Markm

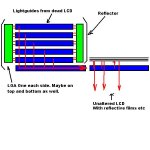

My solution: build a light guide for each turn of the tube out of plexiglass. The lightguide will actually be two pieces of plexi sandwiched. The top piece will be scored on top and in front, the bottom one scored on bottom and at front. I'm hoping this will collect the light from the middle of the coils and redirect it forward through a focusing lense.

Sorry missed that. In a different thread.

They say plexiglas works. I tried some at home and got zilch. Apparently the edges/receiving surfaces have to be polished really well to accept light in the first place, and the light will only stay in the plexi if it enters below a particular angle. Then it stays inside and only comes out a scratch on the smooth surface. I had this brilliant idea of surrounding a fluorescent tube with plexiglas which was sandpapered to allow the light to get in. Trouble is it gets in easy enough, but can also get out. You got to get it into a lightguide and make it stay there for later use.

This might help

Good luck

My solution: build a light guide for each turn of the tube out of plexiglass. The lightguide will actually be two pieces of plexi sandwiched. The top piece will be scored on top and in front, the bottom one scored on bottom and at front. I'm hoping this will collect the light from the middle of the coils and redirect it forward through a focusing lense.

Sorry missed that. In a different thread.

They say plexiglas works. I tried some at home and got zilch. Apparently the edges/receiving surfaces have to be polished really well to accept light in the first place, and the light will only stay in the plexi if it enters below a particular angle. Then it stays inside and only comes out a scratch on the smooth surface. I had this brilliant idea of surrounding a fluorescent tube with plexiglas which was sandpapered to allow the light to get in. Trouble is it gets in easy enough, but can also get out. You got to get it into a lightguide and make it stay there for later use.

This might help

Good luck

Attachments

I've been keeping track of this thread for a while now, i've learned many things and i've heard mention this ALOT,i have an IDEA of what this is but i have no clue on how it looks or what its made of... this MAY be a noob question but....what is a light guide? is there a link to where i can see one?

thanks.

-JimmY-

thanks.

-JimmY-

Light rays always go in straight lines. A lightguide can help it to go around corners, concentrate light or pick up light in one place and move it to another. For example in some electronic equipment you used to have an led on the front panel. Now they put the LED on the circuit board and pipe the light to the front. No long wires needed.

Try

Google lightguide

Google lightguide car

Google lightguide test equipment

Try

Google lightguide

Google lightguide car

Google lightguide test equipment

Remp, that is an amazing setup using the LOA's and the old light guides. 🙂

lol. I'm not sure if it would work or not, but just looking at it makes me think it should win a Rube Golberg design. 🙂

I've seen a couple stacks of 5 broken laptop LCD's go for $10 or $15 on ebay over the past couple days...

I wonder if that would be a good source for these things.

Anyway, I'm still waiting on my LED's, although I'm beginning to think more and more that the array of CCFL's is a really good way to go. 🙂

I wonder if I can persuade my mom to send me $300 so I can buy a new expensive computer flat-panel monitor, a bunch of surplus flourescents, a bunch of components I solder together to drive the flourescents, all with no guarantee I won't snap a cable on the LCD and send it all down the drain (not to mention the $250 or so that I've already sunk into this project)... and I don't even watch TV!

Gyah. I need to work for a company like Lockheed Martin or IBM or Bell Labs who'll give me a budget to invent or improve things with, and let me go play. Homework and working for money just get in the way of my spare-time projects.

--Clint

lol. I'm not sure if it would work or not, but just looking at it makes me think it should win a Rube Golberg design. 🙂

I've seen a couple stacks of 5 broken laptop LCD's go for $10 or $15 on ebay over the past couple days...

I wonder if that would be a good source for these things.

Anyway, I'm still waiting on my LED's, although I'm beginning to think more and more that the array of CCFL's is a really good way to go. 🙂

I wonder if I can persuade my mom to send me $300 so I can buy a new expensive computer flat-panel monitor, a bunch of surplus flourescents, a bunch of components I solder together to drive the flourescents, all with no guarantee I won't snap a cable on the LCD and send it all down the drain (not to mention the $250 or so that I've already sunk into this project)... and I don't even watch TV!

Gyah. I need to work for a company like Lockheed Martin or IBM or Bell Labs who'll give me a budget to invent or improve things with, and let me go play. Homework and working for money just get in the way of my spare-time projects.

--Clint

Most laptops use a triangle shaped lightguide.

Plus I do not think stacking them will work, and the thickness would be really incredible. The one on my LCD is about 3/8 of an inch thick. (just a guess)

Clint - If I had any optics at all I'd let you know. Think I'll see about getting a fresnel in the next few days.

I replaced the film in the backlight with the stuff I got from 3M.. they are right, it works quite well. Even without their fancy reflective stuff for the back it is very bright.

I think CCFLs may work, or LOAs, or something similarily easy. 🙂

Plus I do not think stacking them will work, and the thickness would be really incredible. The one on my LCD is about 3/8 of an inch thick. (just a guess)

Clint - If I had any optics at all I'd let you know. Think I'll see about getting a fresnel in the next few days.

I replaced the film in the backlight with the stuff I got from 3M.. they are right, it works quite well. Even without their fancy reflective stuff for the back it is very bright.

I think CCFLs may work, or LOAs, or something similarily easy. 🙂

The fresnel I used was a $3 page magnifier from Border's bookstore (might have been Barnes & Nobles). That was enough to project an image off my single CCFT-laptop screen in a perfectly dark room.

--Clint

--Clint

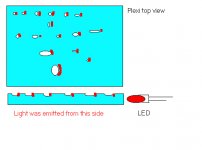

LED Plexi glass experiment

Sorry I have no Pictures

I got some 1/8 plexiglass and bought a cheap LED and board

I drilled holes in no kind of pattern just scattered, then I placed an led to the edge of the plexi glassand wala i had TIF but it was not signifigantly bright as my led and was hard to tell with red anyhow so i experiment more i placed white sheet of paper behind the glass (drilled side) and my results were closer to my led. Also the side which was closer of each drilled radius was the brightess part of the radius. so i think i need to either put LED on each side of plexi or polish the crap of them or get some kind of reflective tape or film for the sides. Or do you think spray painting all surfaces except where light goes in and light goes out.

Next may try it on window glass.

I hope communicated this well.

Sorry I have no Pictures

I got some 1/8 plexiglass and bought a cheap LED and board

I drilled holes in no kind of pattern just scattered, then I placed an led to the edge of the plexi glassand wala i had TIF but it was not signifigantly bright as my led and was hard to tell with red anyhow so i experiment more i placed white sheet of paper behind the glass (drilled side) and my results were closer to my led. Also the side which was closer of each drilled radius was the brightess part of the radius. so i think i need to either put LED on each side of plexi or polish the crap of them or get some kind of reflective tape or film for the sides. Or do you think spray painting all surfaces except where light goes in and light goes out.

Next may try it on window glass.

I hope communicated this well.

Attachments

Plexi Led

Dont know if I relayed it or not the whole radius was lit up just the side facing the led was brighter

Dont know if I relayed it or not the whole radius was lit up just the side facing the led was brighter

I don't know if this will work for LCD backlights, but it certainly works for sidelit plexiglass display panels.

Just lightly sand the side of the panel that you want the light to come out of, and leave the other side shiny. If you use a belt sander, or hand sand in straight lines perpendicular to the light source it could work even better, (from what I remember of my school physics)🙂

Just lightly sand the side of the panel that you want the light to come out of, and leave the other side shiny. If you use a belt sander, or hand sand in straight lines perpendicular to the light source it could work even better, (from what I remember of my school physics)🙂

What about this?

Someone mentioned imbedding the lightsource inside the light guide. What about using liquid acrylic resin to incase a LOA or even a few CCFLs into your light guide?

I've used several types of liquid acrylic to build numerous goodies and it turns out crystal clear and glass smooth nearly each time (clean your containers with alcohol fellas).

-HollywoodBob

Someone mentioned imbedding the lightsource inside the light guide. What about using liquid acrylic resin to incase a LOA or even a few CCFLs into your light guide?

I've used several types of liquid acrylic to build numerous goodies and it turns out crystal clear and glass smooth nearly each time (clean your containers with alcohol fellas).

-HollywoodBob

Crash What CCFT's are you using and where did you buy them from?...

My intention is to squeeze as much light bhind a 4" LCD slapped directly on a projection lens in the smallest possible space 🙂

I found this but it doesn't seem nearly bright enough to significantly improve my output.

though it's been mentioned, I simply can't conceptualize how it would be possible to stack these. seems like if you're using a lightguide (or film) you're kind of stuck with the single source. Please correct me if I'm wrong.

Oh and I threw an e-mail to 3m as well about samples... hopefully they'll come through since this is basically a pipe dream...

Hey, think we can get these guys to sell in ones and two's?

My intention is to squeeze as much light bhind a 4" LCD slapped directly on a projection lens in the smallest possible space 🙂

I found this but it doesn't seem nearly bright enough to significantly improve my output.

though it's been mentioned, I simply can't conceptualize how it would be possible to stack these. seems like if you're using a lightguide (or film) you're kind of stuck with the single source. Please correct me if I'm wrong.

Oh and I threw an e-mail to 3m as well about samples... hopefully they'll come through since this is basically a pipe dream...

Hey, think we can get these guys to sell in ones and two's?

the CCFLs that I have right now came with my panel... somebody posted a source for some CCFLs for about 2 dollars or 2.50 each... I am not sure if enough light can be had from them or not... I am going to get a fresnel this week.. have been lazy so I have not picked one up yet. Then I'll see what I can project with what I have.. going to try a few different things to see how bright I can get it.

Where is everybody?

Whats happening with this very facinating thread? Is eveybody out experimenting whats been discussed.

Where is Remp, it says his account is disabled.

Exipnos.

Whats happening with this very facinating thread? Is eveybody out experimenting whats been discussed.

Where is Remp, it says his account is disabled.

Exipnos.

Re: Where is everybody?

Greetings, our friend remp has asked to be struck from the DIY register. I'm afraid it's our loss 🙁 For reasons of his own, his input will no longer be enjoyed by this forum. I haven't yet coresponded with him personally since his withdrawl of membership, I'll be catching up with him soon 😉 I hope this thread keeps an active interest, I'd like to see it's successfull conclusion.

I'd be happy to pass on any well wishes to our friend remp.

zardoz

Greetings, our friend remp has asked to be struck from the DIY register. I'm afraid it's our loss 🙁 For reasons of his own, his input will no longer be enjoyed by this forum. I haven't yet coresponded with him personally since his withdrawl of membership, I'll be catching up with him soon 😉 I hope this thread keeps an active interest, I'd like to see it's successfull conclusion.

I'd be happy to pass on any well wishes to our friend remp.

zardoz

exipnos said:Whats happening with this very facinating thread? Is eveybody out experimenting whats been discussed.

Where is Remp, it says his account is disabled.

Exipnos.

I was playing around with my LCD and a fresnel just a few minutes ago and if I take all 6 of my CCFTs from the backlight and cluster them together I can get a picture on the ceiling that is easily seen. I will wait now until it gets dark outside and try some more... it is pretty light in here right now.. 4 o'clock so I can still read easily w/o a light. In the next couple of hours it should be dark enough for me to be able to tell HOW bright the picture really is.

Please keep this thread alive, cause I'm very interested in some results!

ps. remp won't post here for a while but you guys are not gonna tell me that it means that this thread is automaticaly 'dead' then.

Best wishes everybody

ps. remp won't post here for a while but you guys are not gonna tell me that it means that this thread is automaticaly 'dead' then.

Best wishes everybody

How genius HollywoodBob!

I suggested in suspending/ embedding the light into a light guide, but had no idea how to do that, nor the equipment. I had given up on that method, but now that i know there's n acryllic which can form into a crystal clear goodness, it may very well work!! I just have to figure out where and for how much I can get it. Let me know what I may need to know about it as I have absolutely the faintest idea about it. Tell me more about end results, etc- surface quality... can it absorb heat without deforming? I was considering remp's method of stacking light guides. I have taken apart 2 15" lcd monitors, and both frickin things have the darn short ribbon cables with circuits right behind. I was thinking of buying a 1/4" huge sheet of lexan or plexiglass (lexan seems crisper, more glass-like), and then cutting it into many sheets equalling the dimeanisions of the display. I would then stack them, and wrap up them in aluminum, or spray them with siver paint, except the exit and entrance ports. However, this is on hold untill i get the fatty on the liquid acryllic.

I promise to get some high-res shots as soon as I get some results. Keep this ball rolllin!

I suggested in suspending/ embedding the light into a light guide, but had no idea how to do that, nor the equipment. I had given up on that method, but now that i know there's n acryllic which can form into a crystal clear goodness, it may very well work!! I just have to figure out where and for how much I can get it. Let me know what I may need to know about it as I have absolutely the faintest idea about it. Tell me more about end results, etc- surface quality... can it absorb heat without deforming? I was considering remp's method of stacking light guides. I have taken apart 2 15" lcd monitors, and both frickin things have the darn short ribbon cables with circuits right behind. I was thinking of buying a 1/4" huge sheet of lexan or plexiglass (lexan seems crisper, more glass-like), and then cutting it into many sheets equalling the dimeanisions of the display. I would then stack them, and wrap up them in aluminum, or spray them with siver paint, except the exit and entrance ports. However, this is on hold untill i get the fatty on the liquid acryllic.

I promise to get some high-res shots as soon as I get some results. Keep this ball rolllin!

Liquid glass

Sweetrobot,

What you want to look for is something called clear casting resin, or "artificial water" it's a binary polymer that when dry is hard as plexi glass and crystal clear. It'll run you about 35$ a gallon. It's used for taxidermy to create realistic water effects.

Or if you want to do it on the ultra cheap just to test, get a sheet of acrylic, and smash it into little bits. Then take the bits and put them in a nice clean jar. Pour in some acetone, just til the plexi bits are covered, and wait 24 hours. The acetone will desolve the bits into a goo. You'll want to let it stand for a little while until it starts to get stiff, I'm sure you want it pourable so this part can get tedious, just stick to it and keep checking. Once it's pourable, get your light and go to town. As it goes the acetone will evaporate and it'll solidify. I've used this method as filler on computer cases and I know it works good but I'm not sure about the large scale aspect.

As for heat sensitivity, if your light will melt a sheet of plexiglass, it'll melt this stuff since it's just the same only not mixed and extruded before you buy it.

Let me know how it turns out.

Everyone,

Has anyone trired the "P" style light guide idea but coating the outer edge with a reflective coating facing inward, then sand blasting the inside to let the light out where you want it?

-HollywoodBob

Sweetrobot,

What you want to look for is something called clear casting resin, or "artificial water" it's a binary polymer that when dry is hard as plexi glass and crystal clear. It'll run you about 35$ a gallon. It's used for taxidermy to create realistic water effects.

Or if you want to do it on the ultra cheap just to test, get a sheet of acrylic, and smash it into little bits. Then take the bits and put them in a nice clean jar. Pour in some acetone, just til the plexi bits are covered, and wait 24 hours. The acetone will desolve the bits into a goo. You'll want to let it stand for a little while until it starts to get stiff, I'm sure you want it pourable so this part can get tedious, just stick to it and keep checking. Once it's pourable, get your light and go to town. As it goes the acetone will evaporate and it'll solidify. I've used this method as filler on computer cases and I know it works good but I'm not sure about the large scale aspect.

As for heat sensitivity, if your light will melt a sheet of plexiglass, it'll melt this stuff since it's just the same only not mixed and extruded before you buy it.

Let me know how it turns out.

Everyone,

Has anyone trired the "P" style light guide idea but coating the outer edge with a reflective coating facing inward, then sand blasting the inside to let the light out where you want it?

-HollywoodBob

operation submerge.

i'll try this technique with a cheap bulb. i'll get the casting resin and try right with it, no time to play around with melting, etc. i also have some pics of my lcd and it's parts- cables, light guide panel, and polarising layers. lemme know if you guys want me to post em if u're qurious.

quick question. say i were to make this guide, to seal off the sides, should i use silver/ mirror metalllic paint, or white?

Thx bob, will keep all posted here.

PS, would hardware stores have it, or perhaps orts/ hobby stores?

i'll try this technique with a cheap bulb. i'll get the casting resin and try right with it, no time to play around with melting, etc. i also have some pics of my lcd and it's parts- cables, light guide panel, and polarising layers. lemme know if you guys want me to post em if u're qurious.

quick question. say i were to make this guide, to seal off the sides, should i use silver/ mirror metalllic paint, or white?

Thx bob, will keep all posted here.

PS, would hardware stores have it, or perhaps orts/ hobby stores?

3M Films

First of all would these films work to improve the amount of light entering the LCD for a typical Procjection Panel (Ovaition) when using a MH lamp? Also, those of you who have obtained samples, what number did you call, what did you ask for and home did you present your request on the phone. The reason I ask is I imagine after enough of us start getting the free samples the "free" part of the process will dry up.

First of all would these films work to improve the amount of light entering the LCD for a typical Procjection Panel (Ovaition) when using a MH lamp? Also, those of you who have obtained samples, what number did you call, what did you ask for and home did you present your request on the phone. The reason I ask is I imagine after enough of us start getting the free samples the "free" part of the process will dry up.

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- The Moving Image

- DIY Projectors

- Step into the Light.....