This is intended to be an extension of another thread concerning The Sound Of Silver, except in this case regarding sonics due to differing solder alloys.

So, we are after experiences, opinions and explanations of sonics when using differing solder alloys.

Eric.

Yes, I agree on the above points.

I also reckon that lead and silver do not go well together sonically.

96Tin/4 Silver (96S) solder is fine by my ear, as is SAVBIT Solder (60/38/2 Copper), but I have always found lead/tin solder containing silver to sound overly and un-naturally bright, and to my ear a long term listening additional irritating quality also.

The 96S on first listen sounds a bit dull or something, but on long term listening I find it to be nicely friendly sounding.

The Savbit I find is a cost effective compromise, and very good for pcb reworking.

I also have found standard 60/40 solder from different sources (Aus, European, US, Asian) to sound different also.

Nowadays, Multicore have quite a few lead free alloys, but I have not tried all of them.

So, we are after experiences, opinions and explanations of sonics when using differing solder alloys.

Eric.

Thee are some thermoelectric effects with different solder alloys apparently.

I'm waiting for the day someone begins selling audio gear with the line that the flux in the solder it is made with is from tree sap (it still is isn't it?) that came from trees someone spent time talking to, therefore the trees are more contented leading to a superior sound. 🙄

I'm waiting for the day someone begins selling audio gear with the line that the flux in the solder it is made with is from tree sap (it still is isn't it?) that came from trees someone spent time talking to, therefore the trees are more contented leading to a superior sound. 🙄

There are some thermoelectric effects with different solder alloys apparently.

Any junction of dissimilar conductors will constitute a Fermi junction won't it ?.

Not sure how alloys fit in this - anybody ?.

Anybody here with opinions of their favoured solder ?.

Eric.

Any junction of dissimilar conductors will constitute a Fermi junction won't it ?.

Not sure how alloys fit in this - anybody ?.

Anybody here with opinions of their favoured solder ?.

Eric.

Homegrown......

Is Prince Charles an audiophile ?.

I've read that he talks to his plants, and other vegie growers swear by it too.

I don't understand how they can eat them after forming such a fond relationship with their crop - a bit like eating a pet chicken or pet pig perhaps.

Eric.

Circlotron said:Thee are some thermoelectric effects with different solder alloys apparently.

I'm waiting for the day someone begins selling audio gear with the line that the flux in the solder it is made with is from tree sap (it still is isn't it?) that came from trees someone spent time talking to, therefore the trees are more contented leading to a superior sound. 🙄

Is Prince Charles an audiophile ?.

I've read that he talks to his plants, and other vegie growers swear by it too.

I don't understand how they can eat them after forming such a fond relationship with their crop - a bit like eating a pet chicken or pet pig perhaps.

Eric.

soon somebody will begin to make resistors

with connection wires (leads) that are made by silver.

why settle for copper, if you are into high end (read: high money/high status)

wouldn't surprise me, if somebody already does this

with connection wires (leads) that are made by silver.

why settle for copper, if you are into high end (read: high money/high status)

wouldn't surprise me, if somebody already does this

The audio version of OS-CON capacitors have leads of OFC at

least. Of course, one cannot help wondering if there is any point

at all to this as long as other components do do not have OFC

leads, the PCB does not use OFC and the solder joints are as

they are.

least. Of course, one cannot help wondering if there is any point

at all to this as long as other components do do not have OFC

leads, the PCB does not use OFC and the solder joints are as

they are.

It seems to me that it only makes sense if all the wiring from microphones to loudspeakers is made of pure silver, or at least OFC, and all is soldered with the correct sonically alloys. Oh, don’t forget the mains. Hopefully your favourite singer has pure silver vocal chords then also, mounted with the correct solder alloy.

😱

LOL (sorry can’t help)

😱

LOL (sorry can’t help)

Keep It On Track....

Let's keep all from going off subject, and no derogatory naysaying smart **** stuff thanks.

Frank and I are serious about this subject, and keen to hear some objective, subjective and reasoned observations and discussions here.

Eric.

Let's keep all from going off subject, and no derogatory naysaying smart **** stuff thanks.

Frank and I are serious about this subject, and keen to hear some objective, subjective and reasoned observations and discussions here.

Eric.

SOLDER

Hello guys,

I see the cynics have had their say already....😀

In fact quite the contrary is true.

The purer the metal the more brittle it will get.

One good reason for not buying your silverwires from a jeweler since they need high tensile strength to work it.

Thought I'd set it straight.

For soldering silver correctly you NEED to use solder that contains at least a couple of % silver.

If it doesn't the joint will not be made effectively.

Also it is best practice not to use contacts of differing metals.

(Eric mentioned it already so caveat emptor.)

This is not just my recommendation but an industrial one: manufacturers state this.

Other points to consider are melting point and type of flux it contains.

Silver solder is handled at different temperatures than copper solders so ideally one has to adjust for it by using more heat and time for it to melt and bond properly.

More to follow, 😉

Hello guys,

I see the cynics have had their say already....😀

I thought these days all copper was OFC, as it's easier to roll and stretch (less brittle)?

In fact quite the contrary is true.

The purer the metal the more brittle it will get.

One good reason for not buying your silverwires from a jeweler since they need high tensile strength to work it.

Thought I'd set it straight.

For soldering silver correctly you NEED to use solder that contains at least a couple of % silver.

If it doesn't the joint will not be made effectively.

Also it is best practice not to use contacts of differing metals.

(Eric mentioned it already so caveat emptor.)

This is not just my recommendation but an industrial one: manufacturers state this.

Other points to consider are melting point and type of flux it contains.

Silver solder is handled at different temperatures than copper solders so ideally one has to adjust for it by using more heat and time for it to melt and bond properly.

More to follow, 😉

In the old Tektronix manuals, it used to say that if silver-loaded solder was not used, the silver would be "leeched" from the suface being soldered.For soldering silver correctly you NEED to use solder that contains at least a couple of % silver.

Cheers,

Solubility Constants....

" .....if silver-loaded solder was not used, the silver would be "leeched" from the suface being soldered."

Yes, this is advice for modern SM components also.

Lead/Tin/Silver helps to avoid component metalisation errosion, but sonically is bad IMO.

Standard 60/40 solder will dissolve copper pcb pads too.

Savbit (2% Cu) helps to avoid this.

Take a listen to modern Panasonic/Technics audio gear - sounds wrongly bright to my ear because of Pb/Sn/Ag solder I say.

Eric.

" .....if silver-loaded solder was not used, the silver would be "leeched" from the suface being soldered."

Yes, this is advice for modern SM components also.

Lead/Tin/Silver helps to avoid component metalisation errosion, but sonically is bad IMO.

Standard 60/40 solder will dissolve copper pcb pads too.

Savbit (2% Cu) helps to avoid this.

Take a listen to modern Panasonic/Technics audio gear - sounds wrongly bright to my ear because of Pb/Sn/Ag solder I say.

Eric.

FERMI JUNCTION

Hello,

IMHO fermi junction apply to semi-conductors,not conductors.

So this would not apply to soldering joints.

Junctions of dissimilar metals or electrical contacts between dissimilar metals can cause a Peltier effect.

Again this will not apply to soldered joints even thoughg dissimilar metals are used the solder alloys will bond with the foreign materials (copper,silver) to form a conductive transit aere for electrons to pass through.

Cheers,😉

Hello,

Any junction of dissimilar conductors will constitute a Fermi junction won't it ?.

IMHO fermi junction apply to semi-conductors,not conductors.

So this would not apply to soldering joints.

Junctions of dissimilar metals or electrical contacts between dissimilar metals can cause a Peltier effect.

Again this will not apply to soldered joints even thoughg dissimilar metals are used the solder alloys will bond with the foreign materials (copper,silver) to form a conductive transit aere for electrons to pass through.

Cheers,😉

Re: FERMI JUNCTION

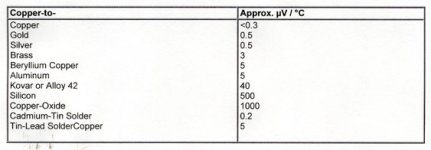

The Seebeck voltage (commonly called the thermal-electric effect) is the result of two dissimilar metals forming a junction. This voltage changes with changes in temperature and is different for different bi-metal pairs. I have attached a table that shows the Seebeck voltage for different metals paired with copper. Yes, solder will create a voltage when paired with copper, although small, and extreamely small for Cadmium-Tin Solder and copper.

Rodd Yamashita

Actually it is the opposite of the Peltier effect. The Peltier effect has to do with the transfer of thermal energy from one metal to the other when a voltage is applied across the bi-metal junction.fdegrove said:Junctions of dissimilar metals or electrical contacts between dissimilar metals can cause a Peltier effect.

Again this will not apply to soldered joints even thoughg dissimilar metals are used the solder alloys will bond with the foreign materials (copper,silver) to form a conductive transit aere for electrons to pass through.

The Seebeck voltage (commonly called the thermal-electric effect) is the result of two dissimilar metals forming a junction. This voltage changes with changes in temperature and is different for different bi-metal pairs. I have attached a table that shows the Seebeck voltage for different metals paired with copper. Yes, solder will create a voltage when paired with copper, although small, and extreamely small for Cadmium-Tin Solder and copper.

Rodd Yamashita

Attachments

The Seebeck voltage....

Very interesting.

This is the very first time I've heard some possible explanation to why some solder sounds better than others...

Actually, ther Seebeck effect is something that is used often. Thermocouples are often used to measure temperature, and generate a voltage differential due to temperature. However, the problem I see with this is that the voltage is DC. (I doubt any of us can hear DC, except when our speaker cones are extended to full range) 🙂

Also, Correct me if I'm wrong here (I may be). But, In a solder joint for the thermocouple effect to be effective, one of the metal junctions needs to be at a different temperature than the other. Going from a copper wire, to solder, to a copper wire should cancel the effect. (That is, unless there is a dramatic temperature gradient across the joint.)

So, that being said, has anyone looked into ther... ...wait, I'll start a new thread on this!

Look for thermal noise thread!

-Dan

Very interesting.

This is the very first time I've heard some possible explanation to why some solder sounds better than others...

Actually, ther Seebeck effect is something that is used often. Thermocouples are often used to measure temperature, and generate a voltage differential due to temperature. However, the problem I see with this is that the voltage is DC. (I doubt any of us can hear DC, except when our speaker cones are extended to full range) 🙂

Also, Correct me if I'm wrong here (I may be). But, In a solder joint for the thermocouple effect to be effective, one of the metal junctions needs to be at a different temperature than the other. Going from a copper wire, to solder, to a copper wire should cancel the effect. (That is, unless there is a dramatic temperature gradient across the joint.)

So, that being said, has anyone looked into ther... ...wait, I'll start a new thread on this!

Look for thermal noise thread!

-Dan

Hi Dan,

Jumping in and out of the Redwings game where Dave' Canucks are kicking our butts.

The Seebeck voltage or thermal-electric effect is present with a bi-metal junction. It is the bi-metal junction itself that produces the voltage (Yes, it is DC), not the difference in temperature (That's the Peltier effect). As the junction temperature changes, the voltage produced by the junction changes (Yes, this is how thermocouples work). Typical thermocouples will produce few mV's + or - at around room temperature. At the upper limits of the thermocouples range (varies for different types) will be in the tens of mV's (30mV or so).

The problems can arise when different parts of the circuit are at different temperatures, possibly affecting the DC offsets. This should only be an issue in the low level circuits where it thermal-electric voltages are larger compared to the signal voltage.

When the junction goes from CU to solder to CU, the voltage will cancel. This will be the case at many of the PCB solder point. But what about the resistor with the ferous leads, or the few places where you use silver or silver coated wire? The thermal-electric voltage will not cancel in this case. There will be a net DC voltage produced by that junction.

So what's the total effect of all the bi-metal junctions in an amp? A contribution to the sound of the amp.

Good or bad? Your guess is as good as mine.

Rodd Yamashita

Jumping in and out of the Redwings game where Dave' Canucks are kicking our butts.

The Seebeck voltage or thermal-electric effect is present with a bi-metal junction. It is the bi-metal junction itself that produces the voltage (Yes, it is DC), not the difference in temperature (That's the Peltier effect). As the junction temperature changes, the voltage produced by the junction changes (Yes, this is how thermocouples work). Typical thermocouples will produce few mV's + or - at around room temperature. At the upper limits of the thermocouples range (varies for different types) will be in the tens of mV's (30mV or so).

The problems can arise when different parts of the circuit are at different temperatures, possibly affecting the DC offsets. This should only be an issue in the low level circuits where it thermal-electric voltages are larger compared to the signal voltage.

When the junction goes from CU to solder to CU, the voltage will cancel. This will be the case at many of the PCB solder point. But what about the resistor with the ferous leads, or the few places where you use silver or silver coated wire? The thermal-electric voltage will not cancel in this case. There will be a net DC voltage produced by that junction.

So what's the total effect of all the bi-metal junctions in an amp? A contribution to the sound of the amp.

Good or bad? Your guess is as good as mine.

Rodd Yamashita

>> Jumping in and out of the Redwings game<<

From michigan are you?

Yeah, I don't know how DC offset affects low level audio signals. You'd probably have to look at each amp, and do a study. I have played with TC's a little, but do not completely understand them. I do konw that they can be fairly low impedance, compared to other things.

I wold think that leakage currents in the circuit board itself could generate similar effects. I know that layout is critical fof some opamps because of board leakage.

-Dan

From michigan are you?

Yeah, I don't know how DC offset affects low level audio signals. You'd probably have to look at each amp, and do a study. I have played with TC's a little, but do not completely understand them. I do konw that they can be fairly low impedance, compared to other things.

I wold think that leakage currents in the circuit board itself could generate similar effects. I know that layout is critical fof some opamps because of board leakage.

-Dan

I use ordinary solder

it is good enough for me

There are a lot of other things I have to change

before coming down/up to the level of my solder-joints

low priority

- but highly interesting to know about

it is good enough for me

There are a lot of other things I have to change

before coming down/up to the level of my solder-joints

low priority

- but highly interesting to know about

Total rubbish

OK fine, let's look at the Seebeck voltages...

5uV/deg C

Let's say the junction gets upto 100 deg C -- .5mV!

You've got to be joking. You could have more of a potential between the legs of the device and what it's soldered to.

I'd love to see someone do a double blind test, all else being equal, and figure out which uses the "better" solder.

OK fine, let's look at the Seebeck voltages...

5uV/deg C

Let's say the junction gets upto 100 deg C -- .5mV!

You've got to be joking. You could have more of a potential between the legs of the device and what it's soldered to.

I'd love to see someone do a double blind test, all else being equal, and figure out which uses the "better" solder.

Let's be happy - that is fun!

Not to do any, is anyhow,

the best way to keep everybody happy 🙂

For matters that are "beyond reasonable doubt", I think it would be a waste of time doing double blind testsschmad said:I'd love to see someone do a double blind test, all else being equal, and figure out which uses the "better" solder.

Not to do any, is anyhow,

the best way to keep everybody happy 🙂

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- Sound of Solder Alloys