My recommended substitute for the discontinued Omron EE-SH3 is the TT Electronics / Optek OPB852A2. There are plenty of these in stock from a couple of sources:

Mouser OPB852A2 [139 in stock] $2.55

https://www.mouser.com/ProductDetail/Optek-TT-Electronics/OPB852A2?qs=N5kmjX/bzE4H5NWiwjnrYA==

DigiKey OPB852A2 [287 in stock] $2.54

https://www.digikey.com/en/products/detail/tt-electronics-optek-technology/OPB852A2/1637233

The resistors are generic and the listed values from any manufacturer will work fine, ¼ watt is all you need.

Ray K

Mouser OPB852A2 [139 in stock] $2.55

https://www.mouser.com/ProductDetail/Optek-TT-Electronics/OPB852A2?qs=N5kmjX/bzE4H5NWiwjnrYA==

DigiKey OPB852A2 [287 in stock] $2.54

https://www.digikey.com/en/products/detail/tt-electronics-optek-technology/OPB852A2/1637233

The resistors are generic and the listed values from any manufacturer will work fine, ¼ watt is all you need.

Ray K

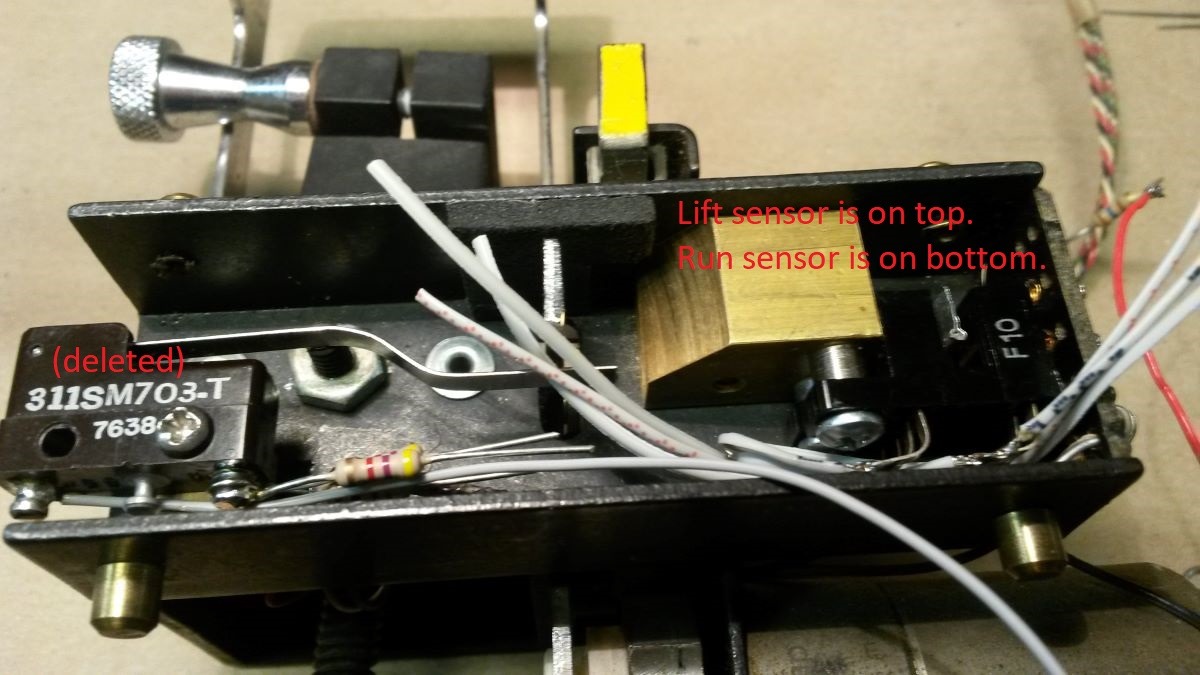

Thanks for your continued support with this mod. I am attempting this as a relative novice so, I have some questions to make sure that I am reading things correctly. I am on mounting the sensors. In the notes to photo#8 the spacers are specified for the run and lift sensors. These are not labeled as such in the diagrams and drawings so, I want to check that I have it right. On the drawings, the run sensor is Q3? This would then correspond to the bottom sensor in photo #7?

I am interested but, forum rules may have oblige you to offer this on the marketplace. I will PM you

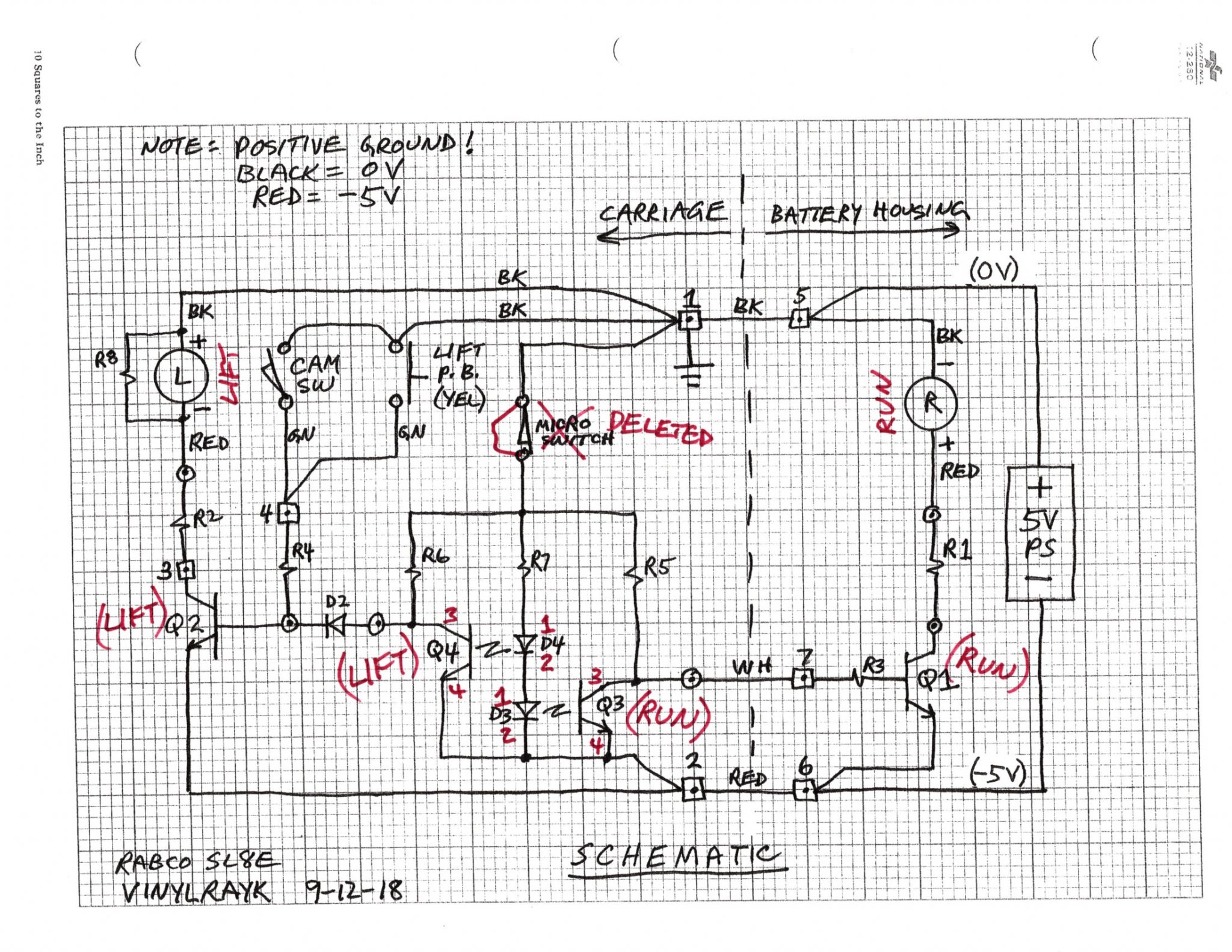

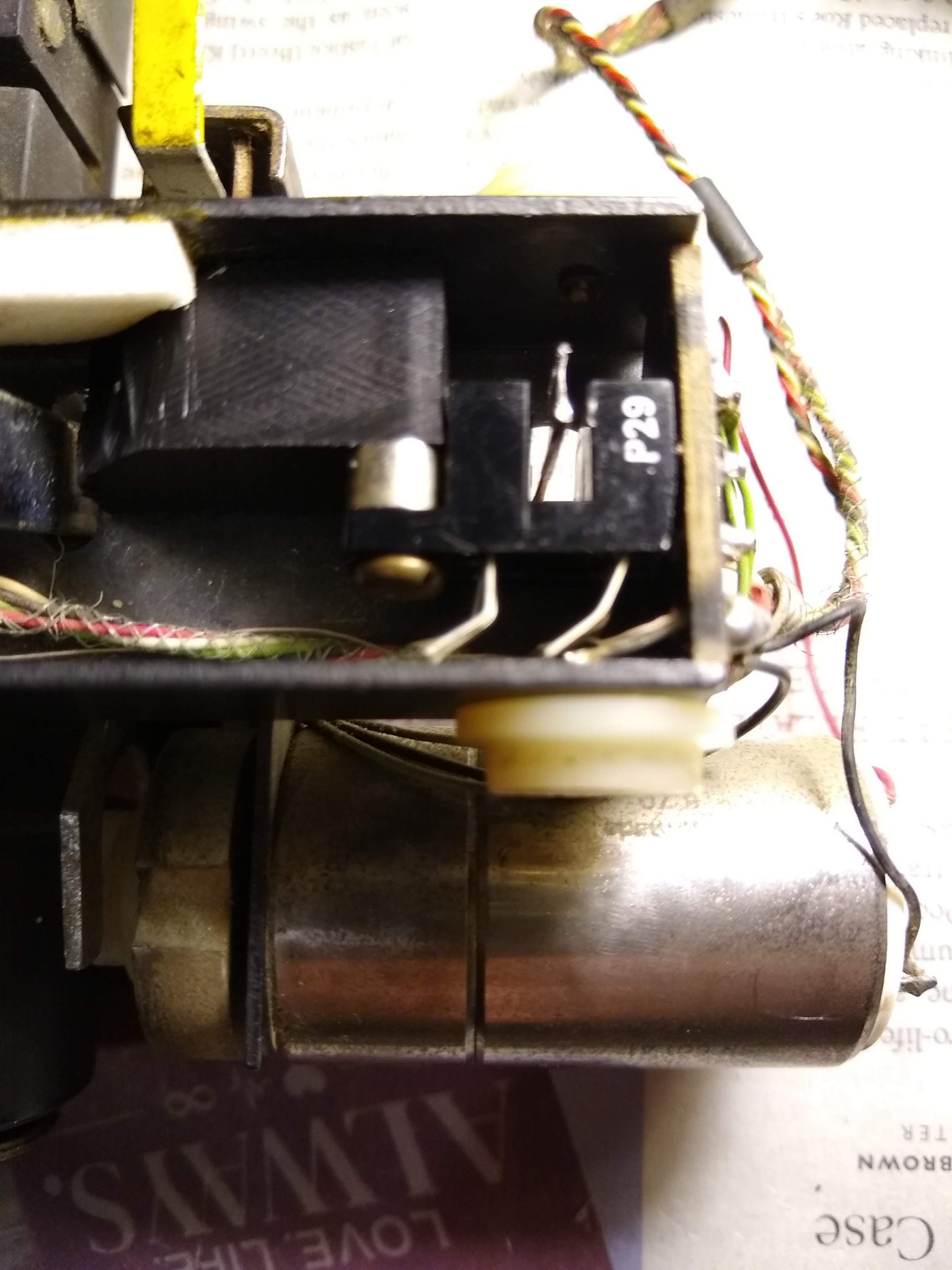

Here are photos B, C, 7, and 8 with added clarification notes as requested.

Ray K

Photo B:

Photo C:

Photo 7:

Photo 8:

Ray K

Photo B:

Photo C:

Photo 7:

Photo 8:

Perfect. More than I could have wished for. Thank you. So, I have assembled and test fitted the sensor block. I must say, that was painstaking work. I am pleased art the result so far. The flag is well centered in the sensor and the offset is 1.1mm on one side and 1.3mm on the other. (Apparently not totally square to the mount.) Close enough?

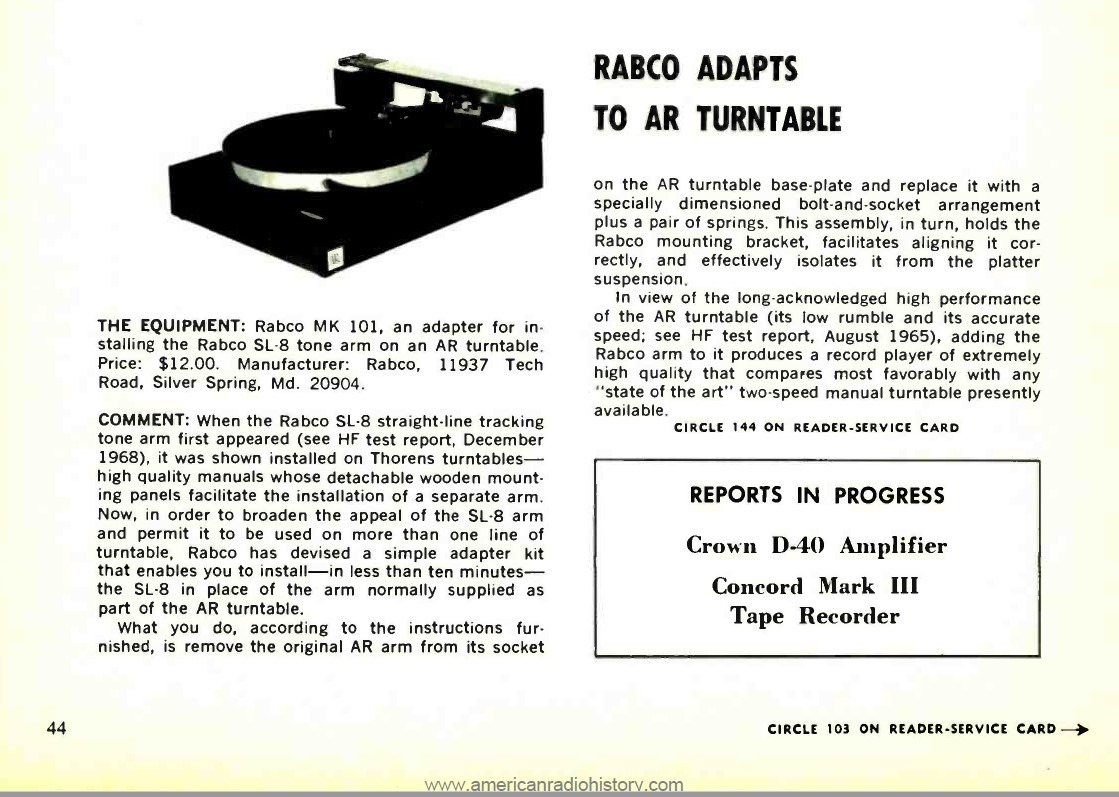

Thanks. I think that is how I ended up here in the first place. I still am looking for more specific information on my AR XA/Rabco as regards refurbishment. I understand that this was one of the original factory designed configurations sold as a kit. Yet, I find almost nothing out there on this. It seems most went for the Thorens platform?

Close enough!The flag is well centered in the sensor and the offset is 1.1mm on one side and 1.3mm on the other. (Apparently not totally square to the mount.) Close enough?

I have now wired/soldered the photsensor block and have a very basic question. Do you insulate the connections? It seems to me they would risk making contact with the carriage chassis which also acts as ground, right? Thanks for your patience with the naive question.

Looking at your photo, I'd recommend bending the tabs farther down to give yourself more clearance to the back of the carriage. Compare to my photo #22. In any case, it never hurts to add insulation. Sticking a single layer of electrical tape between the tabs and the backside of the carriage should do the job.

I, too, have found hardly anything about the AR/SL8E combination online, except that I seem to remember ads at the time promoting the Thorens/SL8(E) and AR/SL8(E) as the two recommended ideal pairings. I've only seen an AR/SL8E combination over on vinylengine.

I did find an ad for the AR/SL8 adapter in the May 1970 issue of High Fidelity magazine:

I don't understand exactly how the adapter worked since the arm/table spring suspension on the AR is different than how the spring suspension is done on the Thorens which I'm familiar with. It would be a great contribution to the knowledge base of vintage audio if you could post some hi-rez photos of your AR XA/Rabco setup?

Ray K

I, too, have found hardly anything about the AR/SL8E combination online, except that I seem to remember ads at the time promoting the Thorens/SL8(E) and AR/SL8(E) as the two recommended ideal pairings. I've only seen an AR/SL8E combination over on vinylengine.

I did find an ad for the AR/SL8 adapter in the May 1970 issue of High Fidelity magazine:

I don't understand exactly how the adapter worked since the arm/table spring suspension on the AR is different than how the spring suspension is done on the Thorens which I'm familiar with. It would be a great contribution to the knowledge base of vintage audio if you could post some hi-rez photos of your AR XA/Rabco setup?

Ray K

Will do once I get it back together. The proper alignment of this mount is exactly what I am trying to track down, btw.Looking at your photo, I'd recommend bending the tabs farther down to give yourself more clearance to the back of the carriage. Compare to my photo #22. In any case, it never hurts to add insulation. Sticking a single layer of electrical tape between the tabs and the backside of the carriage should do the job.

I, too, have found hardly anything about the AR/SL8E combination online, except that I seem to remember ads at the time promoting the Thorens/SL8(E) and AR/SL8(E) as the two recommended ideal pairings. I've only seen an AR/SL8E combination over on vinylengine.

I did find an ad for the AR/SL8 adapter in the May 1970 issue of High Fidelity magazine:

View attachment 1015987

I don't understand exactly how the adapter worked since the arm/table spring suspension on the AR is different than how the spring suspension is done on the Thorens which I'm familiar with. It would be a great contribution to the knowledge base of vintage audio if you could post some hi-rez photos of your AR XA/Rabco setup?

Ray K

Having spent several months at this off and on, I am pretty sure that I have lost my way and am now sending up a rescue flare. I am a relative novice at this so, I wired the retrofit and used a board to facilitate soldering and eventual troubleshooting. I have an intermittent failure. All functions worked, then nothing, then worked again, finally nothing. I deduced that my circuit layout is correct but there is probably bad solder connections or, a component failure. For my troubleshooting, I started at the power end and worked backward. I redid a few of the sketchier solder joints but, I found nothing until I tested the Q2 transistor. It was letting current flow in both directions compared to the spec. So, I replaced it with a spare which tested to spec before install. Still no function of either lift motor or carriage motor. Except, now the newly installed Q2 has same test readings as the original (failed?) transistor. I have to admit that my skills and knowledge are not up to this project. Even if I could trouble shoot, my soldering ineptitude could end up aggravating any rework.

So, I am looking for advice for a salvage plan. The TT has sentimental value and I would be willing to pay someone to restore it. Is there someone out there who would take this on? Should I just revert to the old "whiskers" microswitches?

So, I am looking for advice for a salvage plan. The TT has sentimental value and I would be willing to pay someone to restore it. Is there someone out there who would take this on? Should I just revert to the old "whiskers" microswitches?

Thank youI will send you a PM to see what I can do to help you through this. Don't give up!

Ray

Back at home base. sent you a PM to continue the conversation. Thanks.I will send you a PM to see what I can do to help you through this. Don't give up!

Ray

Sorry, but in my rush, I made several mistakes in the schematics I sent earlier. Hopefully, these will be useable.

I also attached the SketchUp drawing of the OEM Arm as a zip file. Enjoy.

😵Moderator: Would you delete my previous posts # 58, #60, and #61 please. They are incorrect.

I also attached the SketchUp drawing of the OEM Arm as a zip file. Enjoy.

😵Moderator: Would you delete my previous posts # 58, #60, and #61 please. They are incorrect.

Attachments

- Home

- Source & Line

- Analogue Source

- Rabco SL8E Photoelectric Servo Control Retrofit