"let's build one ourselves"

So guys, cool it.

If Mark Whitney is not interested in building or contributing in a positive manner, perhaps he should just leave the thread. I have no personal axe to grind with him, however if he continues along as he has done so then he has no positive contribution. I applaud Mark for his stubbornness but restating the same thing over and over does not seem to advance the thread and its goal. Perhaps he should start another thread such as "why dvd drives are suitable as high quality cd mechanisms" or similar?

Most music systems are used for multiples of hours daily (if they're any good) and if the primary source is cd, then there is a need for a better mechanism than currently available. If the quality of the transport was not a concern why would Sony, Phillips, Matsushita et al focus on the transport mechanisms of the earlier machines?

If the argument becomes one such as "the original machines were intended for continuous use by professionals and radio broadcasters" and thus were built very robustly is not a suitable answer. The same argument could be made concerning broadcast turntables, most of which were clearly superior to their "consumer" brethren. Seems like to me most people would want something better.

I do know there are proponents of using cheap dvd player as a transport or player. I have a friend who insists on using a sub $100 Sony as a player in a very revealing and good sounding system. However he never listens to a stock one. (He does his own modifications, mainly concentrating on upgrading capacitors and resistors in the audio playback chain). However, if he had to pay for such modifications, that sub $100 dvd player would cost well over $1000. So where's the value? I personally have multiple Sony SCHP-100X "Greystations" that sound pretty damn good considering their very humble intent. With mods the Greystations can sound quite good, and at worst non-fatiguing. And the transports are available, but only as Chinese knockoffs now :-(

I've asked anatech for some help with a couple of players I have kicking around, both cd and dvd. I can tell you that given my 'druthers, I'd rather have a great transport (and/or player) with a very serviceable life than almost all of the ones I've seen the inside or have owned. The exceptions have been an early Technics SLP8 cd player and a Sony cd505ESd. Oh and a Cal DX-1 and CALTercet, both of which used Matsushita/Technics mechanisms incorporating the linear "sleds" and upgraded optics made of glass rather than of plastic as in stock Technics players (Technics may have used glass optics in some of their machines, but none that I am aware of).

What would I like to see in a cd player or transport? Well here's my wish list:

To me Einstein's suggestion that things be only as complicated as need be holds true for objects as well as mathematical solutions.

Concerning Mark's sketches of a sled:

I think they basically look good. I'd prefer the use of linear motors for track access, but for a sled that incorporates a motor and stationary optics, it looks quite good. This is what I consider to be a positive contribution to this thread. Thanks Mark.

So guys, cool it.

If Mark Whitney is not interested in building or contributing in a positive manner, perhaps he should just leave the thread. I have no personal axe to grind with him, however if he continues along as he has done so then he has no positive contribution. I applaud Mark for his stubbornness but restating the same thing over and over does not seem to advance the thread and its goal. Perhaps he should start another thread such as "why dvd drives are suitable as high quality cd mechanisms" or similar?

Most music systems are used for multiples of hours daily (if they're any good) and if the primary source is cd, then there is a need for a better mechanism than currently available. If the quality of the transport was not a concern why would Sony, Phillips, Matsushita et al focus on the transport mechanisms of the earlier machines?

If the argument becomes one such as "the original machines were intended for continuous use by professionals and radio broadcasters" and thus were built very robustly is not a suitable answer. The same argument could be made concerning broadcast turntables, most of which were clearly superior to their "consumer" brethren. Seems like to me most people would want something better.

I do know there are proponents of using cheap dvd player as a transport or player. I have a friend who insists on using a sub $100 Sony as a player in a very revealing and good sounding system. However he never listens to a stock one. (He does his own modifications, mainly concentrating on upgrading capacitors and resistors in the audio playback chain). However, if he had to pay for such modifications, that sub $100 dvd player would cost well over $1000. So where's the value? I personally have multiple Sony SCHP-100X "Greystations" that sound pretty damn good considering their very humble intent. With mods the Greystations can sound quite good, and at worst non-fatiguing. And the transports are available, but only as Chinese knockoffs now :-(

I've asked anatech for some help with a couple of players I have kicking around, both cd and dvd. I can tell you that given my 'druthers, I'd rather have a great transport (and/or player) with a very serviceable life than almost all of the ones I've seen the inside or have owned. The exceptions have been an early Technics SLP8 cd player and a Sony cd505ESd. Oh and a Cal DX-1 and CALTercet, both of which used Matsushita/Technics mechanisms incorporating the linear "sleds" and upgraded optics made of glass rather than of plastic as in stock Technics players (Technics may have used glass optics in some of their machines, but none that I am aware of).

What would I like to see in a cd player or transport? Well here's my wish list:

- a manual loaded machine, either top load or front load, but no electro-mechanical means for opening the drawer if so equipped. A sturdy spring could do the job nicely as an assist;

- The best possible optics available, with easy access to facilitate lens cleaning if required;

- electrical adjustments for the transport mechanism that are accessable and easy to adjust;

- A well constructed non-resonant case. It could be metal, it could be wood. I don't care;

- the use of quality components within the player/transport including power supplies and passives. Multiple transformers for display, digital circuits and analog circuits;

- a display "off" capability

- the use of a "standard" set of IR commands to allow the use of almost any remote whether it be a universal remote or not, the machine should be able to be identified so that a universal remote could easily be programmed

To me Einstein's suggestion that things be only as complicated as need be holds true for objects as well as mathematical solutions.

Concerning Mark's sketches of a sled:

I think they basically look good. I'd prefer the use of linear motors for track access, but for a sled that incorporates a motor and stationary optics, it looks quite good. This is what I consider to be a positive contribution to this thread. Thanks Mark.

Last edited:

Listen Mark: You could have posted this earlier.

Instead you doubt everything written here, and

when somebody pushes you in a corner -so to say- you suddenly

wave with a so called "solution" you could have brought up

earlier. But in fact filling this thread with unneccessary remarks

and then saying "Oh, I was the one who gave you this answer."

This scetch can be done in 30 minutes. It is just like drawing

a plane. You only need to know that it needs wings.

Instead you doubt everything written here, and

when somebody pushes you in a corner -so to say- you suddenly

wave with a so called "solution" you could have brought up

earlier. But in fact filling this thread with unneccessary remarks

and then saying "Oh, I was the one who gave you this answer."

This scetch can be done in 30 minutes. It is just like drawing

a plane. You only need to know that it needs wings.

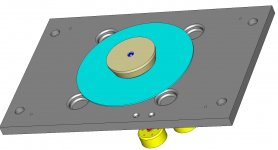

@Nanook

You nailed it. This player will probably survive

the conditions from where your nickname comes from.

The drawing shows nothing new besides the design

needs we already know: Disc motor "upfront"

to fit contemporary lasers, three point bearing.

My design will basically not look different, so I can't

wait to read "i was the one who brought up the design"

in post 852 🙂

You nailed it. This player will probably survive

the conditions from where your nickname comes from.

The drawing shows nothing new besides the design

needs we already know: Disc motor "upfront"

to fit contemporary lasers, three point bearing.

My design will basically not look different, so I can't

wait to read "i was the one who brought up the design"

in post 852 🙂

I am sorry that I gave you the impression that I am in any way preventing this from being build. I haven't stopped anyone from proposing/posting designs. I am just trying to supply some information. What have I said that is incorrect? Or, do you only want people here that agree with you all the time?

How could I have posted it earlier? you only recently posted these goals. And, I did not post it as a "solution", more like a very small first step.

How could I have posted it earlier? you only recently posted these goals. And, I did not post it as a "solution", more like a very small first step.

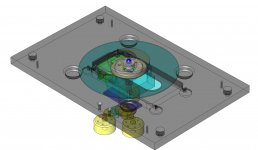

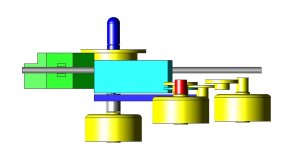

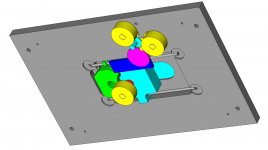

Then there is time to show you that modyfiying an existing design leads to nothing:

This I made based on a Sanyo DV-34 mechanism. CD is moved. Only the fixtures for the motors and the spring-based cone for centering the CD are missing in this drawing.

A 0,2mm steel plate needs to cover the laser, because Sanyo even did

not care to mold a cap protect the laser from dust. And where is Sanyo now?

Bought by Panasonic and no sign that this mech is still being produced.

This, I mentioned in the very beginning, We can´t rely on the companies.

Stated this in the beginning, 80% of the answers ignored this fact

We could have built great mechs from ROM drives around 2000. The first gen.Pioneer/Apple DVD drive I own still runs. Rhe rst has failed, including a CDR-F1 from Yamaha.

So, 1 week of measuring and drawing to find out that the supply from Sanyo is not secure.

BTW, I will need at least two weeks for designing a linear mech. Will take the measures of the permanent magnets and their fixtures from the BU-1.

This I made based on a Sanyo DV-34 mechanism. CD is moved. Only the fixtures for the motors and the spring-based cone for centering the CD are missing in this drawing.

A 0,2mm steel plate needs to cover the laser, because Sanyo even did

not care to mold a cap protect the laser from dust. And where is Sanyo now?

Bought by Panasonic and no sign that this mech is still being produced.

This, I mentioned in the very beginning, We can´t rely on the companies.

Stated this in the beginning, 80% of the answers ignored this fact

We could have built great mechs from ROM drives around 2000. The first gen.Pioneer/Apple DVD drive I own still runs. Rhe rst has failed, including a CDR-F1 from Yamaha.

So, 1 week of measuring and drawing to find out that the supply from Sanyo is not secure.

BTW, I will need at least two weeks for designing a linear mech. Will take the measures of the permanent magnets and their fixtures from the BU-1.

Attachments

Last edited:

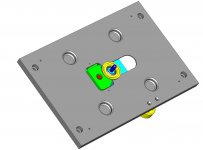

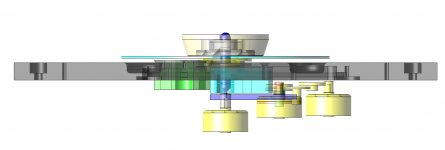

Hi Salar,

What a nice bearing with plenty of surface area to spread out the forces. I really like that one! Is that a magnetic clamp on the flapper by chance?

You can spread out the mechanical adjustments a bit. The height can be dealt with in one area, then the three axis alignment in another. If you have the service manual for the OMS-5 / 7, they have an excellent alignment that corrects for every possible misalignment. The best part is that they use springs and special washers (shoulder washers - brass) that allow the mechanics to stay aligned while adjustments are taking place, sliding on the surface. Once the alignments are adjusted properly they screw down to lock the position. Then there are the more permanent screws that really fix everything into place. Without the spring-washer setup, alignment would be difficult making perfect alignment impossible. The nice thing is that once aligned, nothing moves out of place.

I see the wheel on the sled. What can happen with those is that they tend to roll over any debris, fixing it in place. Maybe a small brush at either end would clear the track without posing too much of a load. Hair and dust move easily before being rolled over, but not after some times!

You have my full support on this design Salar. I think you have a real winner here.

-Chris

What a nice bearing with plenty of surface area to spread out the forces. I really like that one! Is that a magnetic clamp on the flapper by chance?

You can spread out the mechanical adjustments a bit. The height can be dealt with in one area, then the three axis alignment in another. If you have the service manual for the OMS-5 / 7, they have an excellent alignment that corrects for every possible misalignment. The best part is that they use springs and special washers (shoulder washers - brass) that allow the mechanics to stay aligned while adjustments are taking place, sliding on the surface. Once the alignments are adjusted properly they screw down to lock the position. Then there are the more permanent screws that really fix everything into place. Without the spring-washer setup, alignment would be difficult making perfect alignment impossible. The nice thing is that once aligned, nothing moves out of place.

I see the wheel on the sled. What can happen with those is that they tend to roll over any debris, fixing it in place. Maybe a small brush at either end would clear the track without posing too much of a load. Hair and dust move easily before being rolled over, but not after some times!

You have my full support on this design Salar. I think you have a real winner here.

-Chris

Last edited:

Hi Nanook,

That is pretty much where the design was headed beforehand. You really have a good bead on this. Well, one exception. We'll remove the tray motor for you! 🙂

I prefer a motorized tray as they are extremely reliable. With a spring, the tray needs to be decelerated smoothly and it can't hit the end stop. If it does the CD may jump out of the tray. I have serviced some transports like this back in the day for cassettes. So unless we use air pots for this (expensive), the long term control will deteriorate so that tray either doesn't eject, or it hits the stop harder than you would like.

I think that as most of us age, shaky fingers may cry out for a motorized tray. What is the reason you don't want to have a motorized tray?

BTW, YGM.

-Chris

That is pretty much where the design was headed beforehand. You really have a good bead on this. Well, one exception. We'll remove the tray motor for you! 🙂

I prefer a motorized tray as they are extremely reliable. With a spring, the tray needs to be decelerated smoothly and it can't hit the end stop. If it does the CD may jump out of the tray. I have serviced some transports like this back in the day for cassettes. So unless we use air pots for this (expensive), the long term control will deteriorate so that tray either doesn't eject, or it hits the stop harder than you would like.

I think that as most of us age, shaky fingers may cry out for a motorized tray. What is the reason you don't want to have a motorized tray?

BTW, YGM.

-Chris

I once did a tray loader for a CD-pro-ll mechanism. Took two years an a lot of tooling to make it feasible for production.

Stick to top loading, that will take a lot of complexity out and put focus on the real important issue, as to get a drive.

Stick to top loading, that will take a lot of complexity out and put focus on the real important issue, as to get a drive.

Hi MiiB,

In service, we had a lot of trouble with top loading drives from a couple areas.

The disc table can be driven down. Don't ask me how they do it, but it is reasonably common.

The clamp loses it's ability to stay put as it ages.

The clamp goes missing. Again, don't ask me how, but it has happened more than once.

The amount of debris is much greater than a tray type transport. The amount of hair and animal fur is really high with top loading transports. This is a constant thing, cleaner homes have less, but they would have much less with a tray mechanism.

The bay needs to be wider than many I've seen. Also the tray cover can be easily broken at the hinges if acrylic is used. Replaced many over the years. A power cover would be more complicated than a tray. The worst was probably the iris used by Sonic Frontiers. Really cool see it operating though!

Lot's to think about. For me, a tray is by far the easiest to deal with. A wide top load would work too, but the maintenance would likely be a yearly cleaning of the transport. Using the wheel on the sled would make this an unhappy combination since it doesn't wipe the contact area to keep it clean(er).

-Chris

In service, we had a lot of trouble with top loading drives from a couple areas.

The disc table can be driven down. Don't ask me how they do it, but it is reasonably common.

The clamp loses it's ability to stay put as it ages.

The clamp goes missing. Again, don't ask me how, but it has happened more than once.

The amount of debris is much greater than a tray type transport. The amount of hair and animal fur is really high with top loading transports. This is a constant thing, cleaner homes have less, but they would have much less with a tray mechanism.

The bay needs to be wider than many I've seen. Also the tray cover can be easily broken at the hinges if acrylic is used. Replaced many over the years. A power cover would be more complicated than a tray. The worst was probably the iris used by Sonic Frontiers. Really cool see it operating though!

Lot's to think about. For me, a tray is by far the easiest to deal with. A wide top load would work too, but the maintenance would likely be a yearly cleaning of the transport. Using the wheel on the sled would make this an unhappy combination since it doesn't wipe the contact area to keep it clean(er).

-Chris

...from the Great White North...

Salar: where I live dust is a bigger concern than almost anything else environmental. That's why I use a Pioneer Elite PD-54 "Stable Platter" daily since I bought it in the early 90's. Dust simply doesn't fall "up", at least where I am 🙂

Salar: OK. I do like your drawings and the beginning of the mechanism that you are building.

Mark: I prefer folks to be included, so if wanting to help all build a superior transport, I look forward to your positive input. If modifying existing players, then we have to start with someone else's priorities regarding transport design and features. Now if any of you know where I could get an old New Old Stock SLP1200, SLP9 or SLP8, let me know 🙂. Those were/are very good mechanisms with robust construction. Perhaps Tascam has a player that has a good transport similar to what we are trying to build here? And if built as per other Tascam professional products (or Sony, Technics, et al) then should be pretty much bullet-proof. Or NOS Nakamichi OMS5/OMS7 players. And I do know that Sony has made some damn fine transports and optics, as well as Philips.

and to Chris:

I do have a real purpose for the lack of a drawer loading mechanism or rather a powered drawer loading mechanism.

I actually like the original Rega "Planet" and "PLanet 2000" cd players as they seemed to be only as complicated as need be (regarding the top loading and integrated clamping mechanism, but perhaps not the the actual Sanyo mechanism and DAC implementation.

I have found that anything that contributes to complexity can be PITA as far as longevity goes. No nylon gears, etc. Maybe a belt drive mechanism not relying on any gears, etc would work for the tray opening and closing. If my fingers get that shaky, I'll just shoot myself (kidding). I still cue my tonearm using just hand control (no levers, cueing devices, etc), but can see where most will need an easy to use , convenient means of loading a disc. Without relying electronics, a drawer can be a beautiful thing. I've looked at various machines and cannot believe how cheesy drawers are.

As you know Mark, the Pioneer DV-09 has a busted (as in basically exploded) drawer with no service parts available. Other than that it is apparently good. For those that don't know, Mark has been helping me off-line regarding a few dvd players and cd players I have to get them into good operating condition so that I can send them off to new homes (to my kids, and a few I'd like to keep).

So lets move onward. We all need to understand the intent of the thread and all take positive steps to seeing this to fruition (even if I may never be able to afford the pieces needed to build this thing 🙁

@Nanook

You nailed it. This player will probably survive

the conditions from where your nickname comes from.

Salar: where I live dust is a bigger concern than almost anything else environmental. That's why I use a Pioneer Elite PD-54 "Stable Platter" daily since I bought it in the early 90's. Dust simply doesn't fall "up", at least where I am 🙂

The drawing shows nothing new besides the design

needs we already know: Disc motor "upfront"

to fit contemporary lasers, three point bearing.

My design will basically not look different, so I can't

wait to read "i was the one who brought up the design"

in post 852 🙂

Salar: OK. I do like your drawings and the beginning of the mechanism that you are building.

Mark: I prefer folks to be included, so if wanting to help all build a superior transport, I look forward to your positive input. If modifying existing players, then we have to start with someone else's priorities regarding transport design and features. Now if any of you know where I could get an old New Old Stock SLP1200, SLP9 or SLP8, let me know 🙂. Those were/are very good mechanisms with robust construction. Perhaps Tascam has a player that has a good transport similar to what we are trying to build here? And if built as per other Tascam professional products (or Sony, Technics, et al) then should be pretty much bullet-proof. Or NOS Nakamichi OMS5/OMS7 players. And I do know that Sony has made some damn fine transports and optics, as well as Philips.

and to Chris:

Hi Nanook,

That is pretty much where the design was headed beforehand. You really have a good bead on this. Well, one exception. We'll remove the tray motor for you!

I do have a real purpose for the lack of a drawer loading mechanism or rather a powered drawer loading mechanism.

I actually like the original Rega "Planet" and "PLanet 2000" cd players as they seemed to be only as complicated as need be (regarding the top loading and integrated clamping mechanism, but perhaps not the the actual Sanyo mechanism and DAC implementation.

I think that as most of us age, shaky fingers may cry out for a motorized tray. What is the reason you don't want to have a motorized tray?

I have found that anything that contributes to complexity can be PITA as far as longevity goes. No nylon gears, etc. Maybe a belt drive mechanism not relying on any gears, etc would work for the tray opening and closing. If my fingers get that shaky, I'll just shoot myself (kidding). I still cue my tonearm using just hand control (no levers, cueing devices, etc), but can see where most will need an easy to use , convenient means of loading a disc. Without relying electronics, a drawer can be a beautiful thing. I've looked at various machines and cannot believe how cheesy drawers are.

As you know Mark, the Pioneer DV-09 has a busted (as in basically exploded) drawer with no service parts available. Other than that it is apparently good. For those that don't know, Mark has been helping me off-line regarding a few dvd players and cd players I have to get them into good operating condition so that I can send them off to new homes (to my kids, and a few I'd like to keep).

So lets move onward. We all need to understand the intent of the thread and all take positive steps to seeing this to fruition (even if I may never be able to afford the pieces needed to build this thing 🙁

Hi Chris!

The drawings in post #546 are based on an existing Dv-34 mech.

Nothing serious. Linear will be the way to go. But a thick shaft of 6mm

magnetic clamper (or 80mm non magnetic clamper) will stay.

Again, 2 weeks needed.

Is three beam really the way to go? Fear alignment of diffraction grating. any other one- beamers besides Philips? Forgot this in this long thread. Have the One - beamers OMS7 and a Toshiba XR-Z70 to check.

The drawings in post #546 are based on an existing Dv-34 mech.

Nothing serious. Linear will be the way to go. But a thick shaft of 6mm

magnetic clamper (or 80mm non magnetic clamper) will stay.

Again, 2 weeks needed.

Is three beam really the way to go? Fear alignment of diffraction grating. any other one- beamers besides Philips? Forgot this in this long thread. Have the One - beamers OMS7 and a Toshiba XR-Z70 to check.

Hi Salar,

Go magnetic clamper please! A pressure clamper doubles the outside world's influence on the CD, and it has bearings also. Too much mechanical stuff to go wrong. A magnetic clamper detaches from it's holder completely, leaving only the motor assy to connect to the CD as it plays.

Any new head ought to be a three beam setup. The single beam models trade the diffraction grating in for an oscillator and on-purpose mistracking. They must swing the laser back and forth slightly off center to each side and center by having the same amount of beam fall-off on positive - negative swings. You will see the ~ 600 Hz signal on the tracking coil. The single beam units have another advantage too. Because there are fewer optics involved, the energy emitted has higher efficiency as the loses inside the head are lower. In the past that mattered, but with today's highly efficient laser diodes, it doesn't matter.

Single beam systems have disc defects that they don't handle well, as do the three beam systems. All in all, at least the three beam system use the extra two beams to keep the main beam centered on the track (E and F, remember E-F balance adjustments?). I'd rather not have the tracking to find track center affecting the main spot.

I wonder if a number of used heads could be found that need a new laser diode. That suggests that you could breathe new life into a dead head (sticker on a Cadillac - sorry). Couldn't resist the bad joke. The KSS-123A is not a contender due to the sticky guide post issue. Too bad the OMS-7 heads couldn't be found (I know, single beam), they are the best heads I have ever seen. Large though. Any other suggestions? There is probably a warehouse full of completed or castings for a popular head in a warehouse in the far east somewhere.

Why is the Nak OMS-7 the best head? Because the optical path is set up like a laser lab would do. All the adjustments are there with a plastic dust cover giving you access to everything. So all the internal adjustments can be done. I'm sure that any high quality head would be wonderful in the transport that allows complete adjustment in free space. That was Nakamichi's secret. You adjusted all the errors out in the transport. You could do the same with an SF-90 Sanyo, or the deplorable HOP-M3 piece of garbage. The HOP-M3's biggest problem was the all plastic construction. Fix that and I'm sure we would discover another defect in design. The SF-90 types used bars to support the lens and run current to the coils. The solder connections would go open (Also allowing the lens to slip out of place). That one is a no-go as well. I just used the worst two I could think of as examples.

Reinventing the optical path for any new head is something we should probably avoid. Any reasonably priced production head would leave you ahead in this game I think.

-Chris

Go magnetic clamper please! A pressure clamper doubles the outside world's influence on the CD, and it has bearings also. Too much mechanical stuff to go wrong. A magnetic clamper detaches from it's holder completely, leaving only the motor assy to connect to the CD as it plays.

Any new head ought to be a three beam setup. The single beam models trade the diffraction grating in for an oscillator and on-purpose mistracking. They must swing the laser back and forth slightly off center to each side and center by having the same amount of beam fall-off on positive - negative swings. You will see the ~ 600 Hz signal on the tracking coil. The single beam units have another advantage too. Because there are fewer optics involved, the energy emitted has higher efficiency as the loses inside the head are lower. In the past that mattered, but with today's highly efficient laser diodes, it doesn't matter.

Single beam systems have disc defects that they don't handle well, as do the three beam systems. All in all, at least the three beam system use the extra two beams to keep the main beam centered on the track (E and F, remember E-F balance adjustments?). I'd rather not have the tracking to find track center affecting the main spot.

I wonder if a number of used heads could be found that need a new laser diode. That suggests that you could breathe new life into a dead head (sticker on a Cadillac - sorry). Couldn't resist the bad joke. The KSS-123A is not a contender due to the sticky guide post issue. Too bad the OMS-7 heads couldn't be found (I know, single beam), they are the best heads I have ever seen. Large though. Any other suggestions? There is probably a warehouse full of completed or castings for a popular head in a warehouse in the far east somewhere.

Why is the Nak OMS-7 the best head? Because the optical path is set up like a laser lab would do. All the adjustments are there with a plastic dust cover giving you access to everything. So all the internal adjustments can be done. I'm sure that any high quality head would be wonderful in the transport that allows complete adjustment in free space. That was Nakamichi's secret. You adjusted all the errors out in the transport. You could do the same with an SF-90 Sanyo, or the deplorable HOP-M3 piece of garbage. The HOP-M3's biggest problem was the all plastic construction. Fix that and I'm sure we would discover another defect in design. The SF-90 types used bars to support the lens and run current to the coils. The solder connections would go open (Also allowing the lens to slip out of place). That one is a no-go as well. I just used the worst two I could think of as examples.

Reinventing the optical path for any new head is something we should probably avoid. Any reasonably priced production head would leave you ahead in this game I think.

-Chris

Hi Salar,

I'll have to check the next time I have it on the bench. I'm planning to get it up in order to post pictures of an excellent eye pattern. I haven't looked at it for over 10 years easy, so it's time for a clean and check up. It's been in the bedroom playing away the entire time. I think I'm going to stick a 5 disc in there instead.

-Chris

I'll have to check the next time I have it on the bench. I'm planning to get it up in order to post pictures of an excellent eye pattern. I haven't looked at it for over 10 years easy, so it's time for a clean and check up. It's been in the bedroom playing away the entire time. I think I'm going to stick a 5 disc in there instead.

-Chris

Hi Chris!

That would be nice, but evidence could be also found in the service manual?

As previously mentioned, I have several Toshiba XR-Z70 (still like the design),

the lasers (Toshiba OPH32) resemble very much the first gen. Nakamichi Lasers (HLPL 030020 / CA80255A).

I also have first generation OMS-5, but it is broken. No time to fix it in the moment.

Both, the first generation OMS-5 as well as the Toshiba are single beam with 4 photodiodes and linear trackers.

No sign in both service manuals (to the layman) that

a wobble frequency is applied.

Why do I bring this up again?

Because the Toshiba tracks burned CD-R very well.

I use one CD-R with a 500hz tone wich is mixed with a 15kHz tone.

You´ll hear no clicks, but my second gen. OM5-EII does not track that well. (i know that the KSS123A is not that good).

The second generation Nak will produce little klicks randomly in distances of 2-5 second. The Toshiba plays fine.

Maybe this player is a good example for good optics.

When I am not wrong, single beam should be easier to be built - again I am a layman.

Maybe 3 beam allow more tolerances, that´s why they became common.

And we learned from the defunct linear sled, that 3-beam might necessarily not be the best system (But probably is)

But we should discuss one beam linear tracking versus 3 beam linear tracking again before we dig into mechanical laser design.

Nevertheless I will start to design the sled mechanism on the weekend as

we could probably use almost any laser with a moving disc

That would be nice, but evidence could be also found in the service manual?

As previously mentioned, I have several Toshiba XR-Z70 (still like the design),

the lasers (Toshiba OPH32) resemble very much the first gen. Nakamichi Lasers (HLPL 030020 / CA80255A).

I also have first generation OMS-5, but it is broken. No time to fix it in the moment.

Both, the first generation OMS-5 as well as the Toshiba are single beam with 4 photodiodes and linear trackers.

No sign in both service manuals (to the layman) that

a wobble frequency is applied.

Why do I bring this up again?

Because the Toshiba tracks burned CD-R very well.

I use one CD-R with a 500hz tone wich is mixed with a 15kHz tone.

You´ll hear no clicks, but my second gen. OM5-EII does not track that well. (i know that the KSS123A is not that good).

The second generation Nak will produce little klicks randomly in distances of 2-5 second. The Toshiba plays fine.

Maybe this player is a good example for good optics.

When I am not wrong, single beam should be easier to be built - again I am a layman.

Maybe 3 beam allow more tolerances, that´s why they became common.

And we learned from the defunct linear sled, that 3-beam might necessarily not be the best system (But probably is)

But we should discuss one beam linear tracking versus 3 beam linear tracking again before we dig into mechanical laser design.

Nevertheless I will start to design the sled mechanism on the weekend as

we could probably use almost any laser with a moving disc

Last edited:

- Home

- Source & Line

- Digital Source

- Quality CD-Mechanisms are long gone - let us build one ourselves!