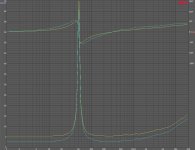

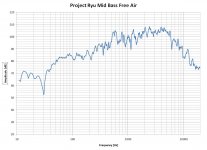

I finally got some time off to do some measurements. I could only measure the mid bass unit in free air for now. Attached are the results. Could be better but i will wait to measure them again in the test enclosure.

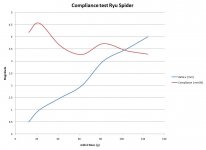

I also got to test compliance on the spider. The difference in value is either due to errors in measuring delta x or due to the setup itself (basically adding mass and using gravity) But with an average 3.5mm/N it looks good in my opinion. Most certainly the surround is a big factor in Cms and with cloth triple roll surrounds it is the limiting factor.

I will run more tests hopefully this weekend.

Recorded a video bending the spider:

[Project Ryu] New Spider Concept Material Resistance - YouTube

I also got to test compliance on the spider. The difference in value is either due to errors in measuring delta x or due to the setup itself (basically adding mass and using gravity) But with an average 3.5mm/N it looks good in my opinion. Most certainly the surround is a big factor in Cms and with cloth triple roll surrounds it is the limiting factor.

I will run more tests hopefully this weekend.

Recorded a video bending the spider:

[Project Ryu] New Spider Concept Material Resistance - YouTube

Attachments

Nice video, looks to be nice and flexible spider you made. Looks like you have lowered F0 to 50Hz..... nice.

Reg. The measurement of compliance, I think it is very difficult to do unless you have expensive laser equipment, mirros and stuff.

Reg. The measurement of compliance, I think it is very difficult to do unless you have expensive laser equipment, mirros and stuff.

I like that, nice piece of machinery.....

Here is some pictures just for inspiration...I have to wait a couple of days so the glue can cure, get back to you with the result.

I forgot.. Can someone help me, how do I cal. fo with respect to mass and complience.

Take care

Here is some pictures just for inspiration...I have to wait a couple of days so the glue can cure, get back to you with the result.

I forgot.. Can someone help me, how do I cal. fo with respect to mass and complience.

Take care

Attachments

Last edited:

Hi, This is maybe an interesting article about the critical damping factor of a driver. Somethimes overseen, but I think pretty important.

View attachment CriticalLSDamping.pdf

View attachment CriticalLSDamping.pdf

I will bee receiving the spiders from Hentai soon, I am so excited and can't hardly wait.

The surroundings chanced the high frequency respond a bit so I mounted the wizzer again, So this is how I will use them for now.....But might chance over time.

Here is some pictures.

Take care

The surroundings chanced the high frequency respond a bit so I mounted the wizzer again, So this is how I will use them for now.....But might chance over time.

Here is some pictures.

Take care

Attachments

I have a question- will an SMPS work as a suitable PSU for a field-coil driver? Places like Connexelectronic have SMPSes at very reasonable prices. You can get an 800W SMPS for $100, or a 1kW SMPS for $120. Surely one of those would be good enough, not so? The reason I ask is that I sometimes look at vintage field-coil drivers on eBay, and I wonder if I will be able to power them with one of these SMPSes.

Thanks,

Deon

Thanks,

Deon

Hi DeonC

You can use any good regulated power supply, but you don't need that kind of power.... If I remember correct my field coil dissipate 40W per unit. But bee sure that the voltages requirement is meet. I have seen some old types using high voltage 100-200V.

You can use any good regulated power supply, but you don't need that kind of power.... If I remember correct my field coil dissipate 40W per unit. But bee sure that the voltages requirement is meet. I have seen some old types using high voltage 100-200V.

Last edited:

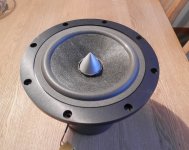

WOW, That looks fantastic..... very nice work. What is the size and how much dose it weigh.

Take care

Take care

WOW, That looks fantastic..... very nice work. What is the size and how much dose it weigh.

Take care

Hi Frank,

The outerdiameter is 15,5cm and 38mm voicecoil opening.

Not super light, 10gr for the cone. could be made lighter without the additional layer of glassfibre maybe 7gr. For the desired Fs 10gr is oke in my case.

cheers

Hi Jef,

Any news on your nice cone.... what type of vax did you use on the former.

I did use Number 8 Mould Release Wax (normal release wax i suppose)

but used polished aluminium as mold and that helped a bit. 2 layers of wax within between 10min to dry.

Just made some parts that i can use my lathe as a winding machine. But for the moment no time for making the voicecoil. Hopefully within two weeks.

Also going to try making paper cones (paper mache). Almost no info on the net to do that. Tricky business...

cheers,

Just a update, from a happy man.

The units is fully assembled now and mounted I a baffle/ large leakage box, and I have been spending some time listing to them.

So how do they sound.....well fantastic they are so nice to listen to and the resolution and level of detail is mind blowing not to mention the level of the dynamic is fantastic. I believe that the field coil contribute to this, the magnetic field is more uniform that the normal ferrite magnet. So I guess there is no return to ferrite magnets.... well at least for now.

I had some people over just to make sure that I was not kidding my self, but they all was blown away by the sound.... And wanted to take them home to them self.

Well I will bee listing some more to my new speakers, man it is a good feeling.

Take care.

The units is fully assembled now and mounted I a baffle/ large leakage box, and I have been spending some time listing to them.

So how do they sound.....well fantastic they are so nice to listen to and the resolution and level of detail is mind blowing not to mention the level of the dynamic is fantastic. I believe that the field coil contribute to this, the magnetic field is more uniform that the normal ferrite magnet. So I guess there is no return to ferrite magnets.... well at least for now.

I had some people over just to make sure that I was not kidding my self, but they all was blown away by the sound.... And wanted to take them home to them self.

Well I will bee listing some more to my new speakers, man it is a good feeling.

Take care.

Attachments

I love the beefiness of the driver frame. You can definitely use the proper screws for the application.

Have you tried different concepts for the spider? What are your thoughts on the fatigue resistance?

Have you tried different concepts for the spider? What are your thoughts on the fatigue resistance?

- Home

- Loudspeakers

- Multi-Way

- Project Ryu - DIY Field Coil Loudspeaker