Is it because of the series 4.7mH inductor why Volvotreter has used Le=5.85mH in Hornresp simulation or should it be 0.36mH (for the old W6-1139SG model, or 0.34mH for the W6-1139SIF, both quite low inductances anyway making the FR look quite bad) instead?

What part of the frequency response and performance suffers first as you use drivers with less and less motorforce (and worse Qes) in the expanding path qw resonator shapes(tapped ‘horn‘)?

This is such an overdamped simulation that reality will sound very disappointing and begs for a bigger TL/etc ??34Hz THorn v3

View attachment 1337548 View attachment 1337549

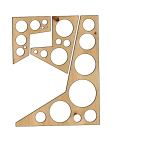

In the Cad model above, If sides aren't fitted over the flare, then it models as a TL with 1/3 offset and smaller bandwidth but lower tune. Anywhere from 20-40Hz can be tuned, changing segments in the template. Even 160 Sd seems best for this low Vas driver, no taper. I will be building that to break it in and then take T/S. But off-topic as doesn't use the TH function

View attachment 1337572 View attachment 1337574

Anyway, that's enough about these. Don't think they qualify. The PRV driver sim looks good

Very difficult to imagine the effects on a driver that only wants 16L behind it. Soon come. I need to find a way to record low bass to present hereThis is such an overdamped simulation that reality will sound very disappointing and begs for a bigger TL/etc ??

What suggests it only ‘wants 16 liters ‘ behind it? I don’t think the suspension stiffness is a good metric for sizing a horn or qw pipe in this case ?

Last edited:

Hey all.

I am planning on building two of the SS15 shortly, I have a lot of ply offcuts at work and was wondering if it's worth making a 3 or 4 sided horn extension that could be clipped on the exit and extend the horn length...

Perhaps the extension panels could be u clipped from each other and packed flat, or even hinged...

any thoughts welcome.

Cheers

I am planning on building two of the SS15 shortly, I have a lot of ply offcuts at work and was wondering if it's worth making a 3 or 4 sided horn extension that could be clipped on the exit and extend the horn length...

Perhaps the extension panels could be u clipped from each other and packed flat, or even hinged...

any thoughts welcome.

Cheers

Phil B thought it was worth doing:I am planning on building two of the SS15 shortly, I have a lot of ply offcuts at work and was wondering if it's worth making a 3 or 4 sided horn extension that could be clipped on the exit and extend the horn length...

Perhaps the extension panels could be u clipped from each other and packed flat, or even hinged...

I posted this over on the Singlesheet Challenge thread but seems relavent here...

Our 2 x SS15 TH`s use extenders ( barn doors) which clamp to the two boxes ... They work very well as the plots from REW below show.. smoothing out the rsponse and extending the low corner a few hz.

And here`s how it all bolts together...

...

...

Our 2 x SS15 TH`s use extenders ( barn doors) which clamp to the two boxes ... They work very well as the plots from REW below show.. smoothing out the rsponse and extending the low corner a few hz.

And here`s how it all bolts together...

Hiya

Yep we added extensions and they work great, and are still going ! You can find out about them at our website... DiY HiFi

Ta

.p.

Yep we added extensions and they work great, and are still going ! You can find out about them at our website... DiY HiFi

Ta

.p.

I knocked up a 3d Model of SS15 from the metric plans.

Included the original in dxf format + a revised dxf with a few cleaned up cuts and overhangs.

Most cnc's can import dxf files if anybody needs to use them, but double check the woofer cut out size and everything else just in case.

Final angle cuts will be done on a panel saw..

Also included a Fusion 360 model.

Change the file extensions' from .txt to .dxf and .f3z to view/use

Cheers

Included the original in dxf format + a revised dxf with a few cleaned up cuts and overhangs.

Most cnc's can import dxf files if anybody needs to use them, but double check the woofer cut out size and everything else just in case.

Final angle cuts will be done on a panel saw..

Also included a Fusion 360 model.

Change the file extensions' from .txt to .dxf and .f3z to view/use

Cheers

Attachments

Hey Phil, I could find many details on the extension on the website, do you have any approx dimensions etc listed that I missed?Hiya

Yep we added extensions and they work great, and are still going ! You can find out about them at our website... DiY HiFi

Ta

.p.

Hiya. I've had a dig and can't find our original cut sheet ! I'll go dig them out of the trailer and measure them up. If you want more info on our build I have a thread running over on Speakerplans for more info.... https://forum.speakerplans.com/th-unity-horn-solar-sound-system_topic63191_page1.htmlThanks Art and Phil B. Love the website and setup Phil, very inspiring!

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge