Personal opinions may vary. I think it is very very much worth the effort.Nobody will touch Quads anymore as it's not worth the effort.

I wasn't talking about sound difference, neither were you if I recall correctly. You mentioned arcing due to loosened stator PCB's.No way 0.2 mm on anything will make any kind of objective difference in the sound.

It isn't if it was caused by arcing. Burned.an occasional visible membrane puncture is nothing to worry about

If you cold puncture it with a paper clip the total diaphragm will rip. Completely different subject.

"Nobody will touch Quads anymore as it's not worth the effort." These guys have built a nice business rebuilding panels and speakers: https://estatsolution.com/elements.html I have used them and can recommend their services. A burned hole in a diaphragm becomes a focus for voltage breakdown. The carbon conducts better and you get a corona around it that arcs easily. With an ultrasonic detector you can easily "hear" the corona from a burned hole.

I would agree that a new design using newer materials and manufacturing is overdue but discounting the assembly as using bookbinding glue is really dismissive. The adhesive needs to be able to stick to plastic (hard), mylar (very hard), paper phenolic, PCB solder resist and handle differential expansion without cracking and handle the stress of the diaphragm. This would be a specialty adhesive. There are new adhesives that might work better (after 40+ years) but you would need to test them to make sure it doesn't have other problems. Ross Walker tells a story about the damping screen. The vendor improved the product by making it conductive (its normally used a a filter medium) and it caused serious problems. Quad had to get the vendor to make the old version specifically for them. Manufacturing is never easy.

I would agree that a new design using newer materials and manufacturing is overdue but discounting the assembly as using bookbinding glue is really dismissive. The adhesive needs to be able to stick to plastic (hard), mylar (very hard), paper phenolic, PCB solder resist and handle differential expansion without cracking and handle the stress of the diaphragm. This would be a specialty adhesive. There are new adhesives that might work better (after 40+ years) but you would need to test them to make sure it doesn't have other problems. Ross Walker tells a story about the damping screen. The vendor improved the product by making it conductive (its normally used a a filter medium) and it caused serious problems. Quad had to get the vendor to make the old version specifically for them. Manufacturing is never easy.

Ah, I see there is some confusion about the nature of the beast here, so let me clarify further. It is not the touching of the mylar membrane to the stator that one needs to fear. The mylar has GIGAohm-meter resistivity and very little stored energy when not pushing air. Any arcing from the mylar to the stator is self-limiting in a very benign way. Forty years ago I would play Kraftwerk too loud on my dad's '57s and the membrane would definitely slap the stators quite often. Those speakers still sound very nice today after a HV supply rebuild; same mylar. Granted, none of our hearing is ultrasonic anymore: that could explain the dearth of cats in the vicinity. Martin-Logans too acquire a greyish patina of carbon from all the dust that self-combusts over the years. Vacuuming regularly picks up most of that and keeps the membrane healthy for a very long time: you can hear the hiss when it becomes too conductive if neglected.

No, the dangerous failure mode is the two stators touching each other after coming unglued from the grids. If your monoblock is pushing a kilowatt of transient at 20 Hz, that could be 50 Joules stored in the magnetic field of the trafo that can all dump into that tiny spark in microseconds through a highly conductive pathway. That's enough energy to weld copper. Then the next weld will be in the trafo, then in your power amp, then if you're lucky the circuit breaker will pop before you get to replace your house wiring or your house. I suppose there may be some wisdom in never powering old Quads with anything other that 20 W of triodes! 😀

Is it worth it? Well, dunno, ymmv. I just finished Elina Garanča's Carmen on the Quads and on the LS50's sitting right next to them, and I can tell you that the little KEFs have a surprisingly similar tonal character and pleasant performance, but the sound stage is a tiny joke compared to the Quads. Take me to the Opera dammit!

No, the dangerous failure mode is the two stators touching each other after coming unglued from the grids. If your monoblock is pushing a kilowatt of transient at 20 Hz, that could be 50 Joules stored in the magnetic field of the trafo that can all dump into that tiny spark in microseconds through a highly conductive pathway. That's enough energy to weld copper. Then the next weld will be in the trafo, then in your power amp, then if you're lucky the circuit breaker will pop before you get to replace your house wiring or your house. I suppose there may be some wisdom in never powering old Quads with anything other that 20 W of triodes! 😀

Is it worth it? Well, dunno, ymmv. I just finished Elina Garanča's Carmen on the Quads and on the LS50's sitting right next to them, and I can tell you that the little KEFs have a surprisingly similar tonal character and pleasant performance, but the sound stage is a tiny joke compared to the Quads. Take me to the Opera dammit!

I have used hot glue in the corners / along edges of loose stator panels too, using a sharp hooked tipped awl to pull stator onto stator matrix (careful not to puncture mylar - I have not yet) . The other benefit is a tiny bit of hot melt glue gets thru the stator hole, runs down the inside of the stator, solidifies, and forms a nice "anchor" to the stator matrix - can't get that with epoxy...one must be careful with all the "stringy" leftover from hot glue, but thats why you thoroughly check before you button everything up...

I. for one, am looking for a better way to attach stator matrix to stator via "anchors" in all corners, instead of the short-sighted method of epoxy on all stator matrix surface area to stator, that will just eventually fail. These speakers are a technical marvel, but the way the stator matrix is attached to the stator is just...well...bad.

The thought of a set of quads I can really drive real hard like my Martin Logan CLS, without worry of breaking loose the stator from stator matrix would be the last speakers I would ever want to own.

I. for one, am looking for a better way to attach stator matrix to stator via "anchors" in all corners, instead of the short-sighted method of epoxy on all stator matrix surface area to stator, that will just eventually fail. These speakers are a technical marvel, but the way the stator matrix is attached to the stator is just...well...bad.

The thought of a set of quads I can really drive real hard like my Martin Logan CLS, without worry of breaking loose the stator from stator matrix would be the last speakers I would ever want to own.

Last edited:

"Ah, I see there is some confusion about the nature of the beast here, so let me clarify further. It is not the touching of the mylar membrane to the stator that one needs to fear. The mylar has GIGAohm-meter resistivity and very little stored energy when not pushing air. Any arcing from the mylar to the stator is self-limiting in a very benign way." doesn't match my experience. Once the air ionizes the temperature is hot enough to easily melt the plastic. Even though the current is limited to the available charge its still enough. I have seen holes in panels where the stators are still quite solidly attached. Big burn marks on the stators as well. The bias voltage (5.2 KV) is very close to the breakdown voltage of air for that gap (approx 7KV at 1 PA at 3 mm.) so it takes little extra voltage to get an arc.

Oh Elina Garanča!!!Ah, I see there is some confusion about the nature of the beast here, so let me clarify further. It is not the touching of the mylar membrane to the stator that one needs to fear. The mylar has GIGAohm-meter resistivity and very little stored energy when not pushing air. Any arcing from the mylar to the stator is self-limiting in a very benign way. Forty years ago I would play Kraftwerk too loud on my dad's '57s and the membrane would definitely slap the stators quite often. Those speakers still sound very nice today after a HV supply rebuild; same mylar. Granted, none of our hearing is ultrasonic anymore: that could explain the dearth of cats in the vicinity. Martin-Logans too acquire a greyish patina of carbon from all the dust that self-combusts over the years. Vacuuming regularly picks up most of that and keeps the membrane healthy for a very long time: you can hear the hiss when it becomes too conductive if neglected.

No, the dangerous failure mode is the two stators touching each other after coming unglued from the grids. If your monoblock is pushing a kilowatt of transient at 20 Hz, that could be 50 Joules stored in the magnetic field of the trafo that can all dump into that tiny spark in microseconds through a highly conductive pathway. That's enough energy to weld copper. Then the next weld will be in the trafo, then in your power amp, then if you're lucky the circuit breaker will pop before you get to replace your house wiring or your house. I suppose there may be some wisdom in never powering old Quads with anything other that 20 W of triodes! 😀

Is it worth it? Well, dunno, ymmv. I just finished Elina Garanča's Carmen on the Quads and on the LS50's sitting right next to them, and I can tell you that the little KEFs have a surprisingly similar tonal character and pleasant performance, but the sound stage is a tiny joke compared to the Quads. Take me to the Opera dammit!

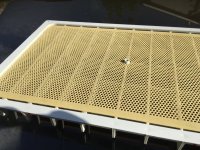

The mylar diaphragm is very thin has very little mass so it doesn't take much energy to heat it up significantly. You can see in the diaphragm picture below all the places the diaphragm has arced. It most certainly has done damage of some sort. It tends to be benign for the operation of the panel compared to the glue losing strength over time. And I'm adding a bonus picture of one of the assembler's hairs stuck in the coating. These speakers aren't exactly assembled to aerospace standards.

Also epoxy isn't a good adhesive (at least the typical 5 minute types that dry hard) for bonding stators to the frames. I'd use something with more flex and also able to bond more securely to the plastic frame material and the stator material.

Sheldon

Also epoxy isn't a good adhesive (at least the typical 5 minute types that dry hard) for bonding stators to the frames. I'd use something with more flex and also able to bond more securely to the plastic frame material and the stator material.

Sheldon

Yes , I used gorilla glue polyurethane, with its typical expansion rate it has to fill those holes with more surface area and holding power after a good cleaning with acetone.

If you V notch the glue bottles filler spout slightly, it will follow the stator edge more easily

Use very little glue on the stator with the mesh as it will spread across it very easily (BTDT !)

Inspect the back side pocket areas afterwards for expansion glue excess

(2017 rebuild)

If you V notch the glue bottles filler spout slightly, it will follow the stator edge more easily

Use very little glue on the stator with the mesh as it will spread across it very easily (BTDT !)

Inspect the back side pocket areas afterwards for expansion glue excess

(2017 rebuild)

Attachments

Last edited:

No you use some wax paper along with 3/4” MDF panel made to fit over the stator area with weight

applied until dry

applied until dry

if you are using PU glue, instead of wax paper, you can use a thin polyethylene sheet (like a home store drop cloth), polyurethane glue doesn't stick to it.

When I glue stators I use 80 lbs of weights to hold the stator in place while the adhesive cures.

Sheldon

When I glue stators I use 80 lbs of weights to hold the stator in place while the adhesive cures.

Sheldon

I ended up using Elmer's E9416 PU glue. It foams less then Gorilla glue and is slight less viscus. I also used a lot less glue then Avwerk did.

IMHO less is better in this case. I think I used well over 50 pounds on each panel when gluing and did all the work on a glass sheet.

John

IMHO less is better in this case. I think I used well over 50 pounds on each panel when gluing and did all the work on a glass sheet.

John

Good morning dear members, thank you for generating this thread regarding Quad ESL. I have a question to formalize. I have a pair of ESL2905 Quad speakers which would work without distortion but when I turned the volume up they would both make sparking noises and obviously when the protection kicked in they would cut out the sound. I removed the dust covers and found that there was a spark in a few places. There is a repair and maintenance service in Valencia, Spain but I live on an island called Menorca, I contacted them and they ask me to send the speakers with the six panels removed and unsoldered from the side guides.

Seeing this new situation, I am trying to find the solution myself since practically what I wanted to avoid was disassembling, desoldering, repairing and reassembling the panels.

Haven't done it yet, just removed them from the side brackets and power supply. And of course I've been inspecting more carefully the different areas, both front and back of both panels. I discovered that the stators are detached in the places where the spark was, likewise, I saw that in other places they still remain adhered, above all to the vertical partitions of the multicell panels.

I also noticed that the horizontal partitions are further apart even in the areas where the stators are still attached. I honestly want to make as little effort as possible, the issue is to spend a lot of time and attend to details.

I want to try to glue the stators without disassembling the panels, what glue can I use? I've seen some suggestions in the threads that promote paperclips or wire to the stators so you can hold them while the glue sets;

I have noticed that there are some detractors of that method because of the risk of breaking mylar. The other option would be to spread them to the twelve panels and re-glue the stators in the cells. Thank you very much for dedicating me a few lines.

Always surprised that people buy these expensive speakers, but don't want to spend the money for a proper repair.

Definitely needed in this case.

https://www.facebook.com/groups/quadesl63/posts/821199252387755

Definitely needed in this case.

https://www.facebook.com/groups/quadesl63/posts/821199252387755

I paid 600 euros for two working, so far, now I use bi-amplifier with TAD 4001 horn loaded at 650Hz 12 dB and Two per baffle. Elegance OB 15" H-shaped. Most of the parts I bought are surplus and I repair them the hardest.

You are right to say that I did not spend a lot of money, I tried, but if I send the speakers to Valencia, 100 kg goes to an unknown place, recommended. On the part of users and partners, they said 720 euros for the complete change of mylar and adjusting the entire system but now they say that I must disassemble and send diy home to be rebuilt.

So, on the one hand, I want to thank you for the information provided that will surely dispel many doubts and I will eventually learn how to do it myself.

Best Regards

Esteban

You are right to say that I did not spend a lot of money, I tried, but if I send the speakers to Valencia, 100 kg goes to an unknown place, recommended. On the part of users and partners, they said 720 euros for the complete change of mylar and adjusting the entire system but now they say that I must disassemble and send diy home to be rebuilt.

So, on the one hand, I want to thank you for the information provided that will surely dispel many doubts and I will eventually learn how to do it myself.

Best Regards

Esteban

https://www.diyaudio.com/community/threads/esl63-repair-question.394596/#post-7250753

Different model but uses exactly the same panels.

When there are traces of arcing visible any attempt at glueing is completely pointless. You need a full rebuild to restore them.

Different model but uses exactly the same panels.

When there are traces of arcing visible any attempt at glueing is completely pointless. You need a full rebuild to restore them.

@dady Let's be honest, if you really bought the set for € 600,00, both you and the seller knew that there was something very wrong with the speakers at the moment of sales and repair / rebuild was necessary immediately or in the very near future.

So you knew there was either a lot of learning and work or a 3K price in the short future.

So you knew there was either a lot of learning and work or a 3K price in the short future.

If I'm not complaining, I simply explained the small turns that were established when I contacted the firm that repairs these speakers in Spain. However, in the forum I only ask to see if someone who judges less and helps more, in giving concrete ideas that one finds in a hobbyist forum, my original comment was that and if someone wants to interpret meta-orthodox ideas they are free to do so but please avoid value judgments.

Here people are free thinkers and free acters and what they want is help in this case and in others it offers the possibility that someone who found a solution shares it.

It seems that you are very well prepared in this area and it is very possible that the information you provide in the forum comes from your vast experience. But in this case, as I told you, I'm not interested in having a debate about why I bought an expensive speaker knowing that I was going to have to repair it later.

From what I could read on the Facebook web page to which you referred me, I have also seen that you are commercially engaged in the commercial repair of these electrostatic panels.

If someone wants or can help me advise what to do, whether to completely disassemble the panels or is there any possibility of fixing them from behind.

Here people are free thinkers and free acters and what they want is help in this case and in others it offers the possibility that someone who found a solution shares it.

It seems that you are very well prepared in this area and it is very possible that the information you provide in the forum comes from your vast experience. But in this case, as I told you, I'm not interested in having a debate about why I bought an expensive speaker knowing that I was going to have to repair it later.

From what I could read on the Facebook web page to which you referred me, I have also seen that you are commercially engaged in the commercial repair of these electrostatic panels.

If someone wants or can help me advise what to do, whether to completely disassemble the panels or is there any possibility of fixing them from behind.

No judgment, just pointing out what has most likely happened and what to do.

The commerce is my brother's, I'm in it for fun and learning about these remarkable speakers.

The advice is also there. Take the panels apart and do a full repair, all the rest is a waist of time and money.

If you want to take short cuts (glue without removing) you will end up with something that makes sound, but is not what a Quad ESL should sound like.

The explanation why it can't work properly that way is also in the text from the link.

Most likely enjoyment will be for a short period before trouble starts again if you don't do it properly.

My quest with these speakers started out because of the bad commercial repair that was done to my ESL's years ago.

It has been, and still is, a wonderful DIY adventure for me. Being well prepared came from 8 years of learning, struggling, failing, reading and testing.

So, no judgement and free advice is there like you asked.

But I can't give you a better answer than taking them completely apart and start learning like I did. The reward in the end will be great.

The commerce is my brother's, I'm in it for fun and learning about these remarkable speakers.

The advice is also there. Take the panels apart and do a full repair, all the rest is a waist of time and money.

If you want to take short cuts (glue without removing) you will end up with something that makes sound, but is not what a Quad ESL should sound like.

The explanation why it can't work properly that way is also in the text from the link.

Most likely enjoyment will be for a short period before trouble starts again if you don't do it properly.

My quest with these speakers started out because of the bad commercial repair that was done to my ESL's years ago.

It has been, and still is, a wonderful DIY adventure for me. Being well prepared came from 8 years of learning, struggling, failing, reading and testing.

So, no judgement and free advice is there like you asked.

But I can't give you a better answer than taking them completely apart and start learning like I did. The reward in the end will be great.

Thank you Mr. Wout31, if in the end it is more accurate to go to the heart of the matter. I know for sure that they are moderately expensive speakers.

They don't last forever and they sound very good for long listening of classical music due to the low distortion. It is also true that due to the way they are built and their constituent materials it seems that they were not electronic devices and they invite those with the ability to rebuild them as if it were a challenge.

I think I understood the philosophy of improving them, repairing a panel or two does not offer a great advantage either and the healthiest thing is to replace the membranes in their entirety, glue the stators from the inside and evenly to avoid differences in distances between the stator and the membrane .

It is very probably that I will send them to Valencia to have the shoemaker take care of the shoes. Then rebuild them by resoldering the panels together.

These panels that I have purchased are very new and clean on the inside, there are no breaks in the anti-dust membrane and it is taut. In such a way that I suspect they will give me satisfaction for a long time.

They don't last forever and they sound very good for long listening of classical music due to the low distortion. It is also true that due to the way they are built and their constituent materials it seems that they were not electronic devices and they invite those with the ability to rebuild them as if it were a challenge.

I think I understood the philosophy of improving them, repairing a panel or two does not offer a great advantage either and the healthiest thing is to replace the membranes in their entirety, glue the stators from the inside and evenly to avoid differences in distances between the stator and the membrane .

It is very probably that I will send them to Valencia to have the shoemaker take care of the shoes. Then rebuild them by resoldering the panels together.

These panels that I have purchased are very new and clean on the inside, there are no breaks in the anti-dust membrane and it is taut. In such a way that I suspect they will give me satisfaction for a long time.

- Home

- Loudspeakers

- Planars & Exotics

- QUAD 2805/2905 dismantling: in pictures (part 2)