Victor, tks for the schematics. I have been at Mr. Bora's site and gone thru the projects but I don't see this one. Is this a new one? I cannot find the site now (sure I had it recorded the address somewhere but I don't remember where.) Can you mention it here again? With that kind of power, I am really worried about the heatsink that's going to serve it. Even if I am going to try it, it will be the 3rd or 4th on the list. Now I amd still scratching my head over the 10pcs TO264 version of the superleach.

!

Yes,this is new idea!

http://bas.elitesecurity.org/

Heatsink's will be of 300mm*2 and with one cooler of 120mm*120mm.

Yes,this is new idea!

http://bas.elitesecurity.org/

Heatsink's will be of 300mm*2 and with one cooler of 120mm*120mm.

bigpanda said:Sorry quasi,

Do you actually mean the Vdss = -200v? If that's what you mean, then the irfp9240 can also fit in though they are more expensive? I happen to have a few piece lying around too.

Yes that's what I mean.

Cheers

Re: !

Nice amp indeed. Not sure about it's relevance in this thread though as it is nothing like the amp here, but nice amp.

Cheers

viktor1986 said:Maybe this link will help...

http://217.26.67.168/uploads/9/3/937415/tecton-MK2sema.pdf

I have in mind too built this amplifier with power supply +/-75V DC,power around 300W 8ohm and 600W 4ohm.

Nice amp indeed. Not sure about it's relevance in this thread though as it is nothing like the amp here, but nice amp.

Cheers

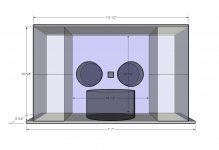

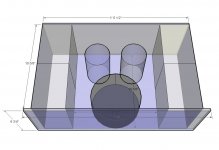

New case

I dropped off some 1/4" aluminum sheet and my heat sink extrusions at the metal shop today. This image is what is being cut. I chopped the quasi boards to just under 10 inches long and the protection circuit PCB will be mounted over each channels PCB in mezzanine fashion. The caps are each 5-3/4" tall and their diameter is 3". The Toroidal is 6-1/4" diameter by 3-1/4" tall.

The interior of the case is 10-5/8" deep by 10-1/2 wide by 6-1/4" tall.

Any thoughts on the component layout?

Shawn.

I dropped off some 1/4" aluminum sheet and my heat sink extrusions at the metal shop today. This image is what is being cut. I chopped the quasi boards to just under 10 inches long and the protection circuit PCB will be mounted over each channels PCB in mezzanine fashion. The caps are each 5-3/4" tall and their diameter is 3". The Toroidal is 6-1/4" diameter by 3-1/4" tall.

The interior of the case is 10-5/8" deep by 10-1/2 wide by 6-1/4" tall.

Any thoughts on the component layout?

Shawn.

Attachments

Finishing the Aluminum

I talked to Arunas(metal shop guy) about the final finish on the aluminum but he didn't seem too "in-tune" with it. The aluminum I purchased is very good surface quality with no gouges just light surface scuffs. Can I polish it myself? I have alot of tools but do not know what is involved. I have briefly read that there are certain polishes that need to be applied to ??? I don't know what?

Any experiences you could recommend?

Jah,

Shawn.

I talked to Arunas(metal shop guy) about the final finish on the aluminum but he didn't seem too "in-tune" with it. The aluminum I purchased is very good surface quality with no gouges just light surface scuffs. Can I polish it myself? I have alot of tools but do not know what is involved. I have briefly read that there are certain polishes that need to be applied to ??? I don't know what?

Any experiences you could recommend?

Jah,

Shawn.

Hi,

can you drill and tap a blind hole in the front plate to mount that big transformer? Or fix a stout L bracket to the case floor for a mounting point behind (next to caps). The L bracket solution may transmit less mechanical vibration into the case.

can you drill and tap a blind hole in the front plate to mount that big transformer? Or fix a stout L bracket to the case floor for a mounting point behind (next to caps). The L bracket solution may transmit less mechanical vibration into the case.

Re: Finishing the Aluminum

I guess Arunas is from Lithuania. No?

TomWaits said:I talked to Arunas(metal shop guy)

I guess Arunas is from Lithuania. No?

AndrewT said:Hi,

can you drill and tap a blind hole in the front plate to mount that big transformer? Or fix a stout L bracket to the case floor for a mounting point behind (next to caps). The L bracket solution may transmit less mechanical vibration into the case.

Mr. T, I guess you would like to see the xfmr flush with the front plate vs. sitting on the bottom. Me too. I'll pick up the pieces of the case in a day or so and play"doll House" inside with the funiture. For rack mounting purposes it is always good to have weight near the front. I don't know if the thing will ever be rack mounted, but it leaves the maximum room inside the case having the xfmr on the front plate.

The aluminum is 1/4" so I could take the front plate back to the shop and have a custom bracket welded on the inside of the plate. Have you ever serviced equipment that you can remove both top and bottom? This is a good goal and I may be able to acheive it. I guess I'm not scoring any "art points" but perhaps next time I'll make it a little more sexy?

Cheers,

Shawn.

Cleaning Heat sinks

What liquid can I submerge my aluminium heat sinks in to strip them as I would like to make them look new-ish? They are large so something economical would be good. Shawn.

What liquid can I submerge my aluminium heat sinks in to strip them as I would like to make them look new-ish? They are large so something economical would be good. Shawn.

Hi,

removable top and bottom is excellent for maintenance/testing, go for it.

Do not weld a bracket onto your face plate. The heat will cause distortion and discolour the parent metal. Even grinding/polishing is unlikely to make the faceplate look homgenious. A good machine shop will be able to blind tap your shallow hole, it's just a bit difficult for us amateurs

Are the sinks painted or anodised or corroded? I suspect the dip will be different for each. Sulphuric for anodise? Caustic for paint? Acidic wheel cleaner for corrosion? Possiblilities not definitive!

removable top and bottom is excellent for maintenance/testing, go for it.

Do not weld a bracket onto your face plate. The heat will cause distortion and discolour the parent metal. Even grinding/polishing is unlikely to make the faceplate look homgenious. A good machine shop will be able to blind tap your shallow hole, it's just a bit difficult for us amateurs

Are the sinks painted or anodised or corroded? I suspect the dip will be different for each. Sulphuric for anodise? Caustic for paint? Acidic wheel cleaner for corrosion? Possiblilities not definitive!

Another finshed amp!!!

Hi guys,

I finaly finshed my quasi amp and place it in the case.

I just want to thanks all the people in this thread for assistance and specially you Quasi for the great amp design😉 .

THANKS

Here are some photos...

Regards

Miodrag Pejin

Hi guys,

I finaly finshed my quasi amp and place it in the case.

I just want to thanks all the people in this thread for assistance and specially you Quasi for the great amp design😉 .

THANKS

Here are some photos...

Regards

Miodrag Pejin

Attachments

Also, I'm planing to add clipping indicator. I build the one from the Rod Elliot site but the LED remained on all the time and I burned some 1/4W resistors.

Any suggestions?

Any suggestions?

Case options

neutrik speakon and xlr...excellent add-ons.

Shawn.

A blind hole is one that does not go all the way through the plate. 1/4" aluminum would not give sufficient thread to bolt a 14 pound xfmr to. It would break free in a short time. Still I love the idea of welding a bracket, however some distortion may show up on the other side as you said. I'm at odds with this. I really want to bolt it to the face somehow.AndrewT said:A good machine shop will be able to blind tap your shallow hole, it's just a bit difficult for us amateurs

Acidic wheel cleaner, I very much like the sound of that. T, there is no finish on them, just gunk. I want to submerge them as it is near impossible to clean in a physical way due to the fins.AndrewT said:Are the sinks painted or anodised or corroded? I suspect the dip will be different for each. Sulphuric for anodise? Caustic for paint? Acidic wheel cleaner for corrosion? Possiblilities not definitive!

Nice! Have you been cranking it up? How is it?pejinm said:Hi guys, I finaly finshed my quasi amp...Regards

Miodrag Pejin

neutrik speakon and xlr...excellent add-ons.

Shawn.

Re: Case options

Hi Shawn,

Mounting plate with multiple bolts? 🙂

You could have - let's say - four threaded blind or visible holes in the front plate. They could carry a reasonably thick plate to hold the transformer. A thread size of M4 or equivalent (sorry to be metric 😉) would be enough to sustain the load of the transformer (provided there are at least four good threads).

A 1/4" sheet still won't hide those threads, but if you can live with a symmetrically placed set of beautiful screwheads, you could still keep the front plate you have...

Regular household cleaner of the stronger kind (bathroom and "multi-dirt" cleaner) is as good as wheel cleaner for the purpose (actually even for cleaning wheels) and way more economic.

Submerging alone won't cut it, you can't dive them into pure acid (safely and economically). But a toothbrush works wonders. 😀

Simply let the chemicals solute the rougher dirt and help it every couple of minutes with the brush (in long brush strokes, not circling or fuzzy).

Hope this helps,

Sebastian. 😉

PS: Don't forget to keep that brush away from the bathroom afterwards! 😉

Hi Shawn,

I really want to bolt it to the face somehow.

Mounting plate with multiple bolts? 🙂

You could have - let's say - four threaded blind or visible holes in the front plate. They could carry a reasonably thick plate to hold the transformer. A thread size of M4 or equivalent (sorry to be metric 😉) would be enough to sustain the load of the transformer (provided there are at least four good threads).

A 1/4" sheet still won't hide those threads, but if you can live with a symmetrically placed set of beautiful screwheads, you could still keep the front plate you have...

Acidic wheel cleaner, I very much like the sound of that. T, there is no finish on them, just gunk. I want to submerge them as it is near impossible to clean in a physical way due to the fins.

Regular household cleaner of the stronger kind (bathroom and "multi-dirt" cleaner) is as good as wheel cleaner for the purpose (actually even for cleaning wheels) and way more economic.

Submerging alone won't cut it, you can't dive them into pure acid (safely and economically). But a toothbrush works wonders. 😀

Simply let the chemicals solute the rougher dirt and help it every couple of minutes with the brush (in long brush strokes, not circling or fuzzy).

Hope this helps,

Sebastian. 😉

PS: Don't forget to keep that brush away from the bathroom afterwards! 😉

Re: Re: Case options

I guess I should try these first, good thinking but I still love the idea of deadly chemicals with magical results.

On that note I may pick up some spoke brushes. Thanks sek, you seem very practical, perhaps you're not a physicist like others in this place, which is refreshing.

Shawn.

Yes, this may be the answer and it won't cost a nickle. "Beautiful screwheads" isn't that racist? 🙂sek said:Hi Shawn, Mounting plate with multiple bolts? 🙂 ... if you can live with a symmetrically placed set of beautiful screwheads, you could still keep the front plate you have...

Regular household cleaner...[/B]

I guess I should try these first, good thinking but I still love the idea of deadly chemicals with magical results.

PS: Don't forget to keep that brush away from the bathroom afterwards! 😉 [/B]

On that note I may pick up some spoke brushes. Thanks sek, you seem very practical, perhaps you're not a physicist like others in this place, which is refreshing.

Shawn.

- Home

- Amplifiers

- Solid State

- Power amp under development