Now, that's a thought. Uses less space, that's an advantage. I don't know about the strength of the dome, will it survive?

We would need to find out how to couple it to the horn (kind of build your own pressure chamber). May be a simpel ring would work, could be a stepped tap shape. One ring on top of the horn to make it fit (as it is a dome, which needs some space not to touch the horn), then a smaller hole and again smaller tap opening both in the panel of the horn. So a 3 step tap. 🙄

Also, the synergy would always be a 3-way horn since the dome's don't go low enough, with 1", mid-range and low/mid.

500 Hz is not a frequency where you could cross a Tapped Horn with, would leave a gap of 300 - 350 Hz.

Will give less stress to the 1" CD. 😀

It is a way to go, but needs much work.

We would need to find out how to couple it to the horn (kind of build your own pressure chamber). May be a simpel ring would work, could be a stepped tap shape. One ring on top of the horn to make it fit (as it is a dome, which needs some space not to touch the horn), then a smaller hole and again smaller tap opening both in the panel of the horn. So a 3 step tap. 🙄

Also, the synergy would always be a 3-way horn since the dome's don't go low enough, with 1", mid-range and low/mid.

500 Hz is not a frequency where you could cross a Tapped Horn with, would leave a gap of 300 - 350 Hz.

Will give less stress to the 1" CD. 😀

It is a way to go, but needs much work.

I thought I'd posted it to this thread, but I can't find my own post.

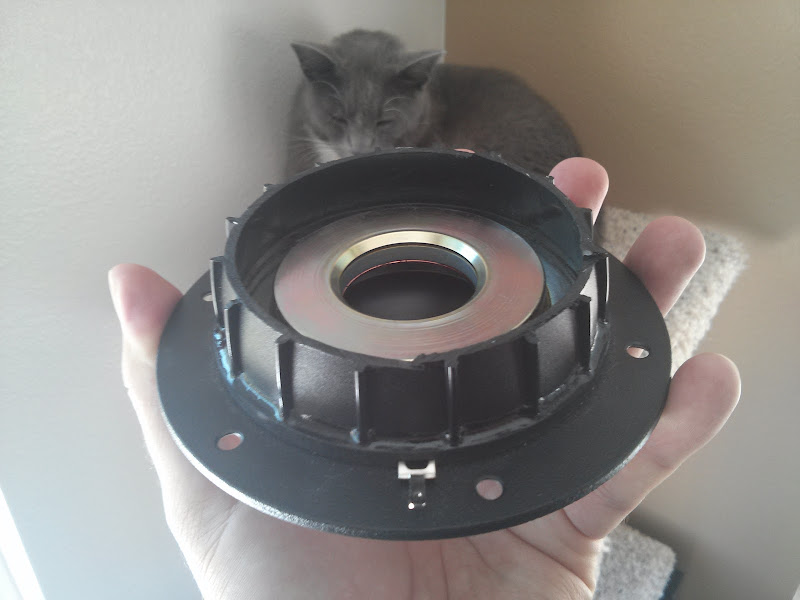

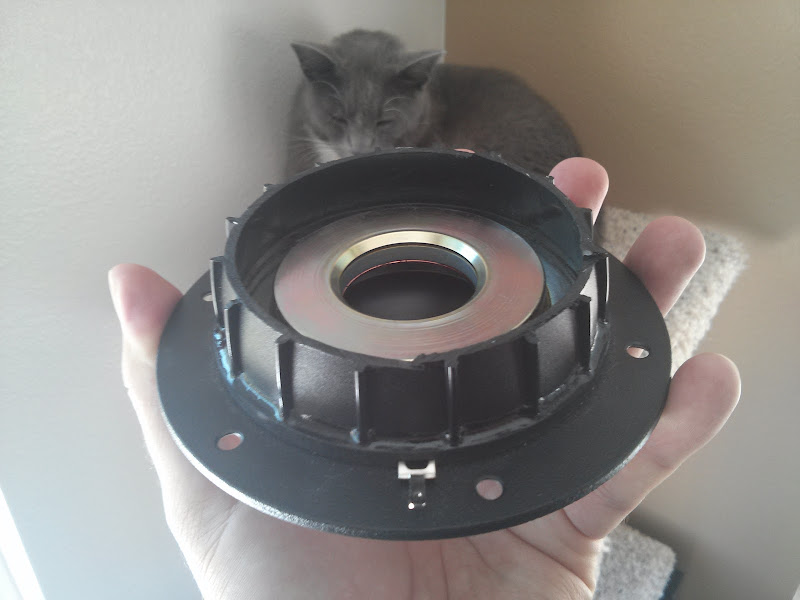

Here's a summary of my experience with the Dayton RS52:

1) YES, it works on a Unity or Synergy horn

2) The Fb is too low, about 250hz IIRC. You want it up around 500hz.

3) To "fix" the FB, saw the driver in half. This reduces the volume of the chamber.

4) Once you've sawed it in half, mount it *upside down* on the horn. So the back chamber in the original driver is now the coupling chamber on the horn. And you have to build a new back chamber. (Because it's upside down now.) The way that I did it was to simply apply clay to the metal mesh that's built into it.

More info, including t/s parameters, here:

http://www.diyaudio.com/forums/multi-way/239808-28-days-later-2.html#post3575880

pics:

If space isn't a factor, I still prefer the Dayton Aurasound clones. They have more xmax which means they have more output.

Here's a summary of my experience with the Dayton RS52:

1) YES, it works on a Unity or Synergy horn

2) The Fb is too low, about 250hz IIRC. You want it up around 500hz.

3) To "fix" the FB, saw the driver in half. This reduces the volume of the chamber.

4) Once you've sawed it in half, mount it *upside down* on the horn. So the back chamber in the original driver is now the coupling chamber on the horn. And you have to build a new back chamber. (Because it's upside down now.) The way that I did it was to simply apply clay to the metal mesh that's built into it.

More info, including t/s parameters, here:

http://www.diyaudio.com/forums/multi-way/239808-28-days-later-2.html#post3575880

pics:

If space isn't a factor, I still prefer the Dayton Aurasound clones. They have more xmax which means they have more output.

Why does the Fb have to be up around 500hz?.......serious question as I have no idea. Lol

Read page one of the thread, it's explained there

Thanks. Read the first few pages. So if I understand it correctly, the formula is based on the drivers ability to work in a compression situation as firing through a slot vent?

Hi There

I did try a old phillips 8 incher for this synergy.

It do go far and wide, but maybe i did not do everything right, it wil not fit

because opening need close to mouth.

But it looks good.

regards

I did try a old phillips 8 incher for this synergy.

It do go far and wide, but maybe i did not do everything right, it wil not fit

because opening need close to mouth.

But it looks good.

regards

Attachments

Last edited:

Thanks. Read the first few pages. So if I understand it correctly, the formula is based on the drivers ability to work in a compression situation as firing through a slot vent?

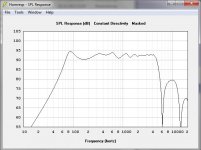

Basically the formula tells you how high the driver will go in a front loaded horn. For instance, if you put a driver with a large heavy cone on a front loaded horn, the mass will limit the high frequency response. So generally you need a low moving mass and a powerful motor to extend the high frequency response. That's why conventional tweeters look like this:

while compression drivers look like this:

Basically big motor + lightweight diaphragm = extended high frequency response

On a Synergy horn, the Pyle PDMR5 works fairly well, but I'm not a huge fan of foam surrounds for Synergy horn midranges. That type of surround doesn't last long, and even worse, it's heavy, which limits high frequency response.

Cone tweeters, like the Goldwood GT-25, work quite well. Low frequency output is obviously limited by the lack of displacement.

An externally hosted image should be here but it was not working when we last tested it.

Here's an interesting driver I stumbled across this morning. The Boss SB6.4. It's a sealed back 6.5" midrange aimed at the car audio market. But it has a feature the Pyle doesn't - an accordian surround. Price is a little bit higher - $20. But still very reasonable.

I might order one of these just to get the specs. The website doesn't list ANYTHING. No QMS, QES, Re, etc.

Thanks Patrick. My question was if one chose to use a dome midrange in such a way that it was not horn loaded but the dome completely exposed to the interior of the horn mount.

Thanks Patrick. My question was if one chose to use a dome midrange in such a way that it was not horn loaded but the dome completely exposed to the interior of the horn mount.

What would be the advantage of going that route?

On a Synergy horn, the Pyle PDMR5 works fairly well, but I'm not a huge fan of foam surrounds for Synergy horn midranges. That type of surround doesn't last long, and even worse, it's heavy, which limits high frequency response.

Cone tweeters, like the Goldwood GT-25, work quite well. Low frequency output is obviously limited by the lack of displacement.

An externally hosted image should be here but it was not working when we last tested it.

Here's an interesting driver I stumbled across this morning. The Boss SB6.4. It's a sealed back 6.5" midrange aimed at the car audio market. But it has a feature the Pyle doesn't - an accordian surround. Price is a little bit higher - $20. But still very reasonable.

I might order one of these just to get the specs. The website doesn't list ANYTHING. No QMS, QES, Re, etc.

I have write the company, so when I hear it I let now.

regards

What would be the advantage of going that route?

From various musings here and elsewhere, there seems to be a real demand for a smaller, home 'hi-Fi' version of a synergy.......one where extreme efficiency and power handling wouldn't be a priority. Combining for dome mids such as the RS52 from Dayton would still provide substantial efficiency and power handling with extension to 300hz and 3khz likely.

Sure, diffraction might be an issue with the HF driver radiating against the exposed dome grilles, but there's mechanical ways of reducing the destructive interference. Would trying out the theory with a sheet of plywood and an already owned 1" horn reduced to the throat?.....I say most definately. The JBL M2 waveguide shows us that there's more than one way to create a suitable guide.

mayhem13,

You're going to have difficulty getting the midranges (particularly domes!) close in enough to the horn's HF throat to reach to 3kHz, even 2kHz is pretty tough to do. The reflection of an internal driver (or port from a driver) will cause a severe null where the distance between mid driver center and tweeter diaphragm becomes 1/4 wave (about 3000/f, in inches). Ports would be easier to get in close than entire driver cones or domes and aren't more difficult or expensive than domes.

You're going to have difficulty getting the midranges (particularly domes!) close in enough to the horn's HF throat to reach to 3kHz, even 2kHz is pretty tough to do. The reflection of an internal driver (or port from a driver) will cause a severe null where the distance between mid driver center and tweeter diaphragm becomes 1/4 wave (about 3000/f, in inches). Ports would be easier to get in close than entire driver cones or domes and aren't more difficult or expensive than domes.

Last edited:

Here is the thing. All you really need is point source to Shroeder. Active crossover/dsp quickly solves other issues. A quick recipe for that and most of us are there. All of you already own 90% of an active dsp. Jriver and an inexpensive pro multi out card solves by brute force what we are trying, for not a really good reason, to finess, imo.

Basically the formula tells you how high the driver will go in a front loaded horn. For instance, if you put a driver with a large heavy cone on a front loaded horn, the mass will limit the high frequency response. So generally you need a low moving mass and a powerful motor to extend the high frequency response. That's why conventional tweeters look like this:

You missed one important thing : the material of the membrane needs to be very stiff, as a horn works as an air impedance transformer and what the membrane has to do when facing at the throat is to put in pressure that very little portion-but dense!

question for hulkss

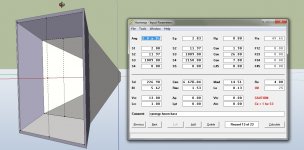

hulkss, I'm going to attempt a build very similar to yours and I'm still trying to make up my mind about the size of the horns and the use of a secondary flare to avoid midrange beaming. I want them to maintain proper directivity down to 300 Hz, but don't want a horn that's 41" wide! I have two questions for you, if you'd be so kind:

1) I noticed that in your spreadsheet you've used 500 Hz as the lower limit for your horn, although it seems you're intending to have the midranges reach down to 300 Hz. The use of 500Hz clearly produces a smaller horn. Am I correct in assuming that this is because you going to use Hughes' method involving foam/cotton instead of the second flare?

2) I saw in Hughes' whitepaper that "Many types of acoustical foam were tried", but he doesn't specify what thickness or density he finally arrived at. How/why did you choose this cotton material, and what's guiding your choice regarding the horn size and the proportion that will be lined with this material?

Here's the 1" thick material I plan to use (as shown around the horn mouth) to absorb sound diffraction: Echo Eliminator

hulkss, I'm going to attempt a build very similar to yours and I'm still trying to make up my mind about the size of the horns and the use of a secondary flare to avoid midrange beaming. I want them to maintain proper directivity down to 300 Hz, but don't want a horn that's 41" wide! I have two questions for you, if you'd be so kind:

1) I noticed that in your spreadsheet you've used 500 Hz as the lower limit for your horn, although it seems you're intending to have the midranges reach down to 300 Hz. The use of 500Hz clearly produces a smaller horn. Am I correct in assuming that this is because you going to use Hughes' method involving foam/cotton instead of the second flare?

2) I saw in Hughes' whitepaper that "Many types of acoustical foam were tried", but he doesn't specify what thickness or density he finally arrived at. How/why did you choose this cotton material, and what's guiding your choice regarding the horn size and the proportion that will be lined with this material?

1) I noticed that in your spreadsheet you've used 500 Hz as the lower limit for your horn, although it seems you're intending to have the midranges reach down to 300 Hz. The use of 500Hz clearly produces a smaller horn. Am I correct in assuming that this is because you going to use Hughes' method involving foam/cotton instead of the second flare?

2) I saw in Hughes' whitepaper that "Many types of acoustical foam were tried", but he doesn't specify what thickness or density he finally arrived at. How/why did you choose this cotton material, and what's guiding your choice regarding the horn size and the proportion that will be lined with this material?

1. I intend to put the horn in a baffle board that will effectively extend its low frequency capability some. The response will be -6db at the lower crossover frequency.

2. The cotton material has better acoustic properties and will work well in a home setting. Hughes was designing a pro-audio product that has additional requirements for durability, resistance to moisture, etc.

I started my Synergy horn project as a backup solution while I was waiting literally years for other solutions I had ordered. The first was a set of three SEOS24 horns with BMS 4594 coaxial drivers. The second was a new Synergy horn from Red Spade Audio.

The SEOS horns amazingly just arrived in the mail (the large ones).

Link: Horns

An externally hosted image should be here but it was not working when we last tested it.

The Red Spade project is now looking like it will happen too:

Link: Red Spade Audio: PSE-144 dispersion

Not sure when I'll get around to building my own horns now.

For what it's worth, I'm having pretty good luck with the FaitalPro 3FE25 as a midrange driver for a Synergy horn. Put a 3" mailing tube on the back, cut to the level of the back of the magnet and sealed between tube and magnet gives about the right back volume. If weight is a problem, you can also go with the neo version (3FE22).

Hulkss -- I'm pretty sure that the sale of the RedSpade Synergy horn in the USA violates Danley's patent.

Hulkss -- I'm pretty sure that the sale of the RedSpade Synergy horn in the USA violates Danley's patent.

I'm pretty sure that the sale of the RedSpade Synergy horn in the USA violates Danley's patent.

What do you actually know about that?

Maybe Paul has an agreement to sell for non-professional use?

Maybe it's OK to sell an incomplete non-functional system? I'm not being provided a crossover network or instructions for one.

Paul has been open about his project for years now.

- Home

- Loudspeakers

- Multi-Way

- Suitable midrange cone, for bandpass mid in Unity horn