A few things:

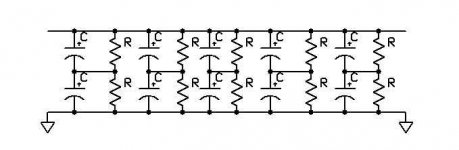

First, you probably don't want the first filter cap to be all that huge. Big input cap = high ripple currents = bad juju. 47u (four in series parallel) is more than adequate in that spot. Save the others for use downstream.

Second, you only need to have one set of resistors to balance the voltage. All of the "middle" junctions are at the same potential so can be connected together. That will simplify things greatly.

Third, the equalizing resistor values aren't too critical. 100K/2W will be fine.

Fourth, try to use high temperature rated caps.

First, you probably don't want the first filter cap to be all that huge. Big input cap = high ripple currents = bad juju. 47u (four in series parallel) is more than adequate in that spot. Save the others for use downstream.

Second, you only need to have one set of resistors to balance the voltage. All of the "middle" junctions are at the same potential so can be connected together. That will simplify things greatly.

Third, the equalizing resistor values aren't too critical. 100K/2W will be fine.

Fourth, try to use high temperature rated caps.

Ultra high voltages? Haven't worked with those for a while.

Still, I'm rebuilding a sixties guitar amp for a friend- tubes, of course (well, valves actually, since it's English, and so is he, and am I for that matter) and am enjoying working with properly sized components on tag board.

I'm one of the survivors of almost all the stupidities mentioned in previous posts (well, apart from the Van de Graf generator - I wonder where I could find…) and they're probably not going to get me before I reach sixty.

Safety? Silly things. If,like me, you find your teeth the best wire strippers, stop. Sooner or later the other end of a a wire will be connected, and it leaves a horrible taste in your mouth.

Don't sweat, or at least get rid of it while working. Dry skin can survive things sweaty skin would transmit straight into vunerable portions. And don't bleed into the components.

Don't try and mend an amp backstage; Light in quantity and open space are essential, not to mention the relative reliability of the power lines.

Keep tools clean; having insulating sleeves on your cutter handles doesn't do any good if they're covered with oil, swarf and sweat.

I had alove affair with 807s, for a while, and they are more or less guaranteed to go off RF unstable from time to time. It's amazing what can get charged up when that happens (usually just tingles; but knowing the volts kicking around, you tend to get very sensitive ti tingles, and jump. Don't.)

Always unplug things, don't just turn them off.

Remember the Leyden jar; a big output tube can hold quite a lot of charge, even when unplugged from the chassis. When it bites you, don't drop it.

Never agree to repair the power supply of a gas laser with multiple, water cooled, totem pole TO3 transistors.

Know your circuit, and what every point does; it might not prevent you from getting shocks, but at least you'll be able to judge how much of a shock you've just had.

Switch mode power supplies are the work of the devil; assume they're out to get you.

Still, I'm rebuilding a sixties guitar amp for a friend- tubes, of course (well, valves actually, since it's English, and so is he, and am I for that matter) and am enjoying working with properly sized components on tag board.

I'm one of the survivors of almost all the stupidities mentioned in previous posts (well, apart from the Van de Graf generator - I wonder where I could find…) and they're probably not going to get me before I reach sixty.

Safety? Silly things. If,like me, you find your teeth the best wire strippers, stop. Sooner or later the other end of a a wire will be connected, and it leaves a horrible taste in your mouth.

Don't sweat, or at least get rid of it while working. Dry skin can survive things sweaty skin would transmit straight into vunerable portions. And don't bleed into the components.

Don't try and mend an amp backstage; Light in quantity and open space are essential, not to mention the relative reliability of the power lines.

Keep tools clean; having insulating sleeves on your cutter handles doesn't do any good if they're covered with oil, swarf and sweat.

I had alove affair with 807s, for a while, and they are more or less guaranteed to go off RF unstable from time to time. It's amazing what can get charged up when that happens (usually just tingles; but knowing the volts kicking around, you tend to get very sensitive ti tingles, and jump. Don't.)

Always unplug things, don't just turn them off.

Remember the Leyden jar; a big output tube can hold quite a lot of charge, even when unplugged from the chassis. When it bites you, don't drop it.

Never agree to repair the power supply of a gas laser with multiple, water cooled, totem pole TO3 transistors.

Know your circuit, and what every point does; it might not prevent you from getting shocks, but at least you'll be able to judge how much of a shock you've just had.

Switch mode power supplies are the work of the devil; assume they're out to get you.

Hello,

In the links at the end of that message you'll see a 1kilowatt amplifer operating under 5000 volts.

THis ampliifer won the "white lamp shout out" during the last "European Triode Festival 2007" in Biezenmortel (The Netherlands)

http://www.audioasylum.com/audio/tubes/messages/20/201989.html

Best regards from Paris.

Jean-Michel Le Cléac'h

In the links at the end of that message you'll see a 1kilowatt amplifer operating under 5000 volts.

THis ampliifer won the "white lamp shout out" during the last "European Triode Festival 2007" in Biezenmortel (The Netherlands)

http://www.audioasylum.com/audio/tubes/messages/20/201989.html

Best regards from Paris.

Jean-Michel Le Cléac'h

chrispenycate said:

Switch mode power supplies are the work of the devil; assume they're out to get you.

No! there's nothing wrong with switchmode power supplies, it's the work of the devil engineer at fault. I've been using smps for tube applications for 35 years.....luv'em.

richj

Shocks....I want to think in terms of a hospital operating room.

1. Insulate the hands with gloves.

2. See the work, light the workspace. Brilliant light, shielded from the eyes. I like a photographic modeling lamp with barn doors and a cool-running bulb.

3. Organize. Hand tools (and parts) arranged on a shelf under the bench until needed, or well off to the side. Avoid placing them where you will have to reach over the work. Pick the tool for the immediate task, then put it back in place.

4. When the power is on, slow way-waaaay down (I think to line up my movements with the sound of Hal's voice at the end in 2001 Space Odyssey).

patch

1. Insulate the hands with gloves.

2. See the work, light the workspace. Brilliant light, shielded from the eyes. I like a photographic modeling lamp with barn doors and a cool-running bulb.

3. Organize. Hand tools (and parts) arranged on a shelf under the bench until needed, or well off to the side. Avoid placing them where you will have to reach over the work. Pick the tool for the immediate task, then put it back in place.

4. When the power is on, slow way-waaaay down (I think to line up my movements with the sound of Hal's voice at the end in 2001 Space Odyssey).

patch

richwalters said:It's well known in agriculture, the hv electric fence is also used in cow stalls to keep rowdy heads and horns down.

richj

In South Africa they are installed on walls to protect properties from intruders. Living in Ferndale (Randburg, Gauteng, one of northern suburbs of Joburg) in 1999 I made one custom system using horizontal output transformers from computer monitors and with photo cameras around (35 mm film, video cameras were too expensive then), so each discharge caused a camera shot and e-mail to my address with time stamp and information of the place where it happened.

...as the result, I always knew when and where to trim a bush. 😉

Once when a rain started after long dry winter I had to shut it down because some salt on insulators shorted the path. That night was stole n a huge battery from landlord's tractor... That night many yards were robbed. Illegal imigrants could not get jobs then even if they found some because they had to go back to motherlands and obtain work permits there that was impossible for them, so the single option to survive for them was to rob or steal.

Always use HV gloves, I do with anything that is dealing with an electrical current...they have saved me a many of times.

First post on the forum so, hi.

I'm at the age where I need to think about setting myself up with some kind of trade and I was thinking about exploring the possibility of pursuing a career in being a studio tech but after reading this thread I'm seriously having second thoughts. I guess I should think about the thousands of people who work at this stuff every day and I guess most of them make it to the next day, alive. But seriously, can someone offer some words of assurance... please? 😱

I'm at the age where I need to think about setting myself up with some kind of trade and I was thinking about exploring the possibility of pursuing a career in being a studio tech but after reading this thread I'm seriously having second thoughts. I guess I should think about the thousands of people who work at this stuff every day and I guess most of them make it to the next day, alive. But seriously, can someone offer some words of assurance... please? 😱

Hi and welcome🙂

It depends what you call a studio tech. Maintaining equipment in a studio environment rarely exposes you to high voltages, other than mains. Fewer pieces of equipment get opened, but go back to a service center or scrapped.

Of course you must be aware of the safety considerations, but it all gets lumped into the risk assessment that must be considered before taking any action.

It depends what you call a studio tech. Maintaining equipment in a studio environment rarely exposes you to high voltages, other than mains. Fewer pieces of equipment get opened, but go back to a service center or scrapped.

Of course you must be aware of the safety considerations, but it all gets lumped into the risk assessment that must be considered before taking any action.

Thanks for the response. Yeah, I'm mainly interested in the maintenance side of things. I am also interested in the making of fancy gadgets too. But from what you've said it sounds like I will mostly be on the safer side of the design table 🙂

Interconnect shock

Thanks everyone of the post. Literally a life saving infos. I am a newbie. And I've already got shocked in the least expected place. Interconnects. I just turned on my vintage tube gear and tried to disconnect an interconnect with one hand on the chassis and the other on the interconnect plug. It was not a pleasing experience! Now, I even insulate the plugs, heavily!

It was not a pleasing experience! Now, I even insulate the plugs, heavily!

Yaho

Thanks everyone of the post. Literally a life saving infos. I am a newbie. And I've already got shocked in the least expected place. Interconnects. I just turned on my vintage tube gear and tried to disconnect an interconnect with one hand on the chassis and the other on the interconnect plug.

It was not a pleasing experience! Now, I even insulate the plugs, heavily!

It was not a pleasing experience! Now, I even insulate the plugs, heavily! Yaho

Regarding interconnects. I'm a busy person but it is easy to overlook things.

I recently got a nasty jolt connecting my collegues computer Notebook to my Sat receiver to reprogram it. Why ? ? ..The following is a typical event that can happen to anyone. Connecting the notebook charger to the notebook which I spotted had a 2 pin AC cord i.e not earthed, I presumed the charger had no split Y caps. I knew the Sat receiver was effectively hard-earthed through the power amps so I connected the notebook with the RS232 cable at the same time to the Sat receiver, cable in hand to chassis.

So I did a check. Disconnecting the RS232, measuring, I noticed 75VAC on the chassis of the notebook to proper ground which presumably comes from stray static leakages /capacitances within the charger unit. The LV output of modern day chargers is mandatory electrically isolated to the user, so this equipment is plastered with safety approval lables, presumably all is safe. However, close examinating the Line Plug I noticed the centre earth pin was snipped off it......obviously to make it fit foreign sockets ! Substituting a proper cable, the 75V AC problem disappeared.

Facit......when borrowing someone elses equipment.....double check the earths and never assume as Notebook is electrically isolated, especially the flanges of port sockets.

richj

I recently got a nasty jolt connecting my collegues computer Notebook to my Sat receiver to reprogram it. Why ? ? ..The following is a typical event that can happen to anyone. Connecting the notebook charger to the notebook which I spotted had a 2 pin AC cord i.e not earthed, I presumed the charger had no split Y caps. I knew the Sat receiver was effectively hard-earthed through the power amps so I connected the notebook with the RS232 cable at the same time to the Sat receiver, cable in hand to chassis.

So I did a check. Disconnecting the RS232, measuring, I noticed 75VAC on the chassis of the notebook to proper ground which presumably comes from stray static leakages /capacitances within the charger unit. The LV output of modern day chargers is mandatory electrically isolated to the user, so this equipment is plastered with safety approval lables, presumably all is safe. However, close examinating the Line Plug I noticed the centre earth pin was snipped off it......obviously to make it fit foreign sockets ! Substituting a proper cable, the 75V AC problem disappeared.

Facit......when borrowing someone elses equipment.....double check the earths and never assume as Notebook is electrically isolated, especially the flanges of port sockets.

richj

Attachments

In terms of unexpected things at the bench, learning from my mistakes has saved me rework time, not to mention my health. Along with keeping loose conductive items under control, it has proven important to have invested in an isolation transformer and breaker...and never park my bench under a shelf.

I had swapped output transistors in a commercial amplifier, it had the sinks running down the middle, fins pointed at each other, noisy blower on one end. I had it on the bench, open enclosure tilted up with sinks parallel with the surface. When I eased on the power I suddenly got smoke puffs down one output board, all in maybe a second or two. And then that sharp smell of burning F4. One channel gone.

A 5/8-inch nut had apparently fallen off the shelf (located right over the bench) lodged down in the dark there, between the bottom edge of the sink, the bases of components, and the chassis. It was soldered to the component legs and left a surface pit on the sink and chassis. The mains breaker, found not defective, had not tripped. I had not seen the nut in there before applying power and obviously was not keeping an eye on the meter.

I hadn't realized that even a little power can cause damage fast. Maybe others are different, but parts (and tools) have a way of moving around on me - they can hide where I don't expect them. That got me to studying how operating rooms are organized.

I had swapped output transistors in a commercial amplifier, it had the sinks running down the middle, fins pointed at each other, noisy blower on one end. I had it on the bench, open enclosure tilted up with sinks parallel with the surface. When I eased on the power I suddenly got smoke puffs down one output board, all in maybe a second or two. And then that sharp smell of burning F4. One channel gone.

A 5/8-inch nut had apparently fallen off the shelf (located right over the bench) lodged down in the dark there, between the bottom edge of the sink, the bases of components, and the chassis. It was soldered to the component legs and left a surface pit on the sink and chassis. The mains breaker, found not defective, had not tripped. I had not seen the nut in there before applying power and obviously was not keeping an eye on the meter.

I hadn't realized that even a little power can cause damage fast. Maybe others are different, but parts (and tools) have a way of moving around on me - they can hide where I don't expect them. That got me to studying how operating rooms are organized.

Capacitors.

Best to discharge with an exceptionally complicated piece of equipment known as a lightbulb 😀 (here in europe with 220VAC).

Don't want 410V running around on charged caps :S

Best to discharge with an exceptionally complicated piece of equipment known as a lightbulb 😀 (here in europe with 220VAC).

Don't want 410V running around on charged caps :S

For a perfect picture of how NOT to be safe see the bread board system about half way down the page. This was at a Hi-Fi show ( VSAC 2008 ) with lots of people milling around.

http://www.6moons.com/industryfeatures/vsac20082/vsac_3.html

http://www.6moons.com/industryfeatures/vsac20082/vsac_3.html

ARRRGHHH  he is wasting a perfectly good pair of 304's in class A !! sheesh. Them things don't grow on trees any more! He could be getting well over a KW from that pair in AB2 with a decent power supply. Well at least he is not pushing them too hard.

he is wasting a perfectly good pair of 304's in class A !! sheesh. Them things don't grow on trees any more! He could be getting well over a KW from that pair in AB2 with a decent power supply. Well at least he is not pushing them too hard.

But I see your point, someone could die pretty quick on that breadboard. An exposed breadboard like that is for the experienced operator's locked room, not the exposed trade show with people blundering about unawares of the hazards. I did look for a key switch.

- - Key switch anyone? - - could save your loved ones and pets some day.

I'll throw this little link about a finger and 900 volts on the table as well, from the AM FONE board, where tube transmitters reign and 1500V is a very common voltage.

http://amfone.net/Amforum/index.php?topic=15766.0

play safely. Let's all outlive our gear so that our greedy relatives can fight over it.

he is wasting a perfectly good pair of 304's in class A !! sheesh. Them things don't grow on trees any more! He could be getting well over a KW from that pair in AB2 with a decent power supply. Well at least he is not pushing them too hard.

he is wasting a perfectly good pair of 304's in class A !! sheesh. Them things don't grow on trees any more! He could be getting well over a KW from that pair in AB2 with a decent power supply. Well at least he is not pushing them too hard. But I see your point, someone could die pretty quick on that breadboard. An exposed breadboard like that is for the experienced operator's locked room, not the exposed trade show with people blundering about unawares of the hazards. I did look for a key switch.

- - Key switch anyone? - - could save your loved ones and pets some day.

I'll throw this little link about a finger and 900 volts on the table as well, from the AM FONE board, where tube transmitters reign and 1500V is a very common voltage.

http://amfone.net/Amforum/index.php?topic=15766.0

play safely. Let's all outlive our gear so that our greedy relatives can fight over it.

My contribution: Extraordinary care needs to be paid when using inverters instead of transformers. I checked for no B+ at least 10 times before i start soldering in one of my circuits, but i soldered a 4700 uF that held a couple of volts at the input of the inverter and this gave me a 60V shock! If the cap did held more charge it would have been capable of developing full B+.

- Home

- Amplifiers

- Tubes / Valves

- Safety Practices, General and Ultra-High Voltage