but I think I have

come negligibly close. Nearly all internals have been more or less finalized. I need to purchase the Tweeter motor to dial it in and model the rest of the melon/cabinet accessories.

Here is the piece I forgot the motor cover which still needs anodizing and I started working on modeling the cabinet I was fearful I would not be able to model it as there is nearly no information anywhere but I think I have

come negligibly close. Nearly all internals have been more or less finalized. I need to purchase the Tweeter motor to dial it in and model the rest of the melon/cabinet accessories.

Attachments

Last edited:

Better pics

You guys deserve better pics so here they are

You guys deserve better pics so here they are

Attachments

Last edited:

Damn, that's pretty. Kudos to your machinist buddy, he does great work. *S*

And the 'globe' in #197, fuzzy as it is in the pic, lookin' good as well.

'First voice' soon? Betcha can't wait....I'd be anxious in your shoes. 'Ell, worse. *L*

And the 'globe' in #197, fuzzy as it is in the pic, lookin' good as well.

'First voice' soon? Betcha can't wait....I'd be anxious in your shoes. 'Ell, worse. *L*

- Home

- Loudspeakers

- Planars & Exotics

- Summer Project - Replication of MBL loudspeaker 101mkII