I will leave the tweeters like that for the moment, i like the extended directivity and due to listening at low levels i don't need more gain, i think that tweeters operate better when kicked with some Watts and not only a couple of mW.

If would saturate/impregnate the cardboard sides with polyester resin thinned with 10% styrene. Coat from both sides and from the outside, drill small holes to puncture as many layers of corrugation as possible but not puncture through. Work with gravity and let the resin flow into the cardboard. Afterwards, laminate the outside with fiberglass chopped strand matt. You could laminate the insides but that will take quite a bit of sanding in difficult locations. Use a slow hardener to give yourself maximum working time and start with a low viscosity resin.

Mayhem, interested concoction. Is this something you recommend for CLD, even between layers of MDF? Is it viscoelastic like green glue?

Or, you could take advantage of that deep Tractrix bend. Attach a straight board across the arc with glue, put another at the bottom, fill with sand.

Good ideas 🙂 thank you!

I am amazed at how they sound! Very coherent, very fast and non fatiguing. I can listen at very low volumes and it sounds incredible. At high levels, also incredible, low distortion is great!

All diy-ers should do one form of synergy speaker, it is really amazing. I almost don't feel the need to check Diyaudio anymore 🙂 .. but i am addicted 🙂)

I am amazed at how they sound! Very coherent, very fast and non fatiguing. I can listen at very low volumes and it sounds incredible. At high levels, also incredible, low distortion is great!

All diy-ers should do one form of synergy speaker, it is really amazing. I almost don't feel the need to check Diyaudio anymore 🙂 .. but i am addicted 🙂)

Good ideas 🙂 thank you!

I am amazed at how they sound! Very coherent, very fast and non fatiguing. I can listen at very low volumes and it sounds incredible. At high levels, also incredible, low distortion is great!

All diy-ers should do one form of synergy speaker, it is really amazing. I almost don't feel the need to check Diyaudio anymore 🙂 .. but i am addicted 🙂)

Not that is does matter much for me but think if to call your build ala Synergy then tweeter should have sat at apex and Visaton as injection port.

Thanks sharing build it sound as one need to do same as you so as to hear improvements when not spraying sound to wide on design axis combined better distortion data 🙂.

Last edited:

Arcgotic,

Great to hear you are enjoying the sound. Hanging a tweeter at the mouth as Byrtt pointed out is not a true synergy but it's coaxial at least. The low distortion is amazing and a stunning sound you never forget.

Great to hear you are enjoying the sound. Hanging a tweeter at the mouth as Byrtt pointed out is not a true synergy but it's coaxial at least. The low distortion is amazing and a stunning sound you never forget.

Mayhem, interested concoction. Is this something you recommend for CLD, even between layers of MDF? Is it viscoelastic like green glue?

No CLD, just incredibly rigid and very low mass. You really can't beat composites or sandwich core construction for anything these days. Affordability is the problem.

If CLD is the goal, sandwich construction of 3mm bendy ply with with a Homasote core glued up with green glue would be my approach.

Not that is does matter much for me but think if to call your build ala Synergy then tweeter should have sat at apex and Visaton as injection port.

Thanks sharing build it sound as one need to do same as you so as to hear improvements when not spraying sound to wide on design axis combined better distortion data 🙂.

Not true, when fase corrected and a use of a HF horn it act as a coaxial horn ( Not Normal tweeter when use of a normal tweeter like here the efficienty is not higher then when the tweer can give,, it is not horn loaded.

I did have a idea of a little horn in it, made with a lathe and pointy on the back for the waves coming out without reflecting..

That was an absolute pleasure to watch.

Yes, best wishes to all for 2016 - and keep on improvising and improving and trying new weird things. It sometimes ends up working better. The whole coaxial approach recently proposed by arcgotic and kees may just sound quite superb.

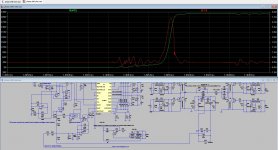

Also best wishes fro me, this moment i am busy with a 160 amps smps fase shift soft switching because my transformer did burn. it is for welding the car in spare time.

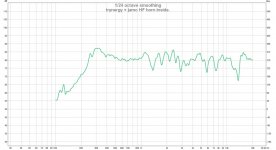

coming week I go measure the new aproach with the trynergy and I am ready now with the saw to make a tangerine faseplug.

Mother is oke again, the bed and such are away and she can helpt thereselfs.

coming week I go measure the new aproach with the trynergy and I am ready now with the saw to make a tangerine faseplug.

Mother is oke again, the bed and such are away and she can helpt thereselfs.

Attachments

Kees,

Good to hear your Mother is well again - great news for a new year. You really are multi talented, being a bonafide amp/SMPS designer. The rest of us would have pulled out a catalog and looked up power supply. You go design and build it. 🙂

Good to hear your Mother is well again - great news for a new year. You really are multi talented, being a bonafide amp/SMPS designer. The rest of us would have pulled out a catalog and looked up power supply. You go design and build it. 🙂

Hars sound accours when compression get pretty high with a faseplug a la tangerine. That is why some compression drivers are very hars sounding, for PA this is not a issue.

regards

Maybe a way could be to use just some wood guides like in some Iwata horn or Tad horns (to create virtual cells like the big multicells horns) ?

A simplier way to putt a non invasive tweeter in a horn while staying with a 2" driver at the apex could be a K-horn pipe tweeter : just a tube and I assume the phase beginns as well at the apex of this tube that coul be outside of the main horn if the tube is slighty bended (to go trough the top wall e.g. to allow to load the pipe with a tweeter a 3/4" size from ScanSpeak classic line...

(PS : but for me, I am on the camp of the BBC curve and even more than -6 DB id good for me : casual listening and better tonal balance on acoustical instruments... I surmise also to not have my 15 years old ears anymore ! 10F cone driver should be good enough for me ! Maybe an aêx at the size of the cone would help ? 6cm apex instead 5cm (2") ? )

Last edited:

That's not bad looking. Photo?

here is first a nice candidate making the trynergy full, but still midbas recides.

http://www.diyaudio.com/forums/multi-way/231669-new-hf-unit-very-nice-looking.html

This is the picture of the horn from where it came.

Attachments

- Home

- Loudspeakers

- Multi-Way

- Presenting the Trynergy - a full range tractrix synergy.