and 38Kg (driver included) for the SS15, not bad but 10Kg more than the THAM15. Any quick way how could I compare the performances of the lf15n401 on the SS15 vs the THAM15 ?

Also, I know 12mm plywood is not recommanded for drivers that are getting more than 500W, but should I try it and renforce some part of the enclosures ?

Also, I know 12mm plywood is not recommanded for drivers that are getting more than 500W, but should I try it and renforce some part of the enclosures ?

Attachments

Last edited:

Hi again guys, so as the weight is a critical limiter in my case, and having compared the enclosure weights of my actual ported one and the Tapped Horn ones, I'm debating if I should upgrade to a TP or just improve the design of the vented one.

Weights :

Actual : 10Kg

THAM15 : 30Kg (the lightest TP and already very heavy for me).

So on, does anyone would recommend a simple design (not forcelly TH) that would be ligther "woodwize" with this driver ? As it's a Neodium magnet it's supposed to perform well in smaller cabinets. I'm open to anything (among ported designs).

Weights :

Actual : 10Kg

THAM15 : 30Kg (the lightest TP and already very heavy for me).

So on, does anyone would recommend a simple design (not forcelly TH) that would be ligther "woodwize" with this driver ? As it's a Neodium magnet it's supposed to perform well in smaller cabinets. I'm open to anything (among ported designs).

The main thing is getting enough stiffness, so panels as thin as 1/4" with more bracing can reduce weight considerably with the trade-off being build complexity. Of course as weight drops, the more speakers can 'dance', so either need to have stacks of them or some way to couple them to the floor/whatever.

The ROAR series with its 'rat's maze' layout would be my choice and start with just a 1/4" BB ply/epoxy construction and brace with small hardwood dowels as required.

GM

The ROAR series with its 'rat's maze' layout would be my choice and start with just a 1/4" BB ply/epoxy construction and brace with small hardwood dowels as required.

GM

Last edited:

It would make a enclosure of 20/25kg indeed. But wow that's pretty thin. I'll ask on the relevant thread what other think. Thanks for the input GM

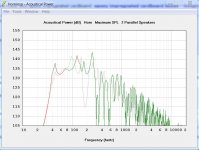

from what I can see, on the low end, for practical purposes, THAM15 and SS15 are the "same" enclosure. The larger cabinet has a bit more "hit". Both exhibit ~.the same excursion and tuned ~ the same.

It would make a enclosure of 20/25kg indeed. But wow that's pretty thin. I'll ask on the relevant thread what other think. Thanks for the input GM

You're welcome!

Not really since stiffness is primarily a function of span, so construct something like a 'bird cage' Maserati's frame and build [have built] it out of corrugated cardboard or that super thin/cheap paneling for indoor use: http://www.autominiaturen.be/data/articles/images/zoom/m_3875.jpg

Another I've used for outdoors are made with epoxy impregnated cardboard: epoxy impregnated cardboard boxes - Google Search

Obviously, if tall, heavy weights are stacked on top, crowd abuse/whatever is an issue, then this dictates materials/construction used, otherwise no need to overbuild, just don't be doing much in the way of dropping unless the corners are triangulated and have corner protectors.

GM

Thanks again for the analysis boss !from what I can see, on the low end, for practical purposes, THAM15 and SS15 are the "same" enclosure. The larger cabinet has a bit more "hit". Both exhibit ~.the same excursion and tuned ~ the same.

Another I've used for outdoors are made with epoxy impregnated cardboard: epoxy impregnated cardboard boxes - Google Search

Wow that an surprising material to use, It is as reliable as PLY in the long term ? And yes the enclosures will def be for outdoor use.

By the way, kind of a newbie question : will there be a big DB / max SPL / Audio difference if I build 2 x THAM15 (wired in //) vs 1 x ROAR15 ? Im studding the options between sound power and weight 🙂

will there be a big DB / max SPL / Audio difference if I build 2 x THAM15 (wired in //) vs 1 x ROAR15 ?

Green-red line is two THAM with 1800 watts each compared to one single ROAR15 with 1800 watts (grey line).

Attachments

Heroes !! Ok the choice is almost made ^^ now looking into dimensions

For info, weightwize with 12mm ply :

Option 1 (2 x THAM15) 40kg

Option 2 (1 x ROAR) 45kg

I just can't realize yet if the perceived "sound power" / SPL difference between 60Hz and 100Hz will be noticable / worst it. I know that +10DB double the perceived sound so 6DB should be +50% difference in this range. The use if for outdoor open air fields.

Edit : ok now I realize 😉

For info, weightwize with 12mm ply :

Option 1 (2 x THAM15) 40kg

Option 2 (1 x ROAR) 45kg

I just can't realize yet if the perceived "sound power" / SPL difference between 60Hz and 100Hz will be noticable / worst it. I know that +10DB double the perceived sound so 6DB should be +50% difference in this range. The use if for outdoor open air fields.

Edit : ok now I realize 😉

Last edited:

(I'm old, ignorant, decrepit and useless so more a "zero" 😱) With two drivers, and given power, two THAM15 should have less heating and less thermal compression than one driver in ROAR15 plus less cone excursion above tuning.

IF one had the means and space then two ROAR15 would be very cool.

Here's Two THAM15 vs Two ROAR15. The little THAM15 does pretty well for so small a cabinet

IF one had the means and space then two ROAR15 would be very cool.

Here's Two THAM15 vs Two ROAR15. The little THAM15 does pretty well for so small a cabinet

Last edited:

Edit : ok now I realize

I guess that graph is the energy distribution in normal modern music.

It really shows why a great mid bass is so important for music reproduction.

All the people I have talked to who has heard the ROAR series play are quite blown away by the power, punch and engaging sound character they have. Even when compared to a lot of different tapped horns.

In my personal view the ROAR is a large step forward in dB/dm3 (liter) and sound quality compared to "normal" tapped horns. I do think they are a strange mix of the punch and vivid and engaging character of large true horns and the low end power of tapped horns.

We hit 143,88 dB with one ten inch driver in a HROAR in a car spl comp a few days ago. The HROAR is designed as a sound quality oriented subwoofer with a 27 Hz tuning. It is not an spl-only one note wonder design. And the driver was very far from its limits.

I think it says a lot of the spl potential of ROAR and HROAR designs.

For info, weightwize with 12mm ply :

Option 1 (2 x THAM15) 40kg

Option 2 (1 x ROAR) 45kg

One ROAR15 (45 kg) can match the output of two THAM15 (80 kg).

Nice spl/kg ratio.

Wow that an surprising material to use, It is as reliable as PLY in the long term ? And yes the enclosures will def be for outdoor use.

Can be, just depends on the app; I mean it won't be for unprotected permanent installs or similar, but properly constructed they can take plenty of abuse except for extreme cold and a better choice overall in high humidity conditions.

GM

One ROAR15 (45 kg) can match the output of two THAM15 (80 kg).

Actually 2 x THAM15 = 40Kg (not 80Kg)

Trying to decide about my other 12" other drivers : RCF MB12N351 - 12" Mid Bass

Also would be amazing to compare the sealed box vs 2x THAM12 vs 1 x ROAR12. I really would like to learn how to do that but I need to learn more about Hornresp. Here is the other thread https://www.diyaudio.com/forums/mul...re-upgrade-2-midbass-drivers.html#post5839347

Also would be amazing to compare the sealed box vs 2x THAM12 vs 1 x ROAR12. I really would like to learn how to do that but I need to learn more about Hornresp. Here is the other thread https://www.diyaudio.com/forums/mul...re-upgrade-2-midbass-drivers.html#post5839347

Hi Again everyone 🙂 I'm trying to decide between a building a pair of sealed box or a pair of THAM12 for these drivers. Anyone know what DB / SPL difference I would get comparing the 2 types of enclosures with the RCF mb12n351 ?

Last edited:

Actually 2 x THAM15 = 40Kg (not 80Kg)

Not in the least! The 15" driver alone weighs its 14kg - i just lifted one of my thams and can assure you: it weighs more than 20kg, rather some 35-40kg (18mm birch ply).

Not in the least! The 15" driver alone weighs its 14kg - i just lifted one of my thams and can assure you: it weighs more than 20kg, rather some 35-40kg (18mm birch ply).

Yes this is what i wrote, 2 x THAM15 = 40Kg (each one 20kg 🙂

No, each one will not weigh 20kg, even if built with 12mm ply like you mentioned somewhere & loaded with a neo driver.

There is a total of 22596 square cm of ply needed to build one (not including bracing, and if you do use 12mm you will need more bracing than the standard plan shows).

Birch ply weighs between 0.65 and 0.7 g per cubic cm, so even in 12mm you will have approximately 19kg of ply (PLUS BRACING), plus the driver, glue, paint, screws, handles, grille (if fitted) so expect at least 30kg for a 12mm version and, as others have said, around 40kg for a normal 18mm build.

There is a total of 22596 square cm of ply needed to build one (not including bracing, and if you do use 12mm you will need more bracing than the standard plan shows).

Birch ply weighs between 0.65 and 0.7 g per cubic cm, so even in 12mm you will have approximately 19kg of ply (PLUS BRACING), plus the driver, glue, paint, screws, handles, grille (if fitted) so expect at least 30kg for a 12mm version and, as others have said, around 40kg for a normal 18mm build.

Roger that David !

Any help about the DB / MAX SPL comparing the THAM12 and sealed enclosure with the RCF MB12N351 - 12" Mid Bass ?

Any help about the DB / MAX SPL comparing the THAM12 and sealed enclosure with the RCF MB12N351 - 12" Mid Bass ?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Ported Sub to Tapped Horn. Few questions before starting