Man I love it when simple fixes solve everything!

Nylon washers on both sides of the cooling fins and the amp is silent.

Malcom, your advice is golden!

Nylon washers on both sides of the cooling fins and the amp is silent.

Malcom, your advice is golden!

Great! You're very welcome.

Don't forget to ground the metal part (cover etc.) of the transformer. Put a shake-proof washer and one of those 'washers with a tag to solder to' touching the metal of the transformer and run a short wire from there to any convenient point on the chassis. By the way, those aren't cooling fins. They are the transformer core laminations.

(It's a safety requirement and also it can only help to reduce hum and buzz.)

Don't forget to ground the metal part (cover etc.) of the transformer. Put a shake-proof washer and one of those 'washers with a tag to solder to' touching the metal of the transformer and run a short wire from there to any convenient point on the chassis. By the way, those aren't cooling fins. They are the transformer core laminations.

(It's a safety requirement and also it can only help to reduce hum and buzz.)

Last edited:

Well Malcolm, I always get excited when improvements are made, but when I put it all back in the cabinet its still humming too loudly through the speaker to be a gig amp miked in the house. I'm at a loss now cause I've done everything I can short of replacing the PT, which it appears I'm going to have to do. It will cost more than half of what I paid for the amp so its back to the Roland JC120. :-(

I'm at a loss now cause I've done everything I can short of replacing the PT, which it appears I'm going to have to do. It will cost more than half of what I paid for the amp so its back to the Roland JC120. :-(

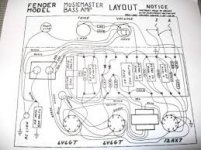

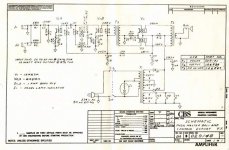

If anybody has suggestions for an upgrade PT [must be QUIET!] then I'd be grateful for any advice. I'm getting outside of my technical ability here so I might have to go with a fender Princeton OR Deluxe PT where the wires are color coded the same as the layout diagram.

I'm at a loss now cause I've done everything I can short of replacing the PT, which it appears I'm going to have to do. It will cost more than half of what I paid for the amp so its back to the Roland JC120. :-(

I'm at a loss now cause I've done everything I can short of replacing the PT, which it appears I'm going to have to do. It will cost more than half of what I paid for the amp so its back to the Roland JC120. :-(If anybody has suggestions for an upgrade PT [must be QUIET!] then I'd be grateful for any advice. I'm getting outside of my technical ability here so I might have to go with a fender Princeton OR Deluxe PT where the wires are color coded the same as the layout diagram.

Attachments

Great! You're very welcome.

Don't forget to ground the metal part (cover etc.) of the transformer. Put a shake-proof washer and one of those 'washers with a tag to solder to' touching the metal of the transformer and run a short wire from there to any convenient point on the chassis. By the way, those aren't cooling fins. They are the transformer core laminations.

(It's a safety requirement and also it can only help to reduce hum and buzz.)

I believe its already grounded to the chassis inside on one of the mounting bolts [older photo before the heater center taps were installed on the cathode]

Attachments

... its still humming too loudly through the speaker to be a gig amp miked in the house.I'm at a loss now cause I've done everything I can short of replacing the PT, which it appears I'm going to have to do...

If the hum is coming from the speaker it won't do any good to replace the PT - that was just a suggestion if it was a hum physically coming from the transformer.

I'm not saying you necessarily have the same problem as in the following link, but you might find it interesting reading:

http://www.chambonino.com/routework/routewk24.html

Last edited:

I believe its already grounded to the chassis inside on one of the mounting bolts ....

But is that mounting bolt still making good electrical contact with the metal of the transformer, now that you have the nylon washers in place?

Yes, the nylon washers are on the outside of the chassis.But is that mounting bolt still making good electrical contact with the metal of the transformer, now that you have the nylon washers in place?

If the hum is coming from the speaker it won't do any good to replace the PT - that was just a suggestion if it was a hum physically coming from the transformer.

I'm not saying you necessarily have the same problem as in the following link, but you might find it interesting reading:

Fender Musicmaster Bass Combo Amp

Thats an interesting link! How on earth would you be able to tell if your wax impregnated board had retained moisture and become conductive?

My amp appears to have lived inside somebodys house all these years, its in quite good condition with no rust anywhere.

My hum is not affected by volume/tone adjustments. It's a low hum that comes on instantly when the amp is switched on and gradually gets louder for five seconds, kinda the same amount of time it takes the tubes to light up. I really thought it was the tubes, but tried 4 nos GE 6aq5's and that didnt change things.I've cleaned and re-tensioned the pins.If my pot cleaner is conductive,that would be a bummer. Can I use acetone on a q-tip to clean the tube sockets?

The PT has very thin wires, unlike any fender unit I've ever seen. Could that be the issue or did the tech who installed it screw something up with the wiring? He's the guy that put the 1meg resistor inline with the pilot lite I presume. Again, I'm not well versed on transformer wiring so this may be out of my reach and over my head...😱

But if theres a way to check that each wire is were it should be I would like to.

Last edited:

Yes, the nylon washers are on the outside of the chassis.

Also, that 'o' ring connector that the PT is grounded to is soldered directly to the chassis by the mounting bolt.

I was thinking you had something like this (in order):

bolt head, metal washer, nylon washer, transform cover, transformer laminations, nylon washer, chassis, grounding tag, nut.

If it is like that, there is no electrical contact between the transformer metalwork and the chassis (or the grounding tag) except for possible accidental contact with the threaded part of the bolt.

bolt head, metal washer, nylon washer, transform cover, transformer laminations, nylon washer, chassis, grounding tag, nut.

If it is like that, there is no electrical contact between the transformer metalwork and the chassis (or the grounding tag) except for possible accidental contact with the threaded part of the bolt.

I was thinking you had something like this (in order):

bolt head, metal washer, nylon washer, transform cover, transformer laminations, nylon washer, chassis, grounding tag, nut.

If it is like that, there is no electrical contact between the transformer metalwork and the chassis (or the grounding tag) except for possible accidental contact with the threaded part of the bolt.

Its like this-

bolt screw head-nylon washer-transformer metal cover-laminations-rubber washers-chassis. Inside the chassis the nuts are all contacting the chassis.

Sound ok?

Its like this-

bolt screw head-nylon washer-transformer metal cover-laminations-rubber washers-chassis. Inside the chassis the nuts are all contacting the chassis.

Sound ok?

No, that’s no good, as the metal parts of the transformer are electrically insulated from ground at present.

It’s a safety issue, because if there was fault inside the transformer, the metal parts could become live and they are easily touched by the user. By grounding them, the fault would cause a fuse to blow instead.

What you need is something like:

Bolt head, shake-proof metal washer, metal cover, laminations, nylon washer, chassis, nylon washer, metal washer, grounding tag, shake-proof washer, nut.

Shake-proof washers give a ‘bite’ into the metal ensuring a good electrical contact.

No, that’s no good, as the metal parts of the transformer are electrically insulated from ground at present.

It’s a safety issue, because if there was fault inside the transformer, the metal parts could become live and they are easily touched by the user. By grounding them, the fault would cause a fuse to blow instead.

What you need is something like:

Bolt head, shake-proof metal washer, metal cover, laminations, nylon washer, chassis, nylon washer, metal washer, grounding tag, shake-proof washer, nut.

Shake-proof washers give a ‘bite’ into the metal ensuring a good electrical contact.

Malcom, I went ahead and decided to mount this thing properly....😱

Went out and bought the fattest bolts that would fit, properly sized star washers and nylon washers. Removed the old ground lug and all the old solder from the chassis,then cleaned and scuffed the ground area on the chassis.Added a new ground lug for the mains and transformer ground,then bolted it down TIGHT and evenly with the suggested washer pattern.

Finally,soldered the ground lug with a 300w iron to the chassis.

Guess what? NOW IT IS SILENT...no...REALLY!

There was a bad ground connection,probably the old solder lug. Honestly,its quieter than all my other amps! [JC120/Roland Bolt 30,Fender champion 600.]

Thank you for saving me from stupidly buying a new PT.Thats about $150.00 that my wife certainly didn't want to me to spend.

I cant believe how quiet this thing is now.

This amp is officially good to go!

A little early,but happy holidays to you and yours and thank you for all your help and time!!!

As a bonus, the transformer is running extremely cool now,just warm to the touch after one hour of power up. It was hotter than hell before and the whole chassis used to be hot,even the faceplate.

Not any more!

Not any more!

Well I might as well keep my mega-thread going cause now its all fun stuff! 😀

Now that noise is no longer an issue, I'd like to tweak it a bit for later breakup / more clean headroom. I've already got a JBL in there but it starts getting crunchy at 11 o'clock. Any values that can be altered for more clean headroom?

What about higher voltage? My PT puts out 352v on the screen but I dropped it down to 293v via a limiting resistor. Can I hit the 6AQ5's with all that? Might increase headroom. [For what its worth, the amp had no limiting resistor when it arrived and still has the original RCA 6AQ5 tubes.]

I could swear it wasnt as crunchy when I got it but with all the hum it had its hard to be certain. But, remember it had a 1k5 cathode bias resistor, now its 330ohm. Maybe upping that again would clean it up?

Malcolm, if your burnt out from my endless noise quest dont sweat it! Maybe somebody else can chime in with some suggestions.[Of course, your help is most welcome and appreciated!] I'm almost 100% there with this amp, just need to fine tune it for maximum clean headroom...

Now that noise is no longer an issue, I'd like to tweak it a bit for later breakup / more clean headroom. I've already got a JBL in there but it starts getting crunchy at 11 o'clock. Any values that can be altered for more clean headroom?

What about higher voltage? My PT puts out 352v on the screen but I dropped it down to 293v via a limiting resistor. Can I hit the 6AQ5's with all that? Might increase headroom. [For what its worth, the amp had no limiting resistor when it arrived and still has the original RCA 6AQ5 tubes.]

I could swear it wasnt as crunchy when I got it but with all the hum it had its hard to be certain. But, remember it had a 1k5 cathode bias resistor, now its 330ohm. Maybe upping that again would clean it up?

Malcolm, if your burnt out from my endless noise quest dont sweat it! Maybe somebody else can chime in with some suggestions.[Of course, your help is most welcome and appreciated!] I'm almost 100% there with this amp, just need to fine tune it for maximum clean headroom...

Last edited:

Well, looks like I found the answer to my clean headroom quest.

My 6AQ5's are running fine on 354v on the screen and I biased the amp pretty cold with an 820ohm bias resistor. Might sound sterile to blues guys but its a beautiful clean tone with ample headroom and breaks up late on the dial.Just what I wanted!

The tubes show no signs of redplating and dont appear any hotter than before so well see how long they last. Fortunately,a fuse is installed and I've got 4 backup 6AQ5's.

One last big Thanks to everybody who helped out along the way. It was so frustrating having so much noise and now this is a perfect little gig amp.

Really sounds wonderfull!

My 6AQ5's are running fine on 354v on the screen and I biased the amp pretty cold with an 820ohm bias resistor. Might sound sterile to blues guys but its a beautiful clean tone with ample headroom and breaks up late on the dial.Just what I wanted!

The tubes show no signs of redplating and dont appear any hotter than before so well see how long they last. Fortunately,a fuse is installed and I've got 4 backup 6AQ5's.

One last big Thanks to everybody who helped out along the way. It was so frustrating having so much noise and now this is a perfect little gig amp.

Really sounds wonderfull!

- Status

- Not open for further replies.

- Home

- Live Sound

- Instruments and Amps

- questions about Fender Musicmaster Bass amp schematic