John,

What is please the best radiation pattern you experiment at home in one of your several synergy designs ? 60°x60° ? less ?, more ?

thank you

@ X : hey, I like the progressive vertical walls design à la Iwata bi-radiall horn 🙂 ! I have to try again to re cut and don't give-up...maybe I will try to find some another foam !

You know my philosophy : if we can match the sensivity of the mouth output from the apex driver with the woofs, we can have a serious mini 100 dB sensivity and more at 1 meter for any amps 🙂 !

For years, I was on the same page as Bang & Olufsen : narrow vertical directivity, wide horizontal directivity. I'd experimented with narrow angle horns from Pyle, and found that the lumpy frequency response didn't sound good, and I found that wide angle waveguides added some 'bounce' off the sidewalls that I liked.

@Weltersys said that narrow angle horns aren't inherently bad, so I wasn't prepared to write off narrow angle horns entirely. (The OS waveguide that I used for many of my projects measured about 100 degrees by 60 degrees.)

When I rented a pair of SH50 Synergy horns, I definitely thought the narrow angle was compelling. Although there was no noticeable 'bounce' off the sidewalls, I found that the SH50s were like listening to a good pair of headphones. Except without the hassle of wearing headphones. And the soundstage has depth.

For me, the DEPTH of the SH50s was one of the most enchanting parts of their presentation. IMHO, the depth of the presentation is due to the fact that the apparent source of the sound varies with frequency. The high frequencies emanate from the throat, the mid frequencies emanate from the middle of the horn. It's a really strange thing, the location of the sound is 'diffuse.' If you had a black curtain in front of the loudspeakers, you'd be hard pressed to say how far away they are. I think this would be particularly 'neat' in a car. Imagine driving down a dark road at light, listening to your tunes, and it's not clear if the soundstage is at the edge of the windshield or further out.

One of my houses has a garage that's adjacent to the living room. One idea I had was to buy a set of Danley SH50s. Then I would cut a hole in the wall that separates the living room from the garage. So the living room would look completely 'stock', and the Danley SH50s would be mounted in the garage, firing right through the wall. It was pure dumb luck that the house was set up like that, but I bet that would image like crazy, and it would look "clean" too. (Pic above is William Cowan's soffit-mounted Unity Horns.)

Last edited:

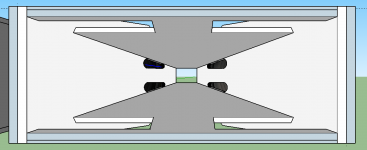

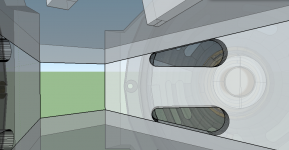

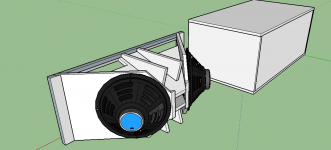

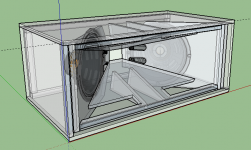

Finbot recently shared a Sketchup model with Art's approval of the Syntrip.

I thought the pics would be useful for reference here as the woofer injection ports are simple and elegant and something similar should be achievable in fomecore.

Cheers Art and Finbot, hope you don't mind.

Dean

I thought the pics would be useful for reference here as the woofer injection ports are simple and elegant and something similar should be achievable in fomecore.

Cheers Art and Finbot, hope you don't mind.

Dean

Attachments

-

Screen Shot 2015-11-11 at 8.57.06 pm.png29.5 KB · Views: 381

Screen Shot 2015-11-11 at 8.57.06 pm.png29.5 KB · Views: 381 -

Screen Shot 2015-11-11 at 6.05.10 pm.png242.7 KB · Views: 379

Screen Shot 2015-11-11 at 6.05.10 pm.png242.7 KB · Views: 379 -

Screen Shot 2015-11-11 at 2.52.29 pm.png61.7 KB · Views: 392

Screen Shot 2015-11-11 at 2.52.29 pm.png61.7 KB · Views: 392 -

Screen Shot 2015-11-11 at 2.32.48 pm.png58.7 KB · Views: 388

Screen Shot 2015-11-11 at 2.32.48 pm.png58.7 KB · Views: 388 -

Screen Shot 2015-11-11 at 2.40.08 pm.png84.6 KB · Views: 214

Screen Shot 2015-11-11 at 2.40.08 pm.png84.6 KB · Views: 214

Thanks for posting the internals of Weltersys' horn given the BR re direct I was planning on using. I think first I will go sealed and see if EQ can get me to 100Hz. I would prefer not to add BR ports to keep the group delay low.

Dean,Finbot recently shared a Sketchup model with Art's approval of the Syntrip.

Cheers Art and Finbot, hope you don't mind.

Finbot's model has not been "approved" by me, there are a number of discrepancies that need to be corrected, the first being "SynTripP" was not spelled correctly :^).

As well as not being approved, don't see any reason to show a sketch of a completely different design in this thread.

Cheers,

Art

If you want a phase plug I'll print you one.

Thanks for the offer. What design phase plug in your experience provides the best improvement in high frequency smoothness? The phase plug can also provide the added function of round to square throat transition.

Thanks John for your testimonials ! You may try open bafle wall mounting with your garage wall, some 12" or FR 15" à la Audionirvana or EMS speaker (they made not only electro magnet speakers)

@ xrq : believe you should stay to sealed woof due to the weak BL of the 10F or mates ? (I mean what could be "air traffic" at the mouth of the horn if you add the vented port ? And when I look at the vented ports of the design above, i can't stop thinking the vertical polar map (and may horizontal as weel) should be punky !

The delay can be maybe managed by FIR phase eq like would say Wesayso or Byrtt if you invest in a Minishark... But I believe the elegance of your design is to stay on Something "simple" : "Glue&Play" system !

So why not the B&C 10"; if it can reach 100 Hz to allow to foot print the subwoof not only below the horn (I'm not sure of the behavior in a sealed when I look at the roll off at around 150 Hz in the datashhet of the B&C10"...I assume to come IE bafle measurement !)

@ xrq : believe you should stay to sealed woof due to the weak BL of the 10F or mates ? (I mean what could be "air traffic" at the mouth of the horn if you add the vented port ? And when I look at the vented ports of the design above, i can't stop thinking the vertical polar map (and may horizontal as weel) should be punky !

The delay can be maybe managed by FIR phase eq like would say Wesayso or Byrtt if you invest in a Minishark... But I believe the elegance of your design is to stay on Something "simple" : "Glue&Play" system !

So why not the B&C 10"; if it can reach 100 Hz to allow to foot print the subwoof not only below the horn (I'm not sure of the behavior in a sealed when I look at the roll off at around 150 Hz in the datashhet of the B&C10"...I assume to come IE bafle measurement !)

Last edited:

Hey Art. Sorry If I was out of line.

My inference was that the 'sharing' was 'approved' but if it's not cool I will request the mods remove the post? Let me know, no hard feelings at all.

The reference to your SynTripP 🙂 was only for an inspirational, easy and elegant way to do woofer back wave injection ports in foamcore. Full credit to you.

As far as competely different designs.... Hmm... They are both kinda multiple drivers loading a sigle horn type projects but anywho. ;P. (yes I am stirring you up a little bit)

Dean

My inference was that the 'sharing' was 'approved' but if it's not cool I will request the mods remove the post? Let me know, no hard feelings at all.

The reference to your SynTripP 🙂 was only for an inspirational, easy and elegant way to do woofer back wave injection ports in foamcore. Full credit to you.

As far as competely different designs.... Hmm... They are both kinda multiple drivers loading a sigle horn type projects but anywho. ;P. (yes I am stirring you up a little bit)

Dean

Hey John.

You mentioned buying a pair of SH50's , is there no diy solution you would prefer? Or just to much effort?

Good to see you about here more again btw.

Dean

You mentioned buying a pair of SH50's , is there no diy solution you would prefer? Or just to much effort?

Good to see you about here more again btw.

Dean

Agree on sticking with sealed enclosure.

I'm getting exited, I feel like something is really brewing...

I'm getting exited, I feel like something is really brewing...

If you want a phase plug I'll print you one.

Hi Patric.

Yes these printers are awesome, Thanks that you want to help, I can try to get dimensions somehow for you, but making it in a drawing program like sketchup is difficult, I think that i can make one tor test with the special made jiggsaw and the woodlathe. I have stuff making a pcb cnc machine who can also making the plugs but this is still far away, expensive stuf to collect.

you now it is just a test, when the speaker do not like it we get more trouble then without, but I like to experiment with it.

You did also a way firing into a cone shape with a smaller hole (synergy port) in it like in the synergy types saying it extent, but think that it not for the very wide 20 khz goal we try to get without 12 dB extra power who get also extra distortion or heat in voicecoil.

regards

Last edited:

Dean,The reference to your SynTripP 🙂 was only for an inspirational, easy and elegant way to do woofer back wave injection ports in foamcore. Full credit to you.

The "easy and elegant" bass reflex port walls are reversed in the pictures you attached...

Art

WHat do you think guys about cheapbord vs ply for damping properties ? Is there any higher density cheapboard then the usual ones for a cleaner cutting ?

I saw in the other MultiWay forum a thread about the best materials measured and was surprised by the properties of the damping, not saying there are also "coated" cheapbord as well for cheap !

I'm of course talking about the top & bottom panels where the woofs are standing on!

I saw in the other MultiWay forum a thread about the best materials measured and was surprised by the properties of the damping, not saying there are also "coated" cheapbord as well for cheap !

I'm of course talking about the top & bottom panels where the woofs are standing on!

"Cheapboard" 🙂 Chipboard is cheap.

I think it would work fine for the top and bottom panels. Thin luaun plywood floor underlayment would work well too. I would bond it to foam core with liquid nails or caulking for CLD. One thing with chipboard is irregular pieces may not hold clean edge for a port when cutting.

I think it would work fine for the top and bottom panels. Thin luaun plywood floor underlayment would work well too. I would bond it to foam core with liquid nails or caulking for CLD. One thing with chipboard is irregular pieces may not hold clean edge for a port when cutting.

Damn, yes, I don't want to drill two RaspBerry Pi, you're right !

I thought about hot glue to proof the "edges" of the ports... or maybe plaster rubber band...

Let us Keep safe the Borneo forests 🙂

I thought about hot glue to proof the "edges" of the ports... or maybe plaster rubber band...

Let us Keep safe the Borneo forests 🙂

"Cheapboard" 🙂 Chipboard is cheap.

I think it would work fine for the top and bottom panels. Thin luaun plywood floor underlayment would work well too. I would bond it to foam core with liquid nails or caulking for CLD. One thing with chipboard is irregular pieces may not hold clean edge for a port when cutting.

Ok good to hear, I was kind of thinking of this. Building out of foamcore and then bonding with 1/8" or 1/4" HDF. I was just wondering if there is a max amount (or optimal amount) of space that the 6.5" woofers should be behind each port? (talking the faitalpro Trynergy, do I refer to this as .7 Trynergy?)

I have did a transparant paint on it who is very nice giving the wood looking very nice and damp also because it is very stiff now but was already strong.

But later on I go paint it white because it is not clean in edges.

regards

But later on I go paint it white because it is not clean in edges.

regards

Attachments

Hey X, do you have like a cutting guide or something that gives the dimensions of the different foam core boards and how they go together?

Ra7 : links of the plans are on the first post.

Those pdf are drawn for 5.1/4 driver; if you want to use it with a 2" cone like the Scan Speak 10F, just print it with multi-pages printing to scale 1 and reduce the 100% to 66% to have a 2" throat size (instead 2.8").

The new littliest horn is an other scaling if this is what you're asking...

Those pdf are drawn for 5.1/4 driver; if you want to use it with a 2" cone like the Scan Speak 10F, just print it with multi-pages printing to scale 1 and reduce the 100% to 66% to have a 2" throat size (instead 2.8").

The new littliest horn is an other scaling if this is what you're asking...

- Home

- Loudspeakers

- Multi-Way

- Presenting the Trynergy - a full range tractrix synergy.