Hi all

In the process of optimizing my turntable set-up, I tried a modified version of what Frank Van Alstine suggests in his excellent “Audio Basics” newsletter (March 1982 issue)

link

That is, instead of his suggestion to apply a small amount of damping material between the main cartridge body and the detachable front (removable stylus assy), I applied a small amount of cyanoacrylate glue, so the detachable front is not detachable anymore, but is rigidly fixed to the cartridge body forever.

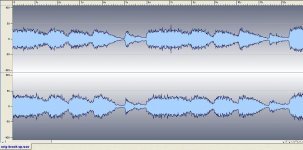

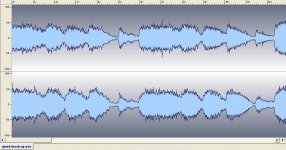

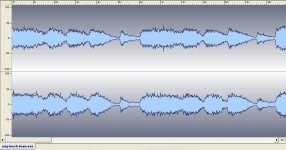

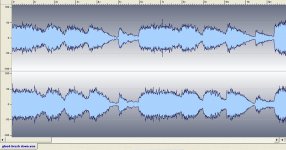

For documentation and analysis, I recorded the output of the RIAA preamplifier from a particular section of a vinyl record, before and after the modification.

My current cartridge is the SHURE M97xE with an 3 position adjustable brush (stylus guard, brush up, brush down).

So, there were 2 recordings before mod.(original, brush up / original, brush down) and 2 recordings after mod. (glued, brush up / glued, brush down). Tracking weight was 1.25gr (brush up) and 1.75gr (brush down) in accordance with cartridge data sheet.

I was expecting some sonic improvements for the reasons explained in the ref. article, but the results surprised me.

There was an increase in the amount of energy transferred from the record grooves down to the coil output, manifested by a 2.7 dB signal increase (peak meter as well as VU meter) at the output of the RIAA preamplifier.

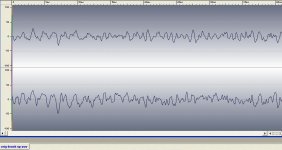

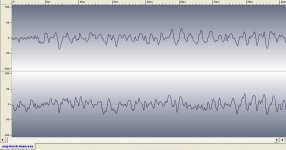

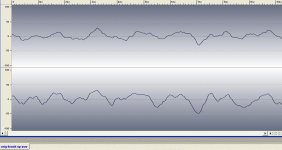

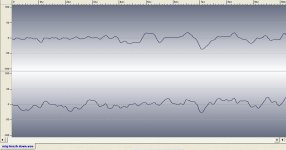

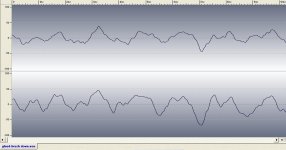

There was a cleaner transfer of this energy documented by sharper, less rounded and more fine rooted amplitude versus time oscillograms. This translates to better sound (with any perceivable adjective added).

In the following attachments you will see sections of the recorded results. They all represent exactly the same music sample. Synchronization of all samples is as exact as feasible (down to 0.1ms).

The first 4 attachments are in 1:630 time scale.

The next 4 are in 1:2 time scale.

The last 4 are in 2:1 time scale.

The 4 recorded samples (WAV audio), although very short (1min, 6 sec., 430ms), can not be downloaded here due to their size (11.1MB each).

I can e-mail them to anyone who is interested, but please tittle your e-mail “M97 recorded” , so I can discriminate from the junk viagra style mail I receive daily (how did they spot my problem actually? )

)

Regards

George

In the process of optimizing my turntable set-up, I tried a modified version of what Frank Van Alstine suggests in his excellent “Audio Basics” newsletter (March 1982 issue)

link

That is, instead of his suggestion to apply a small amount of damping material between the main cartridge body and the detachable front (removable stylus assy), I applied a small amount of cyanoacrylate glue, so the detachable front is not detachable anymore, but is rigidly fixed to the cartridge body forever.

For documentation and analysis, I recorded the output of the RIAA preamplifier from a particular section of a vinyl record, before and after the modification.

My current cartridge is the SHURE M97xE with an 3 position adjustable brush (stylus guard, brush up, brush down).

So, there were 2 recordings before mod.(original, brush up / original, brush down) and 2 recordings after mod. (glued, brush up / glued, brush down). Tracking weight was 1.25gr (brush up) and 1.75gr (brush down) in accordance with cartridge data sheet.

I was expecting some sonic improvements for the reasons explained in the ref. article, but the results surprised me.

There was an increase in the amount of energy transferred from the record grooves down to the coil output, manifested by a 2.7 dB signal increase (peak meter as well as VU meter) at the output of the RIAA preamplifier.

There was a cleaner transfer of this energy documented by sharper, less rounded and more fine rooted amplitude versus time oscillograms. This translates to better sound (with any perceivable adjective added).

In the following attachments you will see sections of the recorded results. They all represent exactly the same music sample. Synchronization of all samples is as exact as feasible (down to 0.1ms).

The first 4 attachments are in 1:630 time scale.

The next 4 are in 1:2 time scale.

The last 4 are in 2:1 time scale.

The 4 recorded samples (WAV audio), although very short (1min, 6 sec., 430ms), can not be downloaded here due to their size (11.1MB each).

I can e-mail them to anyone who is interested, but please tittle your e-mail “M97 recorded” , so I can discriminate from the junk viagra style mail I receive daily (how did they spot my problem actually?

)

)Regards

George

Attachments

Note 1:

This mod is irreversible. The needle can not be removed anymore.

Note 2:

This mode has the risk of rendering the cartridge useless (that is, when glue runs inapropriatelly where the moving part enters the body of the cartridge).

Note 3:

This mod takes just 5 minutes and costs a fraction of the glue cost .

To my ears, it worths the try.

Regards

George

This mod is irreversible. The needle can not be removed anymore.

Note 2:

This mode has the risk of rendering the cartridge useless (that is, when glue runs inapropriatelly where the moving part enters the body of the cartridge).

Note 3:

This mod takes just 5 minutes and costs a fraction of the glue cost .

To my ears, it worths the try.

Regards

George

I forgot to mention it:

On all the diagrams above, upper trace is Left Channel, lower trace is Right Channel.

Regards

George

On all the diagrams above, upper trace is Left Channel, lower trace is Right Channel.

Regards

George

Love this thread

I use the same Shure cart most of the time—works well. As far as a permament change goes, it doesn’t bother me much. In the past I have replaced styluses and never found that it works too well or been successful at all. So as far as I am concerned the cart and stylus is a “marriage” that is made in heaven and hard to dissolve. 😎

I use the same Shure cart most of the time—works well. As far as a permament change goes, it doesn’t bother me much. In the past I have replaced styluses and never found that it works too well or been successful at all. So as far as I am concerned the cart and stylus is a “marriage” that is made in heaven and hard to dissolve. 😎

Hi dvautier

I agree to the "marriage". Besides, the price of an original replacement stylus is not far away from the price of the complete cartridge.

This is a nice you have.

Encouraged by the results of the easy mod, I have progressed as follows:

I trimmed with a fine file all sharp edges of the cartridge and applied with care Cyanoacrylic glue to all the voids present at various points, to force all the external parts to behave as a single mass.

I agree to the "marriage". Besides, the price of an original replacement stylus is not far away from the price of the complete cartridge.

This is a nice you have.

Encouraged by the results of the easy mod, I have progressed as follows:

I trimmed with a fine file all sharp edges of the cartridge and applied with care Cyanoacrylic glue to all the voids present at various points, to force all the external parts to behave as a single mass.

Attachments

Next, I disconnected the cartridge body ground lug from the Blue pin (L gnd). Soldered the cartridge body ground lug to the cartridge body (originally it was loosely attached to it) and with a short wire I brought it in firm electrical contact with the arm shell body.

Regards

George

Regards

George

Attachments

Results of...

Hi George

I admire your initiative but that cyanoacrylite (superglue) makes a heck of a mess😀 I make the things and would have tried a clear epoxy to do the job.

What recording software are you using for those WAV files - Magix AudioLab10?

Still nitpicking (moderators permitting) more elucidating and definitive results could perhaps have been forthcoming if frequency response traces could have been observed on an oscilloscope, playing an appropriate test record with bands from say 15K/cs to 6 K/cs.

One thing is clear from your mod. There's much more deflecting energy in record grooves than most can imagine 😉

bulgin

Hi George

I admire your initiative but that cyanoacrylite (superglue) makes a heck of a mess😀 I make the things and would have tried a clear epoxy to do the job.

What recording software are you using for those WAV files - Magix AudioLab10?

Still nitpicking (moderators permitting) more elucidating and definitive results could perhaps have been forthcoming if frequency response traces could have been observed on an oscilloscope, playing an appropriate test record with bands from say 15K/cs to 6 K/cs.

One thing is clear from your mod. There's much more deflecting energy in record grooves than most can imagine 😉

bulgin

gpapag,

have you tried removing the silver mounting thingy and gluing the black cartridge body directly to the headshell ?

Japanese audiophiles report noticable improvement after such a mod... too bad that I don't have a cartridge to try.

have you tried removing the silver mounting thingy and gluing the black cartridge body directly to the headshell ?

Japanese audiophiles report noticable improvement after such a mod... too bad that I don't have a cartridge to try.

Hi bulgin

As I can concur from your site, you are a music lover, but you have gone a huge step further: You design and build cartridges. This been the case, I am flattered having you commenting on this thread.🙂

You have raised a few important topics (and no nitpicking at all).

1. Kind of Glue, my point of view (P.S.).

When the magnitude of vibration is miniscule and of relatively high frequency (cartridge body), rattling initiates at the very intersection of two surfaces, the energy transfer point. There, only Cyanoacrylate can slip into and kill the beast into it’s nest.

Why? It penetrates into very –very narrow gaps. This is because it has a low viscosity number, a low surface tension and a high wetting angle, all the three ingredients needed for promoting capillary action. Cyanoacrylate for to work, requires parts to be in intimate contact. If the parts are more than merely 0.0005” apart, it doesn’t work well or doesn’t work at all. It works on a molecular level. It doesn’t fill larger gaps. It works high on adhesion and low on cohesion. Thus, it possesses no elasticity and provides no dumping on it’s own.

All these are quite the opposite from what an epoxy is and how it works. Epoxy in my case can be applied only around the external surfaces, dumping any oscillations generated further inside. This woks at the expense of increasing cartridge mass.

At this stage of the moding, I didn’t want to change any design specification of the cartridge (mass is a design spec.). What I wanted to achieve is to improve upon some manufacturing “shortcuts”.

2. Recording software: I use Steinberg Wavelab 4. It is very good.

Recording can be equally well performed with any software. But if precise synchronization ref. an exact time point or event is required, then the choices are dropping down. The software should be able to zoom in time (up to 1/10 of ms is required for to manually synchronize files from vinyl).

But what I find actually more essential is a good (quiet) combination of RIAA pre amplifier and soundcard.

I am using Hagerman Bugle and M-Audio Audiophile USB. The software reads –64dB noise out of this combination (Cartridge connected but not reading the record)

3. I do not have a test record yet. SHURE has produced two test records, ORTOPHON as well, but they don’t manufacture them anymore. What is your suggestion for a test record?

SHURE has produced two test records, ORTOPHON as well, but they don’t manufacture them anymore. What is your suggestion for a test record?

I did some sort of “emulation” of a test record though, connecting the cartridge in series with my frequency generator (at 4.75mv rms) and taking freq. response measurements through the output of the preamplifier.

Results are promising, but I have to take a second look at the data before making them public (they are part of another investigation actually, namely cartridge loading effect on response, which is still in progress).

This may show some quantifying data, but I trust more the method of observing and comparing recordings from music vinyl tracks. It is very cumbersome, but the testing stimulus is the reality itself.

P.S. Well as you say, it makes a heck of a mess to work with it. It flows on any surface extremely fast and goes even where you may not want to. If you want to inhibit the flow to a particular area, oil this area.😎

While you are holding things firmly for these critical 3-10 seconds, your naked finger may become one part with the object you hold before you even understand it. Then you have to use a razor to take them apart (if you realize it in an early stage, acetone may help).

Then you have to use a razor to take them apart (if you realize it in an early stage, acetone may help). So, better wear surgical gloves when working with it.

So, better wear surgical gloves when working with it.

Regards

George

As I can concur from your site, you are a music lover, but you have gone a huge step further: You design and build cartridges. This been the case, I am flattered having you commenting on this thread.🙂

You have raised a few important topics (and no nitpicking at all).

1. Kind of Glue, my point of view (P.S.).

When the magnitude of vibration is miniscule and of relatively high frequency (cartridge body), rattling initiates at the very intersection of two surfaces, the energy transfer point. There, only Cyanoacrylate can slip into and kill the beast into it’s nest.

Why? It penetrates into very –very narrow gaps. This is because it has a low viscosity number, a low surface tension and a high wetting angle, all the three ingredients needed for promoting capillary action. Cyanoacrylate for to work, requires parts to be in intimate contact. If the parts are more than merely 0.0005” apart, it doesn’t work well or doesn’t work at all. It works on a molecular level. It doesn’t fill larger gaps. It works high on adhesion and low on cohesion. Thus, it possesses no elasticity and provides no dumping on it’s own.

All these are quite the opposite from what an epoxy is and how it works. Epoxy in my case can be applied only around the external surfaces, dumping any oscillations generated further inside. This woks at the expense of increasing cartridge mass.

At this stage of the moding, I didn’t want to change any design specification of the cartridge (mass is a design spec.). What I wanted to achieve is to improve upon some manufacturing “shortcuts”.

2. Recording software: I use Steinberg Wavelab 4. It is very good.

Recording can be equally well performed with any software. But if precise synchronization ref. an exact time point or event is required, then the choices are dropping down. The software should be able to zoom in time (up to 1/10 of ms is required for to manually synchronize files from vinyl).

But what I find actually more essential is a good (quiet) combination of RIAA pre amplifier and soundcard.

I am using Hagerman Bugle and M-Audio Audiophile USB. The software reads –64dB noise out of this combination (Cartridge connected but not reading the record)

3. I do not have a test record yet.

SHURE has produced two test records, ORTOPHON as well, but they don’t manufacture them anymore. What is your suggestion for a test record?

SHURE has produced two test records, ORTOPHON as well, but they don’t manufacture them anymore. What is your suggestion for a test record?I did some sort of “emulation” of a test record though, connecting the cartridge in series with my frequency generator (at 4.75mv rms) and taking freq. response measurements through the output of the preamplifier.

Results are promising, but I have to take a second look at the data before making them public (they are part of another investigation actually, namely cartridge loading effect on response, which is still in progress).

This may show some quantifying data, but I trust more the method of observing and comparing recordings from music vinyl tracks. It is very cumbersome, but the testing stimulus is the reality itself.

P.S. Well as you say, it makes a heck of a mess to work with it. It flows on any surface extremely fast and goes even where you may not want to. If you want to inhibit the flow to a particular area, oil this area.😎

While you are holding things firmly for these critical 3-10 seconds, your naked finger may become one part with the object you hold before you even understand it.

Then you have to use a razor to take them apart (if you realize it in an early stage, acetone may help).

Then you have to use a razor to take them apart (if you realize it in an early stage, acetone may help). So, better wear surgical gloves when working with it.

So, better wear surgical gloves when working with it.Regards

George

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Results of M97xE mod