@tinitus

Haven't made a dedicated power supply yet, works great with any transformer + bridge rectifier + good cap filtering

I will do a current source one but not in the near future.

@Andrew

I have dedicated much time studying the rocking mode of the voice coil and i will present at some point the tool i designed for measurement of field irregularities that could excite them.

I assume rocking modes is what you have in mind when saying radial control. This is the only worry if you are referring of the voice coil moving along the diameter of the spider so to speak. There is a minimum number of spokes you need, to be safe in this regard.

I have flipped the spider like a vertical mirror transformation with no change in the rest position.

Why it wouldn't relax eccentrically, i see no reason, perhaps you can elaborate and i will sure look into it.

Haven't made a dedicated power supply yet, works great with any transformer + bridge rectifier + good cap filtering

I will do a current source one but not in the near future.

@Andrew

I have dedicated much time studying the rocking mode of the voice coil and i will present at some point the tool i designed for measurement of field irregularities that could excite them.

I assume rocking modes is what you have in mind when saying radial control. This is the only worry if you are referring of the voice coil moving along the diameter of the spider so to speak. There is a minimum number of spokes you need, to be safe in this regard.

I have flipped the spider like a vertical mirror transformation with no change in the rest position.

Why it wouldn't relax eccentrically, i see no reason, perhaps you can elaborate and i will sure look into it.

I'm prepared to be proven wrong immediately. I've done almost no research on this:

The interlocking X pattern of a treated woven fiber spider is much more supportive of radial loads. Once glued at the inner and outer diameters, even though it's crinkled, it works much more like a set of four "A" arms.

Of course flux density is higher near the pole faces, and hitting them makes noises. Other than that I don't know why centering matters at all. I guess if there's any permeability left to the poles, inductance would increase as the coil approached.

The first "problem" is that the suspension "spoke" in your design, 90 degrees off from the direction of applied radial force, does almost nothing to restrict motion, where in the conventional spider the whole thing, quite literally, is involved at once. Second, there appears to be comparatively little damping of motion in this plane.

The interlocking X pattern of a treated woven fiber spider is much more supportive of radial loads. Once glued at the inner and outer diameters, even though it's crinkled, it works much more like a set of four "A" arms.

Of course flux density is higher near the pole faces, and hitting them makes noises. Other than that I don't know why centering matters at all. I guess if there's any permeability left to the poles, inductance would increase as the coil approached.

The first "problem" is that the suspension "spoke" in your design, 90 degrees off from the direction of applied radial force, does almost nothing to restrict motion, where in the conventional spider the whole thing, quite literally, is involved at once. Second, there appears to be comparatively little damping of motion in this plane.

I understand now better what you mean. It was confusing because this problem you are addressing is not actually a problem for loudspeakers.

The spider's role is not to support radial loads nor to restrict movement of voice coil along its radius. In this type of cone loudspeakers such movement is virtually impossible. Rocking yes which is balance movement with the connection of spider to voice coil as the fixed point and top and bottom of voice coil moving left - right but in opposite directions. and so the spider spokes on one side go up -down and on the opposite side down-up. But for voice coil to go either left or right and spider to contract - expand in that direction without external mechanical force applied i dont see it possible,

Centering matters for rocking yes because like you said flux density is higher near metal so if it is not centered force on one side of the voice coil will push upwards stronger that the other side causing the rocking movement and distortion of course but the force vector will always be parallel to the center axis of voice coil.

Gap symmetry is important as well as it has the same effect. Mapping flux density around the gap was something i always wanted. Since i cant afford a klippel i made my own version with a stepper motor rotating a hall sensor around the gap at specific angles and measuring the flux density. This way you can make a map that looks like a 2pi polar chart showing how smooth the field distribution is. Because this is the best solution to deal with rocking.

What you are saying is true though, the woven material is more supportive of radial loads just as a metal sheet is but i dont find it to be a matter in loudspeakers. Thats the way i see it.

The spider's role is not to support radial loads nor to restrict movement of voice coil along its radius. In this type of cone loudspeakers such movement is virtually impossible. Rocking yes which is balance movement with the connection of spider to voice coil as the fixed point and top and bottom of voice coil moving left - right but in opposite directions. and so the spider spokes on one side go up -down and on the opposite side down-up. But for voice coil to go either left or right and spider to contract - expand in that direction without external mechanical force applied i dont see it possible,

Centering matters for rocking yes because like you said flux density is higher near metal so if it is not centered force on one side of the voice coil will push upwards stronger that the other side causing the rocking movement and distortion of course but the force vector will always be parallel to the center axis of voice coil.

Gap symmetry is important as well as it has the same effect. Mapping flux density around the gap was something i always wanted. Since i cant afford a klippel i made my own version with a stepper motor rotating a hall sensor around the gap at specific angles and measuring the flux density. This way you can make a map that looks like a 2pi polar chart showing how smooth the field distribution is. Because this is the best solution to deal with rocking.

What you are saying is true though, the woven material is more supportive of radial loads just as a metal sheet is but i dont find it to be a matter in loudspeakers. Thats the way i see it.

Sounds good. So in this new suspension the surround is the primary source of T/S relevant damping?

well of course electrical side still dominates system's Q but if your referring only on mechanical side i cant answer precisely at this time.

Yes, I meant "extracoilular". Fascinating work by the way. I'll have to second post #424, and probably go back and read everything that happened since the electromagnet part first attracted.. 🙂

Wow, everybody is so busy building and experimenting, i dont wanna fall behind 😀

the mid-bass units are in tests

Features:

Field coil motor

2" bullet phase plug

Ryu spider

Dual voice coil

Measurements hopefully tomorrow.

WOW...nice midbass

this is my midbass

paper cone

An externally hosted image should be here but it was not working when we last tested it.

almunium PU composite cone

An externally hosted image should be here but it was not working when we last tested it.

i didnt make my own basket,

just buy basket and magnet 😉

like this

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Yes, I meant "extracoilular". Fascinating work by the way. I'll have to second post #424, and probably go back and read everything that happened since the electromagnet part first attracted.. 🙂

Hi, there

You guys are doing a awesome job... How would think that we are talking about DIY units, they are so well made.

A little update on the project. I did mount a wizzer on the new cone, this made it less directional but there was to much output at high frequency. Without the wizzer it's sound more like lagers panel speakers in the high frequency range, it's like nothing is missing but it is more laid back in a nice way.. Dos this make any sense?

One thing I might try is to mount a centre dome, but this can bee done at a later time.. Here is some pictures.

Take care.

You guys are doing a awesome job... How would think that we are talking about DIY units, they are so well made.

A little update on the project. I did mount a wizzer on the new cone, this made it less directional but there was to much output at high frequency. Without the wizzer it's sound more like lagers panel speakers in the high frequency range, it's like nothing is missing but it is more laid back in a nice way.. Dos this make any sense?

One thing I might try is to mount a centre dome, but this can bee done at a later time.. Here is some pictures.

Take care.

Attachments

Yeah, Hard to tell what is bought or what is diy in the builds. Would be nice if people showed. It looks like some are doing full top to bottom diy and some are doing cones and suspensions only. All of them look nice though. Oh yeah Frank that former looks a little worrying lol.

Without the wizzer it's sound more like lagers panel speakers in the high frequency range, it's like nothing is missing but it is more laid back in a nice way.. Dos this make any sense?

ahh, yes 😛

Hi, there

One thing I might try is to mount a centre dome, but this can bee done at a later time.. Here is some pictures.

Take care.

Hi Frank,

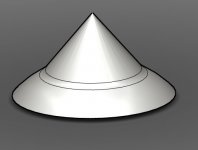

How about a vacuum formed hybrid one piece dustcap with this profile? Sort of a shallow dome with a ring radiator tip.

Attachments

Hi

The pointed end of a egg is perfect,but hard to cut straight.

You can imagine why its not used commercially when trying.(lots of eggs)

This is not a joke,it is a perfect material.Hard,light and silent.

Used them for coral and lowther,many years ago.

Jan

One thing I might try is to mount a centre dome, but this can bee done at a later time.. Here is some pictures.

The pointed end of a egg is perfect,but hard to cut straight.

You can imagine why its not used commercially when trying.(lots of eggs)

This is not a joke,it is a perfect material.Hard,light and silent.

Used them for coral and lowther,many years ago.

Jan

Hi

The pointed end of a egg is perfect,but hard to cut straight.

You can imagine why its not used commercially when trying.(lots of eggs)

This is not a joke,it is a perfect material.Hard,light and silent.

Used them for coral and lowther,many years ago.

Jan

Interesting, very interesting 😀

Hi

The pointed end of a egg is perfect,but hard to cut straight.

You can imagine why its not used commercially when trying.(lots of eggs)

This is not a joke,it is a perfect material.Hard,light and silent.

Used them for coral and lowther,many years ago.

Jan

Drill hole fill with foam. Use a tube the diameter you require and cut around it lightly with a very sharp razor knife. This is more like scribing than cutting. Take your time and it comes out perfect. Sand edge with 800grit. Dissolve foam with appropriate solvent and done.

Now you have an organic metal ceramic dome. 😉

Last edited:

Yes, well i will definitely try it on a pair of tweeters.

Don't limit yourself to just chicken eggs 😉

FYI I do wildlife rescue and many eggs of all species are dud's (sterile). Just don't use an endangered species or a National Bird for experiments. In the US, do not under any circumstances do this with a Bald Eagle. Do not keep even a feather if found! The feds do not play around.

Quail eggs are common enough, as are songbird eggs.

I like the idea with eggshell for the centre dome, very clever thinking.... But sense the eggshell is primevally made from calcium I would use acid to get the size I need, this will give a nicer edge I think.

One question... Do you remove the thin membrane inside the eggshell? I wonder if it will decompose over time.

Take care

One question... Do you remove the thin membrane inside the eggshell? I wonder if it will decompose over time.

Take care

It decomposes, gets nasty and flakes off over time. Washing is normally done.I like the idea with eggshell for the centre dome, very clever thinking.... But sense the eggshell is primevally made from calcium I would use acid to get the size I need, this will give a nicer edge I think.

One question... Do you remove the thin membrane inside the eggshell? I wonder if it will decompose over time.

Take care

I wish they pressurized ping pong balls with acetylene 😀

- Home

- Loudspeakers

- Multi-Way

- Project Ryu - DIY Field Coil Loudspeaker