Be my guest...I won't get in your way.

It's also in Olson's Acoustical Engineering text, sections 5.29 and 5.30. That's also available online.

Chris

It's also in Olson's Acoustical Engineering text, sections 5.29 and 5.30. That's also available online.

Chris

So if you consider a room corner as a secondary "manifold exponential" horn (i.e., exponential loading isn't necessary for loading, but the math is more straightforward in the Olson article) when a horn-loaded loudspeaker is placed near a room corner--especially one with a large horn mouth--then you might see that there is more gain or loss of throat loading at the off-axis woofer ports with a MEH-type loudspeaker in a room corner than with a direct radiating bass bin.

I am making a start on building these and had a question on this. Has plumbers putty been ok over a longer period of time?When I was testing, I just used inexpensive plumbers’ putty (from about any hardware store) and after getting it where it needed to be, left it in. It’s been ok for over a month now, so I think it will be ok for permanent use.

Also re the ports, is the idea to keep the area approximately constant through the putty or is it expanding somewhat?

I am making a start on building these and had a question on this. Has plumbers putty been ok over a longer period of time?

Also re the ports, is the idea to keep the area approximately constant through the putty or is it expanding somewhat?

If i were to do it again, I'd use something like Rock Hard Water Putty or epoxy putty or bondo or the like (I used water putty on the ported versions). The plumber's putty hasn't given any problem to date, but that may not mean it never will, so no need to risk.

The ports in the horn are considerably smaller than the area leading down into them. Like this --

OK thanks. I'm not sure what a UK equivalent of water putty is (nothing obvious leaps out from a search) so will go with a putty (like Standard Yellow-Grey Milliput - For repairing water and fuel systems, filling dents, modelmaking and much more.)

that sounds more like an epoxy than a putty it will work but it may be harder to work with. the trick with these two part things is not to use too much of the hardener. If you do, then it will set so quickly you won't have time to shape it.

The plumber's putty OTOH never hardens; it can always be reworked. that's both its blessing and its curse

The plumber's putty OTOH never hardens; it can always be reworked. that's both its blessing and its curse

This is the water putty --

Durham's Rock Hard Water Putty

Neat stuff, the 2nd part is water. You keep adding water or powder until you get a workable consistency, then start packing it in. It sets in several minutes, then it is essentially a rock. I once thought about using it to mold waveguides.

Durham's Rock Hard Water Putty

Neat stuff, the 2nd part is water. You keep adding water or powder until you get a workable consistency, then start packing it in. It sets in several minutes, then it is essentially a rock. I once thought about using it to mold waveguides.

milliput seems to be widely used for modelling & sculpting and reportedly has a more clay like consistency which is workable for a decent period of time. I'll find out soon enough anyway.that sounds more like an epoxy than a putty it will work but it may be harder to work with. the trick with these two part things is not to use too much of the hardener. If you do, then it will set so quickly you won't have time to shape it.

The plumber's putty OTOH never hardens; it can always be reworked. that's both its blessing and its curse

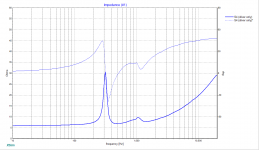

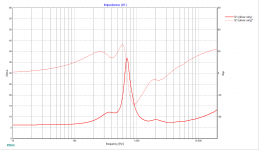

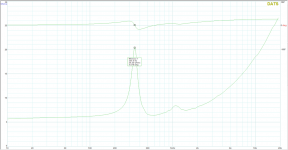

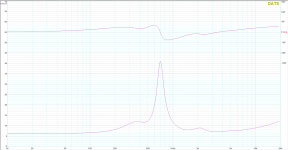

I got the drivers mounted on the horn and plan to take some (no XO) measurements this weekend. I have measured Z on the horn already. Do you have any pics of that data from your original design? It would be nice to cross check against that as I guess that is the best way to tell the way the drivers are mounted is good.

- Home

- Loudspeakers

- Multi-Way

- Small Syns