Re: Total rubbish

Now take a look at the at the table below. You'll see the T-type thermocouple has a bi-metal junction of CU and CU/NI. This combination has a Seebeck voltage of 45uV/degrees C. CU/NI can be found in many connectors used in audio.

Does this have an impact on the overall sound? My guess would that it does, but by how much, I don't know. It starts to make a case for gold plated connectors. In any case, I think it's worth thinking about. Not quite rubbish.

Rodd Yamashita

I use regular solder myself. As you would have read in my previous post, the Seebeck voltage will usually cancel in a solder joint anyway.schmad said:OK fine, let's look at the Seebeck voltages...

5uV/deg C

Let's say the junction gets upto 100 deg C -- .5mV!

You've got to be joking. You could have more of a potential between the legs of the device and what it's soldered to.

I'd love to see someone do a double blind test, all else being equal, and figure out which uses the "better" solder.

Now take a look at the at the table below. You'll see the T-type thermocouple has a bi-metal junction of CU and CU/NI. This combination has a Seebeck voltage of 45uV/degrees C. CU/NI can be found in many connectors used in audio.

Does this have an impact on the overall sound? My guess would that it does, but by how much, I don't know. It starts to make a case for gold plated connectors. In any case, I think it's worth thinking about. Not quite rubbish.

Rodd Yamashita

Attachments

Re: Total rubbish

Yes, but the difference here is that you can actually *measure* what we are talking about, so it's way, way different from the enchanted power cord type debate. The English scientist Lord Kelvin said,"...when you can measure what you are speaking about, and express it in numbers, you know something about it; but when you cannot express it in numbers, your knowledge is of a meagre and unsatisfactory kind..." The problem is at least scientific, and open to rigorous analysis, so it is not purely subjective. Whether or not it affects the sound though, remains to be settled.schmad said:OK fine, let's look at the Seebeck voltages...

5uV/deg C

Let's say the junction gets upto 100 deg C -- .5mV!

You've got to be joking. You could have more of a potential between the legs of the device and what it's soldered to.

Solder sounds

I have been doing straight wire solder A/Bs off and on for years. All solders sound different and you cannot tell how a solder will sound by the amount of various materials in them. For instance, a particular 6% silver/94% tin solder would be sentenced to forever brightness by the anti-silver brigade. However, this particular brand of solder sounds very soft and even rolled off slightly. Very sweet sounding. Not linear, but very nice. Another time we listened to various 5% silver solders and they all sounded dramatically different. Did you know there have been at least 5 or six different versions of Wonder Solder? The latest one is the best: it has been out for about 2 years.

This is how I do my tests. I take two pieces of wire about 4 inches long (one for each hot on each channel) and solder it from the input jack on the amp to the amp input board. This is the straight wire. Then I take another set of the same wires and cut the wire into four pieces and solder it back together with the solder under test. The system is listened to with the reference piece of wire and then the amp is put into mute (not turned off) and the wires with the solder joints are soldered in place of the straight wires (off course, using the same solder on the ends, duh!). Many times we go back and forth and this test is very revealing of the Sound of the solder. Let's say a particular solder sounds brighter than the wire and another solder sounds duller than the straight wire in these tests. Resoldering any one solder joint of these two solders anywhere in an extremely revealing system leaves no doubt to the validity of the tests.

Some are interested in the measurement game, but I have found that there is no substitute for reality. That is, the truth that your ears tell you. Trust your ears, they don't lie. They have no reason to be "right". They just know. Of course, we have to get our monkey mind out of the way to have a direct experience of anything. Still thy mind and experience your soul. Happy listening.

Ric Schultz

I have been doing straight wire solder A/Bs off and on for years. All solders sound different and you cannot tell how a solder will sound by the amount of various materials in them. For instance, a particular 6% silver/94% tin solder would be sentenced to forever brightness by the anti-silver brigade. However, this particular brand of solder sounds very soft and even rolled off slightly. Very sweet sounding. Not linear, but very nice. Another time we listened to various 5% silver solders and they all sounded dramatically different. Did you know there have been at least 5 or six different versions of Wonder Solder? The latest one is the best: it has been out for about 2 years.

This is how I do my tests. I take two pieces of wire about 4 inches long (one for each hot on each channel) and solder it from the input jack on the amp to the amp input board. This is the straight wire. Then I take another set of the same wires and cut the wire into four pieces and solder it back together with the solder under test. The system is listened to with the reference piece of wire and then the amp is put into mute (not turned off) and the wires with the solder joints are soldered in place of the straight wires (off course, using the same solder on the ends, duh!). Many times we go back and forth and this test is very revealing of the Sound of the solder. Let's say a particular solder sounds brighter than the wire and another solder sounds duller than the straight wire in these tests. Resoldering any one solder joint of these two solders anywhere in an extremely revealing system leaves no doubt to the validity of the tests.

Some are interested in the measurement game, but I have found that there is no substitute for reality. That is, the truth that your ears tell you. Trust your ears, they don't lie. They have no reason to be "right". They just know. Of course, we have to get our monkey mind out of the way to have a direct experience of anything. Still thy mind and experience your soul. Happy listening.

Ric Schultz

GAME OVER?

Hi guys,

Thks Rodd,it was the Seebeck voltage I was looking for,couldn't remember the guys' name.

However these are interesting topics as such but can we agree that if existant at all in soldering joints that this would be of negligable influence?

Surely other factors such as noise in the solder joint and the actual proportions of metal content would be of greater influence?

It would be interesting to read the findings of those who use leadfree solder for instance.

Lead is reported to be a sonics' pigs' ear.

Thanks,😉

Hi guys,

Again this will not apply to soldered joints even thoughg dissimilar metals are used the solder alloys will bond with the foreign materials (copper,silver) to form a conductive transit aere for electrons to pass through.

Thks Rodd,it was the Seebeck voltage I was looking for,couldn't remember the guys' name.

However these are interesting topics as such but can we agree that if existant at all in soldering joints that this would be of negligable influence?

Surely other factors such as noise in the solder joint and the actual proportions of metal content would be of greater influence?

It would be interesting to read the findings of those who use leadfree solder for instance.

Lead is reported to be a sonics' pigs' ear.

Thanks,😉

Whether or not it affects the sound though, remains to be settled.

Gee I guess that the price of a fast food meal and the trouble of finding a local Radio Shack is TOO MUCH TROUBLE. These are the same ridiculous arguments I hear about using decent caps, resistors, and wire. If people have made up there mind already and refuse to make the simple effort of a little experimentation and listening they deserve to listen to the most mediocre system possible. I just can't figure out why they feel inclined to tell us what the rest of us what we can hear........

http://www.radioshack.com/product.a...y_name=CTLG_005_006_001_000&product_id=64-026

read there was no difference, heard no difference, said there was no difference,

Fred

Gee I guess that the price of a fast food meal and the trouble of finding a local Radio Shack is TOO MUCH TROUBLE. These are the same ridiculous arguments I hear about using decent caps, resistors, and wire. If people have made up there mind already and refuse to make the simple effort of a little experimentation and listening they deserve to listen to the most mediocre system possible. I just can't figure out why they feel inclined to tell us what the rest of us what we can hear........

http://www.radioshack.com/product.a...y_name=CTLG_005_006_001_000&product_id=64-026

read there was no difference, heard no difference, said there was no difference,

Fred

Attachments

MONKEY BUSINESS

Hi,

Thanks Rick for sharing the info.

You deliverd before I even asked.😎

Hi Fred,

What took you so long?

I know you're a convinced solder fan,it's one of those things you and me (no doubt others too) do when upgrading pre/amps right?

So it would be fair to say that solder does degrade over time and this is worth a mention.

Redoing all soldering points in audio gear with high quality solder will definetely bring it back to original sonic performance.

It can even be better than before.

Actually,while we're at it,can you describe general procedures for that job?

Thx, 😎

Hi,

Thanks Rick for sharing the info.

You deliverd before I even asked.😎

Hi Fred,

What took you so long?

I know you're a convinced solder fan,it's one of those things you and me (no doubt others too) do when upgrading pre/amps right?

So it would be fair to say that solder does degrade over time and this is worth a mention.

Redoing all soldering points in audio gear with high quality solder will definetely bring it back to original sonic performance.

It can even be better than before.

Actually,while we're at it,can you describe general procedures for that job?

Thx, 😎

Hi,

Tin-lead alloy solder joints will become brittle and will crackle over time due to mechanical and thermal stress (thermal expansion of the leads). This is a well-known phenomenon. When a power transistor is mounted without proper strain relief regarding the leads soldered into a PCB, the joint can become loose after time. I have repaired many audio amps of well-regarded manufactures because the TO220 and TO3 became disconnected after time due to improper mounting. Some good reading about the mechanisms involved:

http://www.espec.co.jp/english/env-test/tech-report/pdf_date/a7/e_35.pdf

Also have a look at the many App.notes from semiconductor manufacturers about mounting power devices. But the internet is full of good articles also.

Tin-lead alloy solder joints will become brittle and will crackle over time due to mechanical and thermal stress (thermal expansion of the leads). This is a well-known phenomenon. When a power transistor is mounted without proper strain relief regarding the leads soldered into a PCB, the joint can become loose after time. I have repaired many audio amps of well-regarded manufactures because the TO220 and TO3 became disconnected after time due to improper mounting. Some good reading about the mechanisms involved:

http://www.espec.co.jp/english/env-test/tech-report/pdf_date/a7/e_35.pdf

Also have a look at the many App.notes from semiconductor manufacturers about mounting power devices. But the internet is full of good articles also.

Gee...

Then, the p2p must be the best as all joints are free to move

and so mechanical and thermal stresses would be released...?!?!

JH

Then, the p2p must be the best as all joints are free to move

and so mechanical and thermal stresses would be released...?!?!

JH

halojoy said:

low priority

- but highly interesting to know about

Yes, I agree!

The more we know about, and can remember when designing anything, the better the design will be!

dan

Re: Solder sounds

My only thought here is inductance. How do you know that it is the solder, and not inductance in the shape of the wire? Unless the wires are exactly the same shape, can you be sure that there are no inductance chagnes. If you read curcuit modeling for high frequency RF, you'll find that inductance is very important. Many of the new model software packages take into account the length, and shape of wire/traces to accuratley model inductance. Even bend in the wire is treated as it's own inductor.

My other thought is that if the amp board is warmer than the termials, you may get a larger DC offset, because of a thermal gradient in the wire itself (thermocouple effect again). Is it possible that a sub mV offset on the input could bias the amp differently? (settting the amps output 0 to be not exactly at DC ground) Depends on if the amp is AC or DC coupled, I guess.

I'm not doubting you can hear a difference, I'm just looking for a logical explanation. (In all fairness, I also believe things that I cannot prove, but know to be true. )

Still, very intersting!

-Dan

Ric Schultz said:

This is how I do my tests. I take two pieces of wire about 4 inches long (one for each hot on each channel) and solder it from the input jack on the amp to the amp input board. This is the straight wire. Then I take another set of the same wires and cut the wire into four pieces and solder it back together with the solder under test. The system is listened to with the reference piece of wire and then the amp is put into mute (not turned off) and the wires with the solder joints are soldered in place of the straight wires (off course, using the same solder on the ends, duh!). Many times we go back and forth and this test is very revealing of the Sound of the solder. Let's say a particular solder sounds brighter than the wire and another solder sounds duller than the straight wire in these tests. Resoldering any one solder joint of these two solders anywhere in an extremely revealing system leaves no doubt to the validity of the tests.

Ric Schultz

My only thought here is inductance. How do you know that it is the solder, and not inductance in the shape of the wire? Unless the wires are exactly the same shape, can you be sure that there are no inductance chagnes. If you read curcuit modeling for high frequency RF, you'll find that inductance is very important. Many of the new model software packages take into account the length, and shape of wire/traces to accuratley model inductance. Even bend in the wire is treated as it's own inductor.

My other thought is that if the amp board is warmer than the termials, you may get a larger DC offset, because of a thermal gradient in the wire itself (thermocouple effect again). Is it possible that a sub mV offset on the input could bias the amp differently? (settting the amps output 0 to be not exactly at DC ground) Depends on if the amp is AC or DC coupled, I guess.

I'm not doubting you can hear a difference, I'm just looking for a logical explanation. (In all fairness, I also believe things that I cannot prove, but know to be true. )

Still, very intersting!

-Dan

Pjotr said:Hi,

Tin-lead alloy solder joints will become brittle and will crackle over time due to mechanical and thermal stress (thermal expansion of the leads). This is a well-known phenomenon. When a power transistor is mounted without proper strain relief regarding the leads soldered into a PCB, the joint can become loose after time. I have repaired many audio amps of well-regarded manufactures because the TO220 and TO3 became disconnected after time due to improper mounting. Some good reading about the mechanisms involved:

http://www.espec.co.jp/english/env-test/tech-report/pdf_date/a7/e_35.pdf

Also have a look at the many App.notes from semiconductor manufacturers about mounting power devices. But the internet is full of good articles also.

Hmmmm. Sounds like the old cold solder problem. Usually big devices have poor solders because of the thermal mass they exhibit when soldering. Usually cold solders are seen to be problematic in lower quality equipment, because of poor MRF. Still, I've seen poor joints on high quality stuff too.

However, I've seen very old equipment with very good solder joints, and very new equipment with very poor solder joints. So, in my opinion, it's not the time since the solder, but rather the time it took to solde the joint.

-Dan

BEST POSSIBLE WAY

Hi,

It is always good practice to ensure there is good mechanical contact between components to solder before applying soldering.

In fact a P2P circuit should work perfectly before soldering anything together.

The best possible way to ensure reliability is to use military wire wrapping techniques.

Special tools exist for that but it is a time consuming business.

When soldering most people tend to use way to much solder degrading their circuits in the process.

Cheers,😉

Hi,

Then, the p2p must be the best as all joints are free to move

It is always good practice to ensure there is good mechanical contact between components to solder before applying soldering.

In fact a P2P circuit should work perfectly before soldering anything together.

The best possible way to ensure reliability is to use military wire wrapping techniques.

Special tools exist for that but it is a time consuming business.

When soldering most people tend to use way to much solder degrading their circuits in the process.

Cheers,😉

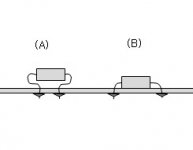

hardwiring

reduces number of solder joints with one (half the number)

and the number of wires (PCB-track) also with one

at every connection it is used

so, if possible that is what I use

if using a different solder alloy can reduce

disturbance to 50%

it will be just as good as hardwiring (almost)

reduces number of solder joints with one (half the number)

and the number of wires (PCB-track) also with one

at every connection it is used

so, if possible that is what I use

if using a different solder alloy can reduce

disturbance to 50%

it will be just as good as hardwiring (almost)

SAMPLE

Hi,

I realise fully that P2P wiring for semi-conductor devices is near impossible to execute.

It lends itself very well to socket based devices such as the vacuum tube.

A pic from a small company that swears by (as I do myself):

Cheers,😉

Hi,

I realise fully that P2P wiring for semi-conductor devices is near impossible to execute.

It lends itself very well to socket based devices such as the vacuum tube.

A pic from a small company that swears by (as I do myself):

An externally hosted image should be here but it was not working when we last tested it.

Cheers,😉

Very informative.jwb said:All of you are off your nut.

Thanks for the contribution,🙄

Rodd Yamashita

I too am struggling with this concept...

The only thing I can think of which explains it is psychoacoustics.

silver=more expensive=better=better sound.

People will actually hear better sound.

This is not a put down, pschoacoustics are probably about 50% of the listening experience, and anything which improves it (like the aforementioned power cables) is justifiable on that basis.

Still, there is justabout zero scientific justification.

I think as engineer types, we resent the idea that psychology can play a huge role in what we hear, and that our observations are far, far from objective.

Just a thought...

The only thing I can think of which explains it is psychoacoustics.

silver=more expensive=better=better sound.

People will actually hear better sound.

This is not a put down, pschoacoustics are probably about 50% of the listening experience, and anything which improves it (like the aforementioned power cables) is justifiable on that basis.

Still, there is justabout zero scientific justification.

I think as engineer types, we resent the idea that psychology can play a huge role in what we hear, and that our observations are far, far from objective.

Just a thought...

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- Sound of Solder Alloys