The M Levinson 37 tray mech is another slim-line design to take into account - the way they do it makes it look very simple to contruct once the pieces are made up:

This appears similar in principle to the Sony mechs used in the X77 and X7** (possibly others too, I can't remember) where the cd and tray movement is linear and the whole pick-up and table block is 'hinged' to the rear and the front raises up once the tray is closed. Hence the turntable lifts up to the CD and up to the fixed position mag. clamp (which sits in the bridge). A clever crook shaped toothed gearwheel runway on the bottom of the tray and a coarse worm spindle is used to effect this. However this is a moving pick-up design.

For a fixed pick-up design, how about looking to the Marantz CD-303 (it wasn't fixed p.u. but I see no reason why it couldn't be).

I think Chris said he had experience of the CD-303 - over to you Chris. 🙂

Last edited:

If you don't like my posts, feel free to ask the moderators to remove them all.

The quality of education provided in this thread would be the less without them IMHO. Regardless of which side of the fence one is, or simply sitting on the fence, they provoke responses! 🙂

Mark, maybe you can help - may I ask you something please. When a run of music CDs be being produced, how many different stampers are used, do they wear and how long do they last in use? If many stampers are needed, is there any QC at the production stage of the stampers themselves to make sure they are 'equal' or is it just the resulting presses that are tested?

Let me add some context. I have two CDs - they are supposed to be the same - when I play them sequencially in the same CD player the volume of errors that one disc will generate can be a very obvious multiple of those generated by the other disc. Neither of the CDs test as faulty (not out of QC limits, no E32 errors [Plextools/Nero]) - in this case the player itself is generating the errors, because it is reading poorly. But playing the just one cd several times will give a repeatedly consistant volume of errors, i.e. the experiment gives a repeatable result. The consistancy only changes with different media, even when that media is supposed to be an identical CD (not a CDR, a normal volume production CD).

I am wondering from where this issue originates.

Thanks, Jon.

Hi Jon,

Anything from a weaker p/u head to a disc motor defective - or both. The performance for two "identical CD players right from the factory can be vastly different. I do not believe that the players are actually adjusted at the factory, but rather have the pots lined up with a card that lays over top. An alignment by a competent technician can make a night and day difference to how a CD player operates. Of course, some heads are better than others too.

So much for identical CD players because they are the same model, even consecutive serial numbers can perform a lot different to each other.

-Chris

Anything from a weaker p/u head to a disc motor defective - or both. The performance for two "identical CD players right from the factory can be vastly different. I do not believe that the players are actually adjusted at the factory, but rather have the pots lined up with a card that lays over top. An alignment by a competent technician can make a night and day difference to how a CD player operates. Of course, some heads are better than others too.

So much for identical CD players because they are the same model, even consecutive serial numbers can perform a lot different to each other.

-Chris

Stamper testing is only done to confirm that the glass-mastering and galvanic process of the stamper making is working correctly.

After start up we check and use the analyser to test the first discs produced. A scanner at the end of the production line does an optical inspection of every disc. The automation separates the rejected discs from the good.

The highest amount I have ever produced from a single stamper was over 260k in production runs of 20k. We only stopped using the stamper when the customer supplied a new master. You can expect all the discs within a production run to have almost identical error rates. Differences between production runs using the same stamper could be caused by the cleaning process of the stamper, will still be very small. This is why they call it replication.

Your two CDs, they could be from different stampers, very likely made on different production lines with different materials and even produced at different locations.

The errors on the original master are corrected during the transfer to HD. Error rates increase during the glass-mastering and stamper making with the disc replication stage only slightly adding to the error rates. Your results are as I would expect when a player is working correctly and the disc errors are not high. Don't forget that scratches and fingerprints also increase error rates.

After start up we check and use the analyser to test the first discs produced. A scanner at the end of the production line does an optical inspection of every disc. The automation separates the rejected discs from the good.

The highest amount I have ever produced from a single stamper was over 260k in production runs of 20k. We only stopped using the stamper when the customer supplied a new master. You can expect all the discs within a production run to have almost identical error rates. Differences between production runs using the same stamper could be caused by the cleaning process of the stamper, will still be very small. This is why they call it replication.

Your two CDs, they could be from different stampers, very likely made on different production lines with different materials and even produced at different locations.

The errors on the original master are corrected during the transfer to HD. Error rates increase during the glass-mastering and stamper making with the disc replication stage only slightly adding to the error rates. Your results are as I would expect when a player is working correctly and the disc errors are not high. Don't forget that scratches and fingerprints also increase error rates.

Last edited:

Chris,

Think you may have misread the post.

Other way around - two identical CDs and one CD player.

Jon.

Hi Jon,

Anything from a weaker p/u head to a disc motor defective - or both. The performance for two "identical CD players right from the factory can be vastly different. I do not believe that the players are actually adjusted at the factory, but rather have the pots lined up with a card that lays over top. An alignment by a competent technician can make a night and day difference to how a CD player operates. Of course, some heads are better than others too.

So much for identical CD players because they are the same model, even consecutive serial numbers can perform a lot different to each other.

-Chris

Think you may have misread the post.

Other way around - two identical CDs and one CD player.

Jon.

Mark,

Thanks for the info. How would you identify where a CD was produced and which stamper was used to stamp the disc?

Noted, but as I said a disc test shows no uncorrectable errors (E32 or CU errors). What I see seems to be pretty much opposite of what you say you would expect, isn't it?

Jon.

Your two CDs, they could be from different stampers, very likely made on different production lines with different materials and even produced at different locations.

Thanks for the info. How would you identify where a CD was produced and which stamper was used to stamp the disc?

Your results are as I would expect when a player is working correctly and the disc errors are not high. Don't forget that scratches and fingerprints also increase error rates.

Noted, but as I said a disc test shows no uncorrectable errors (E32 or CU errors). What I see seems to be pretty much opposite of what you say you would expect, isn't it?

Jon.

Hi Jon,

Ahhh, sorry. I did misread your post.

Mark's responses where not in conflict with mine as I felt we were addressing different aspects. From what I know about CD production, and that is much less than Mark knows, his answers are correct.

-Chris

Ahhh, sorry. I did misread your post.

Mark's responses where not in conflict with mine as I felt we were addressing different aspects. From what I know about CD production, and that is much less than Mark knows, his answers are correct.

-Chris

Thanks for the info. How would you identify where a CD was produced and which stamper was used to stamp the disc?

A Stamper has an identification code (Ident code) at the ID of the stamper. Check if both discs have the same code. Sometimes the Ident code will have the manufactures name. EMI UDEN, DADC, SONOPRESS, PDO or something like that.

Noted, but as I said a disc test shows no uncorrectable errors (E32 or CU errors). What I see seems to be pretty much opposite of what you say you would expect, isn't it?

If the discs were not pressed from the same stamper or that the discs had been damaged would I expect different results for BLER, E22 and E32 (if E22 and E32 are not zero). The important thing is that both discs have no E32 and therefore you know that the DSP was not active. The player was able to do its job without guessing the output signal.

Hi Mark,

The marks are: 'DISCTRONICS', 'WSMCD 101 01' in a large typeface and 'IFPI L502' in a quite small typeface. These are inside the CD construction at the metallic layer and are printed in 'dot matrix' printer style. Both CDs the same.

Separately, still in the centre ID, but 'impressed' on the outside of the plastic on the clear side is 'IFPI 8733' on one and 'IFPI 8749' in small typeface. I can feel these impressions with my finger.

Both discs have no E32 using a disc test in a Plextor drive. However in the CD player (in this case a Pioneer) the error concealment is operative. Fair enough, the CD player is not reading well - I know this - I do not blame the CDs. But playing one CD gives a little error concealment. Playing the other CD (which is identical, I think) uses much greater error concealment - maybe 4-5 times as much.

Jon.

A Stamper has an identification code (Ident code) at the ID of the stamper. Check if both discs have the same code. Sometimes the Ident code will have the manufactures name. EMI UDEN, DADC, SONOPRESS, PDO or something like that.

The marks are: 'DISCTRONICS', 'WSMCD 101 01' in a large typeface and 'IFPI L502' in a quite small typeface. These are inside the CD construction at the metallic layer and are printed in 'dot matrix' printer style. Both CDs the same.

Separately, still in the centre ID, but 'impressed' on the outside of the plastic on the clear side is 'IFPI 8733' on one and 'IFPI 8749' in small typeface. I can feel these impressions with my finger.

The important thing is that both discs have no E32 and therefore you know that the DSP was not active. The player was able to do its job without guessing the output signal.

Both discs have no E32 using a disc test in a Plextor drive. However in the CD player (in this case a Pioneer) the error concealment is operative. Fair enough, the CD player is not reading well - I know this - I do not blame the CDs. But playing one CD gives a little error concealment. Playing the other CD (which is identical, I think) uses much greater error concealment - maybe 4-5 times as much.

Jon.

Dears,

Just come across and see their a excellent project is going.

Will u guys sell the final product in group buy

And will it suitable for shigaclone as well?

Thamks

Just come across and see their a excellent project is going.

Will u guys sell the final product in group buy

And will it suitable for shigaclone as well?

Thamks

@589

My best guess is that both discs were manufactured at Blackburn UK around 2002-2003. One disc on line/mould 33, the other on 49.

If the discs are muting during playback then the concealment is also failing. Does the player have problems with other discs? Is it only a problem with discs that have a longer than average playtime?

My best guess is that both discs were manufactured at Blackburn UK around 2002-2003. One disc on line/mould 33, the other on 49.

If the discs are muting during playback then the concealment is also failing. Does the player have problems with other discs? Is it only a problem with discs that have a longer than average playtime?

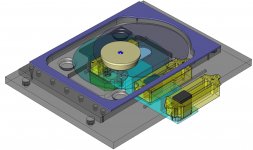

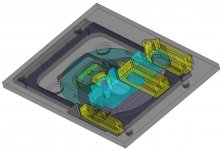

Here we go ... first draft.

Besides the clamper / stabilizer. all parts are drawn transparent,

this might be annoying, sorry for that.

But one might get an idea.

The CD is moving, the laser is fixed.

The drive is based on the BU-1 mechanism. and could be built from them as a start.

I have two of BU-1, in a CDP-103 and CDP-502.

It was fun to have them disassembled and reassemble them

(not very much parts) and see them work flawlessy.

Why the heck did Sony give up on that? You´ll probaby remove

10 screws and the mech is dissassembled. No flimsy breakable washers to remove from gears

to get access. Rugged and simple.

Good for diy: Only the rails fo the laser have to be accurate.

The diver/sensor coils and the magnets allow a little play.

But coils and magnets are weak, as mentioned by others before.

As a test, I switched the player on, while frontplate was facing upwards.

Thus being placed vertically, the laser does not move at all.

I assume the laser weights something between 80 to 100 grams.

Horizontally, the laser moves normal of course.

But with a fixed pickup and moving CD, the mass to be moved by

the magnets will be probably three times as high:

Brushless disc motor, the CD and stabilizer.

This will weight around 250 to 300 grams.

Therefor, I put in two moving coils.

I assume, a second sensor coil is not needed.

Even though the mechanical parts of the two players are the same

(Mechanism-chassis are not, metal for the CDP-103, plastic for the CDP-502),

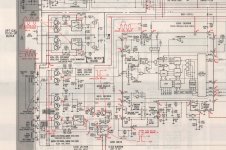

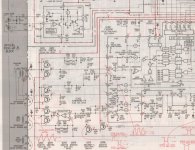

the servo circuitry seems to differ a bit. I would need to add two trannies to

move the second coil, any advice on this? Schematics attached.

The drawing is not finished yet, rails have to be placed, and the spindle Motor is not detailed yet.

All the best,

Salar

Besides the clamper / stabilizer. all parts are drawn transparent,

this might be annoying, sorry for that.

But one might get an idea.

The CD is moving, the laser is fixed.

The drive is based on the BU-1 mechanism. and could be built from them as a start.

I have two of BU-1, in a CDP-103 and CDP-502.

It was fun to have them disassembled and reassemble them

(not very much parts) and see them work flawlessy.

Why the heck did Sony give up on that? You´ll probaby remove

10 screws and the mech is dissassembled. No flimsy breakable washers to remove from gears

to get access. Rugged and simple.

Good for diy: Only the rails fo the laser have to be accurate.

The diver/sensor coils and the magnets allow a little play.

But coils and magnets are weak, as mentioned by others before.

As a test, I switched the player on, while frontplate was facing upwards.

Thus being placed vertically, the laser does not move at all.

I assume the laser weights something between 80 to 100 grams.

Horizontally, the laser moves normal of course.

But with a fixed pickup and moving CD, the mass to be moved by

the magnets will be probably three times as high:

Brushless disc motor, the CD and stabilizer.

This will weight around 250 to 300 grams.

Therefor, I put in two moving coils.

I assume, a second sensor coil is not needed.

Even though the mechanical parts of the two players are the same

(Mechanism-chassis are not, metal for the CDP-103, plastic for the CDP-502),

the servo circuitry seems to differ a bit. I would need to add two trannies to

move the second coil, any advice on this? Schematics attached.

The drawing is not finished yet, rails have to be placed, and the spindle Motor is not detailed yet.

All the best,

Salar

Attachments

Last edited:

Hi Salar,

Just repeat the op amp forward using the same feedback coil connection as for the other one. That should work without loading the original signals.

What do you mean by disc stabilizer? It is a magnetic type, isn't it? If so, the CD can use the pie plate and normal clamper as one wishes. You might be forced to use the normal magnetic clamp used by most.

-Chris

Just repeat the op amp forward using the same feedback coil connection as for the other one. That should work without loading the original signals.

What do you mean by disc stabilizer? It is a magnetic type, isn't it? If so, the CD can use the pie plate and normal clamper as one wishes. You might be forced to use the normal magnetic clamp used by most.

-Chris

Hi Chris,

could you make a quick drawing?

Maybe just by hand and make a photo

from it?

Stabilizer? Well, the one in the drawing

uses a magnet, but in the real world, I am

already using one made of aluminium with 80mm diameter and

76gr. weight. one with a teflon core is planned.

Easier to mill than a version with magnet.

All the best, Salar

could you make a quick drawing?

Maybe just by hand and make a photo

from it?

Stabilizer? Well, the one in the drawing

uses a magnet, but in the real world, I am

already using one made of aluminium with 80mm diameter and

76gr. weight. one with a teflon core is planned.

Easier to mill than a version with magnet.

All the best, Salar

A thing of beauty, Salar...

Salar,

Wow, I congratulate you on your successful disassembly and reassembly of the transport. If the Sony BU-1 is the thing to start with, how do WE (as a group) get hold of these ? Do we see if Sony has a stock of them ? Or do we troll the Interweb looking for them and hope they are in good operating order? (or Troll even further and look for the NEC multi-spin drives?). And short of the BU-1 or HLPL 030020/CA80255A transports what else do we use, KSS 123As?

How do we get the pieces to make the transport otherwise? Yes there will be pieces that may have to be made, but where do we get the basic building blocks otherwise? Am I still missing something? If so please enlighten me and then ignore me 🙂 .

Salar,

Wow, I congratulate you on your successful disassembly and reassembly of the transport. If the Sony BU-1 is the thing to start with, how do WE (as a group) get hold of these ? Do we see if Sony has a stock of them ? Or do we troll the Interweb looking for them and hope they are in good operating order? (or Troll even further and look for the NEC multi-spin drives?). And short of the BU-1 or HLPL 030020/CA80255A transports what else do we use, KSS 123As?

How do we get the pieces to make the transport otherwise? Yes there will be pieces that may have to be made, but where do we get the basic building blocks otherwise? Am I still missing something? If so please enlighten me and then ignore me 🙂 .

Hi Salar,

You've already commented on the extra power it would take to move the disc motor assy, so it seems to be logical to reduce weight in any areas you can. A magnetic clamp has much higher clamping force than a heavier weight. A weight that you now have to fight inertia on. I'd say, metallic disc table and magnetic clamp. If it's still too heavy, then we know why the transports evolved the way they did.

I'm game for a transport that moves the disc instead of the head. But the need for a prototype seems to be screaming out. Try the concept before setting the design in stone. Use what works the best. I personally don't care which part moves as long as high performance can be maintained.

-Chris

You've already commented on the extra power it would take to move the disc motor assy, so it seems to be logical to reduce weight in any areas you can. A magnetic clamp has much higher clamping force than a heavier weight. A weight that you now have to fight inertia on. I'd say, metallic disc table and magnetic clamp. If it's still too heavy, then we know why the transports evolved the way they did.

I'm game for a transport that moves the disc instead of the head. But the need for a prototype seems to be screaming out. Try the concept before setting the design in stone. Use what works the best. I personally don't care which part moves as long as high performance can be maintained.

-Chris

Hi Stew,

The KSS-123A has a problem with the yoke that holds the lens tends to stick on the alignment post. Its a difficult problem to diagnose on top of that.

I think Salar is going for a mechanism that can be produced without having to rely on old transports for parts. I could be wrong here, best Salar addresses that.

-Chris

The KSS-123A has a problem with the yoke that holds the lens tends to stick on the alignment post. Its a difficult problem to diagnose on top of that.

I think Salar is going for a mechanism that can be produced without having to rely on old transports for parts. I could be wrong here, best Salar addresses that.

-Chris

Ringmagnets for a clamper are not easy to find.

The mech of a BU-1 is simple. Can be rebuilt

from scratch. It is just magnets and coils.

Circuity can also be rebuild, I assume?

Again, could someone please make a quick

drawin how two driving coils instead of one

are connected?

The mech of a BU-1 is simple. Can be rebuilt

from scratch. It is just magnets and coils.

Circuity can also be rebuild, I assume?

Again, could someone please make a quick

drawin how two driving coils instead of one

are connected?

Hi Salar,

Ring magnets are the most simple and effective ways to clamp a CD. Almost every junk CD player has one of these just waiting to be plucked for use.

Duplicate the circuitry and connections from IC202, pins 2 and 3 on forward. Connect the same as IC202. You only need a single op amp.

My bench area is all pulled apart, and so is my office. I can't do much more on the computer than answer posts. I can't even scan anything yet.

-Chris

Ring magnets are the most simple and effective ways to clamp a CD. Almost every junk CD player has one of these just waiting to be plucked for use.

Duplicate the circuitry and connections from IC202, pins 2 and 3 on forward. Connect the same as IC202. You only need a single op amp.

My bench area is all pulled apart, and so is my office. I can't do much more on the computer than answer posts. I can't even scan anything yet.

-Chris

- Home

- Source & Line

- Digital Source

- Quality CD-Mechanisms are long gone - let us build one ourselves!