Always use a capacitor to protect the tweeter even if you swear you do not need it.

Nothing like power blips to cause LF to sneak into the output.

No good hearing a compression driver slap around when the power flickers and you know those drivers are likely dead now.

Ouch! Superlian, I feel for you, and that's a pricey booboo. I'm glad that you can get them fixed without having to pony up the money for full replacements. Glenn.

I have a pair of Focal tweeters in need of new dome kits. Where did you get yours ?

I dont remember. A dealer in US. It was over 10 years ago. You should mail Focal directly.

At what frequency was your electronic x-over set to and what order?Now i got answer on mail from Bliesma. Great service 🙂

The cause must be a low frequency signal.

It wasnt used protection capasitor with active crossover.

It is possible to recone them and that will incl freight and VAT cost nearly 50% of new tweeters but its worth it.

//

Around 2-2,2K

This was done aktive with special steep slopes in Audiolense FIR software.

We think that any kind of low frequency signal passed like DC pop?

This was done aktive with special steep slopes in Audiolense FIR software.

We think that any kind of low frequency signal passed like DC pop?

Well the shapes in the dome, matching the grille, clearly showed it must have been overexcursion. Low freq signal is only reasonable explanation.

These can play stupidly loud spls while maintaining composure, and never heard of this happening before with 'normal use.

As for the T34B the dome profile is much shallower and much more difficult for it to happen, luckily as it would have shattered if the same happened.

Looking at the T34A because of the dome shape the clearance in front under the grille, is severly reduced in comaprsion too.

There likely will be some available 3D print waveguides for these too soon, that also help with excursion/headroom on the low end.

I got them both too, and i prefer the B also with the mid i tried mating them too. But it might be room/use/dispersion/music related and a subjective opinion.

Hificompass 2 way pharaoh projects have some comparsions of the two tweeters also, which describes the differences i an decent way to my preferences.

If your using a xo at 2,5 k ish 2nd order or more it is a very robust tweeter

These can play stupidly loud spls while maintaining composure, and never heard of this happening before with 'normal use.

As for the T34B the dome profile is much shallower and much more difficult for it to happen, luckily as it would have shattered if the same happened.

Looking at the T34A because of the dome shape the clearance in front under the grille, is severly reduced in comaprsion too.

There likely will be some available 3D print waveguides for these too soon, that also help with excursion/headroom on the low end.

I got them both too, and i prefer the B also with the mid i tried mating them too. But it might be room/use/dispersion/music related and a subjective opinion.

Hificompass 2 way pharaoh projects have some comparsions of the two tweeters also, which describes the differences i an decent way to my preferences.

If your using a xo at 2,5 k ish 2nd order or more it is a very robust tweeter

Sounds plausible for the damage done to the T34A-4 variable thickness aluminium-magnesium alloy dome.We think that any kind of low frequency signal passed like DC pop?

From the mechanical drawing, it appears the clearance between the dome and grill may be less than the 3mm peak to peak "linear excursion" potential.

The air gap height is 4.5mm, the underhung coil 1.4mm, so if the suspension does not stop movement, almost 3mm forward movement would be possible without the voice coil completely leaving the gap. From the mechanical drawing, the distance between the screen cover and dome is much less than that.

Standard aluminum domes can withstand quite a few beatings before developing cracks, considering there does not seem to be any wear marks, appears the aluminium-magnesium alloy is not so robust.

Since the tweeter's diaphragm is already cracked, would be an interesting experiment to see how much DC voltage is required to for the diaphragm to make contact with the screen. Short "pops" would be required to keep the voice coil from burning up, but my guess is less than 18 volts would be required to make a hit.

Art

The dome is extremely thin. I took mine apart after it stopped working from high spl abuse. No visible damage to the dome, coil, or suspension.

Great tweeter.

Great tweeter.

@weltersys is correct these 2 pics from hificompass clearly shows the difference in the tweeters so does the mfg spec sheets profile pictures, as quoted in the post above. Hence why this might happen to the A more easily, but with less catastrophic results.

Obviously also why the dispersion character is so different, and what makes them sound different too with room interaction etc.

Obviously also why the dispersion character is so different, and what makes them sound different too with room interaction etc.

One possiblity might be the difference in barometric/atmospheric pressure that may have caused the dome to dent. This phenomenon is called vacuum collapse. If a tweeter is assembled in a city of high altitude with lower barometric pressure and the dome and surrounding and the suspension all are air sealed, the dome may collapse if it is taken to a city at sea level.

Just my $0.02 ;-)

Just my $0.02 ;-)

I doubt the diaphragm is sealed that well and it really wouldn't make sense to build a tweeter that way. I've used many home hifi dome tweeters in car audio installs without any dented domes, despite that environment making it likely ie. slamming a car door or trunk. Granted, a metal or other hard dome material will seal better than a cloth dome and any sharp change in air pressure would make damaging the dome a possibility.

More than likely the OP's tweeter suffered from a sharp amplifier transient caused by a blip in the AC line voltage. I've seen this damage before with biamped setups, even when using a DC blocking cap. The more powerful the amplifier, the higher the likelihood it can happen. Also, stray voltage accumulation across a large film coupling cap can occur just from it sitting there and the stored voltage can suddenly unload into the driver when the amp is turned on. This is definitely a good argument for passive crossovers and the use of coupling transformers instead of caps between source, preamp and power amp.

More than likely the OP's tweeter suffered from a sharp amplifier transient caused by a blip in the AC line voltage. I've seen this damage before with biamped setups, even when using a DC blocking cap. The more powerful the amplifier, the higher the likelihood it can happen. Also, stray voltage accumulation across a large film coupling cap can occur just from it sitting there and the stored voltage can suddenly unload into the driver when the amp is turned on. This is definitely a good argument for passive crossovers and the use of coupling transformers instead of caps between source, preamp and power amp.

I fully agree about the clearance and voltage required for the dome hitting the grille. That isn't a good design and should be revised. I would cut the OP a price break on the repair if I was Bliesma. Building a dome with that much excursion capability should factor in some leeway with anything interfering with peak excursion. Otherwise i love Bliesma drivers and think they're some of the best dome transducers available at any cost. I actually prefer the T34A over the T34B in some regards.Sounds plausible for the damage done to the T34A-4 variable thickness aluminium-magnesium alloy dome.

From the mechanical drawing, it appears the clearance between the dome and grill may be less than the 3mm peak to peak "linear excursion" potential.

The air gap height is 4.5mm, the underhung coil 1.4mm, so if the suspension does not stop movement, almost 3mm forward movement would be possible without the voice coil completely leaving the gap. From the mechanical drawing, the distance between the screen cover and dome is much less than that.

View attachment 1015036

Standard aluminum domes can withstand quite a few beatings before developing cracks, considering there does not seem to be any wear marks, appears the aluminium-magnesium alloy is not so robust.

Since the tweeter's diaphragm is already cracked, would be an interesting experiment to see how much DC voltage is required to for the diaphragm to make contact with the screen. Short "pops" would be required to keep the voice coil from burning up, but my guess is less than 18 volts would be required to make a hit.

Art

Having the dome hit the grille is a bad things for sure. The voice coil can still be damaged easily when it is forced outside of normal travel with a low frequency signal.

This is interresting comments on the problem and i think it is right.

The small decrease in fs in the TS parameters also confirm that it has been driven a little «hard» in some way but not that hard. Its more like a driver who have been used for 10-20 year or so? Isnt it like that?

The alu dome, compared with BE, is for sure higher/longer and that explains the better polar response up in frequency.

If it wasnt for the grill i am convinced that this couldtnt happen. If the LF signal dont damage the voice coil it the dome and the suspension can handle much more than we think. I have testet JBL 2451 with original titan membrane directly with heavy bass music with open back chamber (for fun). It was still working. And also mixed the tweeter and bass wire on a two way with Seas DXT alu dome for 20 seconds on moderate volume and It was measuring exactly like before the insidence.

When i pulled out the damage in one of the tweeters with a little stick glue on the finger the impedance peak disapeard in both Dats and in ARTAs frequency response despite the small hairline crack of 2 mm.

Another observation is that the alu material is very very thin, hard and brittle compared with ordinary alu domes. That explains why it is diffcult to pull out and that the dents have sharp edges. This material seems to have a quality between aluminium and beryllium and that is thumbs up.

I will send them to Bliesma for service and repair. And we will probably use them in a waveguide.

The small decrease in fs in the TS parameters also confirm that it has been driven a little «hard» in some way but not that hard. Its more like a driver who have been used for 10-20 year or so? Isnt it like that?

The alu dome, compared with BE, is for sure higher/longer and that explains the better polar response up in frequency.

If it wasnt for the grill i am convinced that this couldtnt happen. If the LF signal dont damage the voice coil it the dome and the suspension can handle much more than we think. I have testet JBL 2451 with original titan membrane directly with heavy bass music with open back chamber (for fun). It was still working. And also mixed the tweeter and bass wire on a two way with Seas DXT alu dome for 20 seconds on moderate volume and It was measuring exactly like before the insidence.

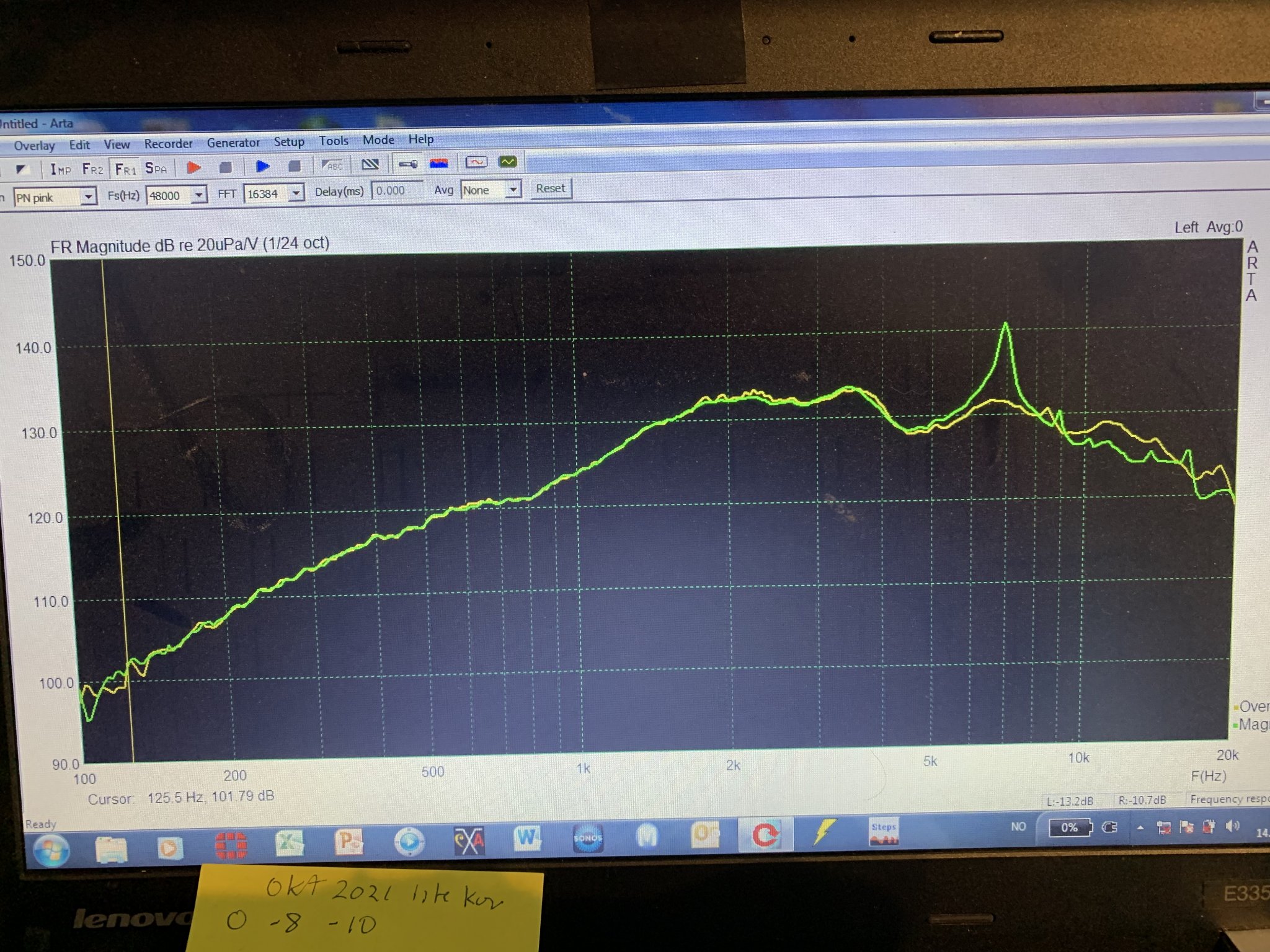

When i pulled out the damage in one of the tweeters with a little stick glue on the finger the impedance peak disapeard in both Dats and in ARTAs frequency response despite the small hairline crack of 2 mm.

Another observation is that the alu material is very very thin, hard and brittle compared with ordinary alu domes. That explains why it is diffcult to pull out and that the dents have sharp edges. This material seems to have a quality between aluminium and beryllium and that is thumbs up.

I will send them to Bliesma for service and repair. And we will probably use them in a waveguide.

I wonder how the T34B would sound in a waveguide in company with the TAD's 1201....And we will probably use them in a waveguide.

;-)

When i pulled out the sharp dent in one of the tweeters it got this small thin hairline crack.

But then the impedance measurement got fine and the peak at 6500 Hz disapeared.

Strange.

This it the two tweeters, the one with the peak have still the dent.

Since it so expensive to fix it (freight and VAT to Norway comes in adittion) i will try to fix the other and se if it can be used. Maybee a distortion measurement is required also? Or that it can be used as a supertweeter over 10K?

But then the impedance measurement got fine and the peak at 6500 Hz disapeared.

Strange.

This it the two tweeters, the one with the peak have still the dent.

Since it so expensive to fix it (freight and VAT to Norway comes in adittion) i will try to fix the other and se if it can be used. Maybee a distortion measurement is required also? Or that it can be used as a supertweeter over 10K?

The hairline crack may be sonically harmless, or it may even have a damping effect. ScanSpeak deliberately slices their cone diaphragms to introduce a damping of the primary cone resonance, and a slice in a paper cone is very similar to a crack in a metal dome.

If the tweeter measures OK, then I would say it is OK. If the impedance curve, FR curve, and harmonic distortions are the same as original, no worries.

It is possible that the crack will grow as a fatigue crack. It will depend on the stress level in the material right at the crack tip when the tweeter is being driven. If it is low, the crack will not grow. There is no way to know this without a ridiculous level of analysis. So I would say just keep an eye on it. Take a good photo of it now, and compare the crack size in the future.

j.

If the tweeter measures OK, then I would say it is OK. If the impedance curve, FR curve, and harmonic distortions are the same as original, no worries.

It is possible that the crack will grow as a fatigue crack. It will depend on the stress level in the material right at the crack tip when the tweeter is being driven. If it is low, the crack will not grow. There is no way to know this without a ridiculous level of analysis. So I would say just keep an eye on it. Take a good photo of it now, and compare the crack size in the future.

j.

- Home

- Loudspeakers

- Multi-Way

- Strange thing happened with Bliesma T34A