For the record -

My MK1 Dais turntable is still going strong after 46 years .

I bought it because in engineering terms its very high quality with the correct light oil the inner platter of the deck holding the spindle slowly goes down in a hydraulic action .

No wear is apparent either in the bush or the spindle .

Sadly the Engineer who designed it has died but those buying record decks should first check the engineering qualities before they are mesmerized by the "bells & whistles " advertising .

It has now been superseded by the "Nottingham Analogue Dais " which costs £5000 mine cost (in 1984 ) £450.

Two American owners on vinyl engine really like the engineering , the second saying that a friend who owns one is a NASCAR driver and states --" the bearings on this table best the bearings in a NASCAR .

I am sorry Mark is giving up , if I had it I would have manufactured the parts myself but I live 5000 miles away from him .

Best of luck Mark .

My MK1 Dais turntable is still going strong after 46 years .

I bought it because in engineering terms its very high quality with the correct light oil the inner platter of the deck holding the spindle slowly goes down in a hydraulic action .

No wear is apparent either in the bush or the spindle .

Sadly the Engineer who designed it has died but those buying record decks should first check the engineering qualities before they are mesmerized by the "bells & whistles " advertising .

It has now been superseded by the "Nottingham Analogue Dais " which costs £5000 mine cost (in 1984 ) £450.

Two American owners on vinyl engine really like the engineering , the second saying that a friend who owns one is a NASCAR driver and states --" the bearings on this table best the bearings in a NASCAR .

I am sorry Mark is giving up , if I had it I would have manufactured the parts myself but I live 5000 miles away from him .

Best of luck Mark .

Thank you Duncan2

Yep, I'm pretty much over it. The main problem is the cost of restoration.

I have a Denon 790 DD table, which isn't much to look at, and it's probably older tha this Sota, but it runs strong, no problems. Doesn't sound the same, but whatever...

Yep, I'm pretty much over it. The main problem is the cost of restoration.

I have a Denon 790 DD table, which isn't much to look at, and it's probably older tha this Sota, but it runs strong, no problems. Doesn't sound the same, but whatever...

Yesterday I bought a 1984 Sapphire motor. It’s the same motor as mine, but wired slightly differently. It’s pulley is about 1.5 times larger than mine, but it turns slower. Larger puller means that it is actually working harder than mine. I couldn’t just connect it to Cosmos control, so I used an outboard power supply. And wow figures went down right away! I could barely hear any. So my motor is kaput. Which gives me hope, yet again: if wow almost went away with this bearing, perhaps it will go down even more with rebuilt bearing. And better motor will certainly improve it even more.

Since I didn’t write it in the existing circuit yet, I couldn’t connect the vacuum. And what a difference! I can never listen to recotds again without vacuum. I think that a good clamp and perifery ring do give some improvement, but I doubt they provide this much improvement.

Since I didn’t write it in the existing circuit yet, I couldn’t connect the vacuum. And what a difference! I can never listen to recotds again without vacuum. I think that a good clamp and perifery ring do give some improvement, but I doubt they provide this much improvement.

Hi marknoir,

Quite a challenge you have on your hands.

Have you measured the old motor for any pulley or shaft runout?

Purely mechanical error rather than some electronic drive issue.

After reading through this and your up and down W/F measurements it really seemed to me to point to the main spindle bearing but I was curious if maybe some pulley runout could also be bringing up the numbers a bit.

The new motor does seem promising-

Dave

Quite a challenge you have on your hands.

Have you measured the old motor for any pulley or shaft runout?

Purely mechanical error rather than some electronic drive issue.

After reading through this and your up and down W/F measurements it really seemed to me to point to the main spindle bearing but I was curious if maybe some pulley runout could also be bringing up the numbers a bit.

The new motor does seem promising-

Dave

Hope it's OK I'm jumping late into this thread. I have exactly the same experience with SOTA lubrication. When I disassembled, mine appeared to have used Phil Woods Tenacious Oil, a bicycle toolbox staple. I substituted Superlube 51004 high viscosity synthetic to good result.After I've replaced all the electrolytics, and re-lubed main bearing with PTFE grease on top, and light PTFE on shaft, wow/flutter actually became worse. W/f was hovering just below .2% before, now it closer to .3%.

If I may ask, what software and test record are you using to measure wow/flutter?

There's a seller on fleabay selling sapphire discs to replace the one in the platter. I bought one but have no idea how one would go about the surgery to perform the exchange (anyone here tried it?)

I'm in a similar place with a Vacuum Star in need of TLC. SOTA are quoting a price high enough that it doesn't make sense to repair, but to replace. That leaves me considering whether to buy another SOTA (after 30 years) or something different.

Last edited:

One could use a drill , chuck side ground flat the size of the hole and attach the sapphire disc with some lite contact cement centered on it with the bottom of the disc/hole interface using some JB weld

A narrow chisel and some light tapping to break the old one out is my guess

Utimate centering is not important but flat and square to the bore is

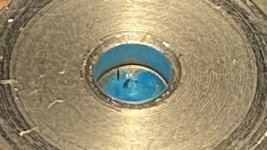

Here’s mine with just a smudge but no pitting which would mean it would only get worse. I believe Marks had this deep pitting resulting in the poor measurements meaning the disc must be replaced

Regards

David

Hi. Long time no hear ))). Yes, mine has a pit/hole smack in the middle. I have-up on this project. I’m using it occasionally. I replaced the Sota belt, which is a smallish diameter and puts a lot of pressure on bearing, with a wide and large aftermarket; I use either light turbine oil, or graphite lock oil. They are very liquid. Anything heavier than that will cause bad wow. I don’t think it’s the sapphire disc in my case as much as the lousy low-torque Pabst (or Papst) motor. The saphire dusc on ebay is huge, it does not fit into the existing hole, but rather lies on top of the old disc. I know, I bought one. Right now, with occasional lubrications, it spins with almost inaudible wow. I got another table since then.

For measurements I use two Apple store sourced programs, rpm pro and wow/flutter meter. I would sell this Cosmos if somebody wanted it.

For measurements I use two Apple store sourced programs, rpm pro and wow/flutter meter. I would sell this Cosmos if somebody wanted it.

Thanks for the reply! I'm thinking the 20-year-old belt might be part of the issue here. I put a double-twist between the platter and motor and DIN-weighted W+F dropped from .15% to about .07%, so in this case, a little tension actually helped.

I'm curious - where did you source the non-Sota belt?

I'm curious - where did you source the non-Sota belt?

If I could get my Cosmos down to even 0.15 I’d be happy. I think I should just sell it as is our part it out. They sell belts on ebay and Amazon, you just measure your old.

marknoir,

May I suggest you go over to Audiokarma Forum. Audiokarma.org Home Audio Stereo Discussion Forums

A long shot for sure but see if they can help you. On the bright side, you learned a hell of a lot about turntables. Maybe with the parts from the Cosmos you make a diy turntable.

Anybody have experience with current SOTA turntables? There are many fans of SOTA. Sota Turntables – Full-line of U.S. made turntables and accessories

May I suggest you go over to Audiokarma Forum. Audiokarma.org Home Audio Stereo Discussion Forums

A long shot for sure but see if they can help you. On the bright side, you learned a hell of a lot about turntables. Maybe with the parts from the Cosmos you make a diy turntable.

Anybody have experience with current SOTA turntables? There are many fans of SOTA. Sota Turntables – Full-line of U.S. made turntables and accessories

Thx. Been all over that forum. Don’t know anything about new Sotas, except that I can’t afford any ))

Try ditching the tank and running straight off the pump.

Haven't read the thread. We have a new Cosmos

Haven't read the thread. We have a new Cosmos

I’m sort, what are you talking about? What has pump got to do with speed instability, worn bearings or bad sapphire plate? Sorry, I don’t have the dow for a new Cosmos. So out mine goes. I’m using a different table, trouble-free.

Try ditching the tank and running straight off the pump.

Haven't read the thread. We have a new Cosmos

My apologies, I just tried running it without vacuum, and w/f figures went down a lot. Very interesting. In any case, this project is over, just waiting for the right person to come and take it off my hands.

I bought a used unit and couldn't get enough vacuum using the pressure tank so, I ditched the tank and ran it straight off the pump.

That’s a different problem. I rebuilt my vacuum unit. I can get any pressure I want out of it. It works perfectly. But the speed issue, worn bushings, plate and hardened rubber lip.. I’m not touching it.

Update. I got a spare platter which I’m experimenting on. The oilite bushings are worn even worse than mine. I took it apart. There’s a thin acrylic mat with cloth layer on top; it’s glued to the rubber layer, that forms a lip (rubber layer in a platter? Strange to me, because it will isolate the top mat from the rest of the platter); it’s glued to the main platter by two rings of - ready? - double-stick tape. I was able to knock-out the spindle piece easily, you can see the sapphire piece in it. The surface had wear, the dark spots inside are cracks. Seems difficult to replace without some very special tooling. I found some more info on the oilite bushings: they can not be drilled out or otherwise “adjusted” or rimmed for the shaft; they are what they are; but they can be “re-lubed”, and should be, after every 1000 hrs of use. It’s done under vacuum, achieving nearly 100% new oil impregnation, or by boilling in oil at 100 C (90%). Both methods require removing them from the platter, that’s too much work, and would probably damage them, so new ones have to be fitted. All of this work by Sota will cost over a grand, and I can see why.

Attachments

Last edited:

Pics are unfocused from here..

Do you have some pics of the record seal as I have never seen how it looks underneath the acrylic top layer ?

Do you have some pics of the record seal as I have never seen how it looks underneath the acrylic top layer ?

Hi. I can take some pictures. Do you want me to post them here or send them directly to you?Pics are unfocused from here..

Do you have some pics of the record seal as I have never seen how it looks underneath the acrylic top layer ?

- Home

- Source & Line

- Analogue Source

- Sota Cosmos: to restore, or?