Would be this amp (the arcwelder) suitable to power a peerless 830500 subwoofer? Anybody use it in that way? Or maybe advice for another amp.

Would be this amp (the arcwelder) suitable to power a peerless 830500 subwoofer? Anybody use it in that way? Or maybe advice for another amp.

Overkill , Just 3 pair outputs and a lower (45-0-45 Vac) trafo for 60 volt

rails would push the peerless to it's limits.

You could even drop the input stage voltage in the cap multipliers to

limit the acrwelder output to a safe level.

All 5 pairs (with 5 pair MT-200 sanken outputs) would most likely push the 500W

subs all the way.

For instance , Dayton Audio UM12-22 12" Ultimax DVC Subwoofer 2 ohms Per Coil

This sub ... wire the 2R DVC in series , 70V rails , 5 pair of the big sankens.

Scary....

PS - for the peerless I would use the arcwelder ... for 500W subs - I would go Class D. Class D could go inside

the sub enclosure , just the plate of the amp could be the heatsink. A 250W arcwelder would have a managable

external heatsink 250mm x 100mm.

OS

Last edited:

Which version of the slewmaster is better distortion wise the EF3 or the Arc Welder edition? What is the difference?

All are EF3.

The smaller 2/3 pair versions would most likely have more distortion with

2/4R loads because of current limitations.

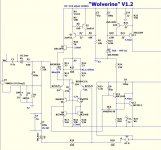

The "arc welder" had massive 20A traces/5 pair , hence the name. At >10A+,

just the layout could increase/decrease THD.

Otherwise , all versions are identical.

If you want go all the way , Arcwelder + 5 pair Sanken MT-200 230W BJT +

1000VA 60-0-60 trafo + 100K uf caps - drives the biggest subs out there !!

OS

The smaller 2/3 pair versions would most likely have more distortion with

2/4R loads because of current limitations.

The "arc welder" had massive 20A traces/5 pair , hence the name. At >10A+,

just the layout could increase/decrease THD.

Otherwise , all versions are identical.

If you want go all the way , Arcwelder + 5 pair Sanken MT-200 230W BJT +

1000VA 60-0-60 trafo + 100K uf caps - drives the biggest subs out there !!

OS

Van I use 7 pairs? I have a big 5U case from modushop and I want to make more use of those big heatsinks. I already have NJW0281 and 0302

Van I use 7 pairs? I have a big 5U case from modushop and I want to make more use of those big heatsinks. I already have NJW0281 and 0302

You could use 10 pairs !

I did a 7 pair version recently +\- 86 vdc rails.

Wow, Holy Smokes!! What IPS did you use?

Spooky. The only smoke was from the 200 watt dummy load resistor.

i dip my dummy loads in a tub full of water, steam can be seen rising...

I did a 7 pair version recently +\- 86 vdc rails.

Nice work evanc!

Can you share gerbers for this Monster?

Thanks.

Thimios

Thimios,

Hello my friend. For this amp I used two arc welder boards per channel. I cut one off to add two more pair of outputs to the standard five pair board.

Harry,

Yes, the two heat sinks make a tunnel with the fan in the back and the vent in the front.

Hello my friend. For this amp I used two arc welder boards per channel. I cut one off to add two more pair of outputs to the standard five pair board.

Harry,

Yes, the two heat sinks make a tunnel with the fan in the back and the vent in the front.

- Home

- Amplifiers

- Solid State

- Slewmaster - CFA vs. VFA "Rumble"